What Is a Circuit Board and How Does It Work

A circuit board is a small, flat board that holds and connects the electronic parts inside your favorite devices. You can think of it as the hidden backbone that keeps everything working together. Copper lines run across the surface, acting like tiny roads that guide electricity between different parts. You find circuit boards in smartphones, computers, smart bulbs, and even in your TV remote. Every time you use these gadgets, you rely on a circuit board to make them work smoothly.

Key Takeaways

A circuit board holds and connects electronic parts using copper traces that guide electricity like tiny roads.

It supports devices by organizing parts, carrying signals, preventing heat, and making gadgets smaller and reliable.

Circuit boards have layers made of strong materials and include parts like resistors, capacitors, transistors, and integrated circuits.

Electricity flows through copper paths to parts that control, store, or switch signals, allowing devices to work smoothly.

Different types of circuit boards fit various needs, and careful design and testing ensure they work safely in everyday electronics.

Circuit Board Basics

What Is a Circuit Board

A circuit board is a flat, sturdy board that holds and connects the parts inside electronic devices. You will see copper lines, called traces, running across the surface. These traces act like tiny highways, guiding electricity to different parts. The board itself is made from a material that does not conduct electricity, which keeps the electrical paths safe and separate.

Think of a circuit board as a city map. The copper traces are the roads, and the electronic parts are the buildings. Electricity travels along these roads to reach each building, making the whole city work together.

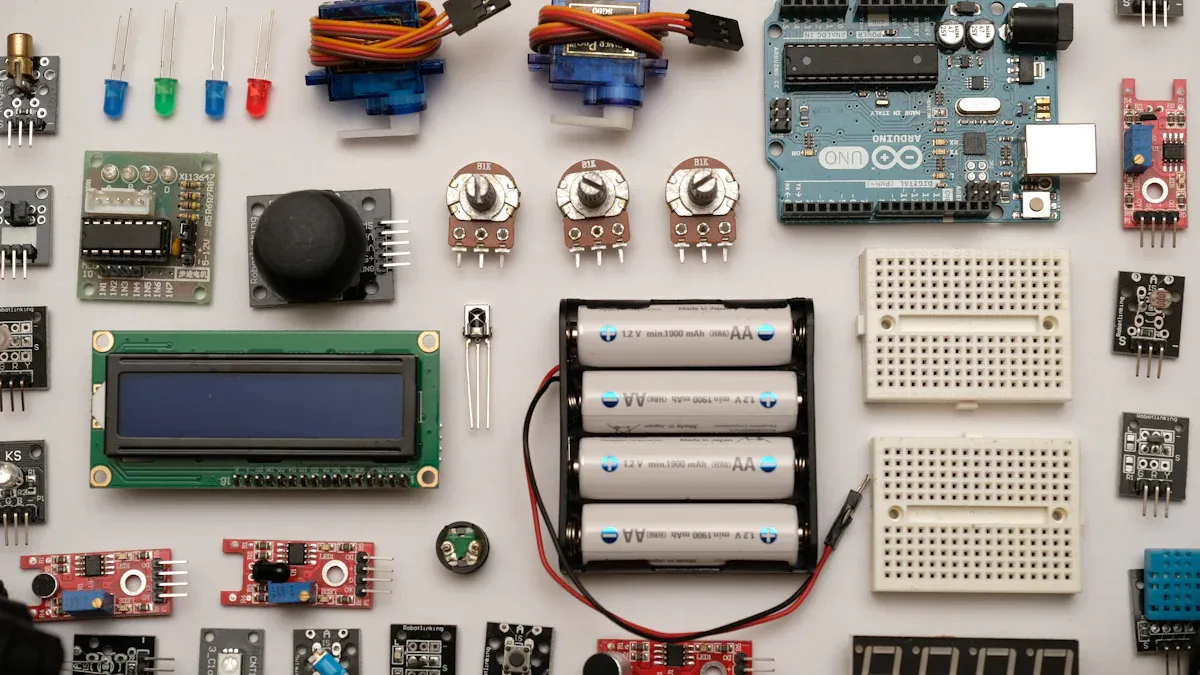

You will find two main types of parts on a circuit board:

Passive components: These include resistors, capacitors, and fuses. Resistors control how much electricity flows. Capacitors store and release energy. Fuses protect the board from too much current.

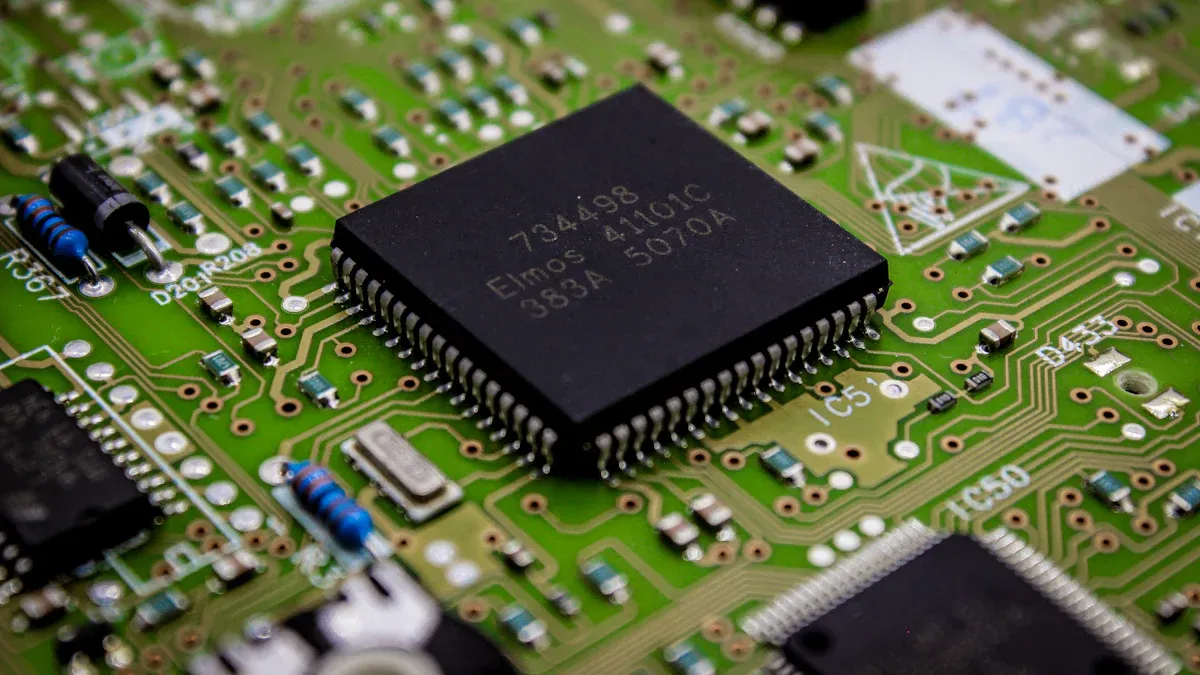

Active components: These include transistors, diodes, and integrated circuits. Transistors can switch or amplify signals. Diodes let electricity flow in only one direction. Integrated circuits combine many parts into a small chip, making devices smarter and faster.

The combination of these parts, along with the copper traces, gives the circuit board its unique abilities. Over time, circuit boards have changed a lot. Early boards were simple and only held a few parts. Today, you will find boards with many layers and millions of tiny parts, allowing devices to be smaller and more powerful.

Main Purpose

The main purpose of a circuit board is to connect and support all the electronic parts in a device. It acts as the backbone, holding everything in place and making sure each part can talk to the others. The copper traces carry electricity and signals between the parts, letting them work together.

A circuit board keeps the parts organized and secure.

It provides clear paths for electricity to travel.

It helps prevent overheating by spreading out heat.

It allows devices to be smaller and more reliable.

You rely on circuit boards every day. They make your phone, computer, and even your microwave work by connecting all the important parts. Without a circuit board, electronic devices would be messy, unreliable, and much larger.

Structure and Components

Layers and Materials

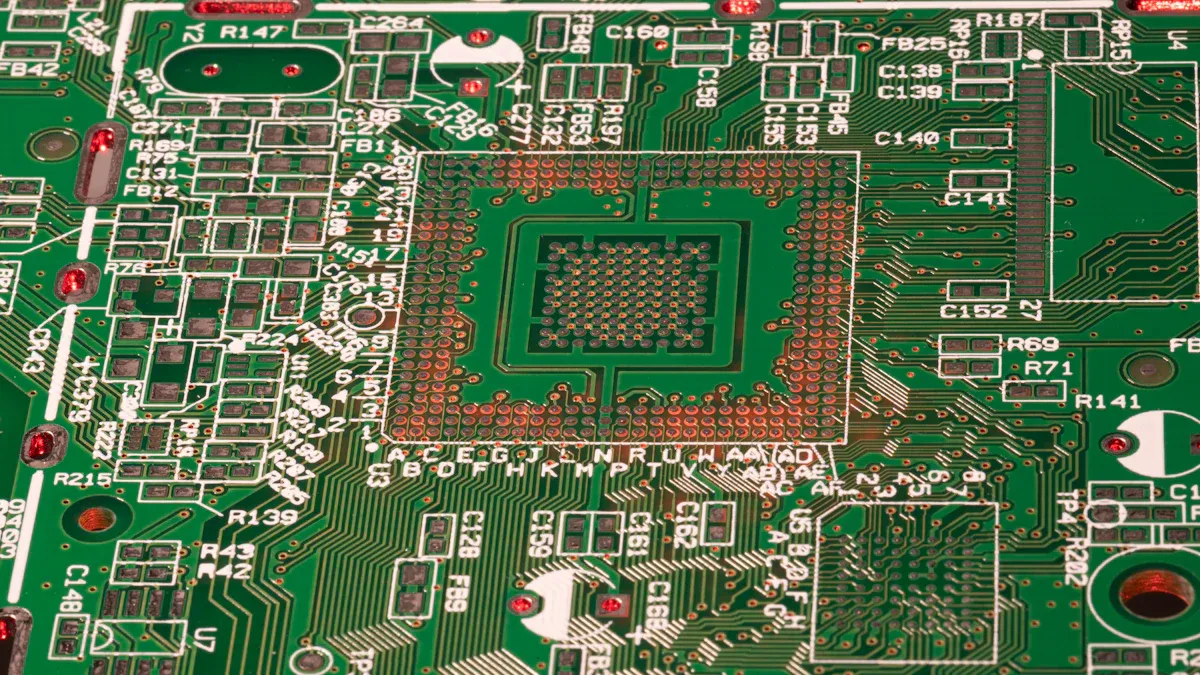

When you look inside a circuit board, you find several layers stacked together. The main layer is called the substrate. Most circuit boards use a material named FR4, which is a fiberglass-reinforced epoxy. FR4 gives the board strength, keeps out moisture, and resists fire. Some boards use other materials like polyimide or even metal cores such as aluminum for special needs. On top of the substrate, thin copper sheets form the pathways for electricity. These copper layers are usually about 35 microns thick. A green layer called solder mask covers the copper to protect it and prevent short circuits. You also see white markings, known as the silkscreen, which help you identify where each part goes.

Tip: The number and arrangement of layers in a circuit board affect how well it works. More layers mean more space for connections and better control over electrical signals.

Key Components

You find many different parts on a standard circuit board. Each part has a special job. Here are some of the most common:

Resistors control the flow of electricity.

Capacitors store and release energy.

Inductors manage changes in current.

Transistors switch or amplify signals.

Integrated circuits handle complex tasks, like processing data.

Diodes make sure electricity flows in only one direction.

Connectors link the board to other devices.

Switches, relays, and fuses help control and protect the circuit.

All these parts work together to make your device function. You also see special features like copper layers, solder mask, and silkscreen, which help organize and protect the board.

Copper Traces and Solder

Copper traces act like tiny roads that connect all the parts on the board. Copper is a great choice because it lets electricity flow easily and does not waste much energy as heat. These traces carry signals and power to every component. Solder holds each part in place and creates a strong electrical connection between the part and the copper pad. Without solder, the parts would not stay attached, and the circuit would not work. Together, copper traces and solder form the backbone of the circuit board, making sure everything stays connected and works as it should.

How a Circuit Board Works

Flow of Electricity

When you power on an electronic device, electricity starts its journey across the circuit board. The copper traces act as highways, guiding electrical signals to each component. You can picture these traces as roads that connect different buildings in a city. Each building represents a part like a resistor, capacitor, or transistor.

Resistors slow down the flow of electricity, helping control voltage.

Capacitors store and release energy when needed, like tiny batteries.

Inductors manage changes in current and block unwanted signals.

Diodes make sure electricity flows in only one direction, protecting the board.

Transistors act as switches, turning signals on or off.

All these parts get soldered onto the board, making strong connections.

The power source sends energy through the traces. As electricity moves, each component changes the signal in its own way. This process lets the circuit board perform its job, whether it is powering a light or running a computer.

Tip: The design and testing of the board make sure electricity flows smoothly, so your device works every time you turn it on.

Signal Routing

Signal routing is how the board directs electrical signals to the right places. You want signals to travel quickly and without interference. The layout of the traces matters a lot. Engineers plan the paths carefully to keep signals strong and clear.

Traces connect each component in the best order, reducing the chance of signal loss.

The board uses multiple layers to separate power, ground, and signal paths. This helps prevent noise and keeps signals clean.

Special routing techniques, like matching the length of certain traces, keep high-speed signals from getting distorted.

Vias, which are tiny holes filled with metal, let signals move between layers.

1. You place components in smart locations to shorten signal paths. 2. You route traces with the right width and spacing to avoid interference. 3. You use ground and power layers to keep voltage steady. 4. You add decoupling capacitors to reduce noise. 5. You test the board to make sure signals reach their destinations without problems.

Note: Good routing prevents problems like crosstalk, where signals jump between traces, and electromagnetic interference, which can cause devices to act strangely.

Coordinated Operation

A circuit board works best when all its parts operate together. You need careful planning to make this happen. The board’s design separates high-voltage and low-voltage areas. This keeps sensitive parts safe from electrical noise. Grounding techniques stop unwanted currents from causing trouble.

Controllers, like microcontrollers or microprocessors, act as the brains of the board. They send out timing and control signals, making sure each part does its job at the right moment. These controllers help memory chips, sensors, and other parts communicate smoothly.

The board’s layers and vias allow signals to travel between different sections. Connectors link the board to other devices or boards, creating a complete system. Mechanical design also matters. You space out parts to avoid stress and make repairs easier.

Block Quote: When you use a device, you rely on the circuit board’s careful design to keep everything running in sync. Each part knows when to act, thanks to the board’s smart layout and control signals.

Types and Manufacturing

PCB Types

You will find many types of printed circuit boards (PCBs) in electronics. Each type has special features and uses. The table below shows the main types, their descriptions, and where you might see them:

PCB Type | Description | Typical Applications |

|---|---|---|

Single Sided PCBs | One copper layer on one side; parts go on one side only. | Calculators, radios, LED lights, power supplies |

Double Sided PCBs | Copper layers on both sides; parts can go on both sides; uses small holes called vias. | Industrial controls, car electronics, amplifiers |

Multi-layer PCBs | Three or more copper layers with insulation between; supports complex circuits. | Computers, phones, medical devices |

Rigid PCBs | Hard, cannot bend; can be single, double, or multi-layered. | Laptops, TVs, cars, airplanes |

Flexible PCBs | Made from bendable plastic; can fold or twist. | Wearables, medical tools, foldable gadgets |

Rigid-Flex PCBs | Mix of hard and flexible parts; good for tight spaces. | Aerospace, military, advanced electronics |

High-Frequency PCBs | Made for signals above 1 GHz; uses special materials. | Telecom, radar, medical imaging |

Aluminum Backed PCBs | Metal base for better heat control. | LED lighting, power modules, car lights |

Tip: Single-sided PCBs cost the least and work for simple devices. Multi-layer PCBs handle complex jobs like computers and smartphones.

Basic Manufacturing Steps

Making a PCB takes careful steps to ensure it works well. Here is a simple outline of the process:

Design the layout using computer software. Place parts and draw copper paths.

Choose the right materials, like FR4 for most boards.

Print the design onto a photosensitive film on the board.

Shine ultraviolet light to harden the film where copper should stay.

Etch away extra copper, leaving only the needed paths.

Drill holes for parts and connections between layers.

Plate the board and holes with copper for good connections.

Mount parts onto the board, often using surface-mount technology.

Solder the parts in place, usually with machines for speed and accuracy.

Add a protective solder mask and print labels for easy part placement.

Note: Each step must be precise. Even a small mistake can cause the board to fail.

Quality and Testing

You want every PCB to work safely and last a long time. Factories use many tests and standards to check quality:

Visual Inspection: Workers or machines look for missing or misplaced parts.

Automated Optical Inspection (AOI): Cameras scan for defects like bad solder joints.

In-Circuit Test (ICT): Special tools check for short circuits and make sure each part works.

Flying Probe Test: Moving probes test electrical paths without needing a custom fixture.

Functional Test: The board runs in a test system to see if it works as planned.

X-Ray Inspection: Checks inside the board for hidden problems.

Common standards include IPC-A-610 for assembly quality and ISO 9001 for good manufacturing practices. Some boards must also meet safety rules like UL 796 and RoHS, which limit harmful chemicals.

Callout: High-reliability boards, such as those in medical or aerospace devices, must pass the strictest tests and follow the toughest standards.

Importance in Electronics

Everyday Devices

You use electronics every day, often without thinking about what makes them work. Inside each device, you find a hidden network that brings everything to life. Most of your favorite gadgets rely on this technology.

Smartphones and tablets help you connect with friends, play games, and learn new things. Their compact designs depend on advanced boards that manage calls, apps, and even high-speed internet.

Laptops and televisions bring entertainment and information right to your fingertips. These devices use complex boards to process images, sound, and data quickly.

Home appliances like refrigerators, washing machines, and coffee makers use boards to control settings, monitor performance, and even connect to Wi-Fi.

Wearable devices such as fitness trackers and smartwatches use small, flexible boards to track your steps, monitor your heart rate, and send notifications.

Other everyday items—clocks, security systems, headphones, thermostats, video game systems, and electric toothbrushes—also depend on these boards for their main functions.

Tip: The next time you use a remote control or set your alarm clock, remember that a tiny board inside makes it all possible.

Why Circuit Boards Matter

You might wonder why these boards are so important. They do more than just hold parts together. They provide strong support and connect every component, allowing electricity to flow where it needs to go. This design keeps your devices reliable and safe.

Over the past decade, these boards have become smaller and more complex. Engineers use new materials and advanced techniques to fit more parts into less space. Flexible designs now let you enjoy bendable screens and wearable tech. Machine assembly ensures that even the tiniest parts fit perfectly, making your devices faster and more efficient.

These boards also help the environment. Companies can recover valuable metals from old electronics, saving energy and reducing waste. Reusing parts lowers the cost of making new devices and cuts down on pollution.

Callout: Without these boards, modern electronics would not exist. They make your devices smarter, smaller, and more powerful, shaping the way you live, learn, and play.

You now know that a circuit board connects and supports every part inside your favorite devices.

You find single-sided, double-sided, and multilayer boards in everything from phones to cars.

These boards help make electronics smaller, more reliable, and easier to produce.

They keep devices cool and safe, while letting signals travel quickly between parts.

Next time you open a gadget, look for the green board with copper lines and tiny parts.

Printed circuit boards are truly the lifeblood of your device, powering the technology you use every day.

FAQ

What is the difference between a PCB and a circuit board?

You often see "PCB" and "circuit board" used for the same thing. PCB stands for "printed circuit board." Both terms describe the flat board with copper traces that connect electronic parts.

Can you repair a broken circuit board?

You can fix some simple problems, like loose solder joints or broken traces, with basic tools. For complex damage, you may need special skills or equipment. Sometimes, replacing the board is easier.

Tip: Always unplug your device before trying any repairs.

Why do most circuit boards look green?

You see green boards because manufacturers use a green solder mask to protect copper traces. Green is popular because it shows defects easily and helps with inspection. Some boards use other colors, like blue or red.

How do you identify parts on a circuit board?

You can look for labels printed on the board, called silkscreen markings. These labels use letters and numbers to show where each part goes. You may also see shapes or outlines that match the parts.

Are circuit boards safe for the environment?

You help the environment when you recycle old circuit boards. Many boards contain valuable metals and some hazardous materials. Proper recycling recovers useful parts and keeps harmful substances out of landfills.

Note: Always recycle electronics at approved centers.

See Also

Understanding The Function And Purpose Of Computer Chips

Exploring How Current Controller Chips Operate Effectively

How Optocoupler Integrated Circuits Function In Electronics