Latest Trends in IGBT Technology for Electric Vehicles

You’ve probably seen how electric cars are changing travel. A big reason for this change is the advancement in New Energy Vehicle IGBT technology. These parts now work more efficiently, stay cooler, and handle more power. For example:

New tech like SiC MOSFETs helps heat flow and speeds up switching. This can make EVs go farther by about 7%.

Better cooling systems have improved how parts are made and shipped. This keeps EVs working well all the time.

These improvements make New Energy Vehicle IGBT crucial for running motors, saving energy, and charging EVs quickly in new EV systems.

Key Takeaways

IGBT technology is important for EVs. It saves energy and works better.

New IGBT systems stay cooler and handle more power. This makes EVs last longer.

Silicon Carbide (SiC) works with IGBT. It switches faster and saves more energy.

Picking IGBT or SiC depends on cost and how well it must work. IGBT is cheaper for big jobs.

The IGBT market is growing fast because more people want EVs and better batteries.

Overview of IGBT Technology in Electric Vehicles

Definition and Functionality of IGBT

Electric cars are efficient because of a part called IGBT. IGBT stands for insulated gate bipolar transistor. It mixes fast switching from MOSFETs with power control from bipolar transistors. This device connects the battery to the motor and controls electricity flow. It helps the motor work well and saves energy by reducing waste.

IGBTs can handle high voltages and currents, which is great for EVs. They turn electrical signals on and off quickly. This lets the motor change speed and power based on driving needs. Smooth acceleration, braking, and energy saving depend on this feature.

Importance of IGBT in Electric Vehicle Technology

Jay Baliga invented the IGBT, changing power electronics forever. In EVs, it manages strong electrical flows. Without it, EVs wouldn’t be as efficient or perform as well.

IGBTs give exact control over electrical power, helping motors run better. This control boosts energy efficiency and makes batteries last longer. By cutting energy waste and heat, IGBTs keep EVs working well in different situations.

Applications in New Energy Vehicle Systems

IGBTs do many jobs in electric cars. They are key to EV technology. Here’s how they help:

Application Area | Description |

|---|---|

Motor Drive | IGBT improves power and energy use by controlling motors. |

Battery Management System | IGBT manages battery charging and safety, making batteries last longer. |

Auxiliary Systems | IGBT runs systems like cooling and braking to save energy. |

Brake System | IGBT turns braking energy into electricity, helping the car go farther. |

These uses show how IGBTs make EVs work better and more reliably. From powering motors to managing batteries, IGBTs help EVs perform at their best.

Latest Advancements in IGBT Technology

Improved Efficiency and Reduced Power Losses

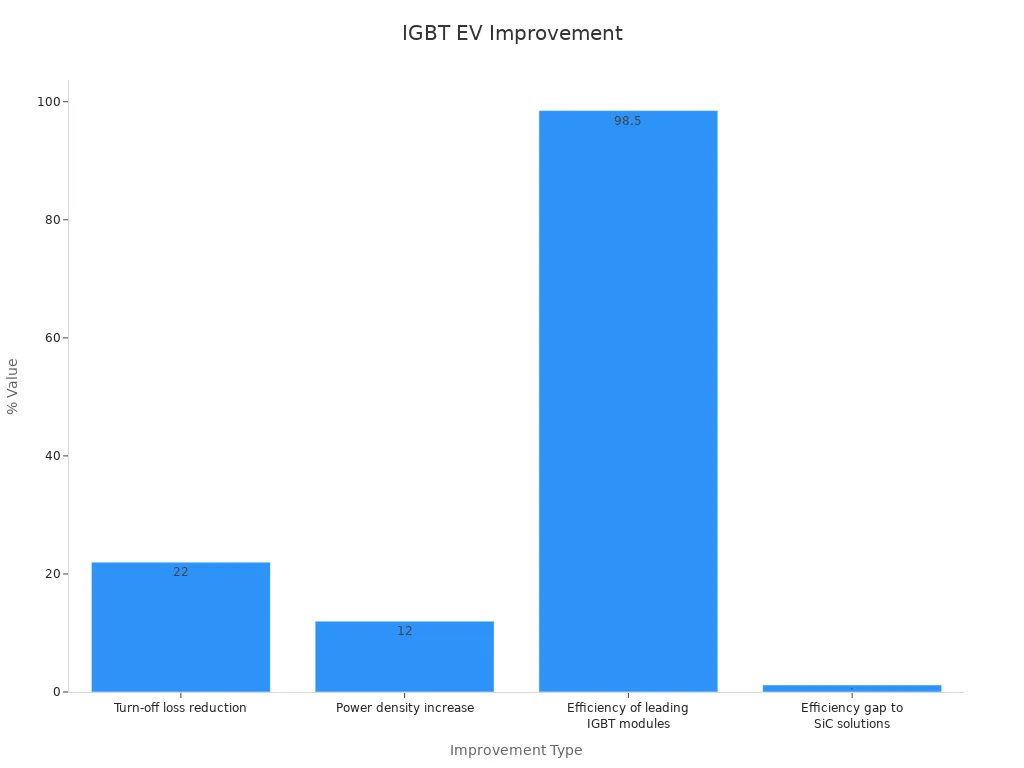

New IGBT technology is now more efficient and wastes less power. Why is this important? Less wasted energy means better battery life and longer driving range.

Today’s IGBT modules are 98.5% efficient at 20kHz switching speeds. They are only 1.2% less efficient than top Silicon Carbide (SiC) options. Turn-off losses have also dropped by 22% in city driving. These changes help electric cars run smoothly, even in tough conditions.

Improvement Type | Value |

|---|---|

Turn-off loss reduction | 22% in city driving |

Power density increase | 12% higher without extra silicon |

Efficiency of top IGBT modules | 98.5% at 20kHz |

Efficiency gap to SiC solutions | 1.2% less than premium SiC |

Junction temperature tolerance | 175°C for high-power use |

These upgrades make IGBT technology more reliable and efficient for electric cars.

Enhanced Thermal Management Solutions

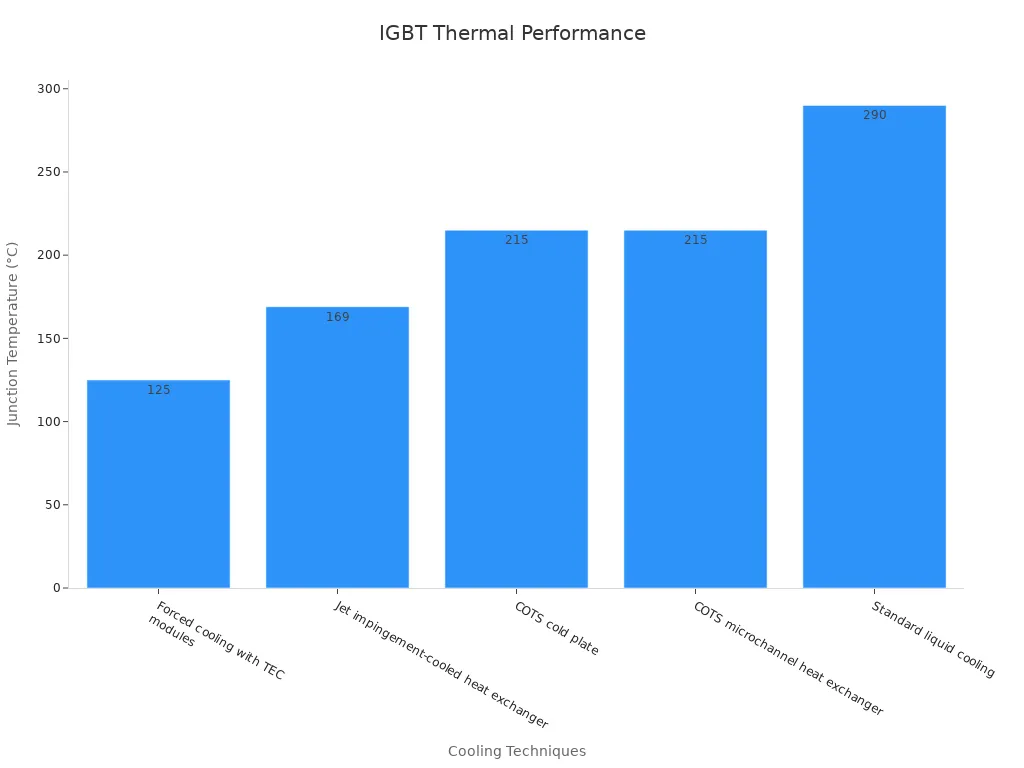

Better heat control is another big improvement in IGBT technology. Managing heat is key to keeping IGBT parts working well for a long time. Without good cooling, high heat can damage parts and shorten their life.

New cooling methods have lowered heat levels in IGBT systems. For instance, jet impingement-cooled heat exchangers bring temperatures down to 169°C at 151W. Thermoelectric cooling (TEC) systems do even better, reducing temperatures to 125°C.

Cooling Method | Temperature (°C) | Heat Load (W) |

|---|---|---|

Standard liquid cooling | 290 | 151 |

COTS cold plate | 215 | 151 |

COTS microchannel heat exchanger | 215 | 151 |

Jet impingement-cooled heat exchanger | 169 | 151 |

Forced cooling with TEC modules | 125 | N/A |

Better thermal interface materials (TIMs), like those with carbon nanotubes, also help with cooling. These improvements keep IGBT parts working well, even under heavy use, making EVs more reliable.

Increased Power Density and Miniaturization

IGBT technology is now smaller and more powerful. Compact modules make electric cars lighter and more efficient. This is important because space and weight matter in EV design.

New materials like Silicon Carbide (SiC) and Gallium Nitride (GaN) help IGBT modules handle more power. These materials also make the modules stronger for tough driving conditions. Trench-gate IGBT technology has boosted power density by 30% in high-voltage uses.

Benefit | Description |

|---|---|

Improved Performance | |

Reduced Energy Losses | Compact modules waste less energy. |

Compact System Design | Smaller systems save space and improve EV design. |

These advancements make IGBT technology better at handling heat, saving energy, and being reliable. Automakers can now build EVs that are stronger, more efficient, and smaller to meet modern demands.

Comparing IGBT and Emerging Technologies

Advantages of IGBT in EV Systems

IGBT technology has many benefits for electric vehicles. The newest EDT3 IGBT chips waste less energy and work more efficiently. This helps save power and lets cars drive farther. These chips work well under both heavy and light loads, keeping performance steady.

Metric | Improvement |

|---|---|

Off-state Voltage | |

Turn-off Time | Reduced from 0.5μs to 0.12μs |

Chip Thickness | Reduced from 5μm to 0.3μm |

Current Capability | Improved |

Operating Junction Temp. | Higher |

IGBT modules lose 20% less energy under heavy use. This makes them great for tough EV tasks. They also stay efficient during light use, like city driving. These modules can handle higher temperatures, making them more reliable in extreme heat.

Tip: IGBT systems are perfect for high-power uses like traction inverters. They are strong and efficient.

Benefits of Silicon Carbide (SiC) Technology

Silicon carbide (SiC) is changing how electric cars work. SiC chips convert power faster and waste less heat than regular silicon chips. This saves energy and improves EV performance.

SiC chips handle heat better, so cooling systems can be smaller.

Faster switching means batteries charge quicker, which is handy for drivers.

SiC chips waste less energy, making them eco-friendly.

Smaller SiC parts make EV systems lighter and more efficient.

SiC chips carry five times more current than silicon chips.

They switch ten times faster, allowing smaller components.

They handle higher voltages, making traction inverters more compact.

SiC chips work well at high temperatures and voltages. They are smaller and lighter, which is great for modern EV designs.

Choosing Between IGBT and SiC for EV Applications

Choosing between IGBT and SiC depends on cost, efficiency, and needs. IGBT systems cost less, so they’re good for heavy-use tasks where price matters. SiC chips are more efficient, especially for lighter tasks, and they switch faster.

Metric | IGBT | SiC MOSFET |

|---|---|---|

Cost | Lower | Up to 3X higher |

Efficiency | Better for heavy loads | Better for light loads |

Switching Speed | Slower | Faster |

On-Resistance | Higher | Lower |

Short Circuit Handling | Stronger | Weaker |

IGBT systems are 98.2% efficient when paired with SiC diodes. SiC MOSFETs with SiC diodes reach about 99% efficiency at full load. SiC converters stay over 90% efficient at high speeds, making them great for lightweight designs.

Note: SiC chips work better but cost more. For budget-friendly EVs, IGBT is a good choice for balancing cost and performance.

Real-World Uses of IGBT in EV Systems

Inverters for Electric Motors

Inverters change battery power into motor power in electric cars. IGBT helps this process work smoothly and reliably. It allows better acceleration, energy use, and motor control.

IGBT inverters are great for controlling electric motors. They handle high power levels easily. Tests show how well they work:

Motor control improves energy use with vector control.

Both types of motors run efficiently with IGBT inverters.

These systems save energy and keep cars running well.

IGBT is key to modern EV inverters. It helps manage energy and improves motor performance.

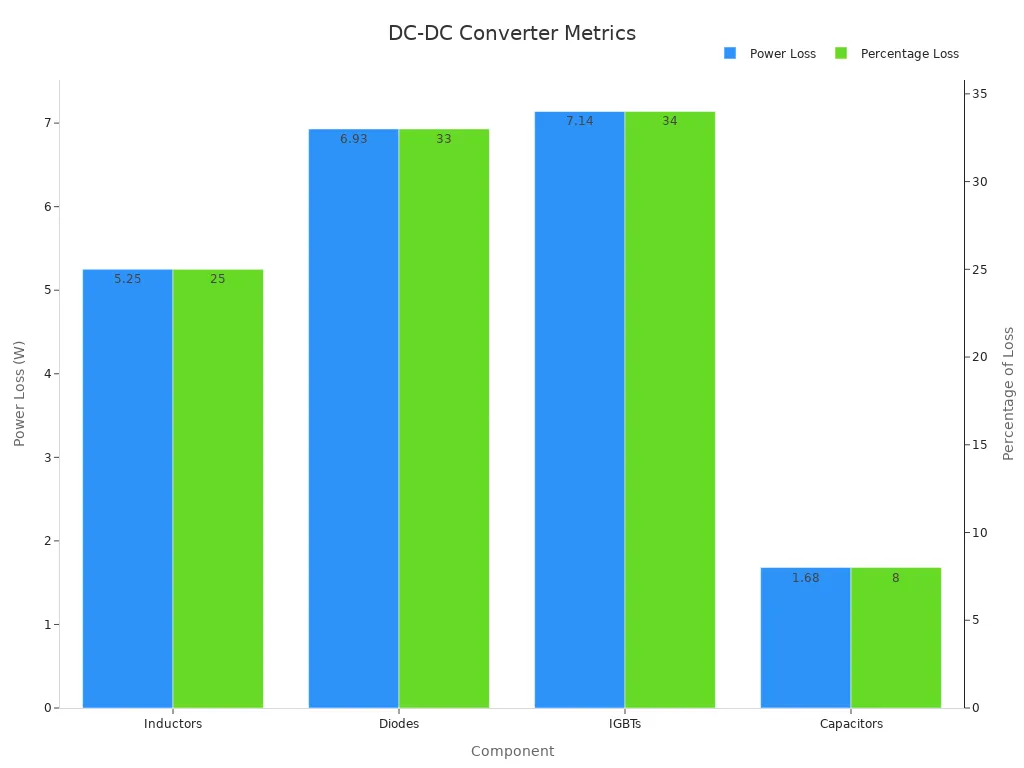

DC-DC Converters for Power Control

DC-DC converters lower battery power for smaller car systems. These systems include lights and screens. IGBT makes these converters work better with less wasted energy.

Here’s how power loss breaks down in DC-DC converters:

Part | Power Loss (W) | Percent of Total Loss |

|---|---|---|

Inductors | 5.25 | 25% |

Diodes | 6.93 | 33% |

IGBTs | 7.14 | 34% |

Capacitors | 1.68 | 8% |

IGBT converters waste less energy. This means more power goes to important systems. It also helps batteries last longer and cars perform better.

Role in Fast-Charging Stations

Fast charging is important for making electric cars popular. IGBT helps charging stations handle high power loads efficiently. While SiC chips are more efficient, IGBT costs less and works well.

Here’s how IGBT helps fast charging:

A 500 kW inverter saves 25 kW, enough to power homes.

A 1 MW system gains 5% efficiency, saving 50 kW.

These savings improve charging speed and energy use.

IGBT makes charging stations faster and reduces wasted energy. This makes electric cars easier to use and better for the environment.

Market Trends and Challenges in IGBT Technology

Growth in the IGBT Market for New Energy Vehicles

The IGBT market for electric cars is growing fast. This growth comes from more people wanting electric cars and better batteries. From 2024 to 2031, the market will grow from $440.99 million to $641.50 million. It will grow by 5.50% each year. Governments are helping by making rules to cut pollution and support green energy.

This growth helps the electric car industry a lot. Better IGBT parts make cars use power more efficiently and work more reliably. This means electric cars can meet what buyers want and help the planet.

Contributions from Leading Manufacturers

Top companies are improving IGBT technology. Big names like Toyota, Mitsubishi, and Bosch lead the way. In North America, companies like Vishay and ON Semiconductor are investing in better parts for electric cars.

Asia Pacific is the biggest player in the IGBT market. Countries like China, South Korea, and India have many semiconductor factories. China’s love for electric cars has increased the need for IGBT parts. This shows how important strong factories and supply chains are for meeting global demands.

Addressing Supply Chain and Cost Challenges

Making IGBT parts has some problems. COVID-19 slowed down getting materials and parts. In China, fewer workers and slow recovery made things harder. Many companies depend on imported parts, which can cause issues.

To fix this, companies are making parts locally and using more suppliers. This lowers costs and makes production more reliable. These changes solve current problems and make IGBT technology stronger for the future.

IGBT 7 devices have greatly improved electric car systems. They make cars use energy better and last longer. These devices also help motors work more smoothly and waste less power. IGBT is very important for running electric cars efficiently.

Silicon carbide (SiC) works well with IGBT. It switches faster and saves more energy in smaller car systems. Together, they make charging and driving electric cars easier. By 2030, over 30 million electric cars are expected to be sold. This means more need for small and powerful IGBT parts. This growth matches the move toward renewable energy, which could make up 80% of global power by 2030.

The future of IGBT looks bright. Companies are making smaller and cooler parts for electric cars. These improvements will help create better car systems and support clean energy goals. Electric cars will become more reliable and eco-friendly.

FAQ

What do semiconductors do in electric cars?

Semiconductors control how electricity moves in EV systems. They help power inverters, converters, and chargers work properly. Without them, motors and batteries wouldn’t run well.

How does IGBT make EV charging better?

IGBT reduces wasted energy and handles high power easily. It speeds up charging and makes it more efficient for long trips.

Why is cooling important for IGBT systems?

Cooling stops IGBT systems from getting too hot. It keeps them reliable and helps them last longer. Better cooling improves EV performance during heavy use.

How are IGBTs different from Silicon Carbide (SiC) chips?

IGBTs cost less and are good for tough tasks. SiC chips save more energy and switch faster, making them great for lighter systems. The choice depends on cost and EV needs.

Can IGBT help fast-charging stations?

Yes, IGBT is important for fast chargers. It handles high power well, saves energy, and speeds up charging for EVs.

See Also

New Developments in Automotive Chip Technology You Should Know

Key Developments Influencing Analog IC Market Trends for 2025

Breakthrough Technologies in Medical Imaging Chips for 2025

Exploring Low Power IoT Chips and Their Practical Uses

Essential MOSFET Concepts Every Electronics Hobbyist Should Know