What is an Interface Control Chip and How Does It Work

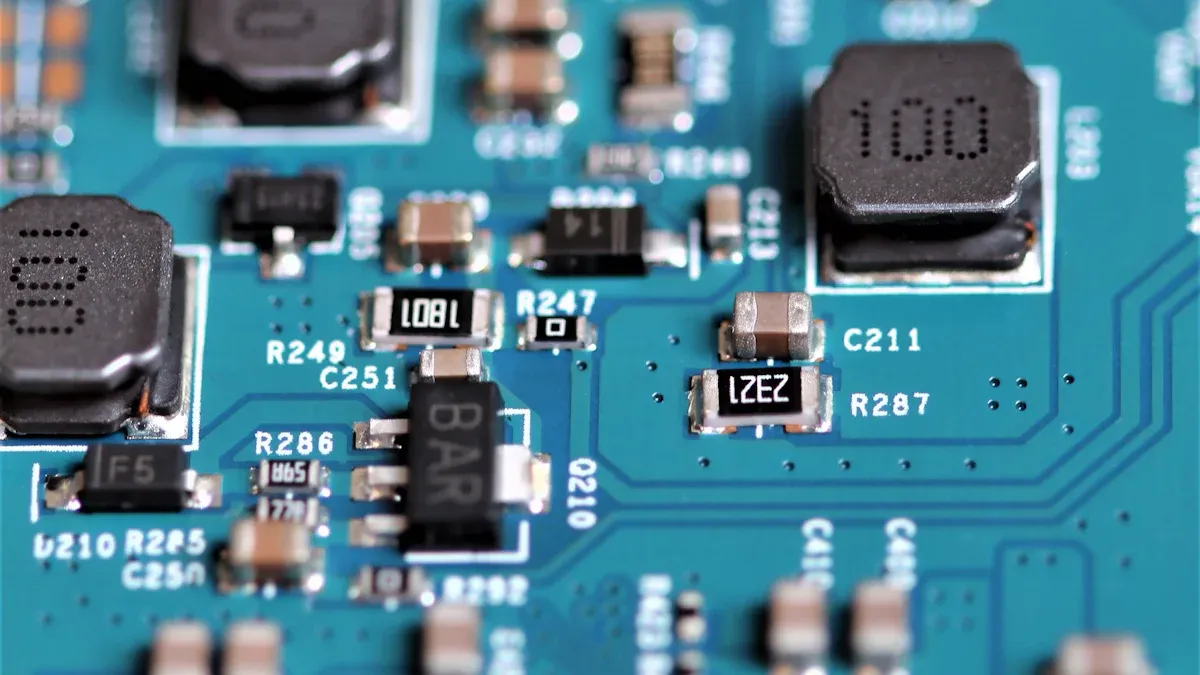

An Interface Control Chip acts as a bridge between different electronic components. This chip manages the flow of information, ensuring that each part can communicate clearly and efficiently. Devices rely on this chip to translate signals and maintain compatibility. Engineers use it to prevent errors and keep systems running smoothly.

The Interface Control Chip plays a key role in making sure devices work together without problems.

Key Takeaways

Interface Control Chips help different parts of electronic devices communicate clearly and efficiently.

They reduce wiring complexity, manage data flow, and prevent errors to keep systems running smoothly.

These chips assign unique addresses and translate signals so devices work together without confusion.

Engineers use them to update device settings easily and support many types of devices for better compatibility.

Interface Control Chips improve device speed, reliability, and power efficiency in consumer, industrial, and embedded systems.

Interface Control Chip Functions

Communication Management

An Interface Control Chip helps different parts of a device talk to each other. It manages the signals that move between subsystems. This chip can reduce the number of wires needed. For example, some interfaces used to need over 70 pins, but new designs only need 16 pins for full duplex operation. This makes devices smaller and easier to build.

The chip also supports long reach distances. Many systems work well up to 20 inches (50 cm), and some can even reach 40 inches (100 cm). Timing is important, too. In Ethernet communication, the chip keeps a 9.6 microsecond gap between data frames. This helps prevent data from getting mixed up.

The Interface Control Chip uses special coding, like 8b/10b block coding, and checks for errors with CRC. These features keep data safe and accurate.

Flow control is another key job. The chip uses buffers to match the speed of different parts. For example, SPI4.2 uses FIFO buffer status to stop overloads or empty buffers. This keeps data moving smoothly and prevents problems.

Reduces pin count for simpler connections

Supports long reach distances between components

Maintains proper timing for data flow

Uses coding and error checks for data safety

Controls data speed with buffers

Address Mapping

The Interface Control Chip assigns addresses to each part of a system. This process is called address mapping. Each device or component gets a unique address. The chip uses these addresses to send data to the right place.

Address mapping helps the system stay organized. It prevents data from going to the wrong part. When a device needs to talk to another, the chip checks the address and sends the message correctly. This makes sure every part works together without confusion.

Assigns unique addresses to devices

Directs data to the correct destination

Keeps the system organized and efficient

Configuration Control

Configuration control lets users or engineers set up how devices work together. The Interface Control Chip stores settings for each component. These settings can include speed, power, and special features.

The chip allows changes without needing to rebuild the hardware. Engineers can update settings through software. This makes it easy to add new features or fix problems. Configuration control also helps the chip support many types of devices, making it flexible.

Configuration control ensures that devices stay compatible and can adapt to new needs.

Stores and manages device settings

Allows updates through software

Supports many types of devices for better compatibility

How It Works

Data Flow Control

An Interface Control Chip manages how data moves between different parts of a device. It uses flow control methods to keep information moving smoothly and prevent overloads. One common method is credit-based flow control. In this system, the chip tracks credits, which show how much buffer space is available. When a device sends data, it uses up credits. When the receiving side processes the data, it returns credits. This balance helps the chip avoid congestion and keeps data flowing at the right speed.

Flow control ensures that each part of the system gets data when it is ready, reducing the chance of dropped or lost information.

The chip also uses performance metrics to measure how well it controls data flow. These metrics include end-to-end quality of service (QoS), congestion avoidance, and per-flit processing. The table below shows some important metrics:

Performance Metric | Description |

|---|---|

End-to-End QoS | Measures the quality of service at the application level, showing data flow efficiency. |

Congestion Avoidance Efficiency | Shows how well the chip prevents congestion inside the system. |

Per-Flit Processing Granularity | Tells how the chip handles small units of data for better control. |

Output Flit Scheduling | Explains how the chip schedules data to keep flow steady. |

Per-Class Service | Lets the chip give different service levels to different types of data. |

Statistical counters help engineers check how well the chip manages data. For example, Cisco systems track the number of flow control frames sent and received, dropped data frames, and events like shutdowns or auto restores. In some cases, systems report millions of transmitted flow control frames and very few dropped packets, showing strong data management.

Protocols like SPI (Serial Peripheral Interface) rely on the Interface Control Chip for fast and reliable data transfer. SPI can run at clock speeds from 100 kHz up to 66 MHz. Dual and Quad SPI types can double or quadruple the data rate compared to single SPI, making the system faster and more efficient.

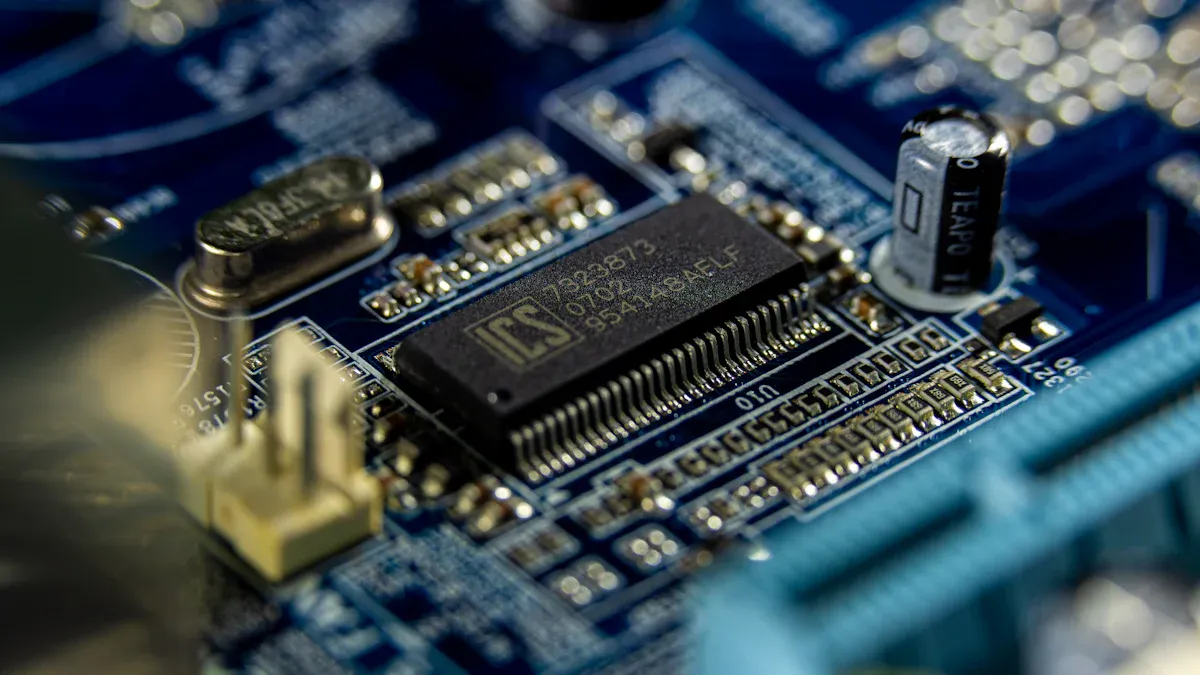

Signal Translation

The Interface Control Chip translates signals between different parts of a device. Each component may use its own way to send and receive data. The chip changes these signals so that every part can understand each other. For example, it can convert parallel signals to serial signals or change voltage levels to match what each device needs.

This translation is important in hardware-software interfaces. When a processor talks to memory or sensors, the chip makes sure the signals match. In SPI communication, the chip handles different bit widths and clock modes. Some systems use 8-bit or 40-bit commands, which allow for precise control and timing. The chip can also support single, dual, or quad data lines, increasing the amount of data sent at once.

Signal translation by the Interface Control Chip helps devices with different designs work together without errors.

Error Handling

Error handling is a key job for the Interface Control Chip. It checks data as it moves through the system and looks for mistakes. The chip uses methods like CRC (Cyclic Redundancy Check) to find errors in data frames. If it finds a problem, it can ask for the data to be sent again or alert the system.

The chip also keeps track of errors using counters. For example, it records the number of dropped packets, watchdog events, and shutdowns. In many systems, these numbers stay low, showing that the chip handles errors well. Some chips use statistical process control to watch for problems in real time and send alerts if something goes wrong.

In advanced systems, the chip can even fix some errors automatically. This keeps the device running smoothly and protects important information. By managing errors, the Interface Control Chip helps maintain high reliability and performance.

Applications

Embedded Systems

Engineers use interface control chips in embedded systems to connect sensors, processors, and actuators. These chips help devices respond quickly and work with high accuracy. Real-time responsiveness and deterministic behavior allow robots and control systems to perform tasks safely and efficiently. Power efficiency and fault tolerance make these chips ideal for devices that run all day without stopping. Many factories and smart machines rely on these chips for precise control and reliable operation.

Embedded systems benefit from interface control chips by gaining improved safety, efficiency, and accuracy in every task.

Consumer Devices

Interface control chips play a major role in smartphones, tablets, wearables, and smart home devices. Modern microprocessors combine many functions—such as data logging, communication, and control—into a single chip. This integration reduces the number of parts, lowers system costs, and saves power. Devices become smaller, lighter, and more reliable. USB interface chips also support fast data transfer and power delivery, meeting the needs of today’s compact and multifunctional gadgets. Low-power microcontrollers, like TI’s MSP430 and Atmel’s SAM L series, help wearables and smart devices run longer on a single charge.

Consumer electronics depend on interface control chips for:

Miniaturization and energy efficiency

Multifunctionality and easy integration

Reliable performance in daily use

Industrial Use

Factories and industrial plants use interface control chips to manage robots, control systems, and IoT-enabled machines. These chips support high-speed data transfer and robust communication, which are vital for smart factories and automated production lines. Infineon's ISOFACE™ interface ICs, for example, offer five times better reliability and cut product launch times in half. They include features like galvanic isolation and protection against short circuits and overheating, which keep systems stable and safe. Thermal interface materials in these chips withstand thousands of test cycles without damage, proving their durability.

Industrial automation relies on interface control chips for stable, long-lasting, and efficient operation in demanding environments.

Key industries using interface control chips:

Consumer electronics

Automotive

Telecommunications

Industrial automation

Healthcare

Benefits

Performance

Interface control chips boost the speed and efficiency of electronic systems. These chips manage data flow, reduce bottlenecks, and help devices process information quickly. By using advanced flow control and signal translation, they keep communication smooth between different parts. Many chips support high-speed protocols, which allow fast data transfer in both consumer and industrial devices.

Devices with interface control chips often show improved response times and smoother operation.

Engineers can measure performance using metrics like end-to-end quality of service and output scheduling. These metrics help ensure that each part of the system gets the right amount of data at the right time. As a result, users experience fewer delays and better overall device performance.

Reliability

Reliability stands as a key benefit of interface control chips. Manufacturers test these chips under tough conditions, such as high voltage, rapid switching, and extreme temperatures. For example, test systems can measure chip performance at up to 1 kV and 25 A, with switching frequencies reaching 1 MHz. These tests check for issues like ON-state resistance and leakage currents.

Mean Time Between Failures (MTBF) often reaches thousands of hours for industrial-grade chips.

Intermittent Operating Life (IOL) tests cycle devices on and off up to 5,000 times at high temperatures.

High-Temperature Operating Life (HTOL) tests run chips near their maximum limits for 1,000 hours.

Temperature Cycling Tests (TCT) expose chips to extreme hot and cold to check mechanical strength.

MTBF gives a good estimate of how long a chip will work without failing, but real-world conditions can affect this number.

Advanced test equipment and software track these results, helping engineers predict how long a chip will last in the field. This focus on reliability means devices can run longer and need fewer repairs.

Compatibility

Compatibility ensures that interface control chips work with many types of devices and systems. These chips follow strict standards for design, data protocols, and power requirements. Standards cover everything from communication methods to physical connections and software interfaces.

Common standards and protocols make it easier for different brands and models to work together.

Compliance testing checks that chips meet all requirements for interoperability.

Compatibility benchmarks include support for file formats, drivers, and security features.

Adhering to open standards allows engineers to mix and match components without worrying about errors or failures.

Tools like Ping and Wireshark help test communication between devices, making sure data moves correctly and securely. This high level of compatibility supports innovation and flexibility in modern electronics.

The Interface Control Chip connects electronic parts and manages how they share information. This chip improves accuracy, lowers power use, and helps devices work faster. New materials and designs let these chips work in tough places and make devices smaller. Many factors, such as integration and packaging, shape how well the chip performs. As a result, modern electronics depend on these chips for strong performance and easy compatibility.

FAQ

What is the main job of an interface control chip?

An interface control chip helps different parts of a device talk to each other. It manages signals, checks for errors, and keeps data moving smoothly. This chip makes sure all parts work together without problems.

Can an interface control chip work with any device?

Most interface control chips follow common standards. They can connect with many types of devices, such as sensors, processors, and memory. Some chips work best with certain brands or systems, so engineers check compatibility before use.

How does an interface control chip handle errors?

The chip uses error-checking methods like CRC. It finds mistakes in data and can ask for the data to be sent again. This keeps information safe and helps devices run without trouble.

Why do engineers use interface control chips in smart devices?

Engineers use these chips to make devices smaller, faster, and more reliable. The chip reduces the number of parts needed. It also helps devices save power and work for longer periods.

See Also

Understanding Current Controller Chips And Their Operational Role

Exploring Industrial Control Chips And Their Automation Functions

A Comprehensive Guide To Communication Chips And Their Functions

How MCU Microcontroller Chips Operate And Their Key Features

The Role And Functionality Of Optocoupler IC Chips Explained