What is a Programmable Logic Chip and How Does It Work

A Programmable Logic Chip lets you create custom digital circuits to fit your needs. You can change how it works by programming its logic, which gives you flexibility not found in fixed chips. Today, these chips play a key role in devices like cars, phones, and industrial machines.

Aspect | Details |

|---|---|

Market Size & Growth | Projected growth from USD 0.80 billion in 2025 to USD 1.46 billion by 2034, CAGR 6.82% |

Key Industry Drivers | Automotive, industrial automation, consumer electronics, aerospace, telecommunications |

Technological Advancements | Integration of AI and machine learning, low-power solutions, 3D IC technology |

You benefit from faster speeds and lower power use compared to older digital circuits, which helps make modern technology more efficient.

Key Takeaways

Programmable Logic Chips let you create custom digital circuits by programming their logic, offering flexibility that fixed chips cannot match.

You can reprogram these chips many times, which saves time and money when testing ideas or updating designs.

These chips contain programmable logic units, interconnects, and memory, working together to perform fast and efficient digital tasks.

They are widely used in cars, industrial machines, consumer electronics, and more, helping control systems and process signals.

Programmable Logic Chips balance speed, cost, and flexibility, making them ideal for rapid prototyping and adapting to changing needs.

Programmable Logic Chip Basics

What Is It

A Programmable Logic Chip is a special type of digital device that lets you create your own logic circuits. You do not need to design a new chip from scratch every time you want a different function. Instead, you can program this chip to do what you need. This makes it very flexible and useful for many projects.

Think of a Programmable Logic Chip as a blank canvas for digital logic. You decide what the chip does by programming it.

Here are some simple facts about these chips:

They use arrays of AND and OR gates that you can program to create custom logic circuits.

You do not get a fixed function at the factory. You set up the chip after you get it.

The chip works in three main steps: you program the logic, the AND gates create product terms, and the OR gates combine them to make the final output.

You can reprogram the chip if you want to change its function.

These chips often combine memory and logic, making them efficient.

You can use them in many places, like counters, decoders, and control systems.

Core Function

The main purpose of a Programmable Logic Chip is to give you control over how a digital circuit behaves. You can change its function as your needs change. This is different from fixed-function logic devices, which only do one job and cannot be changed.

Here is a table that shows how these chips stand out:

Aspect | Description | Example Devices | Purpose / Differentiation |

|---|---|---|---|

Lets you create custom logic using programmable AND and OR arrays | General PAL devices | Gives you flexible logic options | |

Output Logic Macrocells | Lets you choose between different output types (combinational or registered) | PAL16L8, PAL16R8, PAL16R4 | Matches output to your needs |

Fixed vs Variable Output | Early chips had fixed outputs; newer ones let you pick output type | AMD 22V10 | One chip can replace many fixed-function chips |

Product Terms per Output | Lets you set how complex each output is | PAL16 series, AMD 22V10 | Handles simple or complex logic for each output |

You get several benefits from using a Programmable Logic Chip:

You can quickly test new ideas and make changes without building new hardware.

You can use the same chip for many different projects.

You can save money on small production runs because you do not need to order custom chips.

You can update your design easily if your needs change.

Fixed-function logic devices do not offer this kind of flexibility. Once you pick a fixed chip, you cannot change what it does. Programmable Logic Chips let you adapt and grow your designs as needed.

How It Works

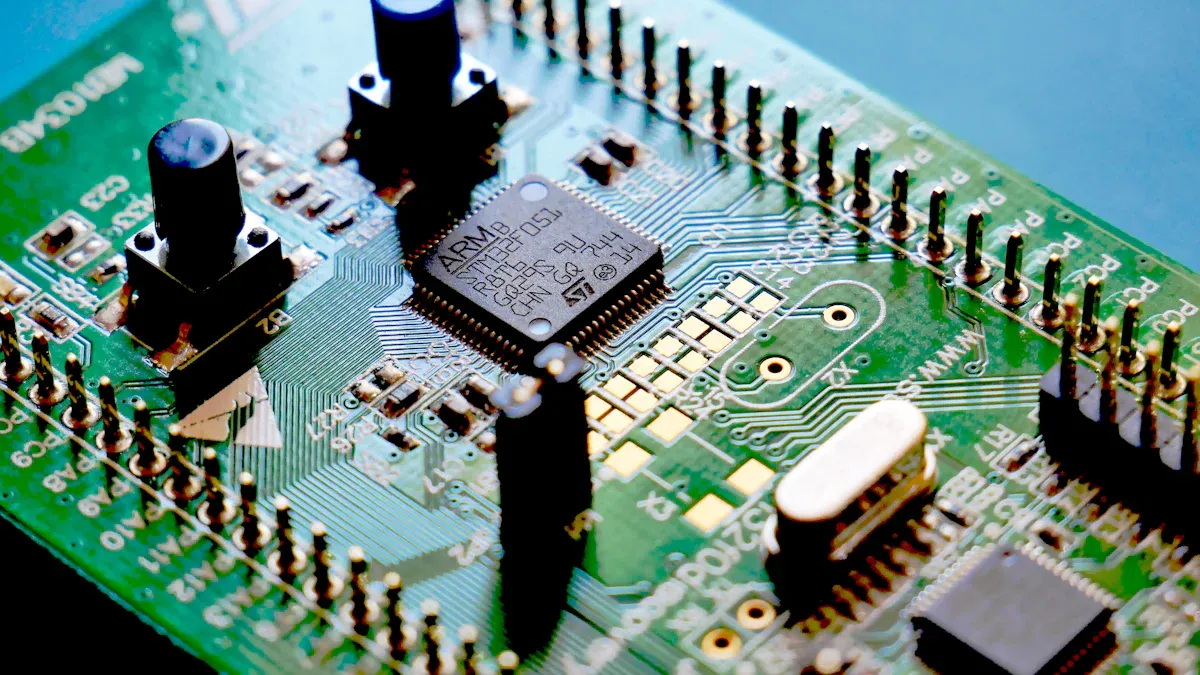

Internal Structure

When you look inside a Programmable Logic Chip, you find many small parts working together. Each part helps the chip perform custom tasks quickly and efficiently. Here are the main components you will find:

Programmable Logic Units: These units contain lookup tables and flip-flops. You can set them up to handle both simple and complex logic. They help the chip process information fast.

Internal Interconnects: These are like tiny roads inside the chip. They connect different logic units. You can program these paths to control how signals move through the chip.

Input/Output Units: These parts let the chip talk to other devices. They manage how data enters and leaves the chip.

Embedded Functional Modules: Some chips include special blocks, like multipliers or digital signal processors (DSPs). These blocks handle math operations quickly.

Clock Management Modules: These modules keep everything in sync. They make sure all parts of the chip work together at the right time.

Embedded Storage Resources: These are memory blocks inside the chip. They store data for quick access during operations.

Note: The way these parts connect and work together affects how fast and efficient your chip will be.

You can see how these features impact performance in the table below:

Metric | Description | How It Relates to Internal Structure |

|---|---|---|

Latency | Time for one operation from input to output | Affected by the number of logic stages and how signals travel inside |

Throughput | Number of operations completed per second | Improved by pipelining and efficient logic unit design |

Propagation Delay | Time for a signal to pass through logic without pipelining | Depends on the design of logic units and interconnects |

Pipelining | Breaking tasks into steps for faster processing | Uses registers and stages inside the chip |

Clock Period | Length of one clock cycle | Set by clock management modules and affects timing for all operations |

Programming Process

You can program a Programmable Logic Chip to do almost any digital task you want. The process starts with a plan. You decide what you want the chip to do, then you describe this plan using a special language.

Most people use hardware description languages like VHDL or Verilog. These languages let you write instructions that tell the chip how to behave. Here is a simple example in Verilog:

module and_gate (input a, input b, output y);

assign y = a & b;

endmodule

This code tells the chip to create an AND gate. You can write more complex instructions to build bigger circuits.

After you finish your code, you use special software to turn your instructions into a configuration file. You load this file onto the chip. The chip then changes its internal connections and logic units to match your design.

You can reprogram the chip if you want to change its function.

Each time you load a new configuration, the chip acts like a brand-new circuit.

This process lets you test ideas quickly and fix mistakes without building new hardware.

Tip: You can use the same Programmable Logic Chip for many different projects by simply changing the program.

When you program the chip, you control how signals move, how fast operations happen, and how the chip connects to other devices. This flexibility makes these chips powerful tools for engineers, students, and hobbyists.

Types and Comparison

PLDs vs. Fixed Logic

You can think of PLDs as digital building blocks that you can shape to fit your needs. Fixed logic devices, like standard logic gates or chips, come with one job. You cannot change what they do after you buy them. PLDs let you decide how the circuit works, so you can update or fix your design without buying new hardware.

PLDs: You program them to perform different tasks. If your project changes, you can reprogram the chip.

Fixed Logic Devices: These chips do only one thing. You cannot change their function.

Tip: If you want to test new ideas or need to fix mistakes, PLDs save you time and money.

Here is a quick comparison:

Feature | PLDs | Fixed Logic Devices |

|---|---|---|

Flexibility | High | None |

Reusability | Yes | No |

Design Changes | Easy | Not possible |

Cost for Changes | Low | High |

PLDs vs. Other Programmable Devices

You might wonder how PLDs compare to other programmable devices like ASICs and microcontrollers. Each type has its own strengths.

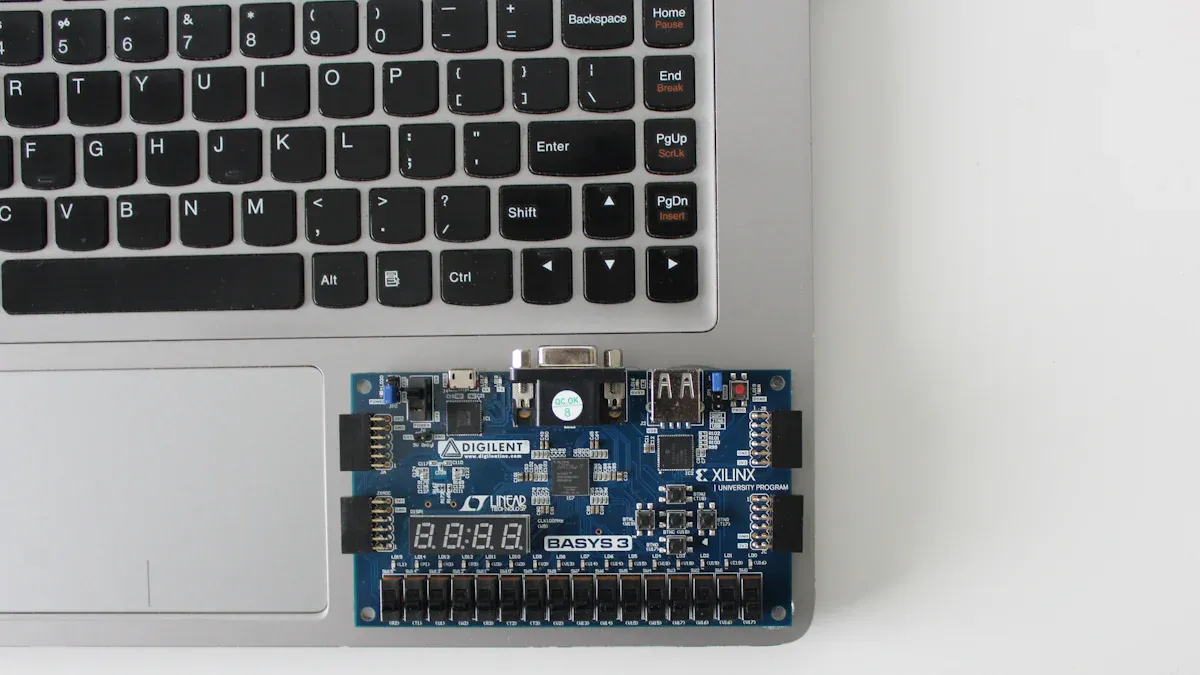

PLDs come in several types: Simple PLDs (SPLDs), Complex PLDs (CPLDs), and Field-Programmable Gate Arrays (FPGAs). SPLDs handle basic logic. CPLDs and FPGAs can manage much more complex tasks. FPGAs, for example, use arrays of logic blocks, memory, and input/output blocks. This setup lets you build advanced digital systems and change them as needed.

When you compare PLDs to ASICs, you see that PLDs give you faster design cycles and more flexibility. ASICs take longer to develop and cost more, but they can reach higher speeds once finished. Microcontrollers offer some flexibility, but you cannot change their hardware logic like you can with PLDs.

Here is a table to help you see the differences:

Device Type | Flexibility | Development Time | Cost | |

|---|---|---|---|---|

ASICs | High | Low | Long | High |

Microcontrollers | Low | Medium | Medium | Medium |

PLDs | Medium | High | Short | Medium |

Note: PLDs give you a strong balance of flexibility and speed. You can use them for rapid prototyping and adapt your design quickly.

Features and Applications

Key Features

You get several important features when you use a Programmable Logic Chip. These features help you build digital systems that fit your needs.

Reconfigurability: You can change the chip’s function by reprogramming it. This makes it easy to update your design or fix mistakes.

Flexibility: You can use the same chip for many different projects. CPLDs and FPGAs let you create only the parts you need, which saves space and power.

Rapid Prototyping: You can test ideas quickly. For example, you might design an answering machine or a traffic light system, then program and test your chip right away. This helps you learn and improve your design fast.

Low Power Use: Many chips use little power, so you can use them in portable devices.

Predictable Timing: CPLDs give you reliable timing, which is important for control systems.

Customizable I/O: You can set up the chip to connect with many types of devices.

You can see how engineers value these features in real projects. FPGAs and CPLDs are popular in automotive, industrial, and consumer electronics because they let you move from idea to working product quickly.

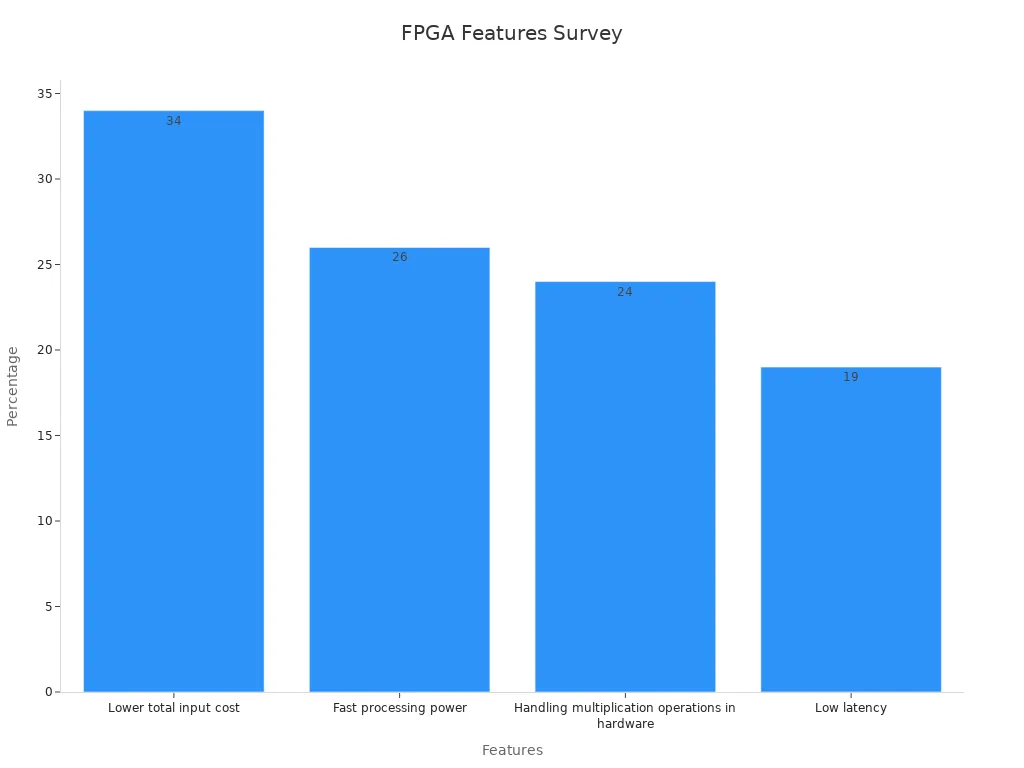

Here is a table showing what engineers value most in these chips:

Feature | Percentage of Respondents | Description |

|---|---|---|

Lower total input cost | 34% | Reduces overall cost in applications. |

Fast processing power | 26% | Handles complex tasks quickly. |

Hardware multiplication | 24% | Improves efficiency for math operations. |

Low latency | 19% | Cuts down on delays, important for real-time tasks. |

Programmable routing | N/A | Lets you control how signals move inside the chip. |

Programmable I/O blocks | N/A | Makes it easy to connect to other devices. |

On-chip memory | N/A | Stores data for fast access. |

AI and Machine Learning integration | Projected 40% adoption | Helps with smart tasks in data centers and new tech. |

Common Uses

You will find Programmable Logic Chips in many real-world applications. These chips help control, process, and manage data in different fields.

Control Systems: Programmable Logic Controllers (PLCs) use these chips to run machines in factories, manage assembly lines, and control robots. PLCs work well in tough environments and support many ways to connect with other systems.

Embedded Systems: You see these chips in cars, smart home devices, and medical equipment. For example, they help engine control units in cars save fuel and lower emissions. In medical devices, they collect and process signals, like heartbeats, with high accuracy.

Signal Processing: Engineers use these chips for tasks like filtering signals, coding images, and designing digital filters. They also help with music synthesis, communication receivers, and even chaos simulations.

Industrial Automation: These chips run sensors and actuators, making sure machines work safely and efficiently.

Energy Industry: FPGAs help manage smart grids and control power networks, making energy use more efficient.

Automotive Safety: You find these chips in systems for cruise control, blind spot warnings, and collision avoidance.

You can use a Programmable Logic Chip to build, test, and improve many types of digital systems. This makes it a key part of modern technology.

Pros and Cons

Advantages

You gain many benefits when you use programmable logic chips in your projects. These chips give you the power to change and update your designs without building new hardware. You can test ideas quickly and fix mistakes with ease. Many engineers choose programmable logic chips because they offer a strong balance between flexibility, speed, and cost.

Here are some key advantages:

You can reprogram the chip many times, which saves time and money.

You can use the same chip for different projects, making it a flexible tool.

You can scale your design as your needs grow.

You can finish your project faster because you do not need to wait for custom chips.

SPLDs and CPLDs are popular in industries like automotive, consumer electronics, and telecommunications because they support innovation and rapid changes.

You can see how programmable logic chips compare to other solutions in this table:

Aspect | FPGA (Programmable Logic Chip) | ASIC (Application-Specific Integrated Circuit) | CGRA (Coarse-Grained Reconfigurable Architecture) |

|---|---|---|---|

Performance | Comparable to ASIC due to custom architecture and parallelism | Extremely high under strict constraints | Fast reconfiguration and good energy efficiency |

Development Cycle | Short, thanks to advanced design tools | Long, due to complex custom design | Long, limited by development ecosystem |

Cost | Lower, because you can reuse and reprogram | High, due to manufacturing | N/A |

Flexibility | High, easy to update and verify | Low, hard to change after making | N/A |

Energy Efficiency | Competitive, but sometimes less than CGRA | High under specific conditions | Often better than FPGA, but limited by ecosystem |

Limitations

You should also know about the limits of programmable logic chips. These chips cannot do everything. Sometimes, you may need a different solution for very complex or high-speed tasks.

Some common limitations include:

You get a limited number of logic cells and interconnects, which can restrict large or complex designs.

You may find the design tools hard to learn, especially if you are new to digital design.

Some chips have limited memory and fewer special features than advanced FPGAs or ASICs.

You may face performance limits, such as slower speeds or higher delays, compared to custom chips.

Some chips need to reload their configuration every time they start, which can slow down activation.

You may have fewer input/output pins, which can limit how many devices you connect.

Complex designs need careful planning to use resources well. You must test your design fully to avoid errors and make sure it works as expected.

You may also face extra costs, such as buying special software or paying for updates. For very large or fast systems, you might need to use FPGAs or ASICs instead. Programmable logic chips work best when you need flexibility, quick changes, and cost savings for small to medium projects.

You have seen how these chips let you build custom digital circuits that fit your needs. Their reprogrammable nature helps you adapt quickly as technology changes. Today, you find them in cars, smart devices, and factories. Market studies show strong growth, with the CPLD market expected to nearly double by 2032. This rise comes from the need for flexible, low-power hardware in industries like automotive, telecom, and IoT. As you use more connected devices, these chips shape the future of electronics.

FAQ

What is the difference between a PLD and an FPGA?

A PLD is a general term for chips you can program to do different logic tasks. An FPGA is a type of PLD that has many logic blocks. You use FPGAs for more complex projects.

Can you reprogram a programmable logic chip more than once?

Yes, you can reprogram most programmable logic chips many times. This lets you update your design or fix mistakes without buying a new chip.

Do you need special software to program these chips?

You need special software to write and load your design onto the chip. Most companies provide free or paid tools for this purpose.

Where can you find programmable logic chips in real life?

You find these chips in cars, phones, factory machines, and even medical devices. They help control systems, process signals, and connect different parts of a device.

See Also

Understanding Computer Chips And Their Functionality Explained

Exploring Interface Control Chips And Their Operational Role

A Detailed Guide To Communication Chips And Their Functions

Power Supply Chips: What They Are And How They Operate

Industrial Control Chips And Their Role In Automation Systems