How PLC Components Work in Industrial Automation Systems

Industrial automation PLC control components are the core of industrial automation systems. They allow you to check inputs, run logic, and manage outputs easily. Each component works together to make machines run smoothly and accurately. These systems handle tasks instantly, which is key for tough industrial jobs. Using industrial automation PLC control components in automation helps work run better, lowers mistakes, and boosts output.

Key Takeaways

PLC parts help do tasks faster and boost work output.

Good input and output parts collect data and control machines well.

A steady power source keeps the system running and avoids stops.

Programming tools make it simple to change PLC settings for better use.

Connecting PLCs with SCADA and HMI systems helps watch and control work better.

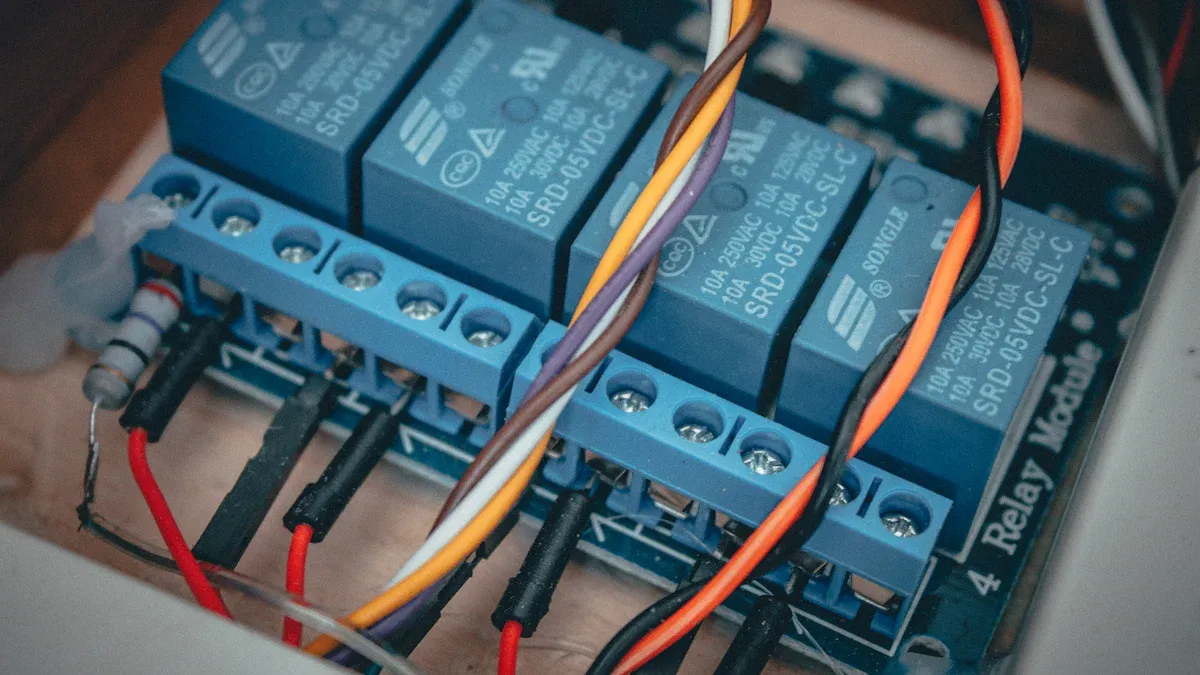

Key Industrial Automation PLC Control Components

Input Modules and Their Role

Input modules bring data into automation systems. They collect signals from sensors and devices, turning them into a format the system understands. These modules track things like temperature, pressure, and flow rates. This helps gather accurate data for quick decisions.

Modern input modules, like the SAT145 and SAR145, have advanced features:

The SAT145 reads thermocouples, turning voltage into temperature and spotting circuit issues.

The SAR145 works with RTDs, converting voltage into temperature and checking for failures.

Each module has its own A/D converter, collecting data at the same time for faster responses.

They can quickly check for problems, reacting to faults in under three seconds.

These features make input modules crucial for collecting accurate data and keeping systems reliable.

Central Processing Unit (CPU) Functions

The CPU is the "brain" of the PLC system. It handles data, runs instructions, and connects all parts. Its speed affects how fast the system reacts and solves problems.

Important CPU features include:

Speed, measured in MHz or GHz, shows how fast it works.

Architecture, like 32-bit or 64-bit, affects how much data it can handle.

For example, in factories, faster CPUs help machines respond quickly, improving productivity. In chemical plants, precise CPUs make processes safer and products better while saving money.

When choosing a PLC, pick a CPU that can handle tough tasks and changing conditions.

Output Modules and Their Importance

Output modules turn processed data into actions for machines and devices. They are key for running motors, valves, and robotic arms. These modules ensure smooth operations and reduce downtime.

In real life, output modules are very useful:

In factories, they control assembly lines for consistent product quality.

In energy systems, they manage power use, cutting waste and improving efficiency.

Using good output modules improves your system’s performance, making it more productive and reliable.

Power Supply and System Stability

The power supply gives energy to all parts of a PLC system. It keeps the system working reliably and smoothly. If the power supply fails, the whole system stops working.

A PLC checks the input voltage all the time. It adjusts settings to keep the output voltage steady. This control loop makes sure the voltage stays within safe limits. A stable power supply helps the system run well and avoids mistakes or breakdowns.

Why is power supply stability important?

Operational Downtime: Losing power stops automated tasks, causing delays and costing money.

Data Loss: If the PLC uses temporary memory, power loss can erase important data.

Equipment Safety Risks: Unsteady power can harm machines and endanger workers.

In industries like factories and hospitals, steady power affects how well systems work and stay safe. A dependable power supply protects equipment and keeps operations running without interruptions.

💡 Tip: Pick a power supply with surge protection and voltage control. This keeps your PLC safe from sudden power changes.

Programming Devices for PLC Configuration

Programming devices help you set up and change your PLC system. They let you write, edit, and upload programs to match your automation needs.

Different tools can be used for programming:

Handheld Programmers: Small and easy to carry, great for quick fixes.

Personal Computers (PCs): Modern PLCs often use PCs with special software for programming. These offer easy-to-use features like testing and fixing errors.

HMI Panels: Some systems have Human-Machine Interface panels for direct programming and monitoring.

When programming a PLC, you use languages like ladder logic or block diagrams. These make it simple to create instructions the PLC can follow.

🛠️ Note: Always save a copy of your PLC programs before changing them. This lets you restore the system if something goes wrong.

Programming devices let you adjust your system as needs change. Learning to use these tools can make your processes better and more efficient.

PLC Integration with Automation Systems

Communication Protocols in PLC Systems

Communication protocols are like languages for PLCs and devices. They help share data smoothly, making control and monitoring easier.

Common communication protocols include:

Profibus: Links automation parts for smooth device communication.

Profinet: Uses Ethernet for fast data sharing and easy scaling.

Ethernet/IP: Sends data quickly and securely with encryption features.

These protocols keep systems reliable. For example, Profinet grows with your needs, while Ethernet/IP ensures fast, secure communication for urgent tasks.

💡 Tip: Pick a protocol based on speed, security, and compatibility.

Interaction with Sensors and Actuators

Sensors and actuators are like the senses and hands of automation. Sensors gather data like temperature or motion. Actuators act based on PLC commands. Together, they create a loop for accurate control.

Examples include:

In Scania’s Pedal Car Line, sensors and actuators improve manufacturing and track performance.

Atlas Copco’s Power Focus System uses sensors for data and actuators for tasks, boosting efficiency.

Standards like ISO 22400 show how sensor data improves operations. Using sensors and actuators well can make systems work better and reduce downtime.

🛠️ Note: Check and adjust sensors and actuators often for accuracy.

Real-Time Control and Data Processing

Real-time control lets PLCs act instantly without delays. This is vital for industries where delays cause big problems.

Here’s a comparison:

System Type | Error Rate | Bad Units | Good Units | |

|---|---|---|---|---|

Old PLC System | 1000 | 5% | 50 | 950 |

New PLC System | 1150 | 1% | 11.5 | 1138.5 |

New PLC systems process data faster, improving production and cutting mistakes. For example, CompactRIO combines tasks in one device, saving time and money. It increased output by 5%, making work more efficient.

Automatic reports and data tools also help. They replace manual work and give real-time updates for better decisions.

📈 Insight: Real-time systems save money by reducing errors and downtime.

Connectivity with SCADA and HMI Systems

SCADA (Supervisory Control and Data Acquisition) and HMI (Human-Machine Interface) systems are important in automation. They help you watch and control automated systems easily. When linked to PLCs, these systems improve how you see and manage processes.

How SCADA Systems Work with PLCs

SCADA systems gather data from PLCs and show it clearly. They let you check performance, find problems, and decide quickly. For example, SCADA can display temperatures, motor speeds, or production numbers on one screen.

Benefits of SCADA include:

Centralized Monitoring: Watch many systems from one place.

Data Logging: Save past data for reports and analysis.

Alarm Management: Get alerts for unusual issues and fix them fast.

Role of HMI Systems in PLC Connectivity

HMI systems let you interact with the PLC easily. They show information using buttons, graphs, and charts. This makes controlling systems simple.

HMI features include:

Touchscreen Controls: Change settings directly on the screen.

Customizable Displays: Adjust the interface to fit your needs.

Real-Time Feedback: See updates about system performance instantly.

Benefits of SCADA and HMI Integration

When PLCs connect with SCADA and HMI systems, you get better control and insights. This setup boosts efficiency and cuts downtime. For example, SCADA can track production lines, while HMI lets workers change machine settings.

💡 Tip: Update SCADA and HMI software often to match your PLC.

By linking PLCs with SCADA and HMI systems, you build a strong network. This helps you run industrial processes with accuracy and dependability.

Benefits of PLC Components in Industrial Automation

Enhancing Efficiency and Productivity

PLC components help make industrial work faster and better. They automate repeated tasks, so workers don’t have to do them manually. This saves time and keeps the quality steady. For example, PLCs help plan resources, organize batches, and improve delivery in factories.

Key benefits include:

Smarter resource use with automation.

Accurate data from sensors for better decisions.

Lower energy use and improved system control.

By making processes smoother, PLCs help produce more in less time. They also reduce mistakes, giving businesses an advantage over competitors.

💡 Tip: Pick PLCs with advanced tools to boost productivity and make updates easier.

Ensuring Reliability and Precision

PLC components are great at being reliable and precise. They control processes carefully, lowering the chance of mistakes. For example, the ICSI Parts System uses PLCs to check parts on assembly lines, ensuring no errors happen.

Other benefits include:

Watching systems in real time to fix problems fast.

Better maintenance planning to avoid unexpected stops.

Strong designs that are easy to maintain for dependable operations.

Modern PLCs focus on staying available and easy to fix, which is important for industries needing high accuracy.

📈 Insight: Reliable PLCs improve product quality and reduce risks during operations.

Flexibility and Scalability in Automation

PLC components are flexible and can grow with your business. They adjust to changes easily, letting you expand or change systems without spending too much.

Key features include:

Modular designs for easy system upgrades.

Simple programming tools for quick changes.

Support for advanced programming languages for harder tasks.

Newer PLCs are cheaper and modular, helping businesses start small and grow later. This makes PLCs a smart choice for long-term automation plans.

🛠️ Note: Pick modular PLCs to make sure your system can expand as your business grows.

Long-Term Cost-Effectiveness

Using PLC components in automation saves money over time. These systems cut costs and improve efficiency, helping businesses stay ahead.

One big benefit is saving on labor costs. Automating repeated tasks means fewer workers are needed, which saves money. PLCs also use energy wisely, lowering utility bills. For example, they adjust power based on what’s needed, so no energy is wasted.

Another advantage is less downtime. PLCs watch processes closely and fix problems early. This keeps production running and avoids big losses. Predictive maintenance is also helpful. It spots issues before machines break, saving on repairs and making equipment last longer.

💡 Tip: Choose PLCs with predictive maintenance to avoid costly repairs and keep machines reliable.

Here’s how PLCs save money in the long run:

Return on Investment (ROI): Automation pays back more than it costs.

Payback Period: You recover costs quickly because of better efficiency.

Optimized Resource Use: PLCs control materials well, cutting waste and saving money.

Better Quality Control: Fewer defects mean less waste and happier customers.

By making production faster and better, PLCs boost output without big extra costs. Over time, these savings grow, making PLCs a smart choice for automation.

📈 Insight: Companies using PLCs often produce more and spend less, giving them an edge in their field.

Applications of PLCs in Industrial Automation

Manufacturing and Assembly Line Automation

PLCs are important for running manufacturing and assembly lines. They control machines, check processes, and keep product quality steady. PLCs can be programmed to do repeated tasks like sorting, welding, or packing. This reduces mistakes and makes production faster.

PLCs are flexible, so they work well in changing environments. For example, when paired with SCADA systems, they can study past data to improve processes and predict repairs. This cuts downtime and boosts efficiency. Their strong design also lets them work in tough conditions, making them essential for critical manufacturing jobs.

Process Control in Various Industries

PLCs are used in industries like oil, medicine, and food production. They follow set instructions in real time to control things like motor speeds, valve positions, and temperatures. This accuracy improves product quality and reduces waste.

Here’s how PLCs are improving different industries:

Industry Sector | How PLCs Are Improving Efficiency |

|---|---|

Manufacturing | Using AI to predict repairs and improve processes |

Oil and Gas | Better automation for smoother operations |

Pharmaceuticals | |

Food and Beverage | Focus on saving energy and being more sustainable |

Using PLCs gives better control over processes, meets industry rules, and increases productivity.

Energy Management and Optimization

PLCs help save energy in factories and other workplaces. They gather data from sensors and use it to find ways to use less energy. For example, PLCs can turn machines on or off based on need or adjust heating and cooling systems to save power.

Main benefits include:

Watching energy use in real time to find savings.

Balancing energy loads to avoid wasting power.

Predicting repairs to stop equipment from breaking.

Using data to plan better energy-saving strategies.

By automating energy use, PLCs lower costs and help the environment. They are a great tool for industries wanting to save money and reduce their impact on nature.

Robotics and Material Handling

Robotics and material handling depend a lot on PLCs for smooth work. These systems control robotic arms, conveyor belts, and other machines. With PLCs, tasks like picking, placing, and moving materials become precise. This is very useful in factories, warehouses, and shipping centers.

A big benefit of PLCs is replacing older controllers. Old systems were slow to process instructions and respond. PLCs fix this with faster feedback and quicker actions. For example, during robot testing, PLCs handle signals, control parts, and manage data all at once. This keeps robots running smoothly without delays.

PLCs also make material handling smarter and more reliable. They follow programmed steps to make decisions automatically, needing less human help. Picture a warehouse where many PLCs work together. If one fails, the others keep working, so there’s no downtime. This setup speeds up responses and boosts reliability.

💡 Tip: Choose PLCs with shared control features to avoid downtime and keep systems running.

Besides control, PLCs improve how robotics and material handling systems work. They cut mistakes, make things safer, and boost productivity. Whether running a factory line or organizing a warehouse, PLCs offer the accuracy and flexibility needed for tough jobs.

Adding PLCs to your robotics and material handling systems can simplify tasks, save money, and help you stay competitive in today’s fast-moving industries.

Challenges and Future Trends in PLC Systems

Overcoming Integration Challenges

Adding PLCs to current systems can be hard. Problems like mismatched parts, high costs, or not enough skilled workers may arise. To fix these issues, plan carefully. Start by checking for risks and gaps in your system. This helps you spot problems early. Then, talk to workers to learn what they need. Knowing their needs helps your system meet work goals.

Making a small test version of your system can help. This saves time and money by testing ideas before using them fully. Simulations can improve the design and catch mistakes early. When building the system, focus on fixing bugs and making it better. Keep improving it to make it faster and more reliable.

These steps make adding PLCs easier and help your system work well.

Addressing Cybersecurity in Connected Systems

As PLCs connect to more devices, hacking risks grow. Protecting your system needs many layers of security. Start by using strong defenses at every level. Update your software often because old programs are easier to hack.

Teach workers how to stay safe online. Training can show them how to spot fake emails and protect important data. Also, check that outside companies follow your safety rules.

Follow safety standards like NERC CIP and IEC 62443. These rules help keep systems safe. Make a plan for handling problems and watch your system closely. Catching issues early stops big problems later.

By focusing on cybersecurity, you can keep your PLCs safe and running smoothly.

IoT and AI Integration in PLCs

IoT and AI are changing how PLCs work. IoT collects live data from sensors, while AI studies the data to improve systems. For example, AI can guess when machines might break. This lets you fix them before they stop working, saving time and money.

Edge computing is also helping PLCs. It processes data near the source, making decisions faster. Open-source tools are becoming popular too. They are cheaper and flexible, helping businesses update their systems easily.

Newer markets are using PLCs to manage energy better. Older systems in developed countries are being upgraded for more efficiency. These changes make PLCs useful in many industries.

Using IoT and AI can open new doors for automation and keep you ahead in business.

The Role of PLCs in Industry 4.0

Industry 4.0 is the next big step in factories. It uses digital tools to make work faster and smarter. Programmable Logic Controllers (PLCs) are key to this change. They connect old machines to new digital systems.

PLCs work with IoT (Internet of Things) devices to collect live data. Sensors send information like temperature or pressure to PLCs. The PLCs then share this data with a central system. This helps you control machines from far away and make quick decisions.

AI (Artificial Intelligence) makes PLCs even better. AI studies the data from PLCs to predict problems or improve schedules. This saves time and money by fixing machines before they break. AI also helps PLCs adjust to changes without needing human help.

PLCs are becoming more popular as factories use Industry 4.0.

The PLC market may grow from USD 12.5 billion in 2023 to USD 19.3 billion by 2032.

Factories use PLCs to handle tough jobs, boost output, and try new ideas.

New PLC designs are easier to upgrade and fit modern factory needs.

Using PLCs keeps your business strong in the digital age. They make factories smarter and more connected, helping you succeed in Industry 4.0.

PLC components are the main part of industrial automation. They check inputs, handle data, and control outputs to keep things running smoothly. These systems help complete hard tasks with accuracy and speed.

Main advantages include:

Efficiency: Automating repeated tasks saves time and increases work output.

Reliability: Watching systems in real time lowers mistakes and keeps things steady.

Adaptability: Easy-to-upgrade designs let systems grow with new needs.

🚀 Future Insight: PLCs are improving with IoT and AI technologies. These updates make automation smarter and more connected, helping businesses succeed in Industry 4.0.

Adding PLCs to your setup gets you ready for faster, smarter, and more dependable industrial operations.

FAQ

What is a PLC, and why is it important in industrial automation?

A PLC is a special computer used in industries. It controls machines and processes to make work accurate and reliable. It also automates repeated tasks and checks live data to save time.

Can PLCs work with older machines in factories?

Yes, PLCs can connect to older machines. They help old equipment work with modern systems. This improves how machines communicate and perform.

How do PLCs improve energy efficiency?

PLCs watch energy use and cut down waste. For example, they turn off unused machines or balance power use. This saves energy and lowers costs.

What programming languages are used for PLCs?

Languages like Ladder Logic, FBD, and ST are common. These make programming simple and allow easy changes to automation tasks.

Are PLC systems secure from cyber threats?

PLCs can stay safe if you follow good practices. Use strong passwords, update software, and teach workers about online safety. Following rules like IEC 62443 also helps protect systems.

💡 Tip: Check your PLC system often to find and fix security issues.

See Also

Exploring Industrial Control Chips And Their Role In Automation

A Guide To Control Chips In Smart Home Devices

Implementing Smart Lighting Solutions Using MCUs By 2025

Effective Methods For Connecting Storage Controllers To IP Networks