How to Use Schottky Barrier Power Rectifiers in Circuits

Schottky barrier power rectifiers play a critical role in modern electronic circuits. You can use them to convert alternating current (AC) to direct current (DC) or protect sensitive components from voltage spikes. Their standout feature is a low forward voltage drop, which minimizes energy loss. For example:

Schottky diodes drop only 0.6V, while standard diodes drop 1.2V.

This reduces power loss from 12 watts (standard diodes) to just 6 watts.

Their fast switching speed further enhances efficiency, making them ideal for high-frequency applications. By incorporating these rectifiers, you can significantly boost your circuit's performance and reliability.

Key Takeaways

Schottky rectifiers lose less energy because of low voltage drop. This makes them great for devices like DC-DC converters.

They switch on and off quickly, working well in fast circuits. Their speed helps devices like RF circuits stay efficient.

Pick a Schottky diode with higher voltage and current ratings. This keeps it safe and working properly in your circuit.

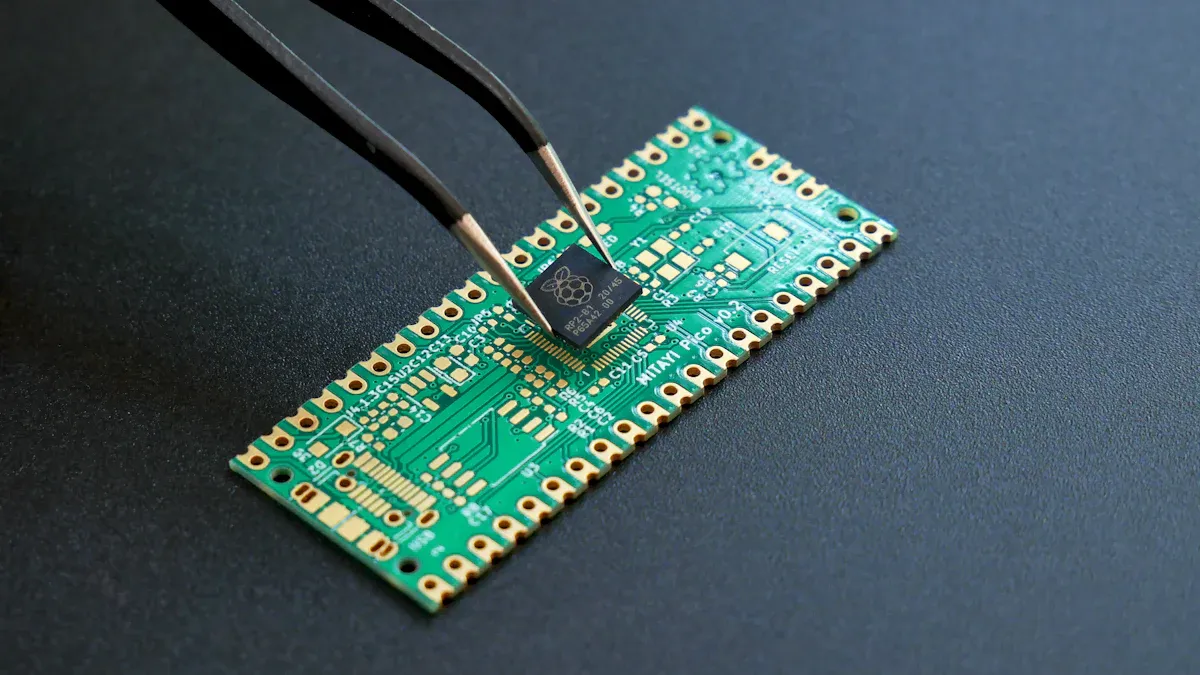

Managing heat is important when using Schottky rectifiers. Add heat sinks or use more copper on PCBs to cool them down.

Be careful with reverse voltage limits. Using a diode past its limit can break it. Always check the specs to make sure it fits.

What Are Schottky Barrier Power Rectifiers?

Schottky Barrier Power Rectifiers are specialized diodes designed for high-efficiency power management in electronic circuits. They stand out due to their unique construction and operational principles, which make them ideal for applications requiring fast switching and low energy loss.

Structure and Key Characteristics

The structure of a Schottky Barrier Power Rectifier is what sets it apart from traditional diodes. Instead of using a p-n junction, it relies on a metal-semiconductor junction to achieve its rectifying behavior. This design reduces the forward voltage drop and enhances switching speed. Below is a breakdown of its key components:

Component | Description |

|---|---|

Metal contact | A metal electrical contact is deposited on a semiconductor, typically n-type for optimal performance. |

Semiconductor type | n-type materials are preferred due to better forward voltage and reverse bias current balance. |

Ohmic contacts | Non-rectifying connections are made to the semiconductor to facilitate current flow. |

This structure creates a narrow depletion region, allowing the rectifier to operate with a forward voltage as low as 0.2 to 0.3 volts. The result is reduced power loss and improved thermal efficiency. Additionally, the low junction capacitance makes these rectifiers suitable for high-frequency applications.

Key operational principles include:

Allowing current to flow in one direction while blocking it in the reverse direction.

Achieving fast switching due to the absence of charge storage in the junction.

Maintaining low thermal noise, which is critical for sensitive circuits.

Why They Are Ideal for Certain Applications

Schottky Barrier Power Rectifiers excel in applications where efficiency and speed are critical. Their low forward voltage drop minimizes energy loss, making them perfect for power-sensitive devices. For example, in DC-DC converters, they reduce heat generation, improving overall system performance.

Their fast switching capabilities also make them indispensable in high-frequency circuits, such as those used in RF and microwave applications. These rectifiers can handle rapid changes in current without significant delays, ensuring smooth operation in demanding environments.

Another advantage is their low leakage current at moderate temperatures, which enhances reliability in voltage regulation and clamping circuits. Compared to traditional diodes, Schottky rectifiers offer superior performance metrics, as shown below:

Parameter | Super Barrier Rectifier (SBR10M100P5Q) | 10A/100V Schottky Diode |

|---|---|---|

Typical Forward Voltage VF(V) (IF 1A @ 85°C) | 0.50 | 0.50 |

1.7 | 18 | |

Typical Leakage Current IR(µA) @ 125°C | 15 | 300 |

Avalanche Energy EAS(mJ) | 400 | 20 |

Reverse Recovery Time trr (nS) | 28.3 | 33.2 |

These characteristics make Schottky Barrier Power Rectifiers a go-to choice for engineers designing efficient, high-performance circuits.

Applications of Schottky Barrier Power Rectifiers

Power Conversion in DC-DC Converters and Power Supplies

Schottky Barrier Power Rectifiers play a vital role in DC-DC converters and power supplies. Their low forward voltage drop reduces energy loss, improving efficiency. For example, while traditional silicon diodes have a forward voltage drop of 0.7V, Schottky diodes operate at just 0.2V to 0.4V. This difference leads to over 5% efficiency improvement in power conversion systems.

You can also benefit from reduced heat generation when using Schottky rectifiers. Lower heat means better thermal management, which enhances the reliability of your circuit. These rectifiers are widely used in power supplies for their ability to handle high currents without significant energy loss.

Feature | Schottky Diodes | Traditional Silicon Diodes |

|---|---|---|

Forward Voltage Drop | 0.2V - 0.4V | 0.7V |

Efficiency Improvement | Over 5% | N/A |

Heat Generation | Reduced | N/A |

Application in Power Supply | Widely used | Less efficient |

Clamping and Protection in ESD and Voltage Regulation

Schottky rectifiers are excellent for clamping and protecting circuits from electrostatic discharge (ESD) and voltage spikes. Their fast switching speed allows them to respond quickly to sudden changes in voltage, safeguarding sensitive components. You can use them in voltage regulation circuits to maintain stable output levels, even under fluctuating input conditions.

Their low leakage current at moderate temperatures ensures reliable performance in clamping applications. This feature makes them ideal for protecting microcontrollers, sensors, and other delicate electronics from damage caused by transient voltages.

High-Frequency Circuits in RF and Microwave Applications

Schottky Barrier Power Rectifiers excel in high-frequency circuits, including RF and microwave applications. Their low junction capacitance and fast switching capabilities allow them to operate efficiently at frequencies ranging from 0.9 GHz to over 7 GHz.

For example, models like the HSMS-286C and HSMS-2820 achieve high efficiency and handle power levels ranging from -10 dBm to 30 dBm. These rectifiers are commonly used in mixers, detectors, and modulators, where precision and speed are critical.

Diode Model | Frequency Range (GHz) | Efficiency (%) | Power Level (dBm) | Load (Ω) |

|---|---|---|---|---|

HSMS-286C | 2 to 3.05 | 60 | 17 | 620-2700 |

HSMS-2820 | 0.9, 1.8, 3.5, 5.5, 7.3 | >78 | -10 to 30 | 5000 |

HSMS-286 | 2 to 3 | >40 | 0 to 10 | 400 |

SMS7630 | 1.7-1.8, 2.1-2.7 | 55-65 | N/A | 2000 |

HSMS-2860 | 2.38, 2.45 | 75.3 | -20 to 10 | N/A |

SMS7630-079 | 1.8 | 21.1 | -20 | 6000 |

By using Schottky rectifiers in high-frequency circuits, you can achieve better signal integrity and lower power consumption, making them indispensable for advanced communication systems.

Advantages and Limitations of Schottky Barrier Power Rectifiers

Advantages: Low Forward Voltage Drop, Fast Switching, High Efficiency

Schottky Barrier Power Rectifiers offer several advantages that make them a popular choice in modern circuits. One of their standout features is their low forward voltage drop. For instance, the 1N5819 diode typically operates with a forward voltage drop of just 0.3 to 0.5 volts, significantly reducing power loss. This characteristic makes these rectifiers ideal for applications like DC-DC converters, where efficiency is critical.

Another key advantage is their fast switching speed. Unlike traditional diodes, Schottky rectifiers do not rely on minority carrier injection, allowing them to switch rapidly. This makes them well-suited for high-frequency applications, such as RF and microwave circuits.

The combination of low forward voltage drop and fast switching leads to reduced power dissipation, which improves overall circuit efficiency. These features allow you to design systems that consume less energy and generate less heat, enhancing both performance and reliability.

Feature | Description |

|---|---|

Low Forward Voltage Drop | Reduces power loss, typically 0.3 to 0.5 volts for models like the 1N5819. |

High Switching Speed | Enables rapid operation, ideal for high-frequency circuits. |

Reduced Power Loss | Minimizes energy dissipation, improving thermal performance. |

Increased Efficiency | Enhances overall system performance in applications like power supplies and converters. |

Limitations: Reverse Leakage Current, Lower Reverse Voltage Rating

Despite their advantages, Schottky Barrier Power Rectifiers have limitations that you need to consider. One major drawback is their high reverse leakage current. This occurs due to thermionic emission and tunneling processes, which can lead to energy loss, especially at higher temperatures. For example, studies show that reverse leakage current increases significantly as temperature rises, impacting the rectifier's efficiency.

Another limitation is their lower reverse voltage rating compared to traditional diodes. Schottky rectifiers are more prone to breakdown under high reverse voltages, making them unsuitable for applications requiring high voltage tolerance. Additionally, their temperature sensitivity can lead to noise generation, which may affect the performance of sensitive circuits.

Advantages | Limitations |

|---|---|

Low Forward Voltage Drop | Temperature Sensitivity |

Fast Switching Speed | Lower Reverse Recovery Time |

Negligible Reverse Recovery Time | High Reverse Leakage Current |

High Temperature Operation | Noise Generation |

Higher Cost |

Understanding these limitations helps you select the right rectifier for your application. By carefully evaluating your circuit's requirements, you can leverage the benefits of Schottky rectifiers while mitigating their drawbacks.

Practical Tips for Using Schottky Barrier Power Rectifiers

Selecting the Right Diode Based on Voltage and Current Requirements

Choosing the correct Schottky diode for your circuit is crucial for achieving optimal performance. Start by identifying the voltage and current requirements of your application. Look for a diode with a reverse voltage rating higher than the maximum voltage in your circuit. This ensures the diode can handle voltage spikes without breaking down. For current, select a diode with a forward current rating that exceeds the peak current in your circuit. This prevents overheating and extends the diode's lifespan.

Pay attention to the forward voltage drop as well. A lower forward voltage drop reduces power loss, making your circuit more efficient. For instance, if you're designing a DC-DC converter, a diode with a forward voltage drop of 0.3V will perform better than one with 0.7V. Always consult the datasheet to verify the diode's specifications and ensure compatibility with your circuit.

Managing Heat Dissipation and Thermal Considerations

Heat management is a critical aspect of using Schottky Barrier Power Rectifiers. These diodes can generate significant heat during operation, especially in high-current applications. To prevent overheating, you need to implement effective thermal management strategies.

One approach is to use heat sinks or thermal pads to dissipate heat away from the diode. Proper PCB design also plays a role. For example, increasing the copper area around the diode can improve heat dissipation. Additionally, consider using diodes with lower reverse leakage currents, as these generate less heat at higher temperatures.

Research has shown various methods to address thermal challenges in Schottky rectifiers. The table below highlights key findings from recent studies:

Study | Focus Area | Key Findings |

|---|---|---|

Multi-anode Schottky diode multiplier circuits | Developed a self-consistent electro-thermal model to predict hot spot temperature. | |

Carlos et al. | Schottky diode frequency doubler chip layouts | Conducted thermal analysis of different layouts. |

Cui et al. | Temperature distribution in diodes | Studied temperature distribution at dissipated powers using multi-physics methods. |

Song et al. | GaN Schottky diodes in frequency multipliers | Provided thermal characterization results for flip-chip configurations. |

By applying these insights, you can design circuits that operate efficiently while minimizing thermal risks.

Designing Circuits for Optimal Performance

To maximize the performance of your circuit, you need to optimize the design around the Schottky Barrier Power Rectifier. Start by minimizing parasitic inductance and resistance in your layout. Shorter traces and proper grounding reduce energy losses and improve efficiency.

Modeling the rectifier's current waveform can also help you fine-tune your design. Studies have introduced analytical equations for output DC voltage and efficiency, which align closely with simulation results. These formulas simplify the optimization process, allowing you to achieve better performance with less trial and error.

In RFID systems, for example, Schottky diodes enhance power conversion rates and switching properties. Research shows that the size of the diode affects its turn-on voltage and input impedance. By selecting the right diode size, you can improve the rectifier's efficiency and ensure stable operation.

Finally, consider the operating frequency of your circuit. Schottky diodes excel in high-frequency applications due to their fast switching speed. Ensure the diode's junction capacitance matches the frequency range of your circuit to avoid performance issues.

Common Mistakes to Avoid with Schottky Barrier Power Rectifiers

Exceeding Reverse Voltage Ratings

One common mistake is using a Schottky rectifier in circuits where the reverse voltage exceeds its rating. Schottky diodes typically have lower reverse voltage ratings compared to standard diodes. When the reverse voltage surpasses the diode's limit, it can lead to breakdown and permanent damage. For example, if your circuit operates at 50V, but the diode's reverse voltage rating is only 40V, the diode will fail under stress. Always check the datasheet to ensure the reverse voltage rating matches or exceeds your circuit's requirements.

To avoid this issue, you should also account for voltage spikes that may occur during operation. These spikes can momentarily exceed the diode's rating, causing failure. Using a diode with a safety margin above the expected voltage can help protect your circuit.

Neglecting Proper Heat Management

Heat management is critical when working with Schottky rectifiers. These diodes generate heat during operation, especially in high-current applications. Neglecting proper heat dissipation can lead to thermal stress and eventual failure. Research shows that at 300°C, the anode Schottky contact begins to fail, and localized heating can cause defects. The table below highlights key parameters related to heat management:

Parameter | Value | Implication |

|---|---|---|

Voltage at partial failure | 4 V | Indicates the threshold at which the anode Schottky contact begins to fail under high temperature. |

Temperature at partial failure | Shows the critical temperature that leads to thermal stress and defect generation. | |

Thermal conductivity of sapphire | ~35 W/m·K | Poor heat dissipation contributes to localized heating and increased thermal stress. |

To prevent overheating, use heat sinks, thermal pads, or increase the copper area on the PCB. These measures improve heat dissipation and ensure reliable operation.

Choosing an Inappropriate Diode for the Application

Selecting the wrong Schottky diode for your circuit can significantly reduce efficiency. Technical reports highlight that improper impedance matching in diode-based circuits leads to mismatches, reducing overall performance. For instance, variations in the input impedance of a diode can disrupt the circuit's efficiency, especially in high-frequency applications.

To avoid this, carefully evaluate your circuit's voltage, current, and frequency requirements. Choose a diode with specifications that align with these parameters. For high-frequency circuits, prioritize diodes with low junction capacitance. For power-sensitive applications, select diodes with low forward voltage drops. Proper selection ensures optimal performance and prevents unnecessary energy loss.

Schottky barrier power rectifiers offer unique advantages that can transform your circuit designs. Their low forward voltage drop and fast switching speed improve efficiency and reduce energy loss. These features make them ideal for applications like DC-DC converters, voltage regulation, and high-frequency circuits. However, you should consider their limitations, such as higher reverse leakage current and lower reverse voltage ratings, when selecting components for your projects.

The high cost of SiC wafers and their complex manufacturing processes can limit the adoption of SiC Schottky diodes, despite their superior performance. This challenge highlights the importance of balancing cost and efficiency when choosing rectifiers for your designs.

Comparative studies also reveal the impressive rectifying ratios of advanced Schottky diodes, as shown below:

Diode Type | Rectifying Ratio at ±1V | Rectifying Ratio at ±2V |

|---|---|---|

Pd/MoS2 | 11 | N/A |

1T′-MoTe2/MoS2 | ~101 | N/A |

1T′-MoTe2/as-prepared MoS2 | N/A | ~1.4 × 10^3 |

1T′-MoTe2/healed MoS2 | N/A | ~5.1 × 10^5 |

By understanding these benefits and challenges, you can confidently incorporate Schottky rectifiers into your circuits. Always evaluate your specific requirements and choose components that align with your design goals. With careful planning, you can harness the full potential of these rectifiers to create efficient and reliable systems.

FAQ

What is the main difference between Schottky diodes and regular diodes?

Schottky diodes use a metal-semiconductor junction, while regular diodes use a p-n junction. This difference gives Schottky diodes a lower forward voltage drop (0.2–0.4V) and faster switching speed. Regular diodes, however, handle higher reverse voltages better.

Can you use Schottky rectifiers in high-voltage circuits?

No, Schottky rectifiers are not ideal for high-voltage circuits. Their reverse voltage ratings are lower than those of standard diodes. For high-voltage applications, consider using silicon or silicon carbide diodes instead.

How do you reduce heat when using Schottky rectifiers?

To reduce heat, use heat sinks, thermal pads, or increase the copper area on your PCB. Choose diodes with lower reverse leakage current. Proper thermal management ensures reliable operation and prevents overheating.

Tip: Always check the diode's datasheet for thermal resistance and power dissipation ratings.

Why do Schottky diodes have higher reverse leakage current?

Schottky diodes have higher reverse leakage current due to their metal-semiconductor junction. This design allows some current to flow in reverse, especially at higher temperatures. You can minimize this by selecting diodes with lower leakage ratings.

Are Schottky diodes suitable for RF applications?

Yes, Schottky diodes work well in RF applications. Their fast switching speed and low junction capacitance make them ideal for high-frequency circuits like mixers, detectors, and modulators.

Note: Ensure the diode's frequency range matches your circuit's requirements for optimal performance.

See Also

Exploring P-channel Powertrench MOSFETs And Their Uses

A Comprehensive Guide To AC-DC Switching Converters

Current Innovations In IGBT Technology For EVs