What Is the Semiconductor Industry and How Does It Work

The semiconductor industry makes small chips for most electronics you use. You need semiconductors in your phone, computer, and medical tools. These materials can stop or let electricity pass through them. This helps them control signals and keep information safe. Semiconductors are very important for modern technology. The semiconductor industry is now worth about $696.54 billion worldwide. This shows how important it is for your life and the world’s economy.

Key Takeaways

Semiconductors help control electricity in things like phones and cars. They make modern technology work. The semiconductor industry has companies that design, make, test, and sell chips all over the world. Engineers design chips and use steps like lithography and etching to make them. Many countries work together to design, build, and test chips. The industry sometimes has problems like not enough supply. But it keeps finding new ways to make chips smarter and smaller.

Semiconductor Basics

What Is a Semiconductor

You might ask why a semiconductor is important. A semiconductor lets electricity move, but not as much as copper. It also does not stop electricity like rubber does. Silicon is the most common semiconductor. You can find silicon in almost every chip. These chips are inside your phone, computer, and car.

Here’s a simple table to help you see the difference between conductors, semiconductors, and insulators:

Property | Conductors | Semiconductors | Insulators |

|---|---|---|---|

Energy Band Structure | Overlapping bands, free electrons | Small bandgap (<2 eV) | Large bandgap (>2 eV) |

Electron Availability | Many free electrons | Some electrons, some holes | Very few free electrons |

Electrical Conductivity | Very high | Medium | Very low |

Electrical Resistivity | Very low | Moderate | Very high |

Electron Behavior | Electrons move freely | Electrons and holes move | Electrons hardly move |

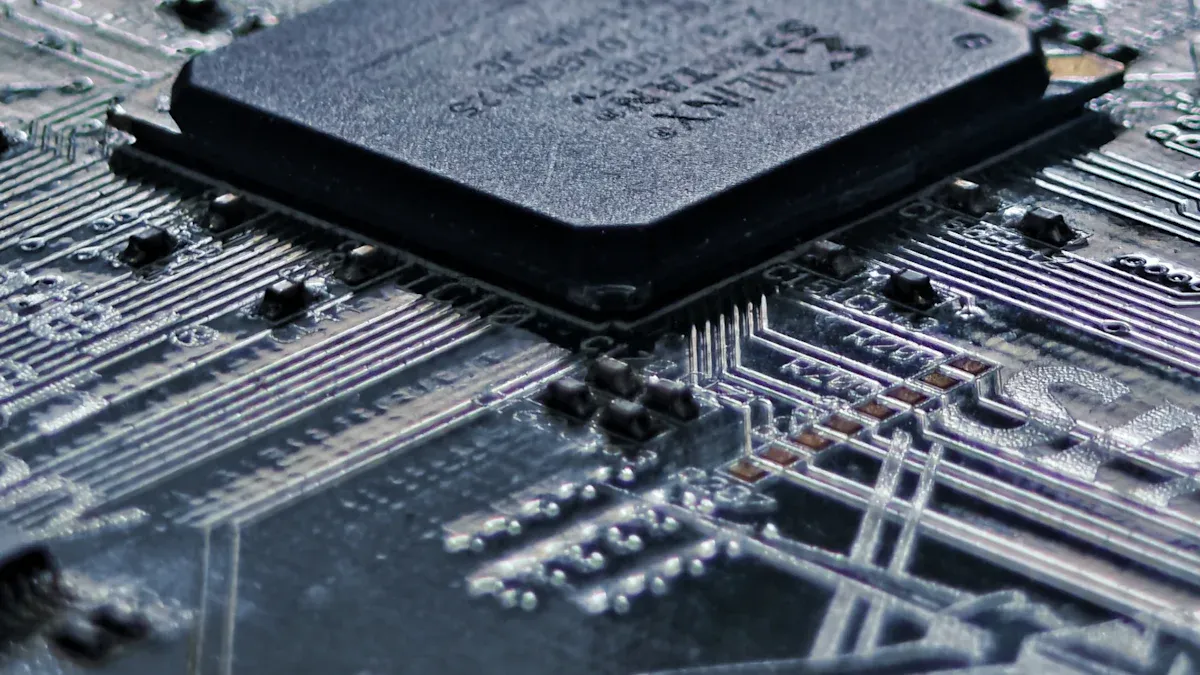

A semiconductor is in the middle of conductors and insulators. It has just enough free electrons to control electricity. This special feature lets us use semiconductors to make chips. These chips can work like tiny switches or memory cells.

Role in Electronics

You use electronics all the time, but you might not know how much you need semiconductors. Every chip in your devices uses a semiconductor. This includes microprocessors in computers and the integrated circuit in your smartwatch. These chips can handle information, save data, and even connect online.

Semiconductor devices help you have fast phones and smart TVs. They also let cars park by themselves. The chip design process decides how each chip works. Some chips are simple sensors. Others are powerful socs that run your favorite apps. Most chips use silicon, but sometimes other materials are used for special jobs.

If we did not have semiconductors, we would not have modern electronics. Semiconductors are the base for things like calculators and medical equipment.

Chips are getting smaller and smarter every year. This means your devices have more features but do not use more power. The semiconductor industry keeps making new things. This helps you get the newest technology in your hands.

Semiconductor Industry Structure

Key Company Types

Many companies help make the chips in your devices. Each company has a special job in the semiconductor industry. Here is a table that shows what each company does:

Company Type | Role Description |

|---|---|

Design Companies | Create and develop semiconductor devices and integrated circuits. They focus on chip design and engineering. |

Manufacturing Companies | Build semiconductor products. They run the factories and make sure chips are made correctly. |

Testing and Quality Assurance | Test chips to make sure they work well and last a long time. |

Equipment and Technical Support | Install and fix the machines that make chips. They also help solve problems when things break. |

Supply Chain and Operations | Plan, move, and deliver chips around the world. They help keep costs low and products on time. |

Marketing and Sales | Tell people about new chips and help sell them to companies and customers. |

Research and Development (R&D) | Find new ways to make chips better, faster, and smaller. They work on the future of the semiconductor industry. |

There are many jobs in this field. Some people fix machines. Others check chips to make sure they work. Some workers help projects go smoothly.

Business Models

Not all companies do the same things in the semiconductor industry. Some companies do everything from start to finish. Others only design chips and let someone else build them. Here is a table that shows the main business models:

Aspect | IDM (Integrated Device Manufacturer) | Fabless Semiconductor Company |

|---|---|---|

Core Operations | Design, manufacture, and sell chips | Focus only on chip design and development |

Manufacturing Control | Full control over making chips | Outsource manufacturing to foundries |

Advantages | Better control over quality and faster to market | More flexible, can focus on new ideas |

Challenges | Very expensive to build and run factories | Must rely on other companies to make chips |

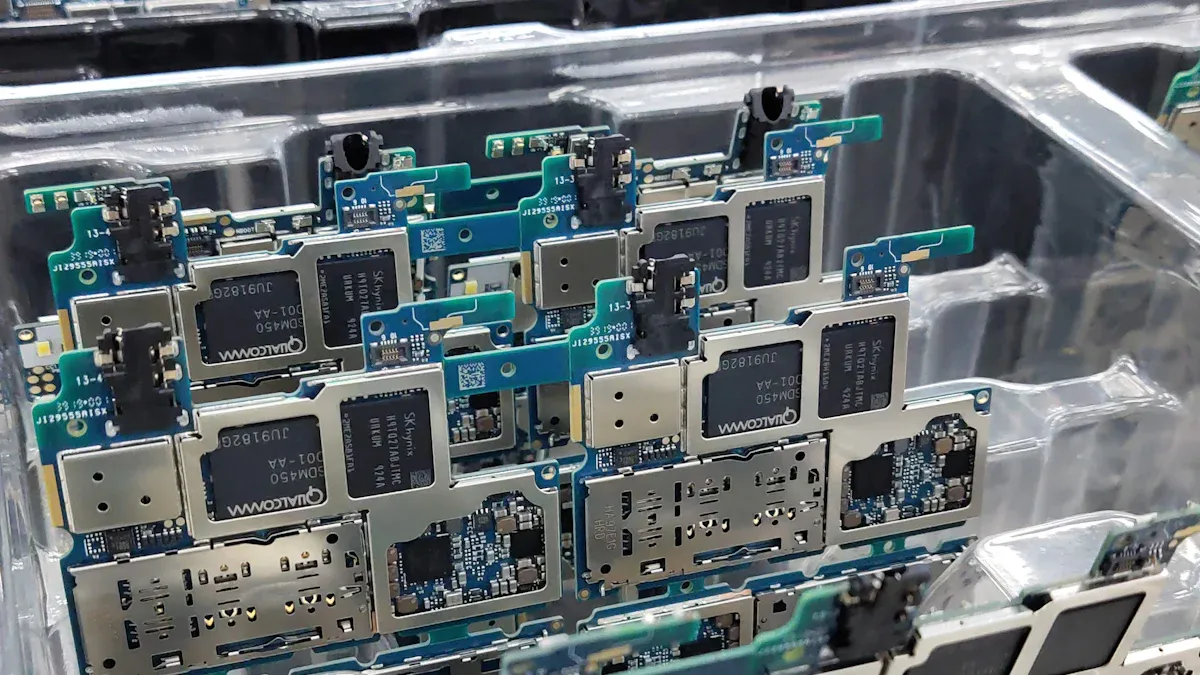

Examples | Intel, Samsung | Qualcomm, NVIDIA |

Business Focus | Handles everything from start to finish | Focuses on design, lets others handle manufacturing |

There are two main types of companies. IDMs do both design and manufacturing. They control the whole process. Fabless companies only design chips. They send their plans to foundries, which are special factories that make chips for many companies.

The fabless-foundry model changed how the world makes chips. Now, more new companies can join the market. Fabless companies work on better chip designs. Foundries like TSMC in Taiwan build the chips. This teamwork helps new technology reach you faster. Apple uses this model to design chips for your phone. TSMC builds those chips.

The fabless-foundry model helps companies save money on factories. They can spend more on making smarter chips. You get better devices and new ideas faster.

Global Supply Chain

The semiconductor industry works all over the world. Chips travel through many countries before you use them. The United States leads in chip design. It also makes most of the machines needed for chip factories. Taiwan, South Korea, and China are top places for making chips.

Taiwan is known for its foundries, like TSMC. TSMC makes chips for many companies. South Korea has big companies like Samsung. Samsung builds memory chips and soc chips. China is building more factories and growing fast. Europe, led by Germany, is strong in making silicon wafers and equipment.

Here is a table that shows what each country does in the semiconductor industry:

Country | Segment | Market Share / Role Description |

|---|---|---|

United States | Semiconductor Manufacturing Equipment (SME) | Makes over 40% of the world’s chip-making machines. Also leads in chip design. |

Japan | SME and Testing | Holds 29% of the SME market. Leads in testing equipment. |

Netherlands | SME | Home to ASML, the only company that makes EUV lithography machines for advanced chips. |

Taiwan | Semiconductor Production | Top producer and exporter of chips. TSMC is the world’s largest foundry. |

South Korea | Production & SME | Major chip producer. Supplies a lot of testing equipment. |

China | Production & SME | Growing fast in chip production. Still catching up in advanced manufacturing. |

Germany | Production | Largest in Europe. Strong in silicon wafer supply and equipment. |

Malaysia | Packaging and Testing | Handles over 13% of the world’s chip packaging and testing. |

Singapore | Equipment | Important for making chip-making machines and research. |

Chips often start as a design in the United States. They are made in Taiwan or South Korea. Then, they go to Malaysia or Singapore for testing and packaging. This teamwork across the world keeps your devices working and helps the semiconductor industry grow.

You use technology every day that comes from this worldwide network. When you pick up your phone, remember its chip may have traveled far to reach you.

Chip Manufacturing Process

When you see your phone or computer, you may wonder how a chip gets inside. Making a semiconductor chip takes many steps. Let’s look at the main parts of this process.

Design Phase

The first step is chip design. Engineers plan what the chip will do. They use special software to draw the circuits. This is like making a house blueprint, but for a chip. You need this plan before building starts.

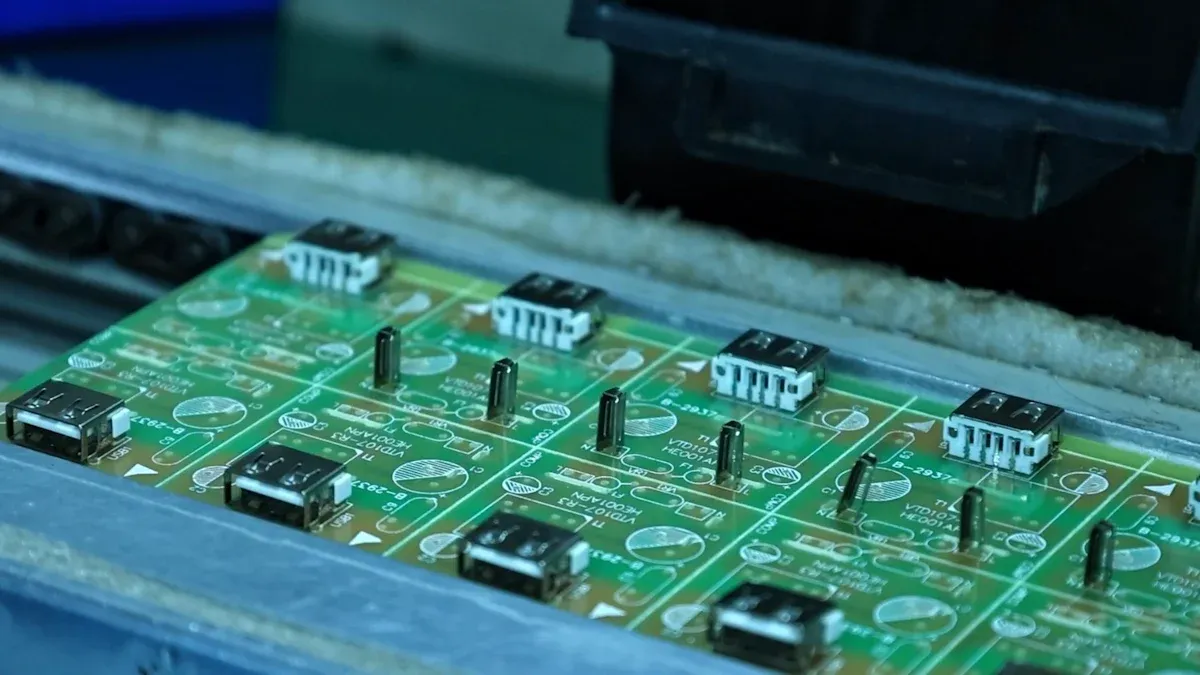

Fabrication Steps

Making a chip is very detailed. Here are the main steps:

Wafer Fabrication: Pure silicon crystals are used first. They are sliced and polished into thin wafers.

Deposition: Different materials are put on the wafer. These can be metals or other semiconductors.

Photoresist Coating: A light-sensitive layer is added on top.

Lithography: UV light shines through a mask. This prints the chip’s circuit pattern onto the wafer.

Etching: Extra material is taken away. This leaves the circuit shapes behind.

Ion Implantation: Ions are shot into the silicon. This changes how the chip handles electricity and forms transistors.

Here is a table to show some key fabrication steps:

Fabrication Step | What Happens Here |

|---|---|

Deposition | Layers of material are put on the wafer |

Lithography | Circuit patterns are made using UV light |

Etching | Extra material is removed to shape the circuits |

Doping | Ions are added to control how the chip works |

These steps happen many times. Each layer adds more detail to the chip. The process must be very clean. Even a tiny bit of dust can ruin a chip.

Assembly and Testing

After fabrication, the next steps are assembly and testing. Here is what happens:

Dicing: The wafer is cut into many small chips.

Die Bonding and Wire Bonding: Each chip is put on a base and connected with tiny wires.

Packaging: The chip is sealed in a case to keep it safe and cool.

Testing: Every chip is tested to make sure it works. Some tests happen before packaging, and some after.

Companies use special tools to check for problems or dirt. They want every chip to be high quality. If a chip fails, it does not get sold. Careful checks help keep your devices safe and working well.

Tip: The whole process, from design to testing, can take months. But it is worth it because you get small and powerful chips in your favorite gadgets!

Industry Impact and Trends

Applications and Sectors

You use semiconductors every day, even if you do not notice. These small chips help many industries work. Here are some main areas that need semiconductors:

Consumer Electronics: Laptops, tablets, phones, and smartwatches all need chips. These chips are made from materials like silicon carbide and gallium nitride.

Telecommunications: Your internet and phone calls use chips in telecom gear. These chips use silicon and other special materials.

Automotive: Modern cars need chips for safety, sensors, and self-driving. These chips can work in hot and rough places.

Manufacturing: Factories use chips to run machines and robots.

Energy & Utility: Power grids and smart meters need chips too.

Other Sectors: Many other products use these chips.

In 2023, car companies bought 17% of all chips. PC, data center, and communications made up 57%. This shows chips are important for cars and computers.

Economic and Global Significance

The semiconductor industry is very important for the world’s economy. It adds about $2.7 trillion to the global GDP. In the United States, over 26 million people have jobs in areas that use chips. That means one out of five workers needs this industry. When there was a chip shortage during COVID-19, U.S. GDP growth dropped by 1%. Car factories and other businesses had to slow down or stop. This shows how much jobs and growth depend on chips.

Here is a table with some big companies and what they do:

Company | Country | Revenue (USD) | Market Influence |

|---|---|---|---|

Monolithic Power Systems | USA | $29.4 billion | Strong in chip design and intellectual property |

ON Semiconductor | USA | $27.0 billion | Focus on design and software tools |

GlobalFoundries | USA | $23.9 billion | Major U.S. manufacturer |

TSMC | Taiwan | N/A | Leading contract manufacturer, key for AI and EVs |

Broadcom | USA | $90 billion (projected) | Drives AI chip innovation and infrastructure |

The U.S. is best at chip design. Taiwan is the top place for making chips. These companies help shape technology for the world.

Challenges and Future

You may have heard about the chip shortage. The semiconductor industry has many problems to solve. Supply chain issues can happen from trade wars, disasters, or missing materials. Earthquakes in Japan or Taiwan can stop chip factories. COVID-19 caused a big problem with supply and demand. This led to delays, higher prices, and worries about security because most chips are made in a few places.

Here are some big problems:

Supply chain issues from world events and disasters

Not enough key materials like neon gas

Some chip parts become outdated very fast

Too much chip making happens in just a few regions

Countries are building new factories and doing more research to fix these problems. The U.S. CHIPS Act and EU Chips Act help build more local factories. Companies use AI and better planning to stop future shortages.

In the future, there will be more money spent on making chips. The U.S. wants to grow its chip factories by over 200% from 2022 to 2032. New things like artificial intelligence, quantum computing, and better wireless networks will change the industry. Scientists keep working to make chips faster and smarter.

The future of the semiconductor industry looks good. You will get even better and more energy-saving electronics soon.

You use chips all the time, like in your phone and car. The industry has many experts who work together around the world. This teamwork and smart planning help new ideas grow. Here is how this system helps make things better:

Aspect | How It Drives Innovation |

|---|---|

Experts can learn more and get better | |

People from different countries share ideas | |

Government Support | Helps pay for research and trains workers |

Chips help run AI, smart homes, and medical tools.

The industry gives people jobs and helps the world’s economy.

You will see even cooler technology as new ideas keep coming.

When you use a device, think about the tiny chip inside. It is making your life better every day.

FAQ

What is the main job of a semiconductor chip?

A chip controls how electricity moves in your devices. It acts like a tiny brain, helping your phone, computer, or car do smart things.

Why do chips keep getting smaller?

Smaller chips use less power and work faster. You get better phones and computers that can do more without getting hot or using lots of battery.

Can you recycle old chips or electronics?

Yes! You can recycle old electronics at special centers. They take out metals and parts to use again. This helps the planet and saves resources.

What happens if there is a chip shortage?

You might see higher prices or delays for new phones, cars, or game consoles. Companies may slow down making products until they get more chips.

See Also

Understanding Computer Chips And Their Functionality Explained

Exploring IC Line Drivers And Their Role In Electronics

Key Features That Differentiate ON Semiconductor Chips