What Are Step-Down Converter ICs

Step-down converter ICs are specialized integrated circuits that reduce a higher input voltage to a lower output voltage. This functionality is essential for modern electronics, enabling devices to operate at precise voltage levels without compromising efficiency.

Several recent trends highlight advancements in these converters:

The BD9V100MUF-C can step down from 48 V to 3.3 V, reflecting growing capabilities in handling higher input voltages.

A minimum on-time of 9 ns demonstrates improved efficiency compared to conventional ICs.

These features cater to automotive applications that demand high performance and energy efficiency.

By integrating these innovations, step-down converter ICs simplify the design of circuits while ensuring reliable voltage regulation for diverse applications.

Key Takeaways

Step-down converter ICs lower high voltages to smaller ones. They are important for modern gadgets.

These ICs help batteries last longer in phones. They give exact voltage and protect delicate parts from harm.

Unlike linear regulators, step-down converters save more energy. They work with over 90% efficiency and waste less power.

Step-down converters are small, save energy, and have safety features. This makes them great for many uses.

The need for renewable energy systems shows why step-down converters matter. They provide steady and efficient power.

The Role and Purpose of Step-Down Converter ICs

Why Voltage Conversion Is Necessary

Modern electronic devices rely on precise voltage levels to function correctly. Many components, such as microprocessors, sensors, and displays, operate at lower voltages than the power sources that supply them. Voltage conversion ensures that these components receive the correct voltage, preventing damage and improving efficiency.

Step-down converter ICs play a critical role in this process. They reduce higher input voltages to the lower levels required by various devices. For example:

In smartphones and laptops, they extend battery life by efficiently lowering the voltage for processors and displays.

Automotive systems use them to power LED lights by stepping down the vehicle's system voltage to levels suitable for LED arrays.

Off-grid solar setups depend on them to convert high solar panel voltages into usable levels for charging batteries or powering appliances.

Factory automation systems rely on them to create the necessary voltage levels for sensors and control circuits from a single high-voltage supply.

Without voltage conversion, these applications would face challenges in maintaining performance, efficiency, and safety.

How Step-Down Converter ICs Simplify Circuit Design

Step-down converter ICs streamline the design of electronic circuits by integrating essential components into a single package. This integration reduces the need for external components, saving space and simplifying assembly. Designers can focus on optimizing other aspects of the system without worrying about complex voltage regulation setups.

Compared to traditional linear regulators, step-down converter ICs offer significant advantages. Linear regulators often waste energy as heat, especially when the input voltage is much higher than the output. In contrast, step-down converters, also known as buck converters, achieve efficiencies exceeding 90%. For instance, a switching regulator can handle varying input and output voltages while maintaining high efficiency, as shown below:

Regulator Type | Input Voltage | Output Voltage | Output Current | Efficiency (%) |

|---|---|---|---|---|

Linear Regulator | 5V | 3.3V | 500mA | 66% |

Linear Regulator | 9V | 3.3V | 500mA | 36% |

Switching Regulator | Varies | Varies | Varies | >90% |

Step-down converter ICs also include features like overcurrent protection, short-circuit protection, and the ability to handle low current loads automatically. These features enhance reliability and make them suitable for a wide range of applications. By simplifying circuit design and improving efficiency, step-down converter ICs have become indispensable in modern electronics.

Operating Principles of Step-Down Converter ICs

Basic Functionality of Voltage Regulation

Step-down converter ICs regulate voltage by reducing a higher input voltage to a stable, lower output voltage. This process ensures that electronic components receive the precise voltage they require to operate efficiently and safely. The regulation process involves monitoring the output voltage and adjusting the input power to maintain a consistent output, even when the input voltage or load conditions change.

Several technical specifications define the functionality of voltage regulation in step-down converter ICs:

Input Voltage

Output Voltage

Output Current

Switching Frequency

Thermal Resistance

Feedback Voltage

Load Regulation

Line Regulation

Temperature Rating

Quiescent current plays a critical role in maintaining efficiency during light-load conditions. Switching frequency affects the size of the system, as higher frequencies allow for smaller components. Thermal resistance ensures proper heat dissipation, preventing damage to the IC. These parameters collectively determine the performance and reliability of the voltage regulation process.

Switching vs Linear Conversion Methods

Step-down converter ICs primarily use switching conversion methods, which differ significantly from linear conversion methods. Switching regulators operate by rapidly turning a switch (such as a MOSFET) on and off, transferring energy in discrete packets. This approach minimizes energy loss and achieves high efficiency, often exceeding 90%. In contrast, linear regulators dissipate excess energy as heat, making them less efficient, especially when the input voltage is much higher than the output.

Key differences between the two methods include:

Efficiency: Switching regulators are more efficient, while linear regulators waste energy as heat.

Noise: Switching regulators generate more noise and ripple due to high-frequency operation. Linear regulators produce minimal noise, making them suitable for sensitive applications.

Size and Weight: Linear regulators require larger heat sinks, increasing their size and weight. Switching regulators, with smaller components, offer a more compact solution.

Complexity: Switching regulators involve more components and require careful design to meet EMI regulations. Linear regulators are simpler but less versatile.

For example, a linear power supply may have a noise level of 0.5 mVrms, while a switching power supply can produce noise levels around 5 mVrms. Despite the noise, switching regulators often provide a lower total solution cost due to their compactness and efficiency.

Key Components in Step-Down Converter ICs

Step-down converter ICs rely on several key components to perform their function effectively:

High-side switch: This component, often a MOSFET, connects the input voltage to the circuit and controls the flow of energy.

Low-side switch: Typically a diode or MOSFET, it ensures current flows through the inductor during the off phase of the high-side switch.

Inductor: Acts as an energy storage element, smoothing the current flow and reducing voltage ripple.

Output capacitor: Filters the voltage to provide a stable output, which is crucial for maintaining performance.

Control circuitry: Generates pulse-width modulation (PWM) signals to regulate voltage and monitors the output for stability.

These components work together to achieve efficient voltage conversion. For instance, the inductor and output capacitor minimize noise and ripple, while the control circuitry ensures precise voltage regulation. The high-side and low-side switches alternate to transfer energy efficiently, maintaining a stable output voltage.

The efficiency of a step-down converter IC can be expressed using the formula:

Efficiency Formula | Description |

|---|---|

The efficiency of a power converter is the ratio of output power to input power, influenced by input and output voltage and current values. |

Efficiency is not constant and depends on the relationship between input and output parameters. Accurate measurement requires assessing all output phases individually, as perceived efficiency can vary based on layout quality and measurement methods.

Key Specifications of Step-Down Converter ICs

Efficiency and Power Loss

Efficiency is a critical specification for step-down converter ICs, as it directly impacts energy savings and thermal performance. These ICs often achieve efficiencies of up to 92% by employing advanced control methods like PWM/PFM hybrid modulation. High efficiency minimizes power loss, which is essential for applications requiring prolonged operation or compact designs.

The following table highlights key benchmarks related to efficiency and power loss:

Specification | Details |

|---|---|

Input Voltage Range | 6 V – 80 V |

Maximum Output Voltage | 72 V |

Efficiency | 92% (using PWM/PFM hybrid modulation) |

Maximum Load Current | 1 A |

Output Voltage Change (Transient) | ≤ 150 mV |

Operating Temperature Range | −20 °C to 130 °C |

Control Method | Current mode control |

Features | User-programmable soft-start, thermal shutdown protection |

Power loss in step-down converters primarily occurs in components like inductors and MOSFETs. For instance, inductors and MOSFETs each contribute approximately 870 mW of power loss, while quiescent current has a minimal impact of 0.9 mW. This data underscores the importance of selecting high-quality components to optimize efficiency.

Component | Power Loss (mW) | Efficiency Impact |

|---|---|---|

Inductor | 870 | Significant |

MOSFETs | 870 | Significant |

Quiescent Current | 0.9 | Minimal |

Noise and Ripple Characteristics

Noise and ripple are important considerations in step-down converter ICs, especially for sensitive applications like audio equipment or medical devices. These ICs employ techniques such as ferrite beads to attenuate noise and improve performance.

Ferrite beads increase series impedance, enhancing noise rejection.

Ripple attenuation depends on the DC resistance of the ferrite bead and filter capacitance.

Accurate noise measurement often requires specialized methods, such as the "ring and tip" scope probe technique.

By addressing noise and ripple effectively, step-down converters ensure stable operation and compatibility with a wide range of devices.

Compactness and Integration

Modern step-down converter ICs are designed with compactness and integration in mind. Manufacturers have achieved significant reductions in component size, enabling these ICs to meet the demands of portable and space-constrained applications. For example, ROHM's latest DC-DC step-down converters reduce component area by 72% compared to older designs.

Research shows that some converter chips measure as small as 1.43 mm × 0.73 mm. This compact size is achieved through advanced fabrication processes like BCD technology, which integrates high-performance components capable of handling high currents and voltages. These innovations make step-down converter ICs ideal for modern electronics, where space and efficiency are paramount.

Input and Output Voltage Range

The input and output voltage range is a critical specification for any step-down converter IC. This range determines the voltage levels the IC can handle at its input and the stable voltage it can provide at its output. Engineers must carefully evaluate these parameters to ensure compatibility with their application.

Most step-down converter ICs support a wide input voltage range to accommodate various power sources. For example, some converters can accept input voltages as low as 3 volts or as high as 80 volts. This flexibility makes them suitable for applications like automotive systems, where the input voltage may vary due to battery fluctuations or alternator output.

The output voltage range is equally important. It defines the range of voltages the IC can regulate and deliver to connected components. Many step-down converters allow users to adjust the output voltage using external resistors or feedback pins. This feature provides versatility, enabling the same IC to power different devices with varying voltage requirements.

Designers must also consider the relationship between input and output voltages. A step-down converter IC typically requires the input voltage to be higher than the desired output voltage. For instance, if the output voltage is set to 5 volts, the input voltage must exceed this value to ensure proper operation.

Applications of Step-Down Converter ICs

Automotive Electronics

Step-down converter ICs play a vital role in modern automotive systems. These ICs ensure stable voltage levels for various components, enhancing performance and reliability. For instance, infotainment systems rely on precise voltage regulation to deliver seamless audio and video experiences. Engine control modules (ECMs) use these converters to maintain a stable power supply, ensuring smooth engine operation. LED headlamp drivers also benefit from step-down converters, as they provide consistent brightness and extend the lifespan of LED lights.

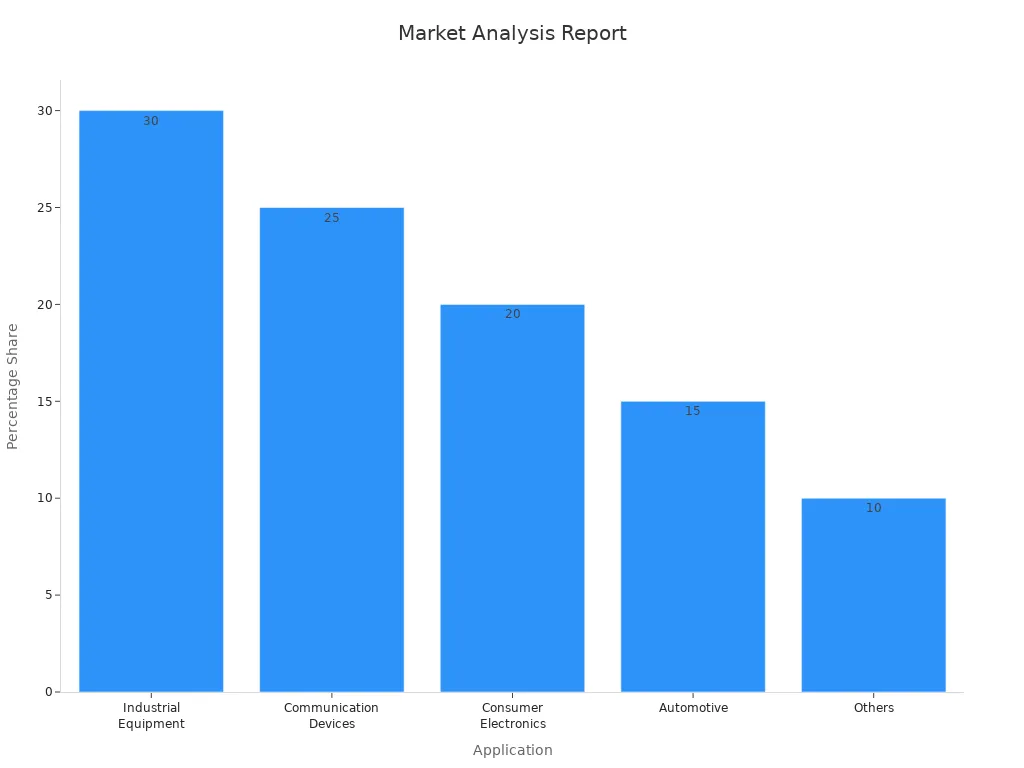

The automotive sector is one of the fastest-growing markets for step-down converter ICs. According to market analysis, automotive applications account for 15% of the total market share, with a rapid growth trend. This growth reflects the increasing adoption of advanced electronics in vehicles, such as electric powertrains and autonomous driving systems.

Application | Description |

|---|---|

Infotainment Systems | Require precise voltage management for optimal performance. |

Engine Control Modules (ECMs) | Utilize buck converters for stable power supply to ensure reliable engine operation. |

LED Headlamp Drivers | Maintain consistent brightness and longevity of LED lights through steady current management. |

Industrial Equipment

Industrial equipment demands robust and efficient power management solutions. Step-down converter ICs meet these requirements by providing stable voltage levels, even in harsh environments. These ICs enhance the performance of automation systems, robotics, and factory machinery by ensuring reliable power delivery. For example, advanced thermal management solutions in step-down converters improve the reliability of industrial equipment, reducing downtime and maintenance costs.

Research highlights the importance of step-down converters in industrial applications. Increased R&D investments have led to innovations in thermal management and power efficiency. Additionally, the rise of 5G technology and IoT devices has created a growing need for efficient power management in industrial settings.

Key Findings | Implications for Industrial Equipment Performance |

|---|---|

Increased R&D investments by manufacturers | Enhanced thermal management solutions improve reliability. |

Growth in 5G technology and IoT devices | Step-down converters optimize performance in connected systems. |

IoT Devices and Consumer Electronics

IoT devices and consumer electronics rely heavily on step-down converter ICs for efficient power management. These ICs enable compact designs and extended battery life, making them ideal for portable gadgets like smartphones, wearables, and smart home devices. By converting high input voltages to lower levels, step-down converters ensure that sensitive components operate safely and efficiently.

Consumer electronics represent 20% of the step-down converter IC market, driven by the demand for smaller, more energy-efficient devices. For IoT applications, these converters support low-power operation, which is crucial for devices that run on limited energy sources like batteries or solar panels. Their compact size and high efficiency make them indispensable in this rapidly growing sector.

Renewable Energy Systems

Renewable energy systems, such as solar and wind power, rely heavily on step-down converter ICs to ensure stable and efficient power delivery. These systems often generate high voltages that need to be converted into lower, usable levels for powering devices or storing energy in batteries. Step-down converters play a crucial role in this process by providing reliable voltage regulation.

The demand for DC-DC converters in renewable energy systems continues to grow. This trend reflects the global shift toward sustainable energy solutions. Step-down converters are essential for maintaining consistent power output, even when input voltages fluctuate due to environmental factors like changing sunlight or wind speeds. Their ability to handle higher voltage levels makes them indispensable in these applications.

Key benefits of step-down converter ICs in renewable energy systems include:

Stable Power Supply: They ensure consistent voltage levels, which is critical for sensitive equipment.

High Efficiency: These converters minimize energy loss, maximizing the overall efficiency of the system.

Compact Design: Their small size allows for integration into space-constrained setups, such as solar inverters or wind turbine controllers.

For example, in a solar power system, step-down converters regulate the voltage from solar panels to charge batteries or power appliances. Without this regulation, the system could experience inefficiencies or even damage to connected devices. Similarly, wind turbines benefit from these converters by stabilizing the variable output caused by changing wind conditions.

The growing emphasis on renewable energy highlights the importance of step-down converter ICs. Their ability to provide reliable and efficient power conversion supports the development of sustainable energy technologies. As renewable energy adoption increases, the role of these converters will become even more significant in ensuring the success of green energy initiatives.

Step-down converter ICs have become indispensable in modern electronics due to their ability to deliver precise voltage regulation with high efficiency. Their compact designs and advanced features, such as instantaneous turn-on for load increases and scalability for parallel operation, make them versatile across industries. For example, the architecture of STMicroelectronics’ step-down converters achieves a remarkable power density of 160W/in², demonstrating their adaptability in demanding applications like data centers. These ICs not only enhance energy efficiency but also enable reliable and space-saving designs, making them ideal for industries requiring precise power management.

FAQ

What is the difference between a step-down converter and a linear regulator?

Step-down converters use switching methods to achieve high efficiency, while linear regulators dissipate excess energy as heat. Switching regulators are ideal for applications requiring compact designs and energy savings. Linear regulators suit low-noise environments but are less efficient.

How do step-down converters improve energy efficiency?

Step-down converters transfer energy in discrete packets using switching techniques. This minimizes power loss and heat generation. Their efficiency often exceeds 90%, making them suitable for devices requiring prolonged operation or compact designs.

Can step-down converters handle fluctuating input voltages?

Yes, step-down converters regulate output voltage even when input voltage varies. Control circuitry adjusts energy transfer to maintain stability. This feature makes them ideal for automotive systems and renewable energy applications.

Are step-down converters suitable for portable devices?

Step-down converters are highly compact and efficient, making them perfect for portable devices like smartphones and wearables. Their ability to extend battery life and reduce component size supports modern consumer electronics.

What factors affect the efficiency of step-down converters?

Efficiency depends on input/output voltage, switching frequency, and component quality. High-quality inductors and MOSFETs reduce power loss. Proper thermal management also ensures consistent performance and reliability.

See Also

Selecting the Ideal SOT-223 Step-down IC for Your Needs

Unveiling the Key Benefits of Low Power Switcher ICs

Understanding IC Demodulators and Their Essential Functions

Defining Low Impedance Switch Chips and Their Applications

Gate Inverter IC Chips: Functionality and Working Principles