What is a microchip and how does it work

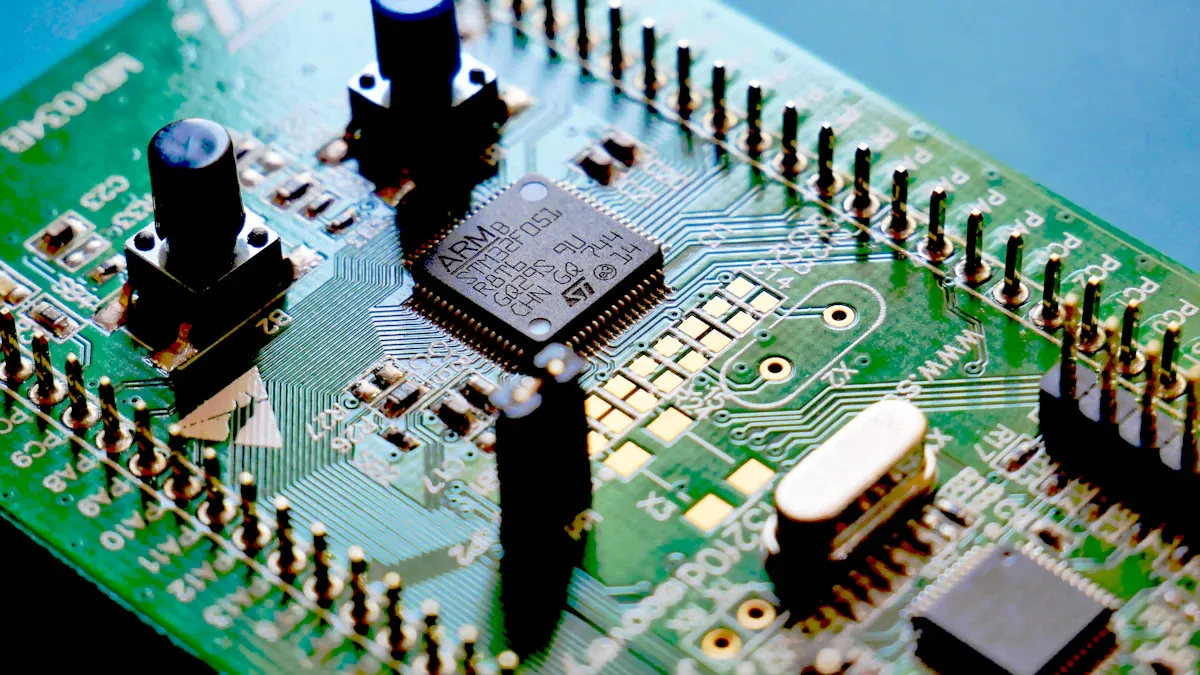

A microchip, also called a chip, computer chip, or integrated circuit (IC), contains billions of tiny parts like transistors, resistors, and capacitors. These parts fit together on a small piece of silicon, making the chip very powerful and compact. Micro chips act as the "brain" in many electronic devices. They process information and control signals by quickly switching electrical currents on and off. This lets devices like phones, computers, and cars follow instructions and store data.

Key Takeaways

Microchips are tiny silicon-based circuits that act as the brain of electronic devices by processing information and controlling signals.

They contain billions of small parts like transistors and capacitors that work together to handle digital and analog tasks efficiently.

Manufacturing microchips involves precise steps in clean rooms to build complex circuits layer by layer and ensure high quality.

Different types of microchips power devices, including microprocessors for computing, memory chips for data storage, and specialized chips for unique tasks.

Microchips improve everyday technology by making devices smarter, faster, and more connected, impacting areas like healthcare, transportation, and communication.

What Are Microchips

Definition

A microchip is a tiny piece of technology that holds many electronic parts on a small slice of silicon. Engineers call it an integrated circuit. Microchips have changed a lot since their invention. Early electronics used vacuum tubes, which were large and used a lot of energy. In 1947, scientists invented the transistor, which made devices smaller and more reliable. The real breakthrough came in 1958 when Jack Kilby and Robert Noyce created the first integrated circuit. This invention allowed many transistors and other parts to fit on one chip.

Over the years, microchips have become smaller and more powerful. In 1971, the first commercial microprocessor appeared, making computers and gadgets more affordable. By the 2000s, microchips could store much more data and work much faster than before. Today, microchips power smartphones, cars, medical devices, and even smart home systems.

Microchips contain several important parts that work together:

Transistors, which act as tiny switches or amplifiers for electrical signals.

Capacitors, which store and release electrical energy.

Diodes, which control the direction of electrical flow.

Resistors, which limit the amount of current in a circuit.

Metal paths, called interconnects, that connect all the parts.

Layers built on a silicon base, with connections between layers made by tiny holes called vias.

These parts allow microchips to process information quickly and efficiently.

Basic Function

Microchips serve as the control centers for electronic devices. They process information, store data, and manage signals. The way they work depends on their type:

Microchip Type | Main Function | Examples of Use |

|---|---|---|

Handle continuous signals, like sound or voltage | Audio amplifiers, radios, voltage regulators | |

Digital Integrated Circuits (ICs) | Work with binary data (0s and 1s) | Computers, smartphones, memory chips |

Mixed-Signal ICs | Combine analog and digital functions | Telecommunication devices, sensors, smartwatches |

Transistors inside microchips switch on and off very quickly. This switching lets the chip perform calculations, store information, and control other parts of a device. For example, in a smartphone, one microchip runs the operating system, while others handle memory, power, and communication.

Micro chips can process both digital and analog signals. Digital chips use binary logic to perform math and logic tasks. Analog chips work with real-world signals, such as sound or light. Some chips, called mixed-signal chips, can handle both types of signals. This flexibility allows microchips to power everything from simple toys to complex medical equipment.

Microchips have become essential in modern life. They help devices think, remember, and communicate, making technology smarter and more useful every day.

Microchip Structure

Silicon and Semiconductors

Silicon forms the foundation of almost every microchip. Manufacturers extract silicon from natural sand and then purify it to create large, single crystals. They slice these crystals into thin wafers, which serve as the base for building micro chips. Silicon stands out as the preferred material because it is abundant, making up about 28% of the Earth's crust. It is also cost-effective and easy to process. Silicon's chemical stability and high temperature resistance make it reliable for use in electronic devices.

Silicon acts as a semiconductor. This means it can conduct electricity under certain conditions but not others. Engineers can control its conductivity by adding tiny amounts of other elements, a process called doping. Doping creates two types of silicon: n-type, which has extra electrons, and p-type, which has extra holes where electrons can go. These two types are essential for making the electronic switches and pathways inside microchips.

Silicon's ability to form a high-quality insulating oxide layer, called silicon dioxide, allows for the creation of dense and complex circuits. This property supports the miniaturization and performance improvements seen in modern electronics.

Other materials, such as germanium and gallium arsenide, sometimes appear in specialized chips. However, silicon remains the top choice because it balances cost, availability, and performance.

Transistors and Circuits

Transistors serve as the building blocks of microchip circuits. Each transistor acts like a tiny switch, turning electrical signals on or off. By arranging billions of these switches in different patterns, engineers create circuits that can process information, store data, and control other parts of a device.

The unique properties of semiconductors allow transistors to switch quickly between on and off states. This switching represents the binary digits 0 and 1, which form the basis of all digital information. Doping silicon to create n-type and p-type regions enables the construction of these transistors and other important components, such as diodes.

Over the years, engineers have made transistors smaller and more efficient. Early transistors measured several centimeters, but today, some are only a few nanometers wide. This miniaturization has allowed billions of transistors to fit on a single chip, greatly increasing processing power and speed. The trend of shrinking transistors, known as Moore's Law, has driven advances in computing and made devices more affordable and powerful.

Transistor miniaturization has led to:

Faster processing speeds

Lower energy use

Smaller device sizes

More affordable electronics

However, making transistors extremely small brings new challenges. Issues like quantum effects and heat buildup can affect performance. To solve these problems, researchers are exploring new materials and designs, such as 3D transistors and quantum computing.

The complexity of microchip design increases costs and limits the number of companies that can produce the most advanced chips. This affects the price and availability of electronic devices for consumers.

Micro chips rely on the careful design and arrangement of transistors and circuits. These tiny components work together to power everything from simple calculators to advanced smartphones.

Making Microchips

Manufacturing Steps

Microchip manufacturing involves many precise steps. Each step must be carefully controlled to create reliable chips. The process starts with raw materials and ends with finished microchips ready for use in devices.

Raw Material Acquisition: Companies collect high-purity silica sand and purify it to remove impurities.

Silicon Ingot Production: Workers use the Czochralski process to grow a large, single-crystal silicon ingot from molten silicon.

Wafer Slicing: Machines slice the silicon ingot into thin wafers using diamond saws.

Wafer Polishing and Cleaning: Technicians polish and clean the wafers to make them extremely smooth and free of defects.

Deposition: Thin layers of materials are deposited onto the wafer to form the base for circuits.

Photoresist Coating: A light-sensitive material called photoresist covers the wafer.

Lithography: Engineers shine ultraviolet light through a patterned mask onto the wafer. This step transfers the circuit design onto the photoresist.

Etching: Chemical or plasma etching removes unwanted material, creating tiny patterns on the wafer.

Ion Implantation: Ions are implanted into the wafer to change its electrical properties, allowing transistors to form.

Layering and Patterning: These steps repeat many times to build complex circuits layer by layer.

Dicing and Packaging: The wafer is cut into individual chips. Each chip is mounted on a substrate and enclosed to protect it.

Microchip factories must use clean rooms and advanced machines. Even a tiny speck of dust can ruin a chip.

Quality Control

Quality control ensures that every microchip works as expected. Factories use many tests and inspections to find defects and guarantee performance.

Quality Control Measure | Description |

|---|---|

Wafer Testing | Screens circuits on wafers for defects and checks early functionality. |

Die Testing | Tests each chip after cutting to remove defective ones before packaging. |

Package Testing | Checks the chip’s enclosure for damage or defects. |

Final Product Testing | Runs full tests on finished chips to confirm they meet all requirements. |

Functional Testing | Verifies that the chip performs its intended tasks. |

Parametric Testing | Measures electrical properties like voltage and current. |

Reliability Testing | Simulates real-world stresses such as heat and humidity to check long-term durability. |

Automated Test Equipment (ATE) | Uses machines to test chips quickly and accurately. |

Statistical Process Control | Monitors production to spot and fix problems early. |

Built-in Self-Test (BIST) | Some chips test themselves to reduce outside testing needs. |

Finds tiny defects using advanced pattern recognition. |

Factories also use Intermittent Operating Life (IOL) testing. This test cycles chips on and off at high temperatures to check for failures. Regular calibration of equipment keeps measurements accurate and reliable. These steps help ensure that only the best chips reach consumers.

Types of Micro Chips

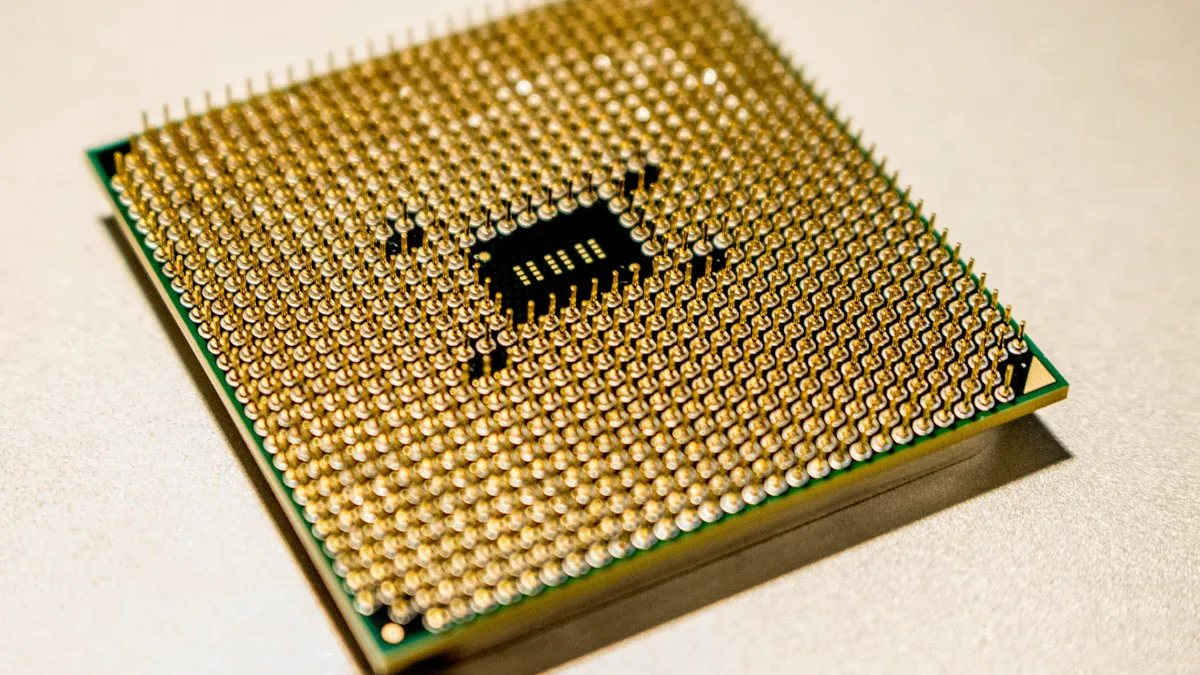

Microprocessors

Microprocessors act as the main control units in many electronic devices. They contain a central processing unit (CPU) that performs calculations and follows instructions. Over time, microprocessors have become more complex. Early models handled only simple tasks, but modern versions can process billions of instructions each second. Devices like laptops, smartphones, and tablets rely on microprocessors to run software and manage hardware.

Microprocessors come in several forms:

General-purpose microprocessors power computers and servers.

Microcontrollers combine a processor with memory and input/output controls for use in cars, appliances, and toys.

Digital signal processors (DSPs) handle audio and video signals in phones and music players.

Graphics processing units (GPUs) create images for games and videos.

A typical microprocessor includes features such as:

Characteristic | Description |

|---|---|

Measures how fast the processor works | |

Number of Cores | Shows how many tasks it can handle at once |

Cache Memory | Stores frequently used data for quick access |

Power Consumption | Affects battery life in portable devices |

Microprocessors have made devices smarter and more efficient by handling complex tasks quickly.

Memory Chips

Memory chips store information for electronic devices. Unlike microprocessors, they do not process data but keep it safe for later use. Memory chips come in two main types: volatile and non-volatile. Volatile memory, such as RAM, loses data when power turns off. Non-volatile memory, like flash storage, keeps data even without power.

Common types of memory chips include:

DRAM (Dynamic RAM): Used as main memory in computers.

SRAM (Static RAM): Works as fast cache memory near the CPU.

Flash Memory: Stores photos, music, and apps in phones and USB drives.

ROM (Read Only Memory): Holds permanent instructions for devices.

Memory Type | Volatility | Typical Use |

|---|---|---|

DRAM | Volatile | Main system memory |

SRAM | Volatile | CPU cache |

Flash | Non-volatile | Phones, SSDs, USB drives |

ROM | Non-volatile | Device firmware |

Memory chips help devices remember settings, store files, and run programs smoothly.

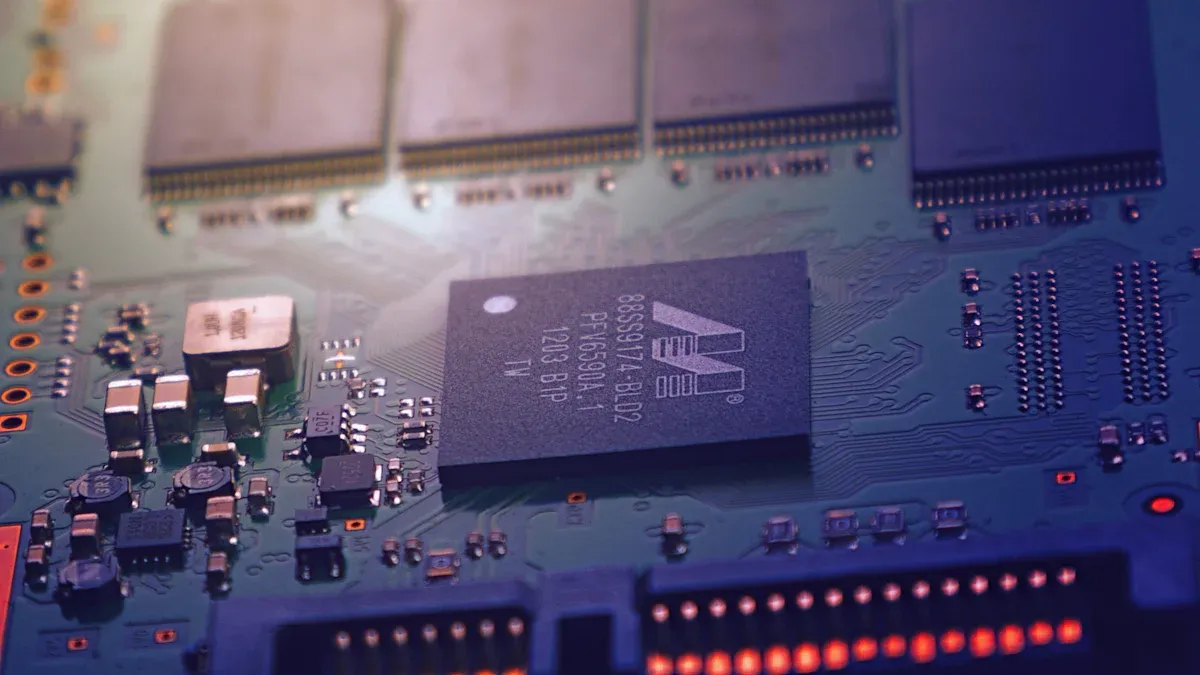

Specialized Chips

Specialized chips perform unique tasks that general-purpose chips cannot handle efficiently. RFID chips, for example, store digital information and communicate wirelessly with readers. People use RFID chips for pet identification, inventory tracking, and contactless payments. These chips come in passive, active, and semi-active forms, depending on how they receive power.

Sensor chips measure things like temperature, pressure, or movement. They appear in fitness trackers, smart thermostats, and medical devices. Many modern micro chips combine sensors, processors, and antennas on a single chip. This integration allows for small, low-power devices that work reliably in many environments.

Other specialized chips include:

Application-specific integrated circuits (ASICs) for tasks like cryptocurrency mining.

System-on-chip (SoC) designs that combine a CPU, GPU, memory, and more on one chip for smartphones and IoT devices.

Specialized chips have expanded the possibilities of technology, making devices more connected, efficient, and responsive to the world.

Micro Chips in Daily Life

Everyday Devices

People use micro chips every day, often without realizing it. Phones, laptops, and smartwatches all depend on these tiny circuits to work. Micro chips process data, store information, and help devices communicate with each other. In homes, laundry machines and smart thermostats use micro chips to automate tasks and save energy. Cars and electric vehicles rely on chips for engine control, safety features, and entertainment systems.

Device Type | How Micro Chips Help |

|---|---|

Smartphones | Run apps, connect to the internet, store photos |

Laptops | Process information, manage files, display graphics |

Cars | Control engines, support navigation, improve safety |

Smartwatches | Track fitness, show notifications, monitor health |

Home Appliances | Automate washing, control temperature, save energy |

Micro chips come in many forms. Logic chips handle processing and instructions. Memory chips store data. Mixed-signal chips combine both digital and analog functions. System-on-a-chip designs pack many features into a single chip, making devices smaller and more efficient.

Micro chips make daily life easier by powering the devices people use for work, school, and fun.

Impact on Technology

Micro chips have changed technology in many ways. In homes, they allow smart devices to connect and work together. People can control lights, security systems, and climate settings from their phones or with voice commands. These smart systems help save energy and keep homes safe.

Micro chips in healthcare power wearable devices that track heart rate and monitor health in real time.

In transportation, chips help cars drive safely and connect to traffic systems.

For communication, chips enable fast wireless connections like Wi-Fi and 5G, making it easy to share information.

Micro chips also play a key role in security. They protect personal data on phones and computers by using hardware-level safeguards. In industry, chips control machines, improve energy use, and help factories run smoothly. New chip designs, such as those using extreme ultraviolet lithography, allow for faster and more powerful devices.

The world depends on micro chips for progress in medicine, travel, communication, and safety. These tiny circuits continue to shape the future by making technology smarter and more connected.

Microchips shape modern technology by powering devices in healthcare, transportation, AI, and daily life. They use advanced materials and tiny circuits to process information quickly and efficiently.

Experts highlight microchips as the foundation of innovation, driving progress in fields like quantum computing and IoT.

The industry faces challenges such as supply chain disruptions and raw material shortages, but ongoing research and education keep advancements moving forward.

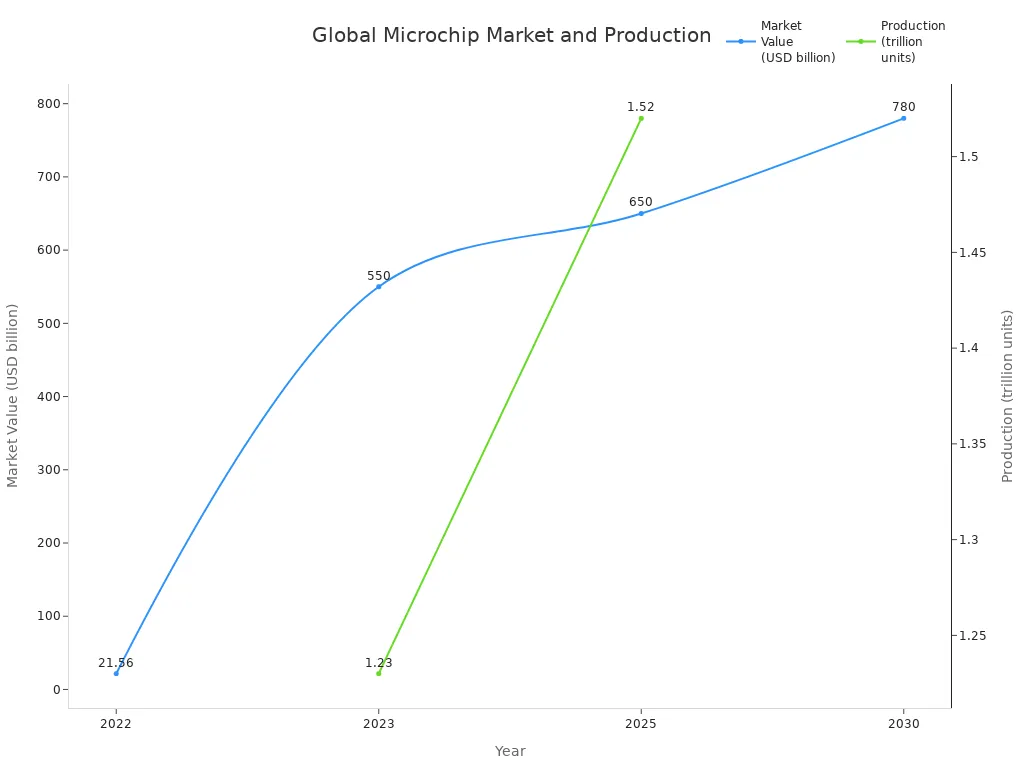

Aspect | Data / Estimate |

|---|---|

Global market value (2023) | USD 550 billion |

Projected value (2030) | Over USD 780 billion |

Annual production (2023) | 1.23 trillion units |

Microchips remain essential to digital life, inspiring new careers and shaping the future of technology.

FAQ

What is the main material used in microchips?

Silicon forms the base of most microchips. Manufacturers choose silicon because it is abundant, affordable, and works well as a semiconductor. Other materials, like gallium arsenide, appear in special chips, but silicon remains the most common.

How small are the parts inside a microchip?

Transistors inside modern microchips can measure just a few nanometers wide. For comparison, a human hair is about 80,000 nanometers thick. This tiny size allows billions of transistors to fit on a single chip.

Why do microchips need clean rooms during manufacturing?

Factories use clean rooms to keep dust and particles away from microchips. Even a single speck of dust can ruin a chip. Workers wear special suits and use filtered air to protect the chips during production.

Can microchips be recycled?

Yes, recycling centers can recover metals and materials from old microchips. Recycling helps reduce electronic waste and saves valuable resources. However, the process requires special equipment to safely handle and separate the tiny parts.

See Also

Understanding MCU Microcontrollers And Their Operational Principles

Exploring Computer Chips And The Way They Function

A Guide To Real-Time Microcontroller ICs And Their Functionality

Breaking Down Communication Chips And Their Working Mechanisms