What Are Digital Serial Temperature Sensors

Digital serial temperature sensors measure temperature and send data in a digital format. These sensors play a vital role in modern technology by offering precise measurements and reliable communication. You can find them in devices across industries, from healthcare to automotive systems. Their compact design makes them ideal for applications requiring small components, such as the Temperature Sensor Digital Serial SOIC form factor. By using these sensors, you enable smarter systems that work efficiently and adapt to changing environments.

Key Takeaways

Digital serial temperature sensors measure temperature accurately and send reliable data.

They use little power, so they work well in battery devices.

Their small size makes them easy to add to many systems.

These include IoT gadgets, medical tools, and car technology.

Digital sensors avoid mistakes of analog ones by giving direct output.

This improves accuracy and cuts down on signal problems.

They work with I2C, SPI, and 1-Wire, making setup easier.

This helps create smarter and more connected devices.

Understanding Digital Serial Temperature Sensors

Definition and Basic Concept

Digital serial temperature sensors are advanced devices designed to measure temperature and transmit the data in a digital format. Unlike traditional analog sensors, these sensors use internal components to ensure accuracy and reliability. Their design includes a temperature sensor, a configuration register, and a unique 64-bit ROM. This ROM allows you to connect multiple sensors on a single bus, making them ideal for systems requiring multi-point temperature monitoring.

These sensors also feature a temperature alarm trigger that retains its settings even during power interruptions. This ensures continuous monitoring, which is critical in applications like medical devices or industrial systems. Additionally, their low power usage (operating between 3V and 5.5V) makes them suitable for battery-operated devices. With a measurement accuracy of ±0.5°C, they provide precise readings for environments where accuracy is essential.

Component/Feature | Description |

|---|---|

Internal Composition | Includes a 64-bit ROM, temperature sensor, non-volatile temperature alarm triggers, and a configuration register. |

Unique 64-bit ROM | Allows multiple sensors on a single bus, ensuring precise identification and communication. |

Temperature Sensor | Measures environmental temperatures with high precision for various applications. |

Temperature Alarm Trigger (Tm) | Maintains alarm settings during power interruptions, crucial for continuous temperature monitoring. |

Configuration Register | Enables users to set operational parameters like resolution and alarm thresholds. |

1-Wire Communication Protocol | Simplifies wiring by allowing power supply and data transmission through a single cable. |

Measurement Accuracy | Offers ±0.5°C accuracy, making it suitable for critical applications like medical devices. |

Operates within 3V to 5.5V, ideal for battery-operated systems. | |

Multi-Point Temperature Measurement | Supports connecting multiple sensors, enhancing data collection in large systems. |

Digital Output | Outputs digital values directly, reducing errors associated with analog processing. |

How They Differ from Analog Temperature Sensors

Digital serial temperature sensors differ significantly from their analog counterparts. Analog sensors measure temperature and output a continuous voltage signal proportional to the temperature. This signal requires additional processing to convert it into a readable format. In contrast, digital sensors eliminate this step by providing a direct digital output. This reduces the chances of errors caused by signal interference or conversion inaccuracies.

Another key difference lies in their communication capabilities. Digital sensors often support protocols like I2C, SPI, or 1-Wire, enabling seamless integration with microcontrollers and other digital systems. Analog sensors, on the other hand, require more complex circuitry for integration. Additionally, digital sensors are more energy-efficient and compact, making them ideal for modern applications like IoT devices and wearable technology.

Overview of the "Temperature Sensor Digital Serial SOIC" Form Factor

The "Temperature Sensor Digital Serial SOIC" form factor is a popular choice for compact and efficient temperature sensing. SOIC stands for Small Outline Integrated Circuit, a design that ensures the sensor occupies minimal space while delivering high performance. These sensors operate within a wide temperature range of -55°C to +125°C, making them suitable for diverse environments.

Their factory-calibrated accuracy and resolution of 0.0625°C allow you to achieve precise temperature readings. The SOIC-8 package includes features like programmable temperature limits and an ALERT pin for real-time notifications. With a supply voltage of just 1.8V, these sensors are energy-efficient and compatible with SMBus and two-wire interfaces. This makes them versatile for applications in consumer electronics, industrial systems, and environmental monitoring.

Specification | Details |

|---|---|

Form Factor | SOIC-8 |

Operating Temperature Range | -55°C to +125°C |

Supply Voltage | 1.8 V |

Resolution | 0.0625°C |

Interface Type | SMBus, two-wire |

Accuracy | Factory-calibrated |

Features | Programmable temperature limits, ALERT pin |

Applications | Consumer, computer, communication, industrial, environmental |

The "Temperature Sensor Digital Serial SOIC" form factor combines precision, efficiency, and versatility, making it a reliable choice for modern temperature sensing needs.

Key Features of Digital Serial Temperature Sensors

High Accuracy and Precision

Digital serial temperature sensors are known for their exceptional accuracy and precision. These sensors undergo advanced calibration processes, such as nonlinear curvature correction and one-point correction after packaging, to achieve an impressive accuracy of ±0.1 °C. Their measurements are highly repeatable, with a standard error on the mean of approximately 0.02 °C when operating at a resolution of 0.06 °C. This level of precision ensures reliable performance in critical applications like medical devices and industrial systems.

Claim/Result | Description |

|---|---|

Calibration Accuracy | Achieved accuracy of ±0.1 °C through nonlinear curvature correction and one-point correction after packaging. |

Standard Error | Measurements repeatable within a standard error on the mean of approximately 0.02 °C for a sensor resolution of 0.06 °C. |

Variation with Temperature | Little significant variation with reference temperature, except at 50 °C due to stabilization issues. |

You can rely on these sensors for consistent performance, even in environments with fluctuating temperatures. Their ability to maintain accuracy across a wide range of conditions makes them a preferred choice for applications requiring dependable temperature monitoring.

Digital Output for Seamless Integration

One of the standout features of digital serial temperature sensors is their ability to provide a direct digital output. Unlike analog sensors, which require additional circuitry to convert voltage signals into readable data, digital sensors simplify the process by delivering temperature readings in a digital format. This eliminates potential errors caused by signal interference or conversion inaccuracies.

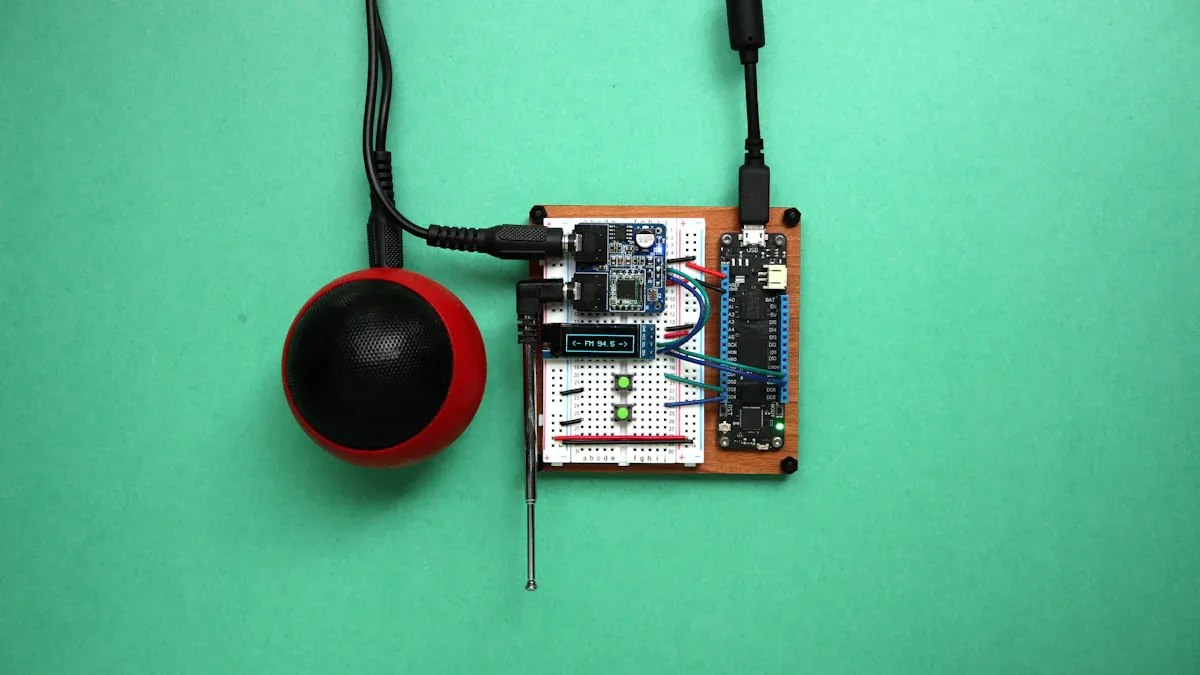

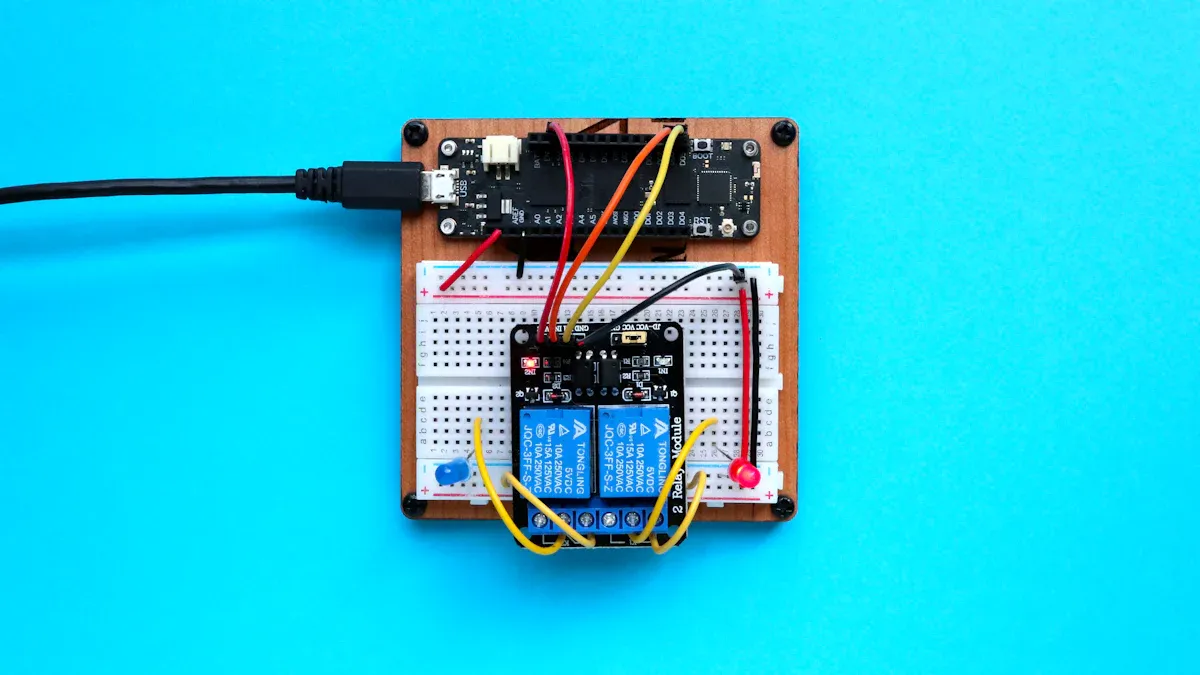

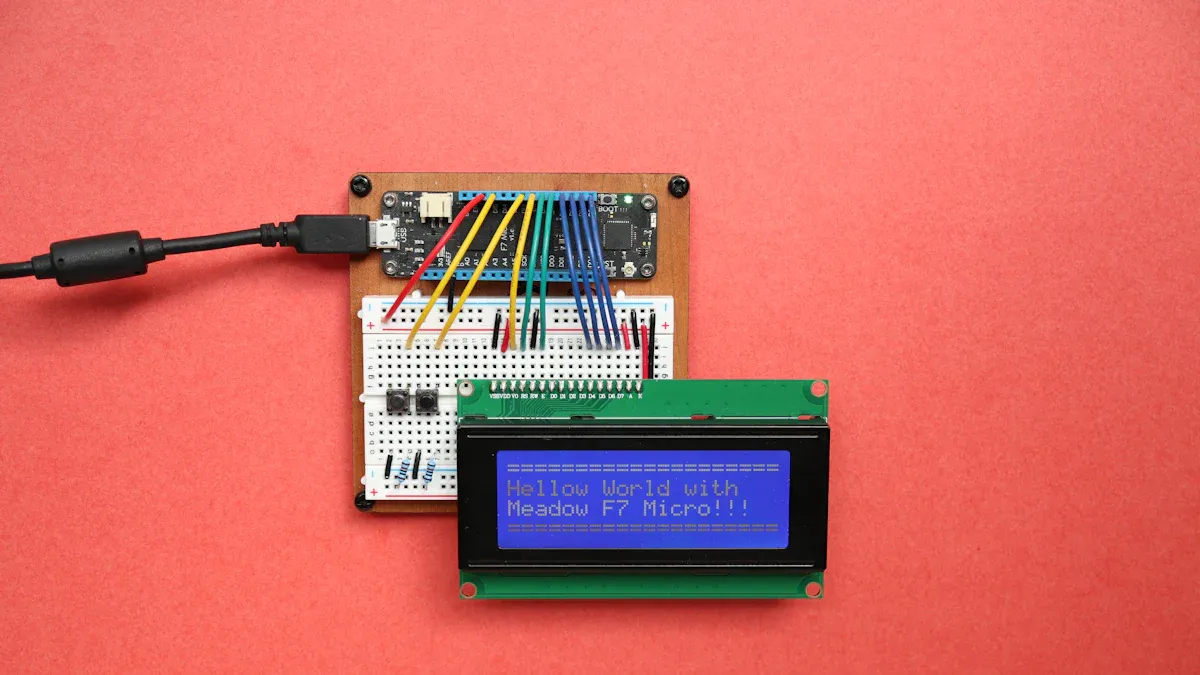

These sensors also support popular communication protocols like I2C, SPI, and 1-Wire. This compatibility allows you to integrate them effortlessly into microcontroller-based systems, IoT devices, and other digital platforms. For example, the "Temperature Sensor Digital Serial SOIC" form factor is designed to work seamlessly with SMBus and two-wire interfaces, making it a versatile option for various applications. By choosing digital sensors, you can streamline your system design and reduce development time.

Low Power Consumption and Energy Efficiency

Energy efficiency is another key advantage of digital serial temperature sensors. These sensors are designed to operate with minimal power, making them ideal for battery-powered devices and energy-conscious applications. For instance, devices like Mica2 consume only 509 µW in active mode, while TinyNode operates at an even lower 489 µW. This low power usage ensures that your systems can run longer without frequent battery replacements or recharges.

Mica2: Consumes 509 µW in active mode.

TinyNode: Consumes 489 µW in active mode.

Demonstrates lower energy consumption compared to other devices.

By incorporating these sensors into your designs, you can create energy-efficient systems that are both cost-effective and environmentally friendly. Their low power requirements also make them suitable for remote or portable applications where energy resources are limited.

Compact design and durability

Digital serial temperature sensors are designed to be both compact and durable, making them ideal for modern applications. Their small size allows you to integrate them into devices where space is limited, such as wearable technology or IoT devices. For example, the "Temperature Sensor Digital Serial SOIC" form factor is a prime example of how these sensors combine efficiency with a minimal footprint. This design ensures that you can use them in systems where every millimeter of space matters.

Durability is another key strength of these sensors. They are built to withstand challenging environments, including extreme temperatures and mechanical stress. Studies have shown that digital temperature sensors maintain excellent performance even after rigorous testing. For instance:

Experimental results from 25 measured samples demonstrated strong agreement with reference data, confirming their reliability.

One-point calibration methods enhance their durability by reducing the need for frequent recalibration.

Their power consumption remains competitive, supporting their compact design without compromising performance.

These features make digital serial temperature sensors a dependable choice for long-term use in critical systems. You can trust them to deliver accurate readings consistently, even in demanding conditions.

Tip: While digital sensors may cost more upfront, their precision and durability often save you money in the long run by reducing maintenance and replacement costs.

Compatibility with communication protocols like I2C, SPI, and 1-Wire

Digital serial temperature sensors excel in their ability to communicate seamlessly with other components in your system. They support widely used communication protocols like I2C, SPI, and 1-Wire, which simplifies integration into microcontroller-based designs. Each protocol offers unique advantages, allowing you to choose the one that best suits your application.

I2C (Inter-Integrated Circuit): This protocol uses just two wires for communication, making it perfect for systems with limited pin availability. It supports multiple devices on the same bus, enabling you to connect several sensors without additional complexity.

SPI (Serial Peripheral Interface): SPI provides faster data transfer rates compared to I2C. If your application requires high-speed communication, this protocol ensures quick and reliable data exchange.

1-Wire: This protocol is ideal for minimizing wiring. It allows both power and data to travel through a single wire, reducing the overall complexity of your design.

The versatility of these protocols ensures that you can integrate digital serial temperature sensors into a wide range of systems, from simple IoT devices to complex industrial setups. For example, the "Temperature Sensor Digital Serial SOIC" form factor is compatible with SMBus and two-wire interfaces, making it a flexible option for various applications.

By choosing sensors with robust protocol compatibility, you can streamline your design process and reduce development time. These sensors not only simplify communication but also enhance the overall efficiency of your system.

How Digital Serial Temperature Sensors Work

Sensing mechanism and data conversion

Digital serial temperature sensors use advanced mechanisms to measure temperature and convert it into digital data. The sensing element detects temperature changes in the environment. This information is then processed by an internal analog-to-digital converter (ADC), which transforms the analog signal into a digital format. This conversion ensures accurate and reliable temperature readings.

These sensors operate with a two-wire serial interface compatible with I2C communication. Their internal registers, such as the temperature register and configuration register, store and manage data. You can configure operational modes like normal mode or shutdown mode to suit your application. For example, shutdown mode reduces power consumption to just 0.1μA, making it ideal for energy-efficient systems. The sensors also support a wide temperature range from -40°C to +125°C, ensuring versatility across various environments.

Feature | Description |

|---|---|

Interface | Two-wire serial interface compatible with I2C |

Registers | Pointer register, temperature register, configuration register, THIGH register, TLOW register |

Operating Modes | Normal mode, shutdown mode, compare mode, interrupt mode |

Addressing | Up to 8 different addresses for flexibility |

Temperature Range | -40°C to +125°C |

Current Consumption | 50μA in normal operation, 0.1μA in shutdown mode |

Role of digital communication protocols

Digital communication protocols play a crucial role in the functionality of these sensors. Protocols like I2C, SPI, and 1-Wire enable seamless communication between the sensor and other components in your system. I2C uses two wires for data transfer, simplifying wiring and allowing multiple devices to share the same bus. SPI offers faster data transfer rates, making it suitable for applications requiring high-speed communication. The 1-Wire protocol minimizes wiring complexity by combining power and data transmission into a single wire.

These protocols ensure efficient data exchange and compatibility with microcontrollers, IoT devices, and industrial systems. For instance, the Temperature Sensor Digital Serial SOIC form factor leverages SMBus and two-wire interfaces for smooth integration. By utilizing these protocols, you can create systems that are both reliable and easy to design.

Data transmission and processing

Data transmission and processing are vital aspects of digital serial temperature sensors. Once the sensor measures and converts temperature data, it transmits this information to a connected device for further processing. The data can be used in various applications, such as smart thermostats, environmental monitoring, and healthcare devices.

For example:

Smart Thermostats: Sensors in devices like Nest thermostats learn user preferences and optimize heating and cooling systems.

Environmental Monitoring: IoT devices equipped with sensors provide critical data for smart agriculture and urban air quality management.

Food Storage and Transportation: Sensors monitor refrigerated environments to ensure food safety during cold chain management.

Healthcare: Wearable devices use sensors for remote patient monitoring, allowing real-time tracking of body temperatures.

These applications highlight the importance of accurate data transmission and processing. By integrating digital serial temperature sensors, you can enhance system efficiency and improve decision-making based on reliable temperature data.

Advantages of digital over analog systems

Digital temperature sensors offer several advantages over analog systems, making them a superior choice for modern applications. These benefits stem from their ability to provide precise, reliable, and easily integrated temperature measurements.

One of the most significant differences lies in how they handle data. Analog sensors output continuous voltage or current signals, which are prone to noise and interference. Digital sensors, on the other hand, deliver discrete digital signals in binary form. This ensures higher accuracy and reduces the risk of errors caused by environmental factors. You can rely on digital sensors for consistent performance, even in noisy environments.

Feature | Analog sensor | Digital sensor |

|---|---|---|

Data output | Continuous voltage or current signals | Discrete digital signals in binary form |

Accuracy | Affected by noise and interference | High accuracy, less affected by noise |

Resolution | Limited, usually lower | High resolution, typically 12-bit or higher |

Signal processing | Requires external ADC | Integrates ADC internally |

Transmission distance | Limited, susceptible to interference | Long-distance transmission with strong anti-interference |

Interface complexity | Simple interface | Complex interface with protocols |

Calibration | Frequent calibration needed | Lower calibration frequency, factory calibrated |

Digital sensors also simplify system design. They integrate an analog-to-digital converter (ADC) internally, eliminating the need for external components. This reduces the complexity of your circuit and saves valuable space. Additionally, digital sensors support advanced communication protocols like I2C and SPI, enabling seamless integration with microcontrollers and IoT devices.

Another key advantage is their ability to transmit data over long distances without significant signal degradation. Analog sensors struggle with interference over extended distances, but digital systems maintain strong anti-interference capabilities. This makes them ideal for applications requiring remote monitoring.

Finally, digital sensors require less frequent calibration. Many come factory-calibrated, saving you time and effort during setup and maintenance. By choosing digital sensors, you gain access to a more efficient, accurate, and reliable solution for temperature monitoring.

Tip: If you need a sensor for high-precision applications, digital options are your best bet. Their advanced features and robust performance make them a worthwhile investment.

Applications of Digital Serial Temperature Sensors

IoT Devices and Smart Home Systems

Digital serial temperature sensors play a crucial role in IoT devices and smart home systems. These sensors enable precise temperature monitoring, which is essential for maintaining comfort and energy efficiency. For example, smart thermostats use these sensors to adjust heating and cooling systems based on real-time data. This ensures optimal energy usage and reduces utility costs.

The growing demand for connected devices has fueled the adoption of digital temperature sensors in smart homes. These sensors integrate seamlessly with IoT platforms, allowing you to monitor and control temperature remotely. Devices like smart refrigerators and air conditioners rely on these sensors to maintain ideal conditions, enhancing convenience and functionality. The market for digital temperature sensors reflects this trend, with a valuation of USD 6.5 billion in 2023 and an expected growth to USD 14.8 billion by 2032. This rapid expansion highlights their importance in creating smarter, more efficient systems.

Note: Incorporating digital temperature sensors into your IoT devices can improve energy efficiency and enhance user experience.

Healthcare and Medical Devices

In healthcare, digital serial temperature sensors are indispensable for precise temperature monitoring. They are widely used in medical devices such as thermometers, incubators, and wearable health trackers. These sensors ensure accurate readings, which are critical for patient care and safety.

The healthcare sector has seen significant growth in the use of digital temperature sensors. Wireless sensors are particularly popular, as they enhance operational efficiency in applications like remote patient monitoring and pharmaceutical storage.

The global temperature sensor market was valued at $3.3 billion in 2020, with a projected CAGR of 5.4% through 2026.

Wireless temperature sensors are in high demand across healthcare, food and beverage, and pharmaceutical industries.

By integrating these sensors into medical devices, you can achieve better accuracy and reliability, improving outcomes in patient care and diagnostics.

Industrial Automation and Manufacturing

Digital serial temperature sensors are vital for optimizing industrial automation and manufacturing processes. These sensors provide precise temperature control, which is essential for maintaining product quality and ensuring safety in temperature-sensitive operations. Industries like pharmaceuticals and chemicals rely heavily on these sensors for thermal regulation.

The industrial market for digital temperature sensors is expected to grow from USD 2.4 billion in 2025 to USD 3.7 billion by 2035, driven by increasing automation and process optimization.

Aspect | Details |

|---|---|

Market Value | Expected to grow from USD 2.4 billion in 2025 to around USD 3.7 billion by 2035. |

Growth Rate | CAGR of approximately 4.6%. |

Key Drivers | Increasing automation, process optimization, and demand for temperature-sensitive manufacturing. |

Industry Applications | Major consumers include pharmaceutical and chemical industries requiring precise thermal control. |

Technological Advancements | Integration of IoT, AI forecasting, and cloud-based diagnostics for enhanced control and efficiency. |

Importance in Industry 4.0 | Vital for energy efficiency, predictive maintenance, and quality assurance in manufacturing processes. |

These sensors also play a key role in Industry 4.0, where energy efficiency and predictive maintenance are priorities. By using digital temperature sensors, you can enhance manufacturing processes, reduce downtime, and improve overall productivity.

Tip: If you work in manufacturing, consider adopting digital temperature sensors to optimize your operations and stay ahead in Industry 4.0 advancements.

Automotive systems and transportation

Digital serial temperature sensors play a key role in modern automotive systems. These sensors monitor critical components like engines, batteries, and climate control systems. Accurate temperature readings ensure that vehicles operate safely and efficiently. For example, in electric vehicles (EVs), temperature sensors help regulate battery performance. Overheating can reduce battery life or even cause safety hazards. By using these sensors, you can maintain optimal battery conditions and improve vehicle reliability.

In transportation, these sensors enhance safety and comfort. They monitor cabin temperatures in buses, trains, and airplanes. This ensures passengers experience a comfortable environment during their journey. Additionally, temperature sensors are vital for refrigerated transport. They help maintain the required temperature for perishable goods like food and medicine.

Application | Purpose |

|---|---|

Engine Monitoring | Prevents overheating and ensures efficient performance. |

Battery Management in EVs | Regulates temperature to extend battery life and prevent safety risks. |

Climate Control Systems | Maintains comfortable cabin temperatures for passengers. |

Refrigerated Transport | Ensures proper storage conditions for perishable goods. |

By integrating these sensors into automotive systems, you can improve safety, efficiency, and comfort. Their reliability makes them indispensable in the transportation industry.

Emerging applications in environmental monitoring

Digital serial temperature sensors are transforming environmental monitoring. These sensors provide accurate data for tracking temperature changes in ecosystems. For example, you can use them to monitor soil temperatures in agriculture. This helps optimize planting schedules and improve crop yields. In urban areas, sensors measure air temperatures to study heat islands. This data supports city planners in designing cooler, more sustainable environments.

Wildlife conservation also benefits from these sensors. Researchers use them to track temperature changes in animal habitats. This helps identify threats like climate change or habitat loss. Additionally, sensors play a role in disaster management. They monitor temperature variations in forests to detect early signs of wildfires.

Tip: Deploying temperature sensors in environmental projects can help you gather valuable data for sustainable solutions.

These emerging applications highlight the versatility of digital serial temperature sensors. By using them, you can contribute to a healthier planet and more efficient resource management.

Importance of Digital Serial Temperature Sensors

Contribution to Technological Advancements

Digital serial temperature sensors have revolutionized how you measure and manage temperature in modern systems. Their ability to provide precise, real-time data has paved the way for innovations in fields like IoT, healthcare, and industrial automation. For example, these sensors enable smart devices to adapt to environmental changes, making them more efficient and user-friendly.

You also see their impact in cutting-edge technologies like autonomous vehicles. These sensors monitor critical components, ensuring safety and reliability. In space exploration, they help maintain optimal conditions for sensitive equipment. By incorporating these sensors, you contribute to advancements that push the boundaries of what technology can achieve.

Fun Fact: NASA uses digital temperature sensors in spacecraft to monitor and regulate onboard systems.

Enhancing Efficiency and Accuracy in Industries

Industries rely on digital serial temperature sensors to improve efficiency and accuracy. These sensors provide consistent and reliable data, which helps you optimize processes and reduce waste. For instance, in manufacturing, they ensure precise temperature control during production, leading to higher-quality products.

Their low power consumption and compact design also make them ideal for energy-efficient systems. You can use them in remote locations or battery-operated devices without worrying about frequent maintenance. This efficiency translates into cost savings and better resource management.

Industry | Use Case | Benefit |

|---|---|---|

Food & Beverage | Monitoring storage temperatures | Ensures product safety |

Pharmaceuticals | Regulating drug manufacturing processes | Maintains quality and compliance |

Renewable Energy | Managing solar panel temperatures | Improves energy output |

Enabling Smarter and More Connected Systems

Digital serial temperature sensors are the backbone of smart and connected systems. They integrate seamlessly with IoT platforms, allowing you to monitor and control environments remotely. For example, in smart homes, these sensors help regulate heating and cooling systems, enhancing comfort and reducing energy costs.

In agriculture, they enable precision farming by providing real-time data on soil and air temperatures. This helps you make informed decisions, improving crop yields and sustainability. Their compatibility with communication protocols like I2C and SPI ensures they work effortlessly with other devices, creating a network of interconnected systems.

Tip: Incorporating these sensors into your projects can make your systems smarter and more responsive to user needs.

Digital serial temperature sensors offer precise, reliable, and energy-efficient temperature monitoring. Their compact design, digital output, and compatibility with protocols like I2C and SPI make them essential for modern systems. You can find these sensors driving innovation in IoT, healthcare, and industrial automation.

Key Takeaway: These sensors not only improve accuracy but also enable smarter, more connected systems.

Consider how they could enhance your projects, whether in smart homes, environmental monitoring, or advanced manufacturing. Their versatility ensures they remain a cornerstone of technological progress.

FAQ

What makes digital serial temperature sensors better than analog sensors?

Digital sensors provide direct digital output, eliminating errors from signal conversion. They offer higher accuracy, better noise resistance, and seamless integration with communication protocols like I2C and SPI. You can rely on them for consistent performance in complex systems.

Can digital serial temperature sensors work in extreme environments?

Yes, these sensors operate in wide temperature ranges, often from -55°C to +125°C. Their durable design ensures reliable performance in harsh conditions, including industrial settings and outdoor applications. You can use them confidently in demanding environments.

How do digital temperature sensors save energy?

Digital sensors consume minimal power, often operating at micro-watt levels. Shutdown modes reduce energy usage further, making them ideal for battery-powered devices. You can extend device life and reduce energy costs by using these sensors.

Are digital serial temperature sensors compatible with IoT devices?

Absolutely! These sensors support protocols like I2C, SPI, and 1-Wire, ensuring easy integration with IoT platforms. You can use them in smart homes, environmental monitoring, and connected devices for real-time temperature tracking.

What industries benefit most from digital temperature sensors?

Industries like healthcare, automotive, and manufacturing rely heavily on these sensors. They ensure precise temperature control for medical devices, EV batteries, and industrial processes. You can also find them in agriculture and environmental monitoring.