What Are PIC Microcontrollers and How Do They Power Automotive Electronics

PIC microcontrollers serve as compact computers that control electronic systems inside vehicles. They help manage tasks in engine control units, airbag systems, and infotainment. Over the past decade, demand for pic automotive solutions has soared, especially with the rise of electric vehicles and advanced driver-assistance systems. The Asia-Pacific region leads this growth, with 32-bit microcontrollers dominating the market.

The automotive sector now drives the fastest growth in microcontroller adoption, reflecting the need for energy efficiency and strong performance.

Key Takeaways

PIC microcontrollers are small, fast, and efficient computers that control many vehicle systems like engines, airbags, and dashboards.

Automotive-grade PICs meet strict tests for heat, vibration, and safety to work reliably in tough car environments.

These microcontrollers support key communication protocols like CAN, SPI, and UART to help vehicle parts share data quickly and safely.

PIC microcontrollers include safety features like error correction and watchdog timers to keep vehicles running smoothly and prevent failures.

Choosing the right PIC microcontroller depends on the project’s needs, including processing power, communication support, temperature range, and safety certifications.

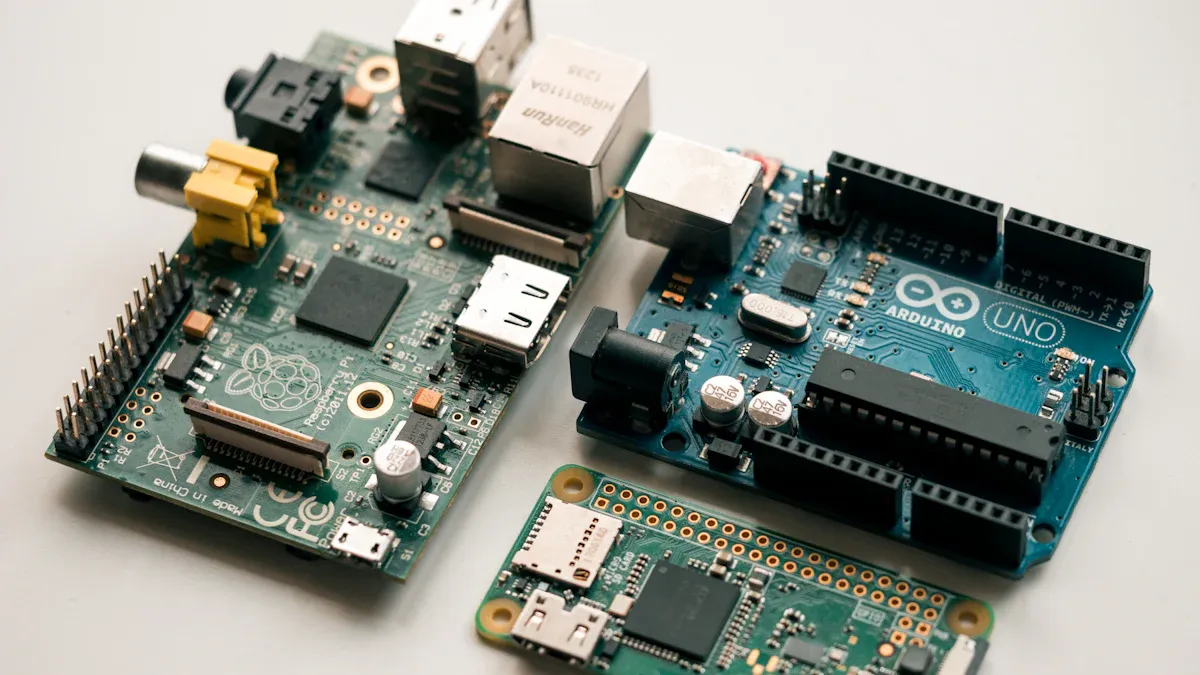

PIC Microcontrollers

What Are PICs

PIC microcontrollers are small, programmable computers that control electronic devices. Engineers use them in many industries, including automotive, because they are reliable and flexible. PIC stands for "Peripheral Interface Controller." These microcontrollers can read data, process information, and control outputs. They help manage tasks like turning on headlights, monitoring engine sensors, or controlling dashboard displays. PIC microcontrollers come in different sizes and types, such as 8-bit, 16-bit, and 32-bit versions. Each type fits different needs, from simple switches to complex vehicle systems.

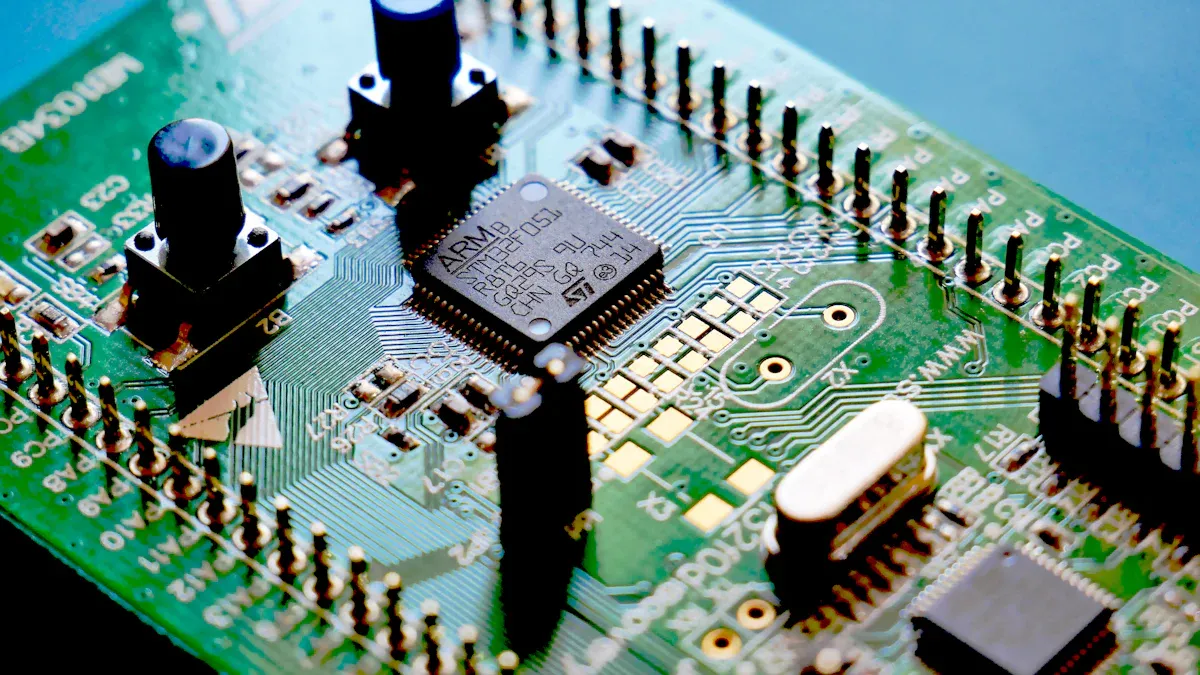

Architecture

A PIC microcontroller contains several important parts that work together to perform tasks. The architecture uses a Harvard design, which separates program memory from data memory. This design increases processing speed and efficiency. The main components include:

Component | Description |

|---|---|

CPU | Uses a RISC instruction set for fast and efficient processing. |

Program Memory (Flash) | Stores the program code and allows reprogramming. |

Data Memory (RAM) | Holds data during operation, including general-purpose and special function registers. |

Special Function Registers | Control device settings, timers, and communication modules. |

Peripherals | Include timers, counters, ADC, PWM modules, and communication interfaces like SPI, UART, and CAN. |

Clock System | Provides timing signals with flexible oscillator options. |

I/O Ports | Offer multiple digital input/output pins for connecting to other devices. |

Interrupt System | Enables quick response to external events, which is important for real-time automotive control. |

This structure allows PIC microcontrollers to support automotive protocols and handle complex control tasks.

Key Features

PIC microcontrollers stand out because of their speed, efficiency, and flexibility. They use a high-performance RISC CPU and support a wide range of communication protocols, such as CAN and LIN, which are essential in vehicles. Their Harvard architecture separates program and data memory, making them faster than many other microcontrollers. PICs come in various bit-widths, from 8-bit to 32-bit, and offer instruction sets ranging from 35 to 80 commands. They consume low power and execute instructions quickly, often in just four clock cycles. Engineers find them easy to program and integrate with many peripherals, which makes them a popular choice for automotive electronics.

Note: PIC microcontrollers offer advanced features and robust performance, making them ideal for modern vehicle systems.

PIC Automotive

Automotive-Grade PICs

Automotive-grade PIC microcontrollers meet strict standards for use in vehicles. Manufacturers design these microcontrollers to handle extreme temperatures, vibrations, and humidity. The AEC-Q100 qualification process tests each device with stress methods like high-temperature operating life, thermal cycling, and mechanical shock. This process ensures that every microcontroller can survive the harsh conditions found in cars and trucks.

Aspect | Description |

|---|---|

Scope | Stress tests for integrated circuits in automotive environments |

Purpose | Ensure quality and reliability for vehicle systems |

Temperature Grades | Grade 0: -40°C to +150°C |

Typical Tests | High-temperature, vibration, humidity, and mechanical shock |

Adaptability | Tests adjust for new technologies and packaging |

Automotive-grade PIC microcontrollers come in 8-bit, 16-bit, and 32-bit variants. Popular families include PIC24F and PIC16F882. Some EM78PXXX families, which are clones of Microchip PIC processors, offer low pin-count, GPIO, and ADC types. These families use 12- and 14-bit processor cores with a 13-bit instruction word. Engineers choose the right variant based on the needs of each automotive system.

AEC-Q100 certification reduces the risk of failures, recalls, and repairs. It also saves time and resources during development.

Communication Protocols

Modern vehicles rely on fast and reliable communication between electronic systems. PIC automotive microcontrollers support several key protocols that help different parts of the car talk to each other.

Communication Protocol | Description | Automotive Relevance |

|---|---|---|

Message-based protocol for real-time data exchange | Used in engine control, diagnostics, and safety systems | |

UART (Universal Asynchronous Receiver/Transmitter) | Serial communication for data transfer | Connects sensors, displays, and other modules |

SPI (Serial Peripheral Interface) | High-speed data exchange between microcontrollers and peripherals | Supports infotainment, sensors, and memory devices |

I²C (Inter-Integrated Circuit) | Connects low-speed peripherals | Links sensors and small devices in embedded systems |

CAN stands out as the most important protocol in automotive applications. PIC microcontrollers use CAN modules to send and receive messages across the vehicle. Some models, like dsPIC33EP, include built-in CAN modules. Others require an external CAN transceiver, such as the MCP2551, to connect safely to the CAN bus. The CAN protocol follows ISO 11898 standards, which define message framing and communication rules. CAN bootloaders allow engineers to update firmware over the CAN bus, making maintenance easier.

PIC automotive microcontrollers also support SPI, UART, and I²C protocols. These protocols help connect sensors, displays, and other devices, making the vehicle smarter and more responsive.

Reliability and Safety

Reliability and safety are top priorities in automotive electronics. PIC automotive microcontrollers include many features to meet industry standards and keep vehicles safe.

Flash memory with error correcting code (ECC) detects and fixes memory errors.

Cyclic redundancy checking (CRC) ensures data integrity in memory and communication.

Deadman timers and windowed watchdog timers monitor software health and reset the system if needed.

Backup system oscillators keep the clock running during power interruptions.

High operating temperature support (up to 150°C) allows use under the hood.

Under-voltage protection prevents damage from low voltage conditions.

5 V operation voltage improves noise immunity in high-noise environments.

Certified Class B software and digital signal processing (DSP) features support ISO 26262 compliance.

Automotive microcontrollers must work in extreme environments. They face temperature swings from -40°F to 300°F, long lifetimes up to 15 years, and exposure to chemicals like oil and antifreeze. Manufacturers test these devices for electrical stresses, vibration, humidity, and electromagnetic compatibility. These tests follow standards such as ISO 16750, SAE J1211, CISPR 25, and ISO 7637. Only microcontrollers that pass all tests can be used in safety-critical automotive systems.

PIC automotive microcontrollers help vehicles stay safe and reliable, even in the toughest conditions.

Automotive Applications

Engine Control

Modern vehicles rely on precise engine management to meet performance and efficiency goals. PIC microcontrollers play a key role in these systems. They process sensor data quickly, which helps the engine respond in real time. Engineers use these microcontrollers to control fuel injection and ignition timing with high accuracy. This leads to better fuel economy and lower emissions.

PIC microcontrollers process sensor data rapidly for real-time engine management.

They control fuel injection and ignition timing for optimal performance.

Built-in analog-to-digital converters (ADCs) improve sensor accuracy.

Embedded analog components reduce noise and signal interference.

Advanced 16-bit and 32-bit architectures allow multitasking and complex operations.

These features help engines run smoothly and safely. The result is improved reliability and efficiency in pic automotive systems.

Dashboard and Displays

Drivers need clear and accurate information from their vehicles. PIC microcontrollers help create digital dashboards that show speed, temperature, fuel level, and more. A typical system uses a PIC microcontroller, such as the PIC18F458, to collect data from sensors and display it on an LCD screen. The microcontroller converts analog signals from sensors into digital data using ADCs. It then sends this data to the dashboard display, often over a Controller Area Network (CAN) bus.

Component/Aspect | Description |

|---|---|

PIC Microcontroller | Collects and processes sensor data |

LCD Display | Shows vehicle status (speed, temperature, battery voltage) |

Communication Protocol | CAN bus transfers data between engine and dashboard |

User Interaction | Buttons or keys allow drivers to request specific information |

This setup gives drivers real-time updates and helps them make safe decisions on the road.

Body and Comfort Systems

PIC microcontrollers also support body and comfort features in vehicles. They control systems like power windows, door locks, lighting, and climate control. These microcontrollers connect to sensors and switches using interfaces such as SPI and UART. For example, a PIC microcontroller can read a signal from a door sensor and activate the central locking system. It can also adjust the air conditioning based on temperature readings.

Many vehicles use pic automotive solutions to manage multimedia, navigation, and voltage monitoring. These systems improve comfort and convenience for drivers and passengers. Integration with various peripherals makes these microcontrollers flexible and reliable for many automotive tasks.

Choosing PIC Automotive

Selection Criteria

Selecting the right PIC microcontroller for automotive projects requires careful evaluation of several factors. Engineers must match the microcontroller’s bit-width and features to the complexity of the application. For example, 8-bit PIC microcontrollers work well for simple tasks like lighting or basic dashboard controls. More advanced systems, such as multimedia or real-time engine management, need 16-bit or 32-bit devices with higher processing power and memory.

Bit-Width | Features | Automotive Project Suitability | |

|---|---|---|---|

PIC10/12/16 | 8-bit | Low power, simple control | Lighting, entry systems |

PIC18 | 8-bit | Enhanced peripherals, moderate memory | Dashboard, lighting control |

PIC24 | 16-bit | More peripherals, higher performance | Advanced controls, communication systems |

dsPIC33 | 16-bit | DSP, real-time processing | Motor control, power management |

PIC32 | 32-bit | High performance, USB/Ethernet, RTOS | Multimedia, networking, real-time processing |

Automotive microcontrollers must support key communication protocols like CAN, SPI, and UART. These interfaces allow the microcontroller to connect with sensors, displays, and other vehicle systems. Devices should also meet automotive standards such as AEC-Q100 and ISO 26262 for safety and reliability. Temperature tolerance, electromagnetic compatibility, and security features are essential for robust operation in harsh environments.

Tip: Always check if the microcontroller supports the required temperature range and has the necessary safety certifications for automotive use.

Practical Tips

When choosing a PIC microcontroller for automotive applications, engineers should:

Define the project’s communication needs. For example, CAN is vital for engine and safety systems, while SPI and UART connect sensors and displays.

Review the datasheet for each communication interface. SPI, for instance, has different modes and speed limits. Set the SPI clock rate to about one-tenth of the slave device’s system clock for reliable operation.

Consider future expansion. Select a microcontroller with extra memory and I/O pins to support new features or updates.

Evaluate safety requirements. Look for features like error correction codes, watchdog timers, and compliance with ISO 26262. These help prevent failures in safety-critical systems.

Use debugging tools such as oscilloscopes or logic analyzers to test and troubleshoot communication links.

Criteria | Explanation |

|---|---|

Operating Temperature | Must support automotive temperature range (-40°C to 125°C) |

EMI/EMC Robustness | Strong electromagnetic compatibility for automotive environments |

Safety Certifications | Compliance with standards like ISO 26262 for safety-critical applications |

A well-chosen pic automotive microcontroller ensures reliable, safe, and efficient vehicle operation.

PIC microcontrollers power many modern vehicle systems. Their Harvard architecture, low power use, and compact size make them ideal for pic automotive solutions. These microcontrollers offer real-time processing, high reliability, and easy integration with automotive protocols.

They help vehicles meet strict safety standards and support features like ADAS and electric power management.

Manufacturers value their cost-effectiveness and robust performance.

As the automotive industry grows, pic automotive microcontrollers will remain essential for safe, efficient, and advanced vehicles.

FAQ

What makes PIC microcontrollers popular in automotive electronics?

PIC microcontrollers offer high reliability, low power use, and strong support for automotive protocols. Engineers choose them for their robust performance in harsh environments. These microcontrollers also meet strict automotive standards.

Can engineers program PIC microcontrollers easily?

Yes. PIC microcontrollers support user-friendly development tools. Engineers use MPLAB X IDE and C programming language. Many resources and libraries help beginners and experts create automotive applications quickly.

How do PIC microcontrollers improve vehicle safety?

PIC microcontrollers include features like error correction, watchdog timers, and voltage protection. These features help prevent system failures. They also support safety standards such as ISO 26262.

Which communication protocols do PIC microcontrollers support in vehicles?

PIC microcontrollers support CAN, SPI, UART, and I²C protocols. These protocols allow different vehicle systems to share data. CAN is the most common protocol for engine and safety systems.

Are PIC microcontrollers suitable for electric vehicles?

Yes. PIC microcontrollers manage battery systems, motor control, and charging stations in electric vehicles. Their efficiency and flexibility make them a strong choice for new automotive technologies.

Tip: Always check the datasheet for supported protocols and safety features before choosing a PIC microcontroller for automotive use.

See Also

Exploring Industrial D Flash Microcontrollers And Their Uses

An Overview Of High-Performance Microcontroller Integrated Circuits

How MCU Chip Microcontrollers Function And Their Features

Understanding Real-Time Microcontroller ICs And Their Operation