What is an Optocoupler and How It Operates in AC/DC Circuits

An optocoupler, also known as an opto-isolator, is a small yet powerful electronic component that transfers signals between two isolated circuits using light. This unique design ensures electrical isolation, protecting sensitive systems from high voltages and electrical noise. Optocouplers operate at isolation voltages ranging from 1,500V to 7,500V, safeguarding circuits against surges caused by lightning or electrostatic discharge.

In AC/DC circuits, optocouplers play a vital role in ensuring safe signal transfer. Whether you're working on industrial automation or consumer electronics, their ability to block high voltages makes them indispensable for shielding components and improving system reliability. Modern devices like Optocoupler AC/DC CONTROLLERS IC further enhance this functionality, offering precise control and protection.

Key Takeaways

Optocouplers use light to send signals between separate circuits. They keep circuits safe and protect parts from high voltages.

They are important in AC and DC circuits. They help signals move safely and stop damage from voltage spikes or electrical noise.

To pick the right optocoupler, think about voltage, speed, and use. This helps it work well in your project.

Optocouplers are great for power supplies, motor control, and communication systems. They make systems safer and more reliable.

When building circuits, optocouplers cut down electrical interference. This makes them useful for any electronic project.

What is an Optocoupler?

Basic components of an optocoupler

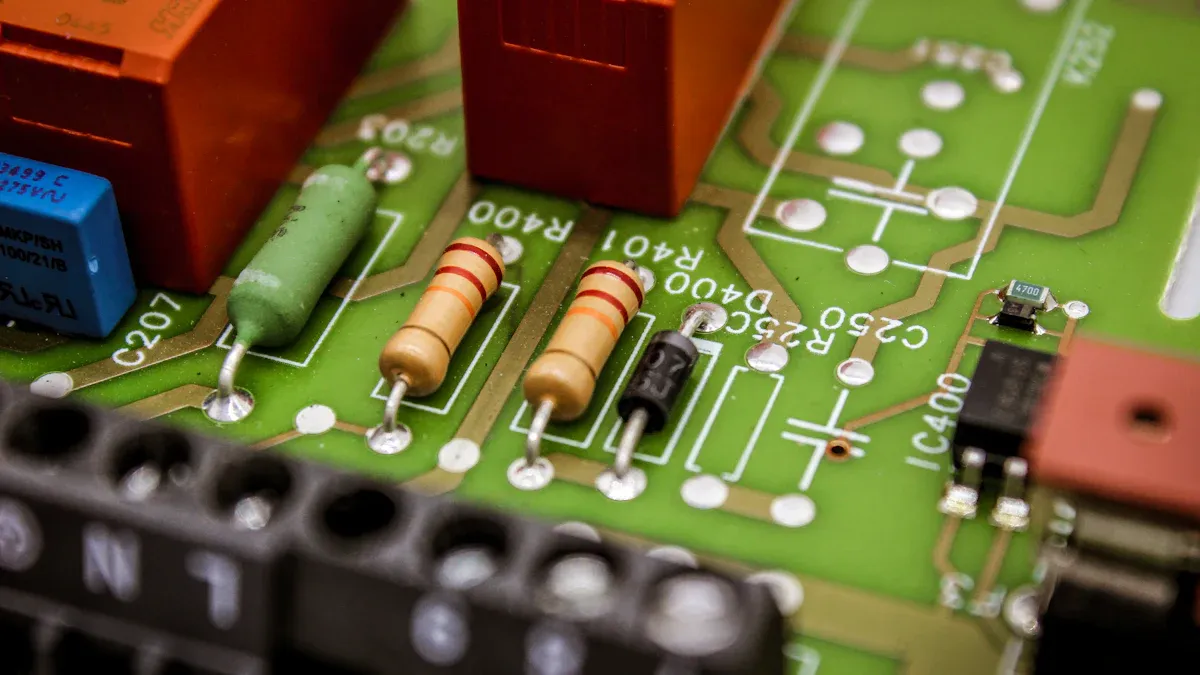

An optocoupler consists of two primary parts: a light-emitting element and a light-sensitive element. The light-emitting element, typically an LED, converts electrical signals into light. This light travels across a small gap to the light-sensitive element, such as a phototransistor or photodiode, which converts the light back into an electrical signal. Both components are enclosed in a light-tight package to prevent external light interference.

Here’s a breakdown of the key components and their roles:

Light emitter: The LED generates light based on the input electrical signal.

Light sensor: The phototransistor or photodiode detects the light and produces an output signal.

Optical isolation barrier: This barrier ensures that no direct electrical connection exists between the input and output, enhancing safety.

Some advanced optocouplers, like Optocoupler AC/DC CONTROLLERS IC, also include additional circuitry for precise control and improved performance.

How it achieves electrical isolation

Optocouplers achieve electrical isolation by using light as the medium for signal transfer. The LED emits light when an electrical signal is applied. This light crosses the isolation barrier and reaches the photodetector, which converts it back into an electrical signal. Since there is no direct electrical connection between the input and output, the circuits remain electrically isolated.

This design provides several benefits:

High isolation voltage: Optocouplers can withstand voltages up to 20 kV, making them ideal for high-voltage applications.

Noise immunity: The optical barrier blocks electrical noise, ensuring clean signal transmission.

Safety compliance: Many optocouplers meet strict safety standards, such as UL 1577 and VDE testing requirements.

For example, in industrial systems, optocouplers protect microprocessors from voltage spikes while maintaining reliable communication.

Common use cases for optocouplers

You’ll find optocouplers in a wide range of applications due to their versatility and reliability. Here are some common use cases:

Microprocessor input/output switching: Optocouplers enable safe communication between microprocessors and external devices.

Power control: They regulate DC and AC power in systems like motor drives and lighting controls.

Signal isolation: Optocouplers isolate sensitive circuits from high-voltage components, reducing the risk of damage.

Power supply regulation: They ensure stable voltage levels in power supplies.

PC communications: Optocouplers provide isolation in USB and serial communication interfaces.

In addition, industries like automotive, medical, and factory automation rely on optocouplers for their ability to handle high voltages and harsh environments. Devices like Optocoupler AC/DC CONTROLLERS IC are particularly useful in these scenarios, offering precise control and enhanced safety.

How Optocouplers Work in AC/DC Circuits

Functionality in AC circuits

Optocouplers play a critical role in AC circuits by providing isolation and ensuring safe signal transfer. When you use an optocoupler in an AC circuit, it acts as a bridge between the high-voltage AC side and the low-voltage control side. The LED inside the optocoupler lights up during the positive half-cycle of the AC signal. This light activates the phototransistor or photodiode, allowing the signal to pass through while maintaining electrical isolation.

In applications like AC motor drives or light dimmers, optocouplers help regulate power without exposing sensitive control systems to high voltages. For instance, in an AC light dimmer, the optocoupler works with a TRIAC to control the brightness of the light. This setup ensures that the control circuit remains safe from the high-voltage AC line.

By using optocouplers, you can achieve precise control over AC systems while protecting your equipment from voltage spikes and surges. Devices like Optocoupler AC/DC CONTROLLERS IC further enhance this functionality by offering integrated control features tailored for AC applications.

Functionality in DC circuits

In DC circuits, optocouplers provide reliable isolation and signal transfer, ensuring that high-voltage and low-voltage sections remain electrically separated. When a DC voltage is applied to the input side, the LED emits light, which activates the phototransistor. This process allows the output side to reflect the input signal without any direct electrical connection.

Here’s how optocouplers behave in DC circuits:

Without input voltage, the phototransistor remains off, and the output stays low.

When input voltage is present, the phototransistor conducts, saturating and causing the output to match the power supply voltage.

Proper resistor values for the input (RE) and output (RS) are essential. RE ensures the LED receives enough current (typically 5-10 mA), while RS stabilizes the output signal.

This functionality makes optocouplers ideal for DC applications like microcontroller interfacing, power supply feedback, and signal isolation in industrial systems. For example, in a compact SMPS (Switched-Mode Power Supply) circuit, an optocoupler like the PC817 provides isolated feedback to the control IC, ensuring stable operation.

Examples of optocoupler applications in AC/DC systems

Optocouplers find diverse applications in integrated AC/DC systems, offering both safety and efficiency. Here are some documented examples:

Application | Description |

|---|---|

Relay Modules | Uses PC817 optocoupler for isolating the relay side from control circuitry. |

AC Light Dimmer | Utilizes both transistor and TRIAC output optocouplers for dimming AC lights and regulating power. |

AC Lights Flashing Control | Employs both types of optocouplers for precise control of AC light flashing. |

Raspberry Pi Emergency Light | Uses a transistor output optocoupler to control LED brightness based on AC power status. |

Compact SMPS Circuit | PC817 provides isolated feedback to the SMPS IC, crucial for stability in compact designs. |

These examples highlight the versatility of optocouplers in handling both AC and DC systems. Whether you’re designing a relay module or a compact power supply, optocouplers ensure safe and efficient operation. Advanced devices like Optocoupler AC/DC CONTROLLERS IC further simplify these applications by integrating specialized features for precise control and protection.

Types of Optocouplers and Their Uses

Phototransistor Optocouplers

Phototransistor optocouplers are the most widely used type, making up about 55% of the optocoupler market. Their popularity comes from their excellent balance of speed, current handling, and affordability. These devices use a phototransistor as the light-sensitive element, which provides reliable signal transfer and electrical isolation. Switching speeds typically range from 2 to 10 microseconds, and they can handle output currents up to 50 mA. This makes them ideal for industrial automation, automotive electronics, and other control systems.

You’ll find phototransistor optocouplers in applications like isolated error amplifiers, DC sensing inputs, and AC sensing inputs. For example, in industrial control systems, they ensure safe communication between high-voltage machinery and low-voltage control circuits. Their versatility and cost-effectiveness make them a go-to choice for many engineers.

Category | Types of Phototransistor Optocouplers |

|---|---|

Phototransistor Optocouplers | Isolated Error Amplifier, Photo Darlington Output, DC Sensing Input, AC Sensing Input |

Photodiode Optocouplers

Photodiode optocouplers use a photodiode as the light-sensitive element. These devices excel in high-speed applications due to their fast response times. They are often used in communication systems, where rapid signal transfer is essential. Photodiode optocouplers also offer excellent noise immunity, making them suitable for environments with significant electrical interference.

In addition to speed, photodiode optocouplers provide precise signal transmission. This makes them a preferred choice for data communication, high-speed logic circuits, and optical encoders. If you’re working on a project that requires quick and accurate signal transfer, photodiode optocouplers are worth considering.

Triac Optocouplers

Triac optocouplers are designed for controlling AC power. They use a light-sensitive TRIAC (Triode for Alternating Current) as the output element. These optocouplers are perfect for applications like light dimmers, motor speed controllers, and solid-state relays. By isolating the control circuit from the high-voltage AC side, they ensure safety and reliability.

For example, in an AC light dimmer, a triac optocoupler works with a TRIAC to adjust the brightness of the light. This setup keeps the control system safe from high voltages while providing precise control over the AC load. If your project involves AC power control, triac optocouplers are an excellent choice.

High-speed optocouplers

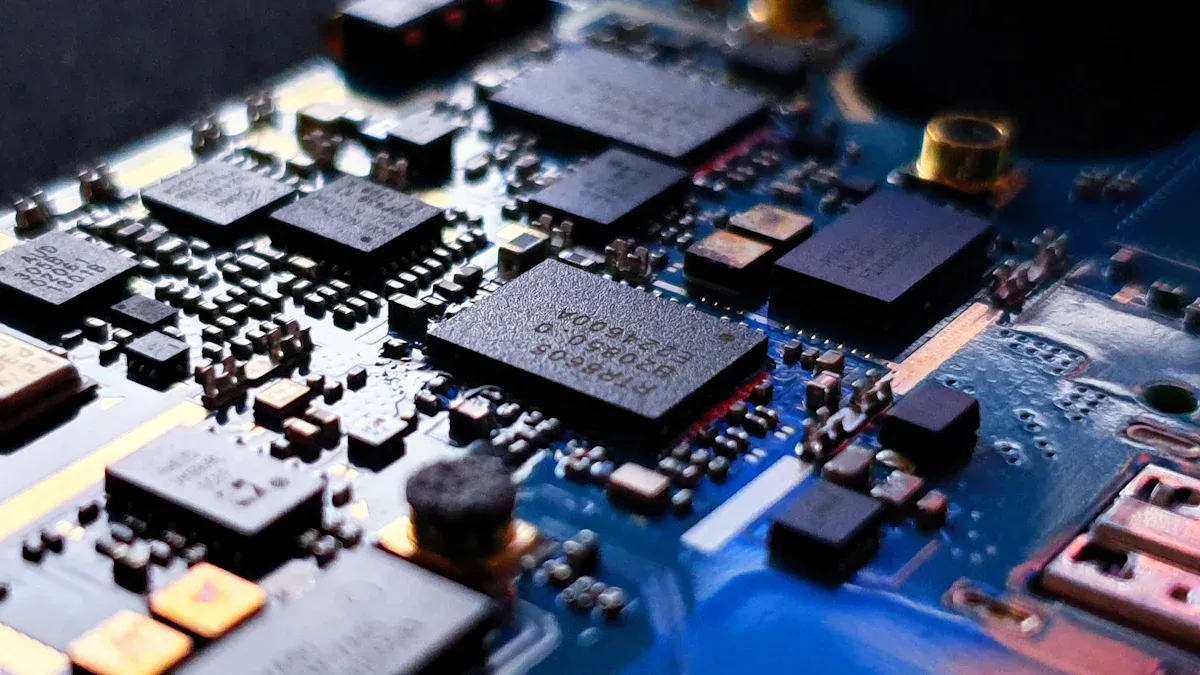

High-speed optocouplers are designed for applications requiring rapid signal transfer. These devices use advanced photodiodes or phototransistors to achieve switching speeds in the nanosecond range. You’ll find them in systems like high-speed communication networks, data transmission circuits, and optical encoders. Their ability to handle fast signals makes them essential for modern electronics.

When working with high-speed optocouplers, you’ll notice their precision in transferring signals without distortion. They excel in environments with high-frequency noise, ensuring clean and accurate data transmission. For example, in fiber-optic communication systems, high-speed optocouplers maintain signal integrity over long distances. Their compact design also makes them suitable for space-constrained projects.

To use high-speed optocouplers effectively, pay attention to their specifications. Look for parameters like propagation delay, rise and fall times, and bandwidth. These factors determine how well the optocoupler performs in your application. By choosing the right model, you can optimize your circuit for speed and reliability.

Optocoupler AC/DC CONTROLLERS IC and other specialized types

Optocoupler AC/DC CONTROLLERS IC represent a specialized category of optocouplers. These devices integrate additional circuitry to provide precise control and enhanced functionality in AC/DC systems. You’ll often see them in applications like power supplies, motor drives, and industrial automation. Their ability to combine isolation with control makes them a versatile choice for complex systems.

These controllers simplify circuit design by offering built-in features like voltage regulation, feedback control, and fault detection. For instance, in a switched-mode power supply (SMPS), an Optocoupler AC/DC CONTROLLERS IC ensures stable operation by providing isolated feedback to the control IC. This integration reduces the need for external components, saving space and improving efficiency.

Other specialized optocouplers include devices tailored for high-voltage applications, automotive systems, and medical equipment. Each type addresses specific challenges, such as handling extreme temperatures or meeting stringent safety standards. By exploring these options, you can find the perfect optocoupler for your project.

Applications of Optocouplers in AC/DC Circuits

Power supply isolation

Optocouplers play a critical role in isolating power supplies, ensuring safety and stability in your circuits. By separating the high-voltage side from the low-voltage control side, they protect sensitive components from voltage spikes and surges. For example, in AC-operated switching power supplies, optocouplers prevent ground loops by providing an isolated feedback path. This isolation enhances the reliability of your system, especially in remote load applications.

When comparing performance, optocouplers demonstrate excellent phase and gain margins. For instance, an optocoupler achieves a phase margin of 60.2 degrees and a gain margin of 18.7 dB. While opto-emulators offer higher bandwidth and faster transient response, optocouplers remain a reliable choice for most power supply designs. Their ability to reduce load-step response by over 50% without additional capacitors highlights their efficiency in maintaining stable operation.

Signal interfacing between high and low voltage systems

When working with systems that involve both high and low voltage levels, optocouplers ensure safe and effective signal interfacing. They isolate the high-voltage side from the low-voltage side, protecting your sensitive components from power surges. This isolation also prevents electrical noise from interfering with your signals, ensuring clean and accurate data transmission.

Optocouplers are widely used in interface cards to maintain signal integrity. For example, they enable smooth communication between slower RS232 or CANbus interfaces and high-speed RS485 systems. With propagation delays as low as 2 nanoseconds, optocouplers support asynchronous data communication at speeds of up to 50 MBd. This makes them ideal for applications requiring high-speed and noise-free signal transfer.

Noise reduction in sensitive circuits

In sensitive circuits, electrical noise can disrupt signal integrity and degrade performance. Optocouplers help mitigate this issue by isolating noisy components from the rest of the system. By using light to transfer signals, they block electrical noise and ensure reliable operation in environments with significant interference.

Research shows that optocouplers contribute to noise reduction by analyzing the noise performance of their LED and phototransistor components. Techniques like DC current-voltage and noise measurements assess their reliability and quality. These findings confirm that optocouplers are essential for maintaining signal clarity in analog-to-digital converters (ADCs) and other noise-sensitive applications.

For example, in mixed-signal systems, optocouplers isolate digital signals from analog front ends, improving ADC performance. Their ability to suppress electrical noise makes them a valuable addition to your circuit design, especially in industrial and medical applications.

Protection against voltage spikes and surges

Voltage spikes and surges can damage sensitive electronic components, especially in circuits that handle high voltages. Optocouplers provide an effective solution by isolating vulnerable parts of your system from these sudden electrical disturbances. Their ability to transfer signals using light ensures that high-voltage transients do not directly affect low-voltage control circuits.

Optocouplers excel in suppressing voltage spikes due to their high common-mode rejection capability. This feature allows them to maintain accurate signal transmission even in noisy environments. For example, optocouplers like the ACPL-782T are designed to sense battery voltage and protect microcontroller units (MCUs) from transients. These devices can handle rapid voltage swings of several hundred volts within tens of nanoseconds, demonstrating their robustness in high-stress conditions.

Here are some key benefits of using optocouplers for surge protection:

They isolate the control circuit from high-voltage spikes, preventing damage to sensitive components.

Their high common-mode rejection ensures reliable operation in noisy environments.

They can withstand sudden voltage changes, making them ideal for industrial and automotive applications.

In addition to their protective capabilities, optocouplers also enhance system reliability. By blocking voltage surges, they reduce the risk of component failure and extend the lifespan of your devices. This makes them a valuable addition to circuits that operate in environments prone to electrical noise or transient events.

When designing your circuit, consider optocouplers as a safeguard against voltage spikes. Their ability to combine isolation, noise immunity, and surge protection ensures that your system remains safe and functional under challenging conditions.

Advantages and Limitations of Optocouplers

Key advantages (e.g., electrical isolation, noise immunity)

Optocouplers offer several benefits that make them essential in circuit design. They provide electrical isolation by transmitting signals through light, ensuring safety when working with high voltage differentials. This feature protects sensitive components and prevents damage caused by voltage spikes or surges.

Another advantage is their immunity to electromagnetic interference (EMI). Optocouplers perform reliably in environments with high electrical noise, such as industrial settings. This makes them ideal for applications where clean signal transmission is critical.

You can also rely on optocouplers to prevent issues like ground loops and noise in electronic circuits. Their ability to maintain signal integrity across isolation barriers ensures stable and reliable operation. These qualities have made optocouplers a trusted solution for decades, even as newer technologies emerge.

Common limitations (e.g., speed, temperature sensitivity)

Despite their advantages, optocouplers have some limitations. Their speed is often slower compared to alternative isolation methods. The response time of phototransistors limits their ability to handle high-speed data transmission. This makes them less suitable for applications requiring rapid signal transfer.

Temperature sensitivity is another challenge. Optocouplers may experience performance degradation at extreme temperatures. Studies, such as those by Chen et al. (1995) and Liu et al. (2005), have shown that thermal resistance impacts their efficiency. For instance, self-heating effects can reduce their reliability in high-temperature environments.

Study | Focus | Findings |

|---|---|---|

Chen et al. (1995) | Thermal characteristics of VCSELs | Investigated thermal management in devices. |

Liu et al. (2005) | Self-heating effects of VCSELs | Analyzed thermal resistance and performance. |

Mutig et al. (2009) | Temperature-dependent analysis | Studied stability at high temperatures. |

Lee et al. (1995) | Thermal management of VCSEL modules | Examined thermal resistance in arrays. |

These limitations highlight the importance of considering environmental factors and application requirements when selecting optocouplers.

Comparison with alternative isolation methods

When comparing optocouplers to other isolation methods, such as digital isolators, you’ll notice some key differences. Digital isolators excel in certain areas, but optocouplers remain a strong choice for many applications.

Low-power consumption: Digital isolators are more efficient for battery-powered devices since they don’t require a light source.

High-speed data transmission: Digital isolators handle faster signals, making them better for high-speed communication.

Low electromagnetic interference (EMI): Digital isolators resist EMI more effectively due to their capacitive isolation technology.

Wide operating temperature range: Digital isolators perform well in extreme environments, including outdoor applications.

While digital isolators offer these advantages, optocouplers still dominate in scenarios where cost-effectiveness, simplicity, and proven reliability are priorities. For example, in power supply designs, optocouplers like the Optocoupler AC/DC CONTROLLERS IC provide robust isolation and feedback control, ensuring stable operation.

How to Select the Right Optocoupler

Key factors to consider (e.g., voltage rating, speed, type)

Choosing the right optocoupler starts with understanding the key factors that influence its performance. Voltage rating is one of the most critical aspects. Optocouplers like the PC817 offer isolation voltage ratings exceeding 5,000 Vrms, ensuring robust protection in high-voltage environments. You should also consider the current transfer ratio (CTR), which measures efficiency. CTR values typically range from 50% to 600%, providing flexibility for various applications.

For safety compliance, parameters like creepage and clearance are essential. Creepage refers to the shortest distance between two conductors over a material's surface, while clearance measures the distance through air. These factors ensure compliance with standards like EN 60950 and UL 1577. Additionally, switching speed plays a vital role in applications requiring rapid signal transfer. High-speed optocouplers excel in these scenarios, offering nanosecond-level response times.

Tip: Always check the datasheet for electrical characteristics, switching times, and safety ratings to match the optocoupler to your circuit's requirements.

Matching optocouplers to specific applications

Matching an optocoupler to your application involves analyzing its features and how they align with your circuit's needs. For example, photovoltaic-output optocouplers work well in low-noise amplifier designs. They can bias depletion-mode devices effectively, making them ideal for sensitive analog circuits. When selecting load resistors, measure the optocoupler's I-V characteristics to ensure optimal performance.

In industrial automation, specialized optocouplers handle extreme conditions like high temperatures and electrical noise. Automotive applications often require high-temperature optocouplers due to their reliability in harsh environments. For aerospace systems, optocouplers with nonlinear characteristics provide precise control and signal isolation.

Use high-speed optocouplers for communication systems requiring fast data transfer.

Choose triac optocouplers for AC power control in light dimmers or motor drives.

Opt for phototransistor optocouplers in general-purpose isolation tasks.

Tips for evaluating datasheets and specifications

Evaluating datasheets is crucial for selecting the right optocoupler. Start by reviewing the electrical characteristics table, which provides minimum, typical, and maximum values for parameters like forward current and isolation voltage. Check the switching characteristics table for signal transfer speeds and propagation delays. For safety, refer to the insulation ratings table to confirm compliance with agency approvals.

When analyzing CTR graphs, pay attention to saturated and non-saturated values. Adjust forward current based on the device type and consider temperature deviations using datasheet graphs. Degradation factors, such as temperature and forward current, can impact the optocoupler's lifetime. Understanding these details helps you make informed decisions.

Note: Look for datasheets that include detailed graphs and tables. These resources simplify the evaluation process and ensure you select an optocoupler that meets your application's requirements.

Optocouplers are essential components that provide electrical isolation and reliable signal transfer using light. They protect sensitive circuits from high voltages and noise, ensuring safety and efficiency in AC/DC systems. Whether you're designing power supplies, motor controllers, or communication interfaces, optocouplers offer a dependable solution for maintaining system integrity.

Tip: When working on your next project, consider optocouplers for their ability to enhance safety and reduce electrical interference. Their versatility makes them a valuable addition to any circuit design.

By understanding their operation and applications, you can confidently integrate optocouplers into your designs for better performance and protection.

FAQ

What is the main purpose of an optocoupler?

An optocoupler isolates two circuits electrically while transferring signals using light. It protects sensitive components from high voltages and noise, ensuring safe and reliable operation in electronic systems.

Can optocouplers work with both AC and DC circuits?

Yes, optocouplers work in AC and DC circuits. They isolate high-voltage AC systems and provide stable signal transfer in DC circuits. Their versatility makes them suitable for various applications.

How do you choose the right optocoupler for your project?

Focus on key factors like voltage rating, speed, and type. Check the datasheet for specifications such as isolation voltage and current transfer ratio. Match the optocoupler to your circuit’s requirements.

Are optocouplers affected by temperature?

Optocouplers can experience reduced performance at extreme temperatures. High temperatures may impact their efficiency and reliability. Always check the temperature range in the datasheet before using them.

What are common applications of optocouplers?

You’ll find optocouplers in power supplies, motor controllers, communication interfaces, and industrial automation. They ensure electrical isolation, noise reduction, and protection against voltage spikes in these systems.

See Also

Exploring Optocoupler IC Chips: Functionality and Operation

AC to DC Switching Converters: How They Operate

Photodiode Sensor ICs: Their Functions and Applications

High Density Optically Coupled Isolators: Purpose and Applications