How to identify a brand new original chip supplier in 2025

You need to identify a brand new original chip supplier with care in 2025. If you skip verification, you risk exposing your business to serious threats. In recent years, unverified suppliers have shipped chips with hidden vulnerabilities, causing security problems and even threatening national infrastructure. You may also face price swings, counterfeit parts, and supply disruptions, especially when relying on lesser-known sources. Always use formal, trusted channels and check every detail before you buy.

Unverified suppliers can lead to:

Security breaches through hidden hardware.

Counterfeit or substandard chips.

Unstable pricing and unreliable deliveries.

Key Takeaways

Always verify chip suppliers by checking their legal documents, physical address, and reputation before buying.

Inspect every chip’s markings, surface, pins, and packaging carefully to spot signs of counterfeiting.

Use trusted tools like microscopes and X-ray machines to confirm chip authenticity against official samples.

Follow industry standards and new technologies like blockchain and AI to protect your supply chain.

If you suspect counterfeit chips, quarantine them, report immediately, and review your buying process.

Brand New Original Chip Supplier

Supplier Verification

When you search for a brand new original chip supplier, you must start with a thorough verification process. Many companies face challenges such as long lead times, complex manufacturing steps, and the risk of counterfeit chips. You can avoid these risks by following a structured approach to supplier verification.

Check Company Registration and Legal Documents

Always confirm the supplier's official registration. Ask for business licenses, tax documents, and proof of compliance with local and international regulations. The U.S. CHIPS Act now requires detailed documentation of component origins and verification processes. This step ensures that you only work with suppliers who meet strict legal standards. Document verification helps protect your business from forgery and tampering. It also supports compliance with Anti-Money Laundering (AML) and Know Your Customer (KYC) rules.Verify Physical Address and Website

Visit the supplier's physical location if possible. If you cannot visit, use trusted third-party inspection services. Check that the address matches official records. Review the supplier’s website for professionalism, up-to-date information, and consistency with their business claims. A legitimate brand new original chip supplier will have a transparent online presence.Review Payment Terms and On-Site Inspection

Reliable suppliers offer clear payment terms and do not pressure you into risky transactions. Avoid suppliers who insist on unusual payment methods or refuse standard contracts. If possible, conduct an on-site inspection to observe their operations, quality control systems, and production capacity. This step helps you confirm that the supplier can meet your needs and deliver genuine chips.

Tip:

Do not rely on paperwork alone. Combine document checks with physical and digital verification to reduce fraud risk and ensure compliance.

References and Reputation

You need to assess the reputation of any brand new original chip supplier before making a commitment. References and third-party reviews provide valuable insights into a supplier’s reliability and performance.

Request Customer References

Ask for a list of previous or current customers. Contact them directly to learn about the supplier’s communication, responsiveness, and professionalism. Direct feedback helps you understand how the supplier handles problems and meets deadlines.Review Performance Metrics

Request data on on-time delivery rates, defect rates, and customer satisfaction scores. These metrics show how well the supplier performs over time.Check Financial Stability and Certifications

Review financial statements or credit reports to confirm the supplier’s ability to fulfill commitments. Verify certifications such as ISO 9001 or IATF 16949 for automotive chips. These certifications show that the supplier follows industry standards.Conduct Site Visits or Audits

If possible, visit the supplier’s facility. Observe their operational capabilities, quality control systems, and compliance with safety and environmental regulations.Use Third-Party Reviews and Testimonials

Look for verified reviews and testimonials from real customers. These reviews confirm that others have purchased and used the supplier’s chips. Third-party audits and security questionnaires also help you assess risks related to security, compliance, and business continuity.

Note:

Verified reviews and references reduce the risk of fake or misleading information. They help you make informed decisions and protect your business from unreliable suppliers.

You face many challenges when identifying a brand new original chip supplier. The process takes time and effort, but thorough verification and reputation checks help you avoid costly mistakes and ensure a secure supply chain.

Chip Authenticity

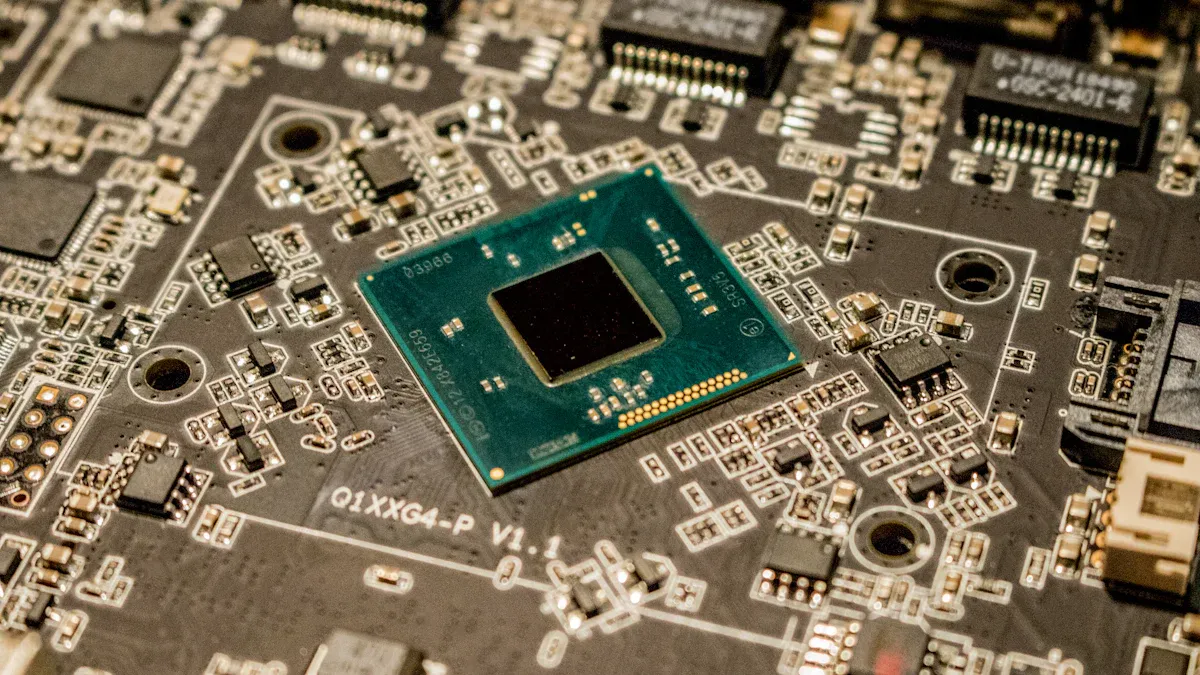

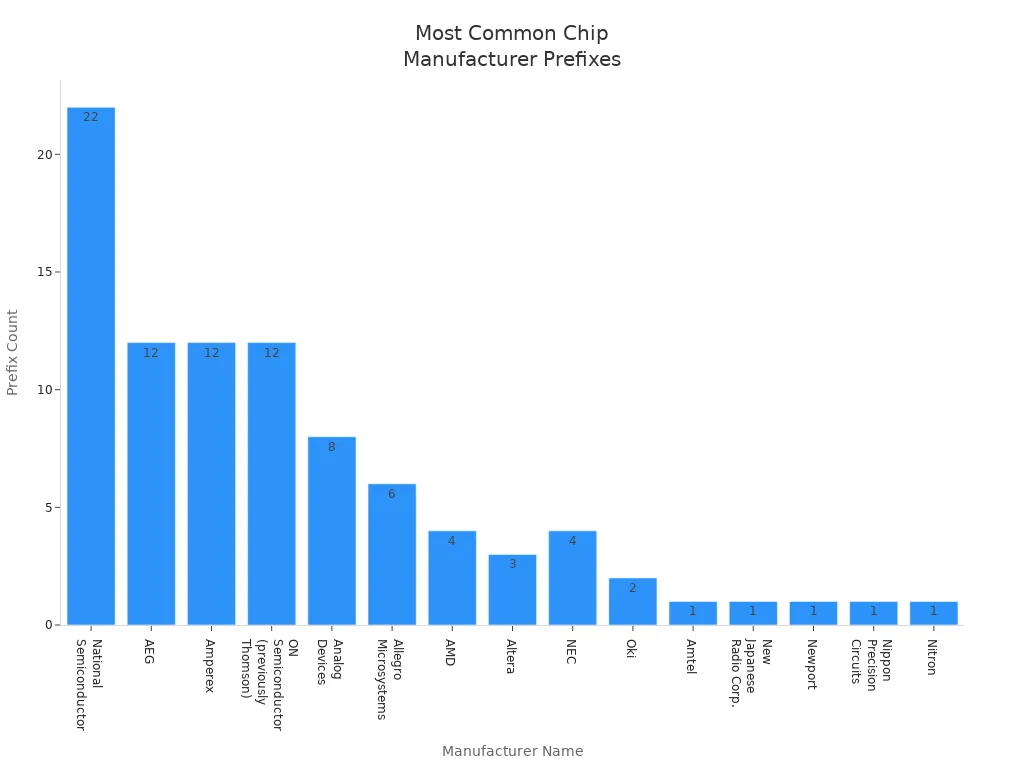

Markings and Codes

You must check the markings and codes on every chip you receive. Original chip manufacturers use specific prefixes and codes to identify their products. These markings help you confirm the chip’s origin and authenticity. If you see a code or prefix that does not match the manufacturer’s records, you should treat the chip as suspicious.

Manufacturer Prefix | Manufacturer Name |

|---|---|

AM | Advanced Micro Devices |

A | National Semiconductor |

AMSREF | Advanced Monolithic Systems |

ADC | National Semiconductor |

OM | AEG |

PCD | AEG |

COP | National Semiconductor |

PCF | AEG |

DAC | National Semiconductor |

SAA | AEG |

DM | National Semiconductor |

SAB | AEG |

DP | National Semiconductor |

SAF | AEG |

DS | National Semiconductor |

SCB | AEG |

F | National Semiconductor |

SCN | AEG |

L | National Semiconductor |

TAA | AEG |

LF | National Semiconductor |

TBA | AEG |

LFT | National Semiconductor |

TCA | AEG |

LH | National Semiconductor |

TEA | AEG |

LM | National Semiconductor |

A | Allegro Microsystems |

LMC | National Semiconductor |

STR | Allegro Microsystems |

LMD | National Semiconductor |

UCN | Allegro Microsystems |

LMF | National Semiconductor |

UDN | Allegro Microsystems |

LMX | National Semiconductor |

UDS | Allegro Microsystems |

LPC | National Semiconductor |

UGN | Allegro Microsystems |

LPC | National Semiconductor |

EP | Altera |

MF | National Semiconductor |

EPM | Altera |

MM | National Semiconductor |

PL | Altera |

NH | National Semiconductor |

A | AMD |

UNX | National Semiconductor |

Am | AMD |

PB | NEC |

AMPAL | AMD |

PC | NEC |

PAL | AMD |

PD | NEC |

OM | Amperex |

UPD | NEC |

PCD | Amperex |

UPD8 | NEC |

PCF | Amperex |

NJM | New Japanese Radio Corp. |

SAA | Amperex |

NSC | Newport |

SAB | Amperex |

SM | Nippon Precision Circuits |

SAF | Amperex |

NC | Nitron |

SCB | Amperex |

MM | Oki |

SCN | Amperex |

MSM | Oki |

TAA | Amperex |

MC | ON Semiconductor |

TBA | Amperex |

EF | ON Semiconductor |

TCA | Amperex |

ET | ON Semiconductor |

TEA | Amperex |

GSD | ON Semiconductor |

V | Amtel |

HCF | ON Semiconductor |

AD | Analog Devices |

L | ON Semiconductor |

ADEL | Analog Devices |

LM | ON Semiconductor |

ADG | Analog Devices |

LS | ON Semiconductor |

ADLH | Analog Devices |

M | ON Semiconductor |

ADM | Analog Devices |

MC | ON Semiconductor |

ADVFC | Analog Devices |

MK | ON Semiconductor |

AMP | Analog Devices |

OM | ON Semiconductor |

BUF | Analog Devices |

PCD | ON Semiconductor |

CAV | Analog Devices |

PCF | ON Semiconductor |

CMP | Analog Devices |

SAA | ON Semiconductor |

DAC | Analog Devices |

SAB | ON Semiconductor |

You should also check the part number, batch code, serial number, and date code. Manufacturers use traceability systems that assign unique identifiers to each chip. These identifiers often appear as QR codes, RFID, or NFC tags. You can scan these codes to upload product data into traceability platforms. This process lets you cross-check the batch, serial, and date codes against the manufacturer’s database. If the codes match, you confirm the chip’s authenticity and track its movement through the supply chain.

Many batch codes use the Julian Date format. This format combines the year and the day of the year (YYDDD). By decoding this, you can find the exact production date and verify it with the manufacturer’s records. Some brands use blockchain technology to create tamper-proof records. You can instantly verify a chip’s history by checking the linked serial number. AI-powered authentication systems now analyze product details and confirm authenticity with high accuracy.

Tip:

Always compare the markings and codes on your chip with official manufacturer data sheets and online verification tools. If you find any mismatch, do not use the chip.

Surface and Printing

You need to inspect the chip’s surface and printing with care. Counterfeiters often alter the surface to hide the chip’s true identity. You can spot many signs of tampering if you know what to look for.

Ghost markings may appear after testing.

Surface texture may differ from genuine chips.

Directional sanding marks or microblasting traces often show up.

Secondary coatings or blacktopping can cover the original surface.

Scratches, unidirectional abrasions, or stains may indicate prior use.

Inconsistent or incorrect part markings, such as wrong fonts or misplaced logos, are red flags.

Poor quality or blurred markings suggest remarking.

Polishing traces, like fine lines or micro-marks from previous printing, may be visible.

Uneven or blurred printing, or mismatched marking clarity and pin newness, can signal counterfeiting.

Exposed bond wires or signs of refurbishing, such as solder splash, are also warning signs.

You should use the right tools to inspect chips. Optical microscopes help you see scratches, pits, and surface defects. Scanning electron microscopes (SEMs) give you high-resolution images of nanoscale details. Manual visual inspection under magnification lets you check pad plating, roughness, and coating quality. Automated optical inspection (AOI) uses cameras and light sources to detect defects quickly. X-ray inspection reveals hidden solder joints and internal defects.

Tool/Technique | Description | Advantages | Limitations |

|---|---|---|---|

Optical Microscopes | Use visible or UV light to inspect surface morphology and detect defects like scratches and pits. | High resolution, easy to use, non-destructive. | Limited magnification, limited depth of field, resolution limited by light wavelength. |

Scanning Electron Microscopes (SEMs) | Use electron beams to generate high-resolution images revealing nanoscale surface details. | Extremely high magnification and resolution, detailed topographical info. | Requires sample prep, high vacuum environment, possible charging effects on non-conductive samples. |

Manual Visual Inspection (MVI) | Visual inspection under magnification to check pad plating firmness, roughness, brightness, and coating quality. | Low cost, simple, quick, requires only magnification and trained staff. | Limited to visible components, misses hidden or small defects, challenging for complex boards. |

Automated Optical Inspection (AOI) | Uses multiple light sources and cameras to capture images and compare with design specs for defect detection. | Faster than MVI, reduces human error, detects many defects including solder issues and polarity. | Cannot inspect hidden components (e.g., under BGAs), less effective for densely populated boards. |

X-Ray Inspection | Uses x-rays to see through chip packages and inspect hidden solder joints and internal defects. | Ideal for complex, densely populated boards; reveals hidden solder defects and internal bubbles. | More expensive, complex, suitable mainly for high-volume complex boards. |

Note:

You should always compare the chip’s surface and printing with a known genuine sample. If you see any sign of tampering, do not use the chip.

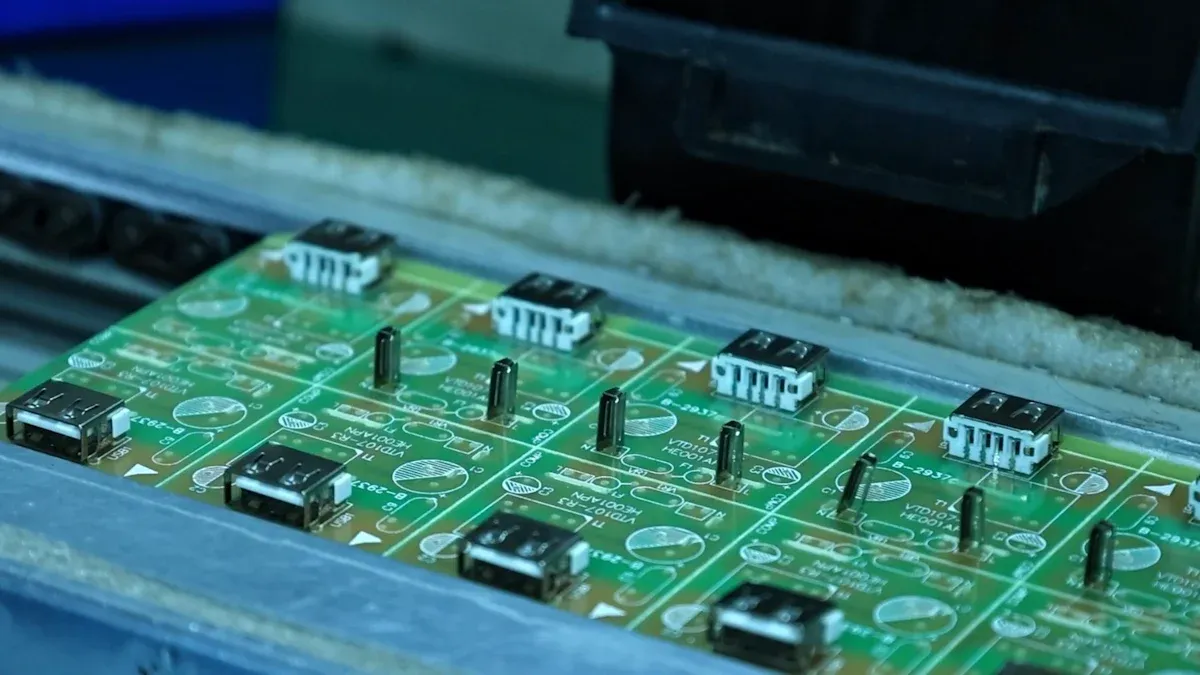

Pins and Packaging

You must examine the pins and packaging of every chip you receive. Counterfeit chips often have inconsistencies in these areas. You can spot many problems by comparing the chip to official datasheets and genuine samples.

Markings and labels may look blurry, have incorrect logos, or miss date codes.

Package color or texture may seem unusual.

Pin configuration or size may not match the official datasheet.

Resurfacing marks, such as grinding or sanding, often appear when someone reprints markings.

Tampering or re-coating can cause differences in finish, such as shiny versus matte surfaces.

A mismatch in pin count or package type is a strong warning sign. For example, a chip marked as 8-pin but found in a 20-pin package is suspicious.

Absence or damage to original mold flashing and crisp embossed characters on package edges may indicate tampering.

Sandblasting or chemical etching to remove original markings often leaves uneven edges or altered pin 1 indicators.

Consistent texture on top and bottom surfaces supports authenticity. Inconsistencies suggest counterfeiting.

In 2025, industry standards for chip packaging and labeling focus on sustainability and smart technology. Many manufacturers use eco-friendly materials, such as biodegradable or recyclable packaging. Smart packaging now includes QR codes, RFID tags, and NFC chips. These features help you verify authenticity and track chips through the supply chain. Minimalist and transparent packaging designs build trust and support e-commerce.

Advanced packaging techniques, such as 2.5D and 3D integration, chiplets, and system-in-package (SiP) designs, are now common. Panel-level packaging (PLP) has replaced wafer-level packaging for many products. PLP uses large rectangular panels, which improve cost efficiency and chip protection. These standards help you identify genuine chips and avoid counterfeits.

Alert:

Always compare pins and packaging with official datasheets and trusted samples. If you find any mismatch, report the chip and do not use it.

Advanced Trends 2025

Authentication Technology

You see rapid changes in chip authentication technology in 2025. Manufacturers now use advanced methods to keep chips secure and original. You find these technologies in many devices, from smartphones to cars and payment systems.

Biometric authentication, such as fingerprint recognition chips with in-display sensing, is now common. You unlock devices or verify identity with just a touch.

Quantum-resistant cryptography protects chips from future cyber threats. This technology keeps your data safe even as computers become more powerful.

AI-powered security features help chips detect and block fake attempts. Machine learning improves accuracy and stops spoofing.

Hardware security modules (HSMs) store sensitive keys and data inside the chip, making it hard for attackers to steal information.

Digital watermarking and blockchain tracking add extra layers of protection. Watermarks embed unique patterns into each chip, while blockchain records every step in the supply chain. This combination makes it almost impossible for counterfeiters to copy or hide fake chips.

Tip:

You should always look for chips with these features. They help you avoid counterfeits and keep your devices secure.

Industry Standards

You must follow new industry standards to ensure chip authenticity and supplier reliability. These standards set clear rules for manufacturing, tracking, and verifying chips.

Standard/Requirement | Description |

|---|---|

Drives secure semiconductor manufacturing and supply chain traceability in the U.S. | |

Develops unique identifiers, supply chain traceability, and authentication protocols | |

Defense Fund Requirements | Secure boot, hardware root-of-trust, anti-tamper packaging, and embedded authentication |

Enforcement | Non-compliance risks losing federal funding and strict traceability enforced by authorities |

International groups like ISO and SAE also create rules to fight counterfeit chips. You see standards such as ISO 27036 and SAE AS5553, which help manage supply chain risks. Regular audits and electronic testing methods help you spot fake parts before they reach your products. Early investment in these standards reduces risks and costs for your business.

Note:

Following these standards protects your supply chain and builds trust with your customers.

Suspected Counterfeits

Immediate Actions

When you suspect a chip may be counterfeit, you must act quickly to protect your supply chain and customers. Start by looking for common warning signs:

Misspelled words, inaccurate logos, or odd markings on the chip.

Scratches, inconsistent fonts, or shapes that do not match genuine parts.

Packaging that looks tampered with or resealed.

Missing or altered serial numbers and logos.

Unusually low prices or offers from unknown sellers.

You may also find advanced security features like optical or electrical watermarks, cryptographic identities, or unique chemical markings. These features help you confirm if a chip is genuine.

If you identify any of these signs, follow these steps:

Quarantine the suspected chips. Keep them separate from your inventory to prevent accidental use.

Notify your internal quality or compliance team right away.

Begin a detailed inspection. Use visual checks, chemical analysis, or electrical testing to confirm your suspicion.

Document your findings. Take clear photos and record all details about the chips and their packaging.

Train your team to recognize and report suspicious parts in the future.

Review your procurement process. Only buy from original manufacturers or authorized suppliers.

Track all components in your supply chain to maintain traceability.

Tip:

Regularly check industry databases like GIDEP, NASA, or ERAI for updates on counterfeit risks.

Reporting

You have a legal duty to report suspected counterfeit chips, especially if you work with government contracts. In the United States, the Federal Acquisition Regulation (FAR) requires you to:

Screen the GIDEP database before making purchases.

Report any counterfeit or suspect parts to both your Contracting Officer and GIDEP within 60 days of discovery.

Follow contract clauses, such as FAR 52.246-26, which outline your reporting duties for critical or mission-essential items.

Avoid sharing trade secrets or confidential information in your reports.

GIDEP serves as the official reporting channel for U.S. and Canadian defense contracts. If you operate outside these markets, check your local regulations for reporting requirements.

Note:

Timely and accurate reporting helps protect the entire industry from counterfeit threats and supports safer supply chains.

You secure your business when you follow a clear process to identify a brand new original chip supplier. Start with supplier verification, regular audits, and chip authenticity checks using advanced tools. Trusted suppliers protect your systems and reputation. Stay alert to new industry trends and technologies, such as digital product passports and traceability systems. These steps help you avoid counterfeit risks and keep your supply chain strong. Always choose vigilance and keep learning to stay ahead.

FAQ

How do you verify a chip supplier’s authenticity?

You should check business licenses, legal documents, and physical addresses. Ask for references and review third-party audits. Always compare supplier information with official records. Use only trusted channels for purchases.

What tools help you inspect chip authenticity?

You can use optical microscopes, X-ray machines, and automated inspection systems. These tools help you spot surface defects, hidden damage, and mismatched markings. Always compare results with genuine samples.

Why do you need to check chip packaging?

Packaging often reveals counterfeits. You should look for mismatched labels, unusual textures, or missing codes. Compare packaging with official datasheets. Authentic packaging uses smart features like QR codes or RFID tags.

What should you do if you suspect a counterfeit chip?

Quarantine the chip. Notify your quality team. Document all findings and report the issue to industry databases like GIDEP. Never use or resell suspicious chips.

Are there industry standards for chip supplier verification?

Yes. You must follow standards like ISO 9001, SAE AS5553, and the CHIPS Act. These set rules for supplier checks, traceability, and reporting. Compliance helps you avoid risks and build trust.

See Also

Key Advances Boosting Homegrown Memory Chip Production 2025

Current Developments Influencing Analog Integrated Circuits 2025

New Directions In Automotive Chip Technology Innovations