What is an Integrated Battery Monitor IC and How Does It Work

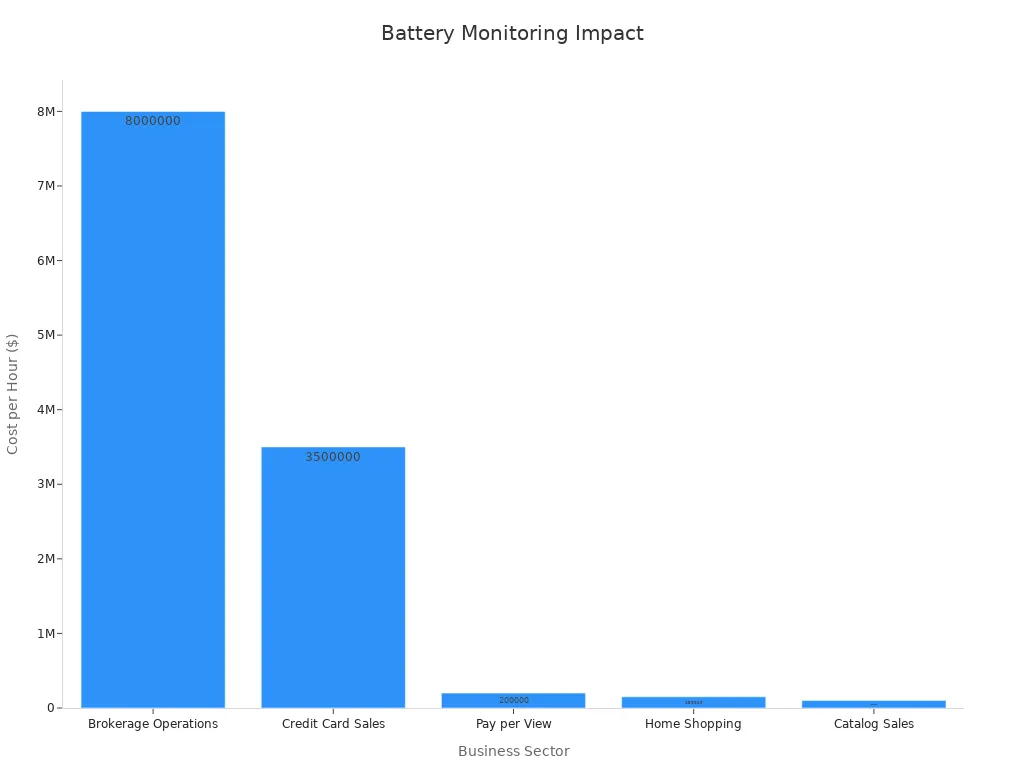

An Integrated Battery Monitor IC is a specialized chip that tracks important battery details like voltage, current, temperature, and charge level. This technology helps prevent overcharging, deep discharging, and overheating, which can cause permanent damage. Real-time monitoring keeps batteries safe and reliable, especially when battery capacity drops below 70-80% of its rated output. Many industries depend on reliable batteries, since even one hour of unplanned downtime can cost millions of dollars.

People rely on Integrated Battery Monitor ICs to make sure their devices work efficiently and safely every day.

Key Takeaways

Integrated Battery Monitor ICs track battery voltage, current, temperature, and charge to keep batteries safe and reliable.

These chips measure battery data in real time with high accuracy, helping prevent damage from overcharging, overheating, or deep discharging.

Cell balancing ensures all battery cells charge evenly, which extends battery life and improves performance.

Strong communication features let these ICs share battery health data with other systems for quick responses to problems.

Integrated Battery Monitor ICs are vital in many fields like smartphones, electric vehicles, and medical devices to improve safety and efficiency.

Integrated Battery Monitor IC Basics

What It Is

An Integrated Battery Monitor IC is a mixed-signal chip that helps manage and monitor important battery parameters. These chips combine analog and digital technology to measure voltage, current, temperature, and the state of charge in real time. Engineers design these ICs to work with many types of batteries, from small cells in smartphones to large packs in electric vehicles.

Key technical characteristics of an Integrated Battery Monitor IC include:

High measurement accuracy for voltage, current, and temperature

Extremely low power consumption

Ability to monitor multiple battery cells at the same time

Built-in cell balancing functions

Real-time monitoring for safety and performance

Enhanced integration to reduce system complexity

Support for accurate state-of-charge and state-of-health estimation

Predictive maintenance features

Efficient operation in high-voltage, large battery packs

Multi-functional integration to improve scalability and reduce wiring

These features make the Integrated Battery Monitor IC a vital part of modern battery management systems.

How It Works

The Integrated Battery Monitor IC uses both analog and digital parts to keep track of battery health. The analog section senses signals from the battery, such as voltage and current. It uses components like analog-to-digital converters (ADCs) and digital-to-analog converters (DACs) to turn these signals into digital data. The digital section processes this data to monitor battery status and send information to other devices.

Continuous monitoring of voltage, current, and temperature is essential. Scientific studies show that this helps detect early signs of problems like lithium plating and dendrite formation in lithium-ion batteries. These issues can cause batteries to lose capacity or even catch fire. Advanced sensing in these ICs helps balance safety, aging, and fast charging.

The process of real-time monitoring involves sensors that collect data every few microseconds. For example, some battery monitor ICs sample battery pack current every 8 microseconds. This fast data collection helps detect sudden changes, such as overcurrent or overheating, before they become dangerous. The IC can react quickly to faults, sometimes even without help from the main controller.

Aspect | Description |

|---|---|

Process | Real-time data acquisition using sensors and controllers for synchronized smart battery management. |

Benefits | More accurate battery parameter estimation, improved safety, and longer battery life. |

Implementation | Integration of charge regulators, smart monitors, and wireless communication. |

Outcome | Enhanced battery management, predictive maintenance, and reliable operation. |

The IC also uses special designs to keep analog and digital signals separate. This helps reduce noise and keeps measurements accurate. Features like floating outputs prevent ground loops, and fast current clamping protects against short circuits. High-resolution measurement of leakage current helps detect small problems that could affect battery life.

Integrated Battery Monitor ICs support real-time monitoring, which is crucial for predicting battery lifespan and ensuring safety. Systems using these ICs have shown over 98% accuracy in tracking battery health during long-term tests. This level of precision allows for better prediction of remaining useful life and helps prevent unexpected failures.

Core Functions

Voltage and Current Sensing

An Integrated Battery Monitor IC measures the voltage and current of each battery cell with high precision. The chip uses advanced sensors and digital processing to track these values in real time. Experimental results show that voltage sensing accuracy often exceeds 98%, sometimes reaching above 99% when compared to standard multimeter readings. Coordinate measurement accuracy can reach between 99.96% and 99.99%. These high levels of accuracy help engineers trust the data for battery management. Machine learning models, such as transformer-based and RNN-based systems, filter out noise and keep fault detection reliable even when conditions change. This level of precision ensures that the battery operates safely and efficiently.

Temperature Monitoring

Temperature monitoring protects batteries from overheating and failure. The IC tracks temperature changes and can trigger warnings if the battery gets too hot or too cold. The following table shows how temperature monitoring helps prevent battery failures:

Aspect | Numerical Data | Explanation |

|---|---|---|

±0.2 °C at 24h increasing to ±0.6 °C at 120h | Shows stability and gradual drift in temperature sensing, highlighting need for calibration to maintain accuracy over long-term operation. | |

Voltage Measurement Deviation Over Time | ±0.02 V at 24h increasing to ±0.06 V at 120h | Voltage measurements are more stable but also show drift, supporting combined monitoring. |

Temperature Rise Rate vs Charge/Discharge Rate | 0.5 °C/min at 0.5 C to 5.5 °C/min at 3 C | Demonstrates how higher charge/discharge rates cause rapid temperature increases, emphasizing importance of monitoring to prevent thermal runaway. |

Warning Thresholds for Temperature and Voltage | Four warning levels defined, e.g., first-level warning triggered when temperature rises from 35–55 °C to 42–65 °C in 10 min and voltage drops from 400–425 V to 398–375 V | Quantitative thresholds enable early fault detection and timely warnings. |

System Accuracy and Error Rates | Accuracy: 80%, False Alarm Rate: 4%, Omission Rate: 4% | High accuracy and low error rates indicate effective early warning capability. |

Impact of Threshold Perturbations on Accuracy | ±10% temperature threshold change causes ±4% accuracy change; combined perturbations can reduce accuracy by up to 8% | Highlights sensitivity and importance of precise threshold calibration. |

Calibration Effectiveness | Calibration every 48h reduces temperature deviation at 120h from ±0.6 °C to ±0.3 °C | Demonstrates that periodic calibration improves long-term monitoring reliability. |

These numbers show that careful temperature monitoring, combined with voltage checks and regular calibration, helps catch problems early and keeps batteries safe.

Cell Balancing

Cell balancing keeps all battery cells at similar charge levels. This process prevents some cells from aging faster than others. The IC can use active or passive balancing methods. Recent studies highlight several benefits:

Active cell balancing improves voltage uniformity and reduces capacity loss, which extends battery life.

Engineers use state of health (SOH) by comparing discharge capacity and resistance to initial values, which helps track battery health.

Machine learning with active balancing improves predictions for how long a battery will last.

Active balancing saves energy and works faster than passive methods, though it is more complex.

High temperatures speed up battery aging, so balancing and thermal management work together to protect the battery.

Advanced balancing circuits, like those using capacitors or inductors, increase efficiency and speed, which is important for electric vehicles.

These features help batteries last longer and perform better in demanding applications.

Communication Features

Communication features allow the Integrated Battery Monitor IC to share data with other systems. The chip supports protocols like CAN, LIN, USB, Ethernet, and Wi-Fi. These options make it easy to connect the IC to a battery management system (BMS) or other controllers. Manufacturers test these systems under tough conditions, such as aging batteries and extreme temperatures, to make sure communication stays reliable. The design meets strict aerospace and defense standards, which means it works well even in critical environments. Strong communication features help engineers monitor batteries in real time and respond quickly to any issues.

Safety and Benefits

Protection Mechanisms

Integrated Battery Monitor ICs protect batteries from dangerous conditions. These chips watch for overcharge, overdischarge, and high temperatures. When the IC detects a problem, it can stop charging or discharging right away. This quick action helps prevent fires and damage. Many manufacturers design their chips to meet strict safety standards. The table below shows how different companies build safety into their battery monitor ICs:

Manufacturer | Chip Model | Key Safety Features | Precision / Speed | Safety Standard / Validation |

|---|---|---|---|---|

Texas Instruments | BQ79614-Q1 | Real-time temperature tracking, automatic halt/restart to prevent overheating | Monitors 14 batteries in 128μS | Meets ASIL D automotive safety integrity level |

STMicroelectronics | L9963 | Redundant circuit for ADC cross detection to ensure driving safety if ADC fails | Accuracy error 2mV, reads 96 units in 4ms | Automotive-grade IC with redundant safety features |

Analog Devices Inc | LTC6811-1 | High precision, real-time monitoring of up to 12 series batteries | Measurement error <1.2mV, detects in 290μs | Fourth-generation integrated high-voltage battery stack monitor |

Safety standards like ASIL D show that these chips can handle critical situations in cars and other important devices.

Efficiency and Reliability

Integrated Battery Monitor ICs help batteries last longer and work better. Accurate state-of-charge measurement prevents overcharging and deep discharging, which can damage batteries. These ICs use smart methods, such as coulomb counting and model-based algorithms, to track battery health. This careful monitoring leads to longer battery life and fewer failures.

Fewer parts are needed because one IC can monitor many battery cells at once.

Battery systems become lighter and cost less to build.

Improved accuracy and stability help devices run longer on a single charge.

In 2019, better battery management saved 60 million tons of CO2 emissions, with a 30% drop in vehicle emissions from the year before.

New designs increase power density and reliability, making batteries safer and more efficient.

Accurate monitoring also means fewer false alarms and better performance over time. These benefits make Integrated Battery Monitor ICs a key part of safe, reliable, and efficient battery-powered devices.

Applications

Consumer Electronics

People use battery-powered devices every day. Smartphones, tablets, laptops, and wearable gadgets all depend on safe and efficient batteries. Companies like Qualcomm have added battery management technology to their Snapdragon chipsets. This technology helps smartphones and wearables check battery status and manage charging. Quick charging, temperature monitoring, and adaptive charging algorithms keep devices safe and extend battery life. Market reports show that North America and Asia-Pacific lead in using these chips. The Li-ion Battery Management ICs market reached $3.5 billion in 2024 and could grow to $10.2 billion by 2033. This growth comes from the rising demand for reliable batteries in consumer electronics.

Note: Regulatory and safety standards push companies to use better battery monitoring. These rules help protect users and improve device performance.

Automotive and Industrial

Electric vehicles (EVs) and hybrid cars need strong battery systems. Battery monitor chips help these vehicles track each cell’s voltage, current, and temperature. Tesla uses advanced battery management chips to keep EV batteries safe and long-lasting. In factories, battery-powered robots and backup power systems also use these chips. They help prevent downtime and keep machines running smoothly. Energy storage systems, such as those used for solar and wind power, rely on accurate battery monitoring to store and deliver energy safely.

Application Area | Example Devices | Main Benefits |

|---|---|---|

Automotive | Electric vehicles, hybrids | Safety, longer battery life |

Industrial | Robots, backup power, storage | Reliable operation, efficiency |

Medical Devices

Medical devices must work safely at all times. Lithium batteries in equipment like infusion pumps, portable monitors, and defibrillators need careful monitoring. Battery management chips check the state of charge, health, and temperature. They also limit charging current and use extra temperature sensors for added safety. These features help prevent overcharging and overheating, which could harm patients or damage equipment. Real-time monitoring supports doctors and nurses by making sure devices stay powered and reliable.

Medical batteries need:

State of charge and health checks

Internal resistance and life cycle tracking

Redundant safety features

Reliable battery monitoring in medical devices protects patient safety and ensures critical equipment works when needed.

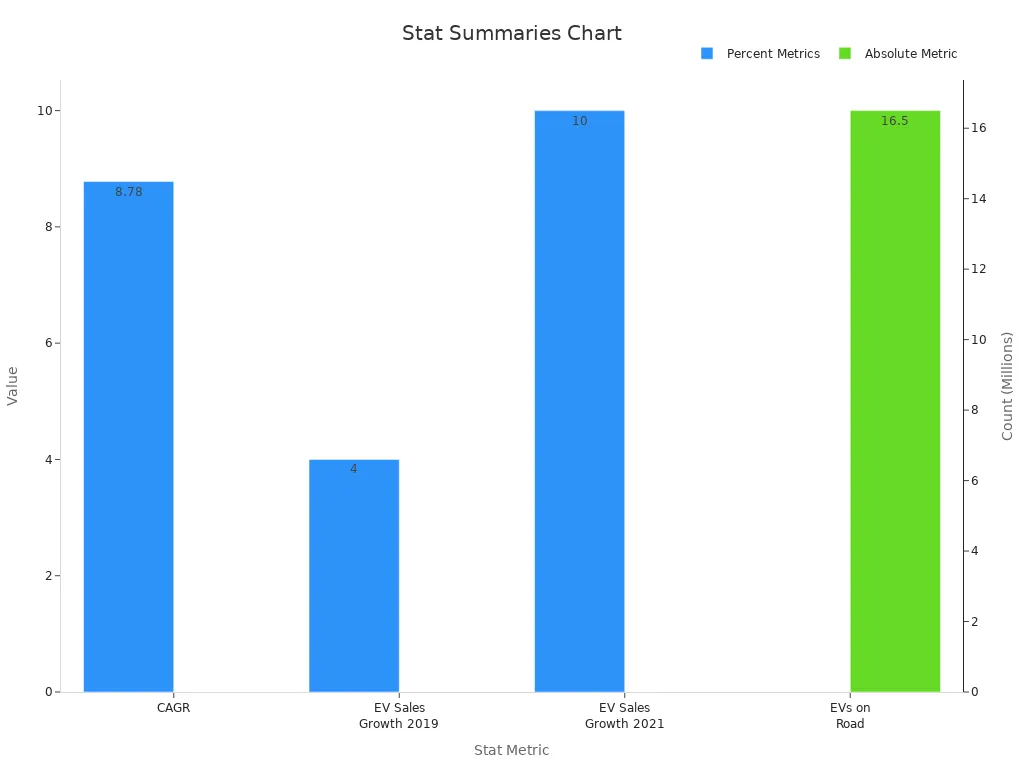

Integrated Battery Monitor ICs help devices stay safe, efficient, and long-lasting. These chips track battery voltage, current, and temperature, which prevents damage and keeps batteries working well. Many industries now use these ICs because electric vehicles and smart devices need reliable power. The table below shows how the market for these chips is growing:

Statistic / Trend | Details |

|---|---|

CAGR (2025-2030) | 8.78% growth expected in global Battery Management IC Market |

EV Sales Growth | Increased from 4% in 2019 to 10% in 2021 globally |

Number of EVs on Road | Approximately 16.5 million as of 2021 |

Key Market Drivers | Rising EV and HEV adoption, consumer electronics demand, renewable energy integration |

Technological Advancements | New ICs improve monitoring and balancing |

Market Trends | Growth fueled by smart cities, IoT, and better battery safety |

As technology advances, more people will depend on Integrated Battery Monitor ICs to keep their devices safe and running longer.

FAQ

What is the main job of an Integrated Battery Monitor IC?

An Integrated Battery Monitor IC checks battery voltage, current, and temperature. It helps keep batteries safe and working well. The IC also sends important data to other parts of the device.

How does cell balancing help batteries last longer?

Cell balancing makes sure each battery cell has a similar charge. This process stops some cells from wearing out faster than others. Balanced cells help the whole battery pack last longer.

Can these ICs prevent battery fires?

Yes! The IC can spot problems like overheating or overcharging. It can quickly stop charging or discharging to prevent fires or damage.

Where do people use Integrated Battery Monitor ICs?

Smartphones

Electric vehicles

Medical devices

Backup power systems

These ICs help many devices stay safe and reliable every day.

See Also

How Battery Charge Controller ICs Operate And Function

Exploring System Monitor Chips And Their Operational Role

A Complete Guide To Battery Charger Controller IC Functions

How Current Controller Chips Work And Their Key Functions

The Role And Function Of Fully Integrated Processors Explained