Understanding the Different Types of Components Found on a PCB

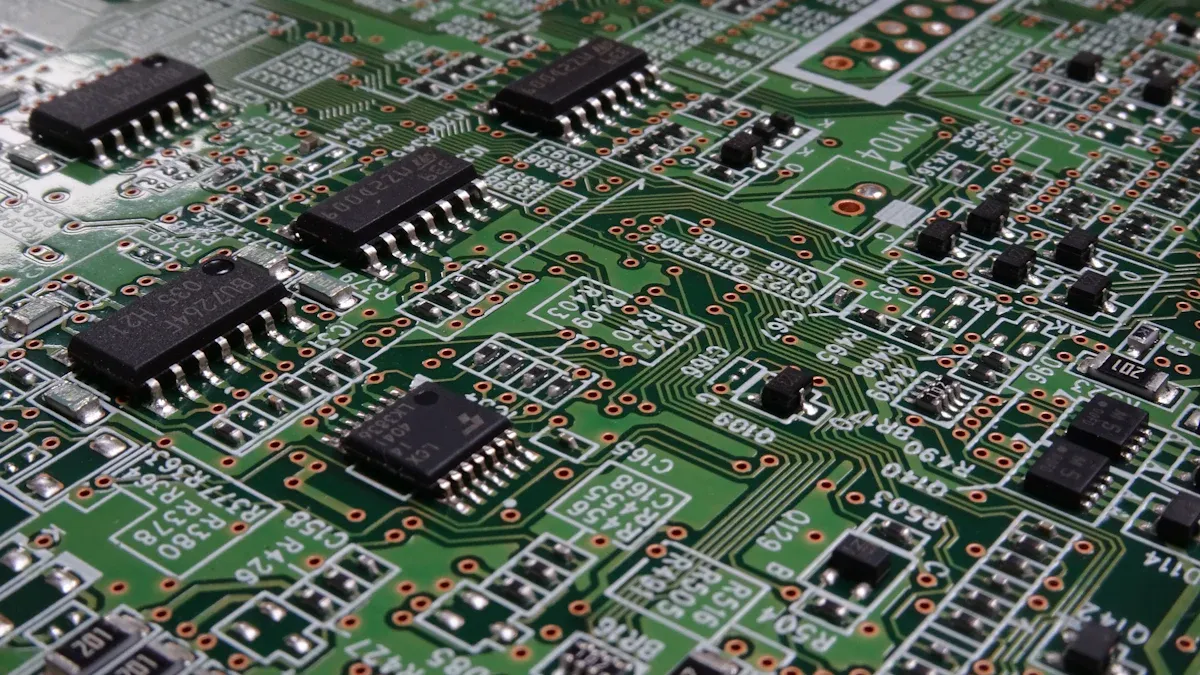

Printed circuit boards contain many different parts, each playing a special role in how devices work. You will find four main categories on most PCBs:

Passive components, like resistors, capacitors, and inductors

Active components, such as diodes, transistors, and integrated circuits

Electromechanical parts, including switches and relays

Connectors, which link different sections or connect to other devices

Understanding the parts of a pcb helps you see how signal flow, power distribution, and mechanical support come together in devices like smartphones and TVs. Recognizing these components gives you a strong foundation for learning about electronics and PCB design.

Key Takeaways

PCBs form the base of electronic devices by holding parts and connecting them with copper traces for power and signals.

Four main component types on PCBs are passive parts, active parts, electromechanical parts, and connectors, each with a unique role.

Passive components like resistors and capacitors control and store energy, while active components like transistors and ICs amplify and process signals.

Identifying components uses reference designators, markings, and package types to help with assembly and troubleshooting.

Common PCB problems come from faulty parts, soldering issues, or misidentification, but careful checks and good skills keep devices reliable.

What Is a PCB?

Definition

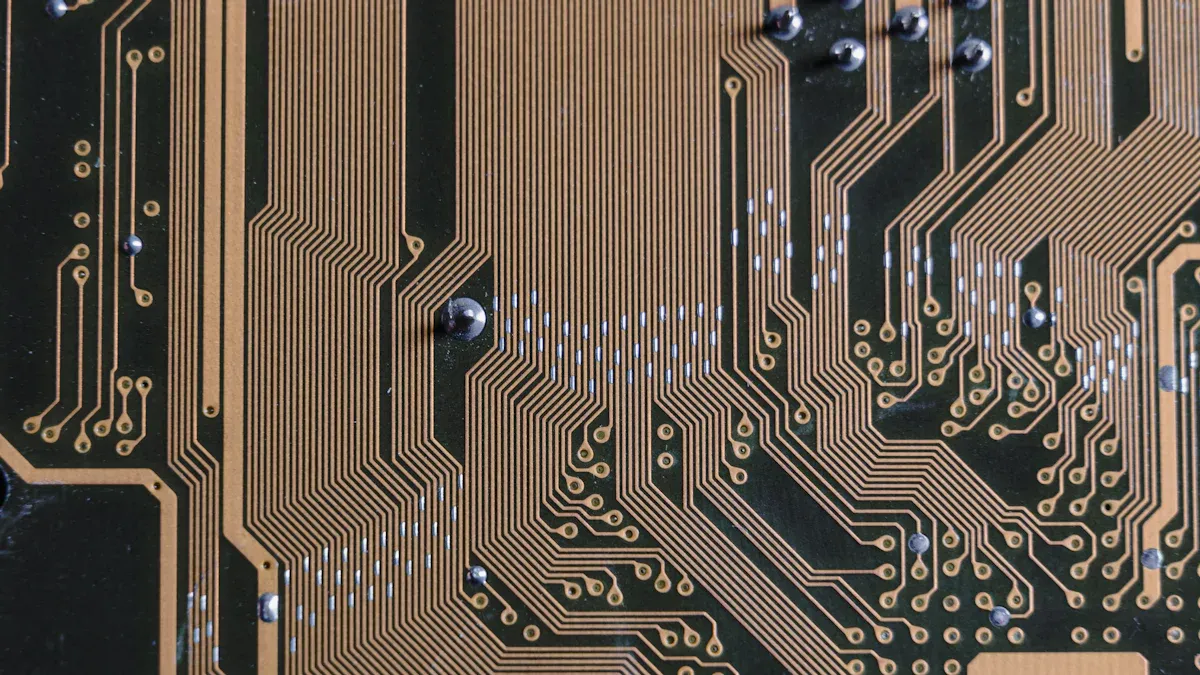

A printed circuit board, or PCB, forms the base of almost every electronic device you use. You can think of a PCB as a flat board that holds and connects all the electronic parts in a device. The board itself is made from layers of materials. The main layer is usually fiberglass, which gives the board strength and keeps electricity from leaking between parts. On top of this, thin copper lines create paths for electricity to travel. These copper traces connect different components, such as resistors and chips, so they can work together.

Industry groups like the Institute for Printed Circuits (IPC) set the standards for how PCBs are made and used. IPC has published hundreds of standards that guide the design, materials, and quality of PCBs. These standards help make sure that PCBs are safe, reliable, and work the same way in devices all over the world. When you see a PCB, you are looking at a product shaped by these important rules.

Tip: The green color you often see on PCBs comes from a protective layer called the solder mask. This layer keeps the copper from rusting and helps prevent short circuits.

Role in Electronics

You will find PCBs at the heart of almost every electronic device, from smartphones to washing machines. PCBs give you two main things: a strong base to hold parts and a way to connect them with copper traces. These traces act like tiny roads, carrying power and signals between components. This setup lets your device work smoothly and keeps everything organized.

PCBs make devices smaller, lighter, and more reliable. Before PCBs, people had to connect parts with lots of wires, which took up space and often caused problems. Now, with PCBs, you get compact designs that are easier to build and fix. The layered structure of a PCB also helps protect the circuits and makes sure signals travel where they should. When you use any modern gadget, you rely on the PCB inside to keep everything running as it should.

Parts of a PCB

When you look at the parts of a pcb, you will see four main categories. Each group has a special job in making circuits work.

Passive Elements

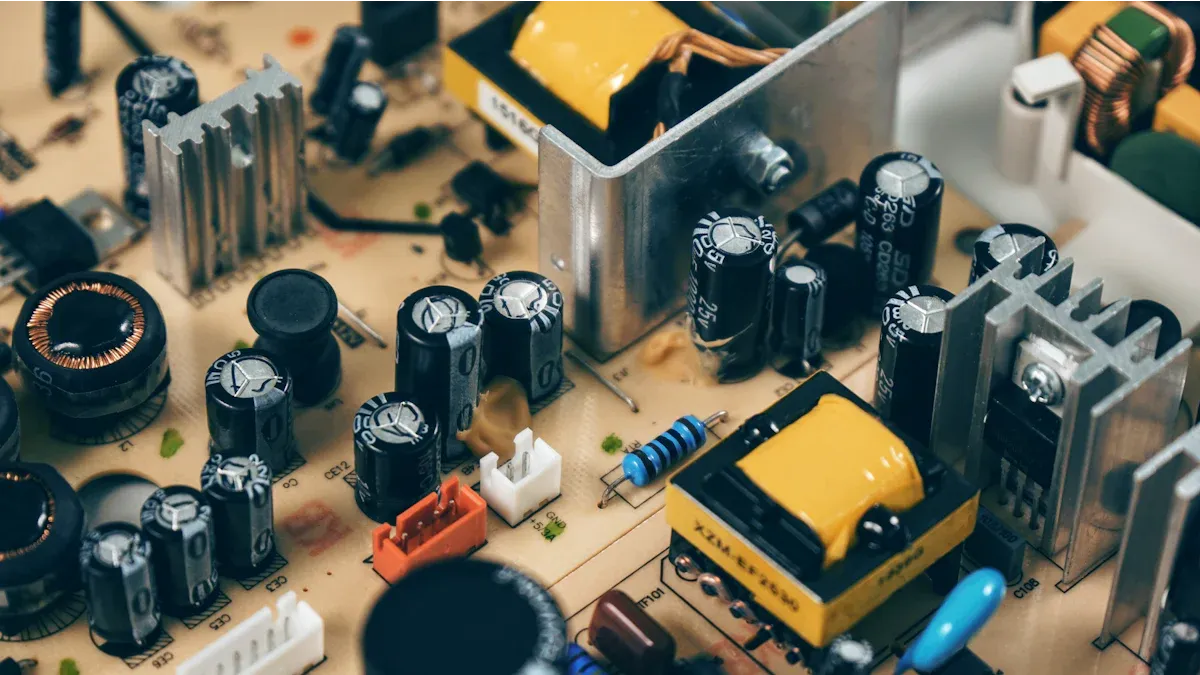

Passive elements do not add energy to a circuit. You use them to control, store, or filter electrical signals. Here are some of the most common passive elements you will find:

Resistors: Control how much current flows and help divide voltage.

Capacitors: Store and release energy, filter out noise, and keep voltage steady.

Inductors: Store energy in a magnetic field and block sudden changes in current.

Transformers: Change voltage levels and provide isolation between circuits.

Ferrite Beads: Block high-frequency noise, especially on power lines.

Potentiometers/Trimmers: Let you adjust resistance to fine-tune circuits.

Fuses: Protect circuits by breaking the connection if too much current flows.

Tip: You often see resistors and capacitors in almost every electronic device. They help keep signals clean and safe.

Passive Component | Main Function(s) | Typical Use |

|---|---|---|

Resistors | Control current, divide voltage | Voltage dividers, current limiting |

Capacitors | Store/release energy, filter noise | Power supply filtering, decoupling |

Inductors | Store energy, filter noise | EMI suppression, filters |

Transformers | Change voltage, isolate circuits | Power supplies, adapters |

Ferrite Beads | Block high-frequency noise | Power lines, RF suppression |

Potentiometers | Adjustable resistance | Tuning, calibration |

Fuses | Over-current protection | Power input protection |

Active Elements

Active elements add energy to a circuit or control the flow of electricity. These parts of a pcb let you amplify signals, switch currents, or process information.

Active Component | Role in Circuit Operation |

|---|---|

Transistors | Amplify signals, act as switches |

Diodes | Allow current in one direction, protect circuits |

Integrated Circuits | Combine many functions like memory, logic, or signal processing |

Run code, control other parts | |

Voltage Regulators | Keep voltage steady |

Op-Amps | Amplify voltage, process signals |

You will find transistors and integrated circuits in almost every modern device. They make computers, phones, and even simple toys work.

Electromechanical Components

Electromechanical components use both electrical and mechanical actions. You use them to control circuits or move parts.

Switches: Turn circuits on or off.

Relays: Use a small electrical signal to control a larger current.

Connectors with moving parts: Some connectors have locking mechanisms or springs.

Switches and relays help you control power and signals safely. You often see them in control panels and appliances.

Connectors

Connectors link different parts of a pcb or connect the board to other devices. They come in many shapes and sizes, each with a special job.

Board-to-board connectors: Join two PCBs for data or power.

Wire-to-board connectors: Attach wires to the board, often for sensors or motors.

Power connectors: Deliver power to the circuit.

FFC/FPC connectors: Connect flexible cables, common in phones and laptops.

Audio/Video connectors: Carry sound or video signals, like HDMI or RCA.

Header connectors: Rows of pins for general connections.

Connectors make it easy to build, repair, or upgrade devices. You can swap out parts or add new features without soldering.

Note: The right connector keeps your signals strong and your device safe from damage.

You now know the main parts of a pcb and how each group helps your electronics work.

Key Component Types

Resistors

Resistors are one of the most common parts of a pcb. You use them to control how much electric current flows through a circuit. They help divide voltage, generate heat, power LEDs, match circuits, and set timing for other components. You can find resistors in almost every electronic device.

Aspect | Details |

|---|---|

Primary Functions | Resist electric current, divide voltage, generate heat, power LEDs, match/load circuits, control gain, fix time constraints |

Common Types | Fixed Resistors (carbon composition, wire-wound, thin film, thick film, fusible), Variable Resistors (potentiometers, rheostats), Non-linear Resistors (thermistors, varistors, light-dependent resistors), Surface Mount Resistors |

Fixed resistors have a set value and come in types like carbon film (common in consumer devices), wire-wound (for high power), and thin film (for precision). Variable resistors, such as potentiometers, let you adjust resistance. Non-linear resistors change resistance with temperature or light. Surface mount resistors are tiny and fit directly onto the board, making them perfect for compact devices.

Tip: When you adjust the volume on a radio, you often use a potentiometer, which is a type of variable resistor.

Capacitors

Capacitors store and release electrical energy. You use them to filter noise, smooth out voltage, and help with timing in circuits. Capacitors come in many types, each with special features.

Capacitor Type | Key Characteristics | Common Applications |

|---|---|---|

Ceramic | Small size, high capacitance, high-frequency, low ESR | Noise decoupling, high-frequency filtering |

Electrolytic | High capacitance, larger size, energy storage | Power supply smoothing, audio circuits |

Film | Stable, precise, long lifespan, low losses | Filtering, timing circuits |

Mica | Exceptional stability and tolerance, rugged | Precision applications requiring longevity |

SMD | Compact, surface-mountable, various dielectric types | Modern compact electronics |

You often see ceramic capacitors near chips to filter out high-frequency noise. Electrolytic capacitors store more energy and help smooth power supplies. Film and mica capacitors work well in circuits that need stable and precise timing.

Note: Capacitors play a big role in keeping signals clean and devices running smoothly.

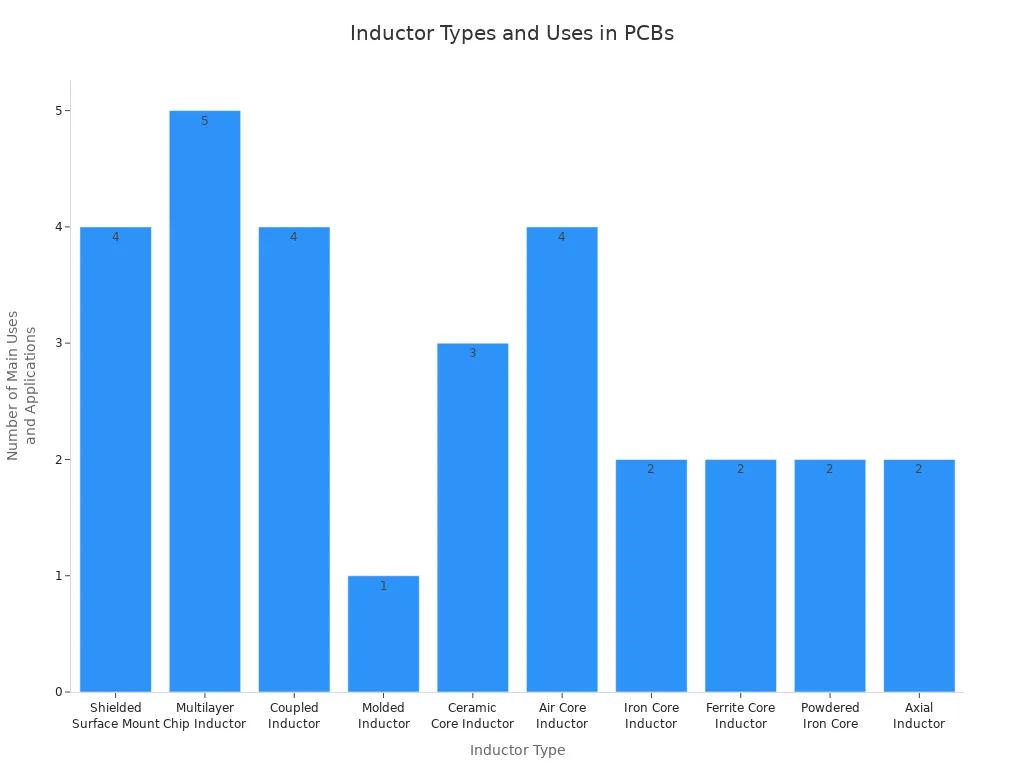

Inductors

Inductors store energy in a magnetic field when current flows through them. You use them to filter signals, reduce noise, and manage power in circuits. Inductors come in many shapes and sizes, each suited for different jobs.

Inductor Type | Main Uses in PCB Designs | Typical Applications and Prevalence |

|---|---|---|

Shielded Surface Mount | EMI reduction, compact size, power supplies, DC-DC converters | Mobile devices, servers, motherboards, wireless applications |

Multilayer Chip Inductor | High inductance in small size, surface mount technology | Bluetooth, wireless LANs, motherboards, wearables, single board computers (SBCs) |

Coupled Inductor | Energy transfer via mutual inductance, converters, transformers | Cuk, flyback, single-ended primary-inductor converters, transformers |

Molded Inductor | General circuit board use with molded insulation | Circuit boards |

Ceramic Core Inductor | Low distortion, heat loss, high-frequency applications | RF circuits, small-signal filtering, LC filter circuits |

Air Core Inductor | High-frequency, low noise, no magnetic core losses | RF tuning, filter circuits, snubber circuits, TV and radio receivers |

Iron Core Inductor | Power management, low-frequency filtering | Transformers, high-frequency applications |

Ferrite Core Inductor | High-frequency filtering, EMI suppression | Switch-mode power supplies, EMI suppression |

Powdered Iron Core Inductor | Power converters, output filters | Transformers, DC inductors |

Axial Inductor | Line filters, boost converters | Line filters, boost converters |

You find inductors in power supplies, radios, and devices that need to block or filter certain signals.

Diodes

Diodes let electricity flow in only one direction. You use them to convert AC to DC, protect circuits, and process signals. Diodes come in many forms, each with a special job.

Diode Type | Typical Function on PCB |

|---|---|

Rectifier Diode | Converts AC to DC, used in power circuits and bridge rectifiers. |

Zener Diode | Maintains constant voltage, used in voltage regulation and overvoltage protection. |

Schottky Diode | Low forward voltage drop and fast switching, used in switching power supplies and RF circuits. |

LED | Emits light for status display and indicators. Requires current limiting. |

Photodiode | Converts light to electrical current, used in sensors and optical communication. |

Avalanche Diode | Protects against high-voltage surges by conducting during breakdown, used in automotive and industrial PCBs. |

You see LEDs on many PCBs as indicator lights. Zener diodes keep voltage steady, while rectifier diodes help power supplies work. Schottky diodes switch quickly and save energy in fast circuits.

Transistors

Transistors act as switches or amplifiers. You use them to turn signals on and off or make weak signals stronger. Transistors are key parts of a pcb, found in almost every electronic device.

Transistor Type | Function | Applications |

|---|---|---|

Bipolar Junction Transistor (BJT) | Uses a small base current to control a larger current between emitter and collector | Signal amplification, audio amplifiers |

Field Effect Transistor (FET) | Voltage at the gate controls current flow between drain and source | Switching circuits, current regulation |

N-channel MOSFET (NMOS) | Allows electron flow when on | Switch-mode power supplies, LED drivers |

P-channel MOSFET (PMOS) | Allows hole flow when on | High voltage circuits, power amplifiers |

Metal-Oxide-Semiconductor FET (MOSFET) | High input impedance and low power consumption, ideal for high-speed switching | Computer circuits, audio amplifiers |

Junction Field-Effect Transistor (JFET) | Uses junction voltage to control channel conductivity | Signal amplifiers, sensor circuits |

You find BJTs in amplifiers and FETs in switching circuits. MOSFETs work well in computers and power supplies. Always check the markings and ratings to use the right transistor for your circuit.

Tip: Transistors make modern electronics possible by controlling signals and power with great precision.

Integrated Circuits

Integrated circuits, or ICs, are tiny chips that combine many electronic parts into one package. You use ICs to process data, control signals, and manage power. ICs make devices smaller, faster, and more reliable.

ICs can handle digital signals (like in computers), analog signals (like in audio equipment), or both.

You find ICs in almost every modern device, from smartphones to washing machines.

ICs reduce the number of separate parts of a pcb, saving space and energy.

Some common types include:

Digital ICs: Process binary data for computers and logic circuits.

Analog ICs: Handle continuous signals, such as amplifying sound.

Mixed-Signal ICs: Combine digital and analog functions, used in communication devices.

Power ICs: Manage voltage and power distribution.

Note: ICs allow you to build complex devices with fewer parts and greater efficiency.

Potentiometers

Potentiometers are adjustable resistors. You use them to control things like volume, brightness, or speed. Turning the knob or sliding the lever changes the resistance, which adjusts the output.

Potentiometers work as voltage dividers or variable resistors.

You find them in audio equipment (volume controls), light dimmers, and calibration settings.

Trimmer potentiometers, or trim pots, are small and used for fine-tuning circuits after assembly.

Slide potentiometers, also called faders, are common in audio mixers.

Tip: When you adjust the brightness of a lamp or the volume of a speaker, you often use a potentiometer.

Transformers

Transformers transfer electrical energy between circuits. You use them to change voltage levels, provide isolation, and filter noise. Transformers are important parts of a pcb, especially in power supplies.

Voltage stepping up or down: Transformers can increase or decrease voltage as needed.

Signal isolation: They keep different parts of a circuit separate for safety.

Power regulation: Transformers help manage and stabilize power.

Noise filtering: They block unwanted signals.

Common types include:

Planar Transformers: Flat, high-power, used in telecom.

Pulse Transformers: Transmit signals and provide isolation.

Switching Transformers: Used in switch-mode power supplies.

Audio Transformers: Match impedance and reduce noise in audio devices.

Note: Transformers help keep your devices safe and efficient by managing power and signals.

SCRs

Silicon-controlled rectifiers (SCRs) are special switches for controlling power. You use SCRs to manage large amounts of electricity in circuits like motor drives, lighting dimmers, and power supplies.

SCRs convert AC to DC and allow you to control when current flows.

You find SCRs in industrial automation, electric vehicles, and renewable energy systems.

They help regulate power, protect circuits, and improve efficiency.

Tip: SCRs are key in circuits that need precise control of high power.

Sensors

Sensors detect changes in the environment and turn them into electrical signals. You use sensors to measure things like temperature, light, sound, and motion.

Common sensors on PCBs include temperature sensors, light sensors, and ultrasonic distance sensors.

Sensors help devices respond to their surroundings, like turning on a fan when it gets hot or adjusting screen brightness.

They act as the "eyes and ears" of electronic devices.

Note: Sensors make your devices smarter by letting them sense and react to the world.

Switches

Switches let you control the flow of electricity in a circuit. You use switches to turn devices on or off, select modes, or reset systems. Switches come in many forms, each with a unique job.

Switch Type | Description & Features | Typical Applications |

|---|---|---|

Push Button | Press to complete circuit; simple and reliable | Doorbells, calculators, general electronics |

Tactile Switch | Provides feedback (click or bump) when pressed | Remote controls, keyboards |

Toggle Switch | Lever flipped up/down; stays in position | Light switches, power tools |

Rotary Switch | Turn knob to select settings | Ovens, washing machines, radios |

DIP Switch | Multiple small switches in a row for configuration | Older computers, remote controls, garage door openers |

You find push buttons in toys and remotes, toggle switches in power tools, and DIP switches in older electronics for setting options.

Relays

Relays are electrically operated switches. You use relays to control high-power circuits with a low-power signal. Relays provide isolation and protection between different parts of a pcb.

Electromechanical relays use magnets to open or close contacts.

Solid-state relays use electronic parts for switching.

Relays control motors, heaters, and other heavy loads.

They keep control circuits safe from high voltage or current.

Tip: Relays are essential for safely switching large amounts of power in many devices.

Identifying Components

Visual Clues

You can spot different components on a PCB by looking for certain clues.

Reference designators printed on the board help you match each part to its type. For example, "R" stands for resistor, "C" for capacitor, and "L" for inductor.

Markings and labels on the parts themselves give you more information. Resistors often use colored bands, while ICs show part numbers.

Component size and shape also help. Through-hole parts look larger and have leads that pass through the board. Surface-mount parts are smaller and sit flat on the surface.

Polarity markings show you which way to place parts like diodes and electrolytic capacitors. Look for "+" or "-" signs or colored bands.

Magnifying tools and good lighting make it easier to see small details, especially for tiny surface-mount parts.

Tip: Use a multimeter or component tester if you need to check a part’s value or function.

Package Types

You will find two main package types on PCBs:

Through-hole packages have long leads that go through holes in the board. These parts stand taller and are easier to handle.

Surface-mount technology (SMT) packages are much smaller and sit directly on the board’s surface. You often need tweezers or a magnifier to work with them.

Each package type affects how you solder and repair the board. Through-hole parts are easier for beginners, while SMT allows for smaller, more complex designs.

Reference Designators

Reference designators are codes printed near each component. These codes use a letter to show the type and a number to make each part unique. For example, "R1" means the first resistor, "C2" means the second capacitor. The industry follows the ASME Y14.44-2008 standard for these codes. You will see them on the silkscreen layer, close to each part but not hidden underneath.

Designator | Component Type | Alternate Designators |

|---|---|---|

R | Resistor | LDR, VDR, VR |

C | Capacitor | N/A |

L | Inductor Coil | N/A |

D | Diode | LED |

Q | Transistor (all types) | FET, JFET, TFTMOSFET |

U | IC | |

S | Switch | SW, SUS |

K | Relay | RY, RLA |

T | Transformer | VT |

F | Fuse | N/A |

XTAL | Crystal Oscillator | Y |

These designators help you match the physical part to the schematic and the Bill of Materials (BOM). They make assembly, troubleshooting, and repairs much easier.

Note: Learning to read reference designators is a key skill for anyone working with electronics.

Troubleshooting

When you work with PCBs, you may face problems that stop your circuit from working. Knowing how to spot and fix these issues helps you keep your projects running smoothly.

Faulty Parts

Faulty parts can cause your circuit to fail or act strangely. You might see problems like open circuits, short circuits, or damaged components. These issues often come from things like moisture, dust, heat, or even old age. Sometimes, electrical stress such as static electricity or power surges can damage parts. You can use visual checks, special testing tools, or even stress tests to find these problems.

Here is a table showing common causes of component failure and how you can detect them:

Cause Category | Common Causes | Impact on PCB Functionality | Detection Methods |

|---|---|---|---|

Soldering Defects | Cold joints, excess solder | Weak connections, opens, shorts | Visual inspection, AOI, ICT |

Environmental Failure | Moisture, dust, heat | Corrosion, loss of function | Visual inspection, stress tests |

Electrical Stress | ESD, overvoltage | Burnt or damaged parts | Electrical testing |

Aging Failure | Old or worn-out components | Intermittent or total failure | Lifecycle analysis, testing |

Tip: Always check for signs of burnt, cracked, or swollen parts. These are clues that something has failed.

Soldering Issues

Soldering problems are a leading cause of PCB failure. If you use too much or too little solder, or if the temperature is wrong, you can create weak joints or even short circuits. Common soldering issues include solder bridges, cold joints, and lifted pads.

Soldering Issue | Description & Cause | Best Prevention Practice |

|---|---|---|

Solder Bridge | Excess solder connects two points | Use just enough solder |

Cold Joint | Not enough heat, dull or lumpy joint | Heat iron properly, allow time |

Lifted Pad | Too much heat or force | Avoid overheating, use gentle force |

Tombstoning | Uneven heating lifts one side of part | Ensure even heating |

You can prevent most soldering issues by using the right amount of solder, keeping your tools clean, and working at the correct temperature.

Note: Good soldering skills help you avoid many common PCB problems.

Misidentification

If you mix up components or place them in the wrong spot, your circuit may not work or could even get damaged. Misidentifying parts can cause open or short circuits, leading to burnt-out components or even a ruined PCB. You might see blown fuses, melted parts, or failed devices.

To avoid these mistakes, always double-check part labels and use clear markings on your board. Automated inspection systems and strong marking methods, like barcodes or serial numbers, help you track and identify every part. These steps reduce human error and make it easier to fix problems before your device leaves the workbench.

Remember: Careful identification and quality checks keep your projects safe and reliable.

Understanding the parts of a pcb gives you the power to design, repair, and troubleshoot electronics with confidence. You gain skills in identifying components, testing circuits, and choosing the right board for your project.

You improve device performance and reliability by learning how to spot faults and use diagnostic tools.

You stay up to date with trends like miniaturization, flexible boards, and advanced materials.

For deeper learning, explore tutorials, webinars, and design software from trusted sources such as Cadence and OrCAD.

FAQ

What is the difference between active and passive components?

Active components control or add energy to a circuit. Examples include transistors and ICs. Passive components only store or manage energy. You see resistors and capacitors as common passive parts.

How can you tell if a component is faulty?

You can look for signs like burnt marks, cracks, or swelling. Use a multimeter to test for open or short circuits. Faulty parts often cause devices to stop working or behave strangely.

Why do some components have polarity?

Some parts, like diodes and electrolytic capacitors, only work in one direction. You must place them correctly. If you reverse them, the circuit may not work or the part could get damaged.

Can you replace a surface-mount component with a through-hole one?

You can sometimes replace them if the values match and the board allows it. Surface-mount parts are smaller. You may need to adjust the layout or use adapter boards.

See Also

Top FPGA Boards From Leading Manufacturers Compared

Key Differences Between Evaluation And Development Boards

How Communication Chips Function And Their Key Features