What is a Real Time Microcontroller IC and How Does It Work

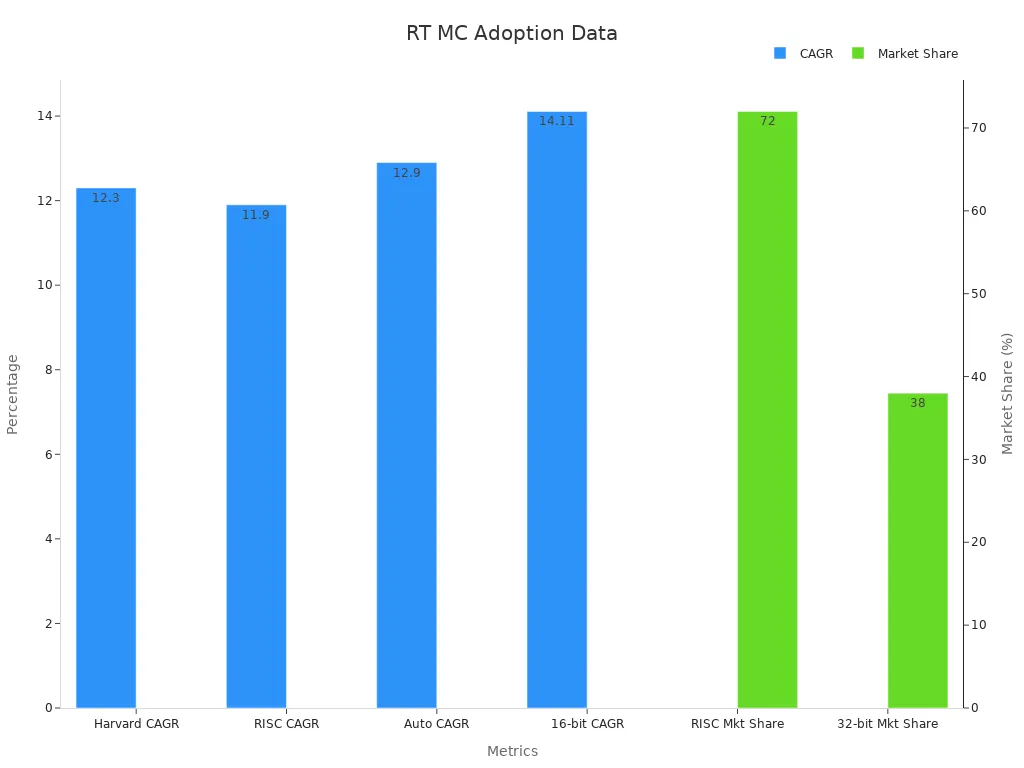

A Real Time Microcontroller IC is a small computer chip that helps machines respond quickly and predictably to signals or events. This chip works inside devices that must react within a strict time limit, such as cars or factory robots. Many companies choose these microcontrollers for their speed and reliability. The chart below shows strong growth in the use of real-time microcontrollers, especially in industries that need fast and accurate control.

Key Takeaways

Real Time Microcontroller ICs help devices respond quickly and predictably to important events within strict time limits.

These microcontrollers combine a processor, memory, input/output ports, and timers on one chip to manage real-time tasks efficiently.

They use special features like low-latency interrupts and real-time operating systems to prioritize urgent jobs and keep timing accurate.

Real-time microcontrollers save power by finishing tasks fast and entering low-power modes, making them ideal for battery-powered devices.

Industries like automotive, industrial automation, and smart home technology rely on these chips for safety, control, and fast responses.

Real Time Microcontroller IC

Definition

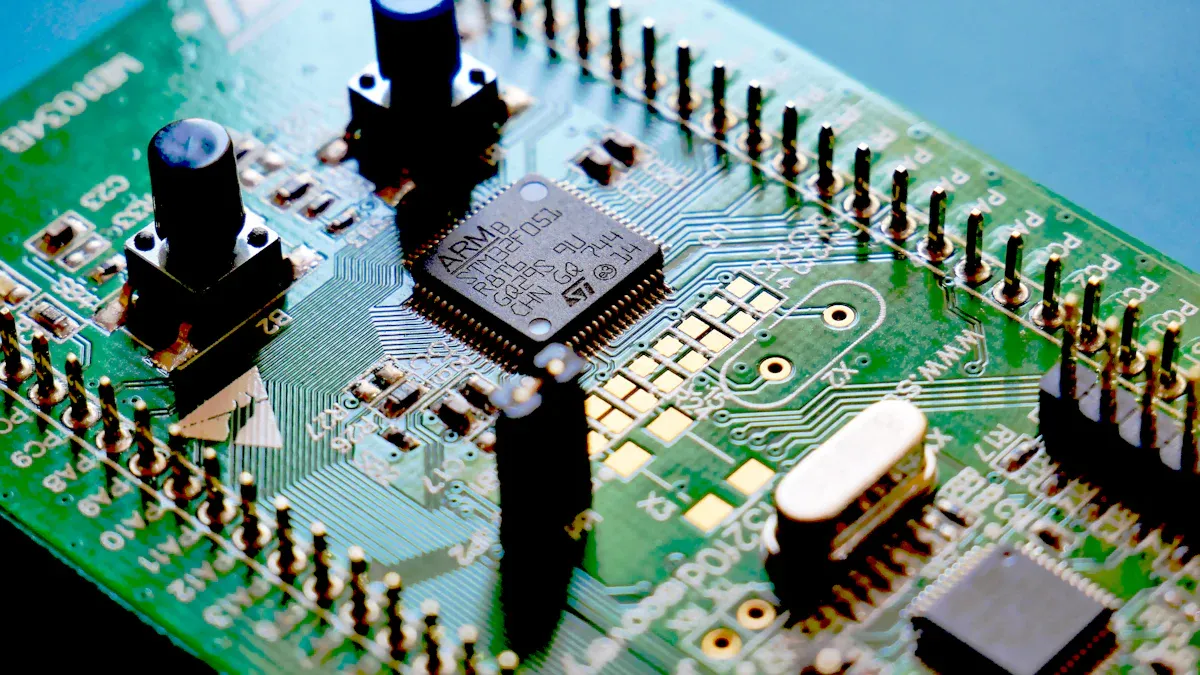

A Real Time Microcontroller IC is a specialized integrated circuit that acts as the brain of many embedded systems. It combines several important components on a single chip:

A processor core that runs instructions and controls operations.

Memory for storing data and programs.

Programmable input and output (I/O) ports for connecting to sensors, actuators, and other devices.

Timers and communication interfaces like UART, SPI, and I2C.

These microcontrollers are designed to handle tasks that must happen within strict time limits. They help devices interact with the outside world quickly and reliably. Popular platforms include ARM Cortex-M series, Arduino, and ESP32. Each platform offers unique features for different embedded applications.

Note: Microcontrollers often include extra features such as analog-to-digital converters (ADCs), pulse-width modulation (PWM) outputs, and real-time clocks. These features help them manage real-world signals and events.

Purpose

The main purpose of a Real Time Microcontroller IC is to ensure that devices respond to events or signals within a guaranteed time frame. This is very important in systems where delays can cause problems or even danger. For example, in a car’s airbag system, the microcontroller must detect a crash and trigger the airbag in milliseconds.

Key roles of a Real Time Microcontroller IC include:

Running dedicated tasks with real-time constraints.

Managing hardware peripherals and communication modules.

Providing a compact and cost-effective solution for embedded systems.

Balancing performance, power consumption, and size.

These microcontrollers allow devices to interact with sensors, actuators, and displays efficiently. They also support multitasking and task prioritization, often with the help of a Real-Time Operating System (RTOS) like FreeRTOS. This ensures that critical tasks always get the attention they need.

Real-Time vs. Standard Microcontrollers

Real-time microcontrollers and standard microcontrollers may look similar, but they serve different needs. The main difference lies in how they handle timing and predictability.

Feature | Real-Time Microcontroller IC | Standard Microcontroller |

|---|---|---|

Timing Guarantees | Yes, strict and predictable | No, may vary |

Task Scheduling | Deterministic, often with RTOS | Basic or none |

Response to Events | Fast and bounded | May be delayed |

Use Cases | Motor controllers, safety systems, industrial automation | Simple gadgets, basic controls |

Benchmarks Used | Dhrystone, CoreMark | |

Energy Efficiency (Active Mode) | High, completes tasks quickly | Varies |

Real Time Microcontroller ICs guarantee that tasks finish within a set time. For example, a SysTick timer interrupt can occur every 1 millisecond, ensuring regular updates. Standard microcontrollers do not offer this level of timing control. They work well in devices like smoke detectors or simple toys, where timing is less critical.

Performance benchmarks also highlight differences. Real-time microcontrollers use tests like CoreMark and ULPBench to measure processing speed and energy use during real-time tasks. These benchmarks show that 32-bit microcontrollers, while faster, can also be more energy efficient because they finish tasks quickly and return to low-power modes.

Tip: When choosing a microcontroller for a project, always consider if the application needs strict timing and predictable responses. Real Time Microcontroller ICs are best for time-sensitive and mission-critical systems.

How It Works

Real-Time Processing

A Real Time Microcontroller IC processes data by following strict timing rules. It must complete tasks within a set time, no matter what else is happening in the system. This is called deterministic behavior. For example, in a factory robot, the microcontroller reads sensor data and sends commands to motors in milliseconds. If it misses this deadline, the robot could make a mistake or stop working.

Microcontrollers avoid unpredictable delays by limiting dynamic memory allocation. Unlike desktop computers, they do not use virtual memory or garbage collection. This design choice helps them keep timing predictable. Engineers use special tests, called micro-benchmarks, to measure how fast the microcontroller responds under different conditions. These tests help ensure the system meets safety standards in industries like automotive and aerospace.

Many modern microcontrollers now include AI features. These features allow them to analyze data and make decisions in real time, without sending information to the cloud. For example, a hospital robot can use a Real Time Microcontroller IC to control its motors, read sensors, and even recognize objects, all within a few milliseconds.

Architecture

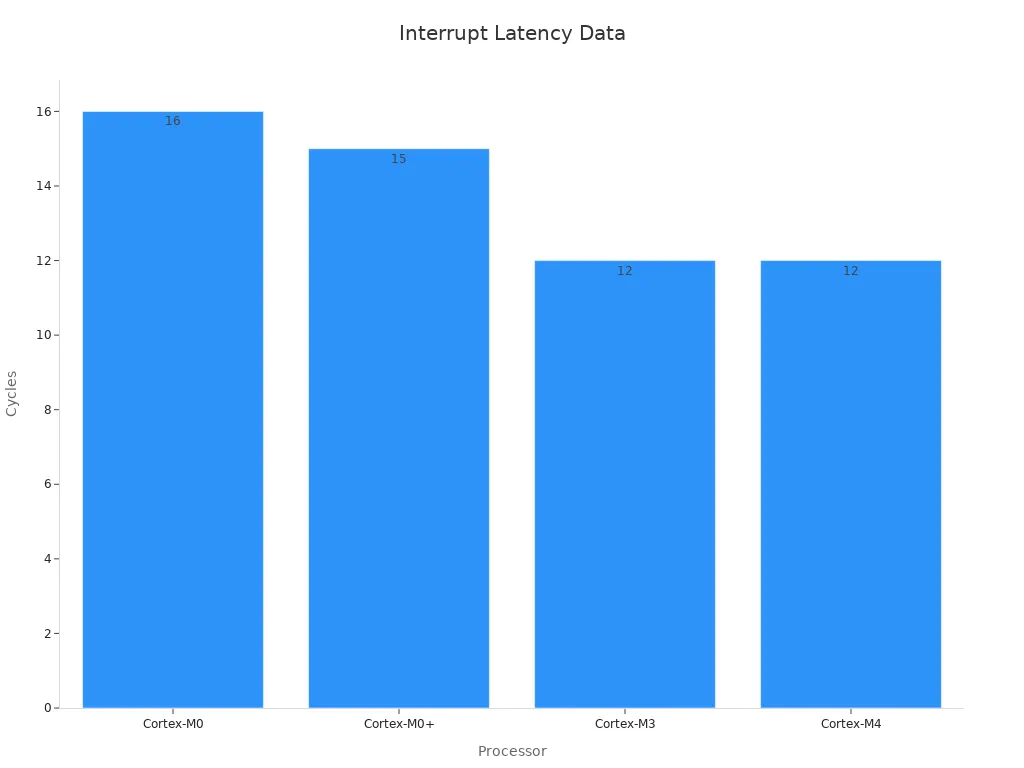

The architecture of a Real Time Microcontroller IC includes several features that reduce latency and jitter. Latency is the delay before the microcontroller starts a task. Jitter is the variation in response time. Both must be very low for real-time systems.

ARM Cortex-M processors use special techniques to keep latency and jitter low:

Feature | Description |

|---|---|

Tail Chaining | Skips some steps when switching between interrupts, making response faster. |

Late Arrival | Handles high-priority interrupts quickly, even if another task is running. |

Interrupt Nesting | Allows more important tasks to interrupt less important ones, keeping timing predictable. |

Processor | Interrupt Latency (cycles) |

|---|---|

Cortex-M0 | 16 |

Cortex-M0+ | 15 |

Cortex-M3 | 12 |

Cortex-M4 | 12 |

Clock systems also play a big role. Features like programmable clocks, phase-locked loops (PLLs), and real-time clocks (RTC) help keep timing accurate. These systems adjust the clock speed based on what the microcontroller needs to do, saving power and improving performance. Some microcontrollers use special clock chips to keep timing stable, even when temperature or power changes.

Task Scheduling and RTOS

Task scheduling is how a Real Time Microcontroller IC decides which job to do next. Many real-time systems use a Real-Time Operating System (RTOS) to manage this process. The RTOS gives each task a priority. High-priority tasks, like emergency stops or safety checks, always run first. If a lower-priority task is running, the RTOS can pause it and switch to the more important one.

This method is called preemptive multitasking. It helps the microcontroller meet strict timing deadlines. For example, if a sensor detects a problem, the RTOS makes sure the microcontroller responds right away. Studies show that using an RTOS improves system efficiency. Tools like IoTST measure how well the scheduler works, showing where delays happen and helping engineers make the system faster.

In some advanced systems, engineers combine an RTOS with a general-purpose operating system. They use dynamic isolation to balance real-time needs with other tasks. This setup keeps critical jobs running on time while letting the system handle more complex work.

Note: Real-time clocks (RTC) and real-time clock/calendar (RTCC) modules help the RTOS keep track of time, making sure tasks run exactly when needed.

Handling Inputs and Outputs

Handling inputs and outputs (I/O) quickly and accurately is a key job for any Real Time Microcontroller IC. Many microcontrollers use Configurable Logic Blocks (CLBs) to speed up I/O tasks. These hardware blocks handle things like data encoding, fault detection, and power sequencing much faster than software alone.

CLBs allow the microcontroller to react to changes in sensors or switches almost instantly.

They help with tasks like Manchester coding, which is used for fast data communication.

Hardware-based fault detection lets the system respond to errors right away, keeping devices safe.

Power sequencing logic in CLBs ensures that devices turn on and off in the correct order, improving reliability.

CLBs can also provide backup for critical functions, so the system keeps working even if software fails.

In real-world tests, microcontrollers like the Arduino MEGA 2560 have shown they can control devices with less than 5% error and respond in just a few seconds. This level of performance is good enough for many real-time control jobs, from lab equipment to home automation.

Components

CPU Core

The CPU core acts as the brain of a real-time microcontroller IC. It executes instructions and manages all operations inside the chip. Many modern microcontrollers use up to two Cortex-M55 cores running at speeds up to 400MHz. Multi-core designs help the microcontroller handle several tasks at once. This setup improves real-time processing and keeps the system fast and reliable. The CPU’s speed and design decide how quickly the microcontroller can respond to events. In advanced systems, dual real-time cores allow efficient task handling with low power use.

Note: Multi-core microcontrollers often appear in wearables and security cameras, where fast object detection and real-time responses matter most.

Memory

Memory stores both data and program instructions. Real-time microcontrollers use different types of memory for different jobs:

SRAM: Offers fast, temporary storage for data the CPU needs right away. Sizes range from 128KB to 13.5MB.

MRAM: Provides non-volatile storage up to 5.5MB, keeping data safe even when power is off.

Flash Memory: Holds the main program code and important data. It keeps information even after shutdown.

EEPROM: Allows rewriting data at the byte level, which helps extend the memory’s lifespan.

Fast memory access lets the microcontroller process information quickly and meet strict timing needs.

I/O Interfaces

I/O interfaces connect the microcontroller to the outside world. These ports and communication channels let the chip talk to sensors, actuators, and other devices. A rich set of interfaces includes:

Ethernet, USB, SDIO, I3C, CAN-FD

UART, SPI, I2C for serial communication

PWM outputs, timers, ADCs, DACs, and comparators

These features support real-time data exchange and control. For example, timers and ADCs help the microcontroller read sensor values and send commands to motors without delay.

Component Category | Features and Importance |

|---|---|

I/O Interfaces | Rich set enables real-time interaction with environment and efficient communication. |

Timers and Interrupts

Timers and interrupts play a key role in real-time performance. Timers measure time intervals and trigger actions at precise moments. Interrupts let the microcontroller stop what it is doing and respond to urgent events right away. Together, they help the system react quickly to changes, such as a button press or a sensor signal. Timers also support functions like pulse-width modulation and event counting, which are vital in motor control and automation.

Tip: The integration of CPU, memory, I/O, and timers in a single chip makes real-time microcontrollers efficient and cost-effective for embedded applications.

Applications

Industrial Automation

Factories and production lines depend on real-time microcontroller ICs to keep machines running smoothly. These chips control robots, conveyor belts, and sensors. They help machines react quickly to changes, such as a new item on a conveyor or a safety switch being pressed. Engineers use microcontrollers to monitor temperature, pressure, and speed. When a sensor detects a problem, the microcontroller can stop the machine in milliseconds. This fast response prevents accidents and reduces waste. Many factories use microcontrollers to automate tasks, improve product quality, and save energy. As industries move toward smart manufacturing, real-time microcontrollers play a key role in connecting equipment and collecting data for analysis.

Automotive Systems

Modern vehicles rely on real-time microcontroller ICs for safety and efficiency. These chips power advanced driver-assistance systems (ADAS) and electric vehicle controls. Key applications include:

Adaptive Cruise Control and Lane-Keeping Assistance

Tire Pressure Monitoring and Automatic Emergency Braking

Microcontrollers process sensor data instantly, helping drivers avoid accidents. They control motors, lighting, and battery systems in electric cars. As electric and autonomous vehicles become more common, automakers demand microcontrollers with higher performance and reliability. Companies continue to innovate by combining analog, digital, and mixed-signal features in compact chips. Stricter safety rules and better sensors also drive the need for advanced microcontrollers. These trends help vehicles use less energy and operate more safely.

IoT and Consumer Electronics

Real-time microcontroller ICs power many smart devices at home and in daily life. Popular uses include smart thermostats, fitness trackers, and home security systems. These chips offer:

Low power consumption for long battery life (2–10 years)

Built-in wireless connections like Wi-Fi and Bluetooth

Support for real-time operating systems (RTOS) for precise timing

Microcontroller families such as PIC18, STM32L0, and PIC24F stand out for their energy efficiency and wireless features. Developers use modular boards and Arduino-compatible tools to build new products quickly. The market for these chips grows as more people use smart appliances, wearables, and connected gadgets. Leading companies focus on adding security, AI, and better connectivity to meet the needs of modern IoT devices. Regional demand remains strong in North America, Europe, and Asia-Pacific, reflecting the global shift toward smart, connected living.

A Real Time Microcontroller IC helps devices respond quickly and predictably to important events. This chip uses special features to keep timing accurate and reliable. Many industries use these microcontrollers in cars, factories, and smart devices. People who build time-sensitive systems should consider using a Real Time Microcontroller IC.

Key features:

Fast and predictable responses

Strong support for safety and control

Useful in many real-world applications

FAQ

What makes a microcontroller "real-time"?

A real-time microcontroller guarantees that it completes tasks within a set time. This feature helps devices respond quickly and predictably to important events. Engineers use these microcontrollers in systems where timing matters most.

Can real-time microcontrollers run multiple tasks at once?

Yes, many real-time microcontrollers use a Real-Time Operating System (RTOS). The RTOS lets the chip switch between tasks quickly. High-priority jobs always get attention first.

Tip: Using an RTOS helps keep critical systems safe and reliable.

Where do people use real-time microcontroller ICs?

People use these chips in cars, robots, medical devices, and smart home products. They help machines react fast to signals from sensors or buttons.

Application Area | Example Devices |

|---|---|

Automotive | Airbags, ABS, ADAS |

Industrial | Robots, PLCs |

Consumer Electronics | Smart thermostats, wearables |

How do timers and interrupts help real-time systems?

Timers measure time and trigger actions at exact moments. Interrupts let the microcontroller stop its current work to handle urgent events. These features keep the system fast and accurate.

Do real-time microcontrollers use a lot of power?

No, most real-time microcontrollers use very little power. They finish tasks quickly and then enter low-power modes. This design helps devices run longer on batteries.

See Also

Understanding MCU Microcontroller Chips And Their Operation

Exploring The Features Of High-Performance Microcontroller ICs

How Current Controller Chips Work And Their Key Functions

Industrial D Flash Microcontrollers And Their Practical Uses

Integrated Battery Monitor ICs Explained And Their Functionality