What is an IC Circuit Board and How Does It Work

An ic circuit board is a type of printed circuit board assembly that holds and connects integrated circuits and other electronic parts. You use this board to route electrical signals and support the tiny chips that power your devices. Today’s ic circuit boards take advantage of new technology, such as:

Laser direct imaging for sharper features

Additive manufacturing for less waste

3D-printed electronics for complex designs

These advances help you get smaller, more reliable, and faster electronics.

Key Takeaways

An IC circuit board holds tiny chips and parts that work together to process data and control devices.

Copper traces on the board act like roads, carrying electrical signals and power to each component.

Different board types and IC packages help fit designs into small spaces and manage heat and signals.

IC circuit boards power many devices, from smartphones to industrial machines, making them faster and smarter.

Choosing and caring for the right board improves your device’s performance, reliability, and lifespan.

IC Circuit Board Components

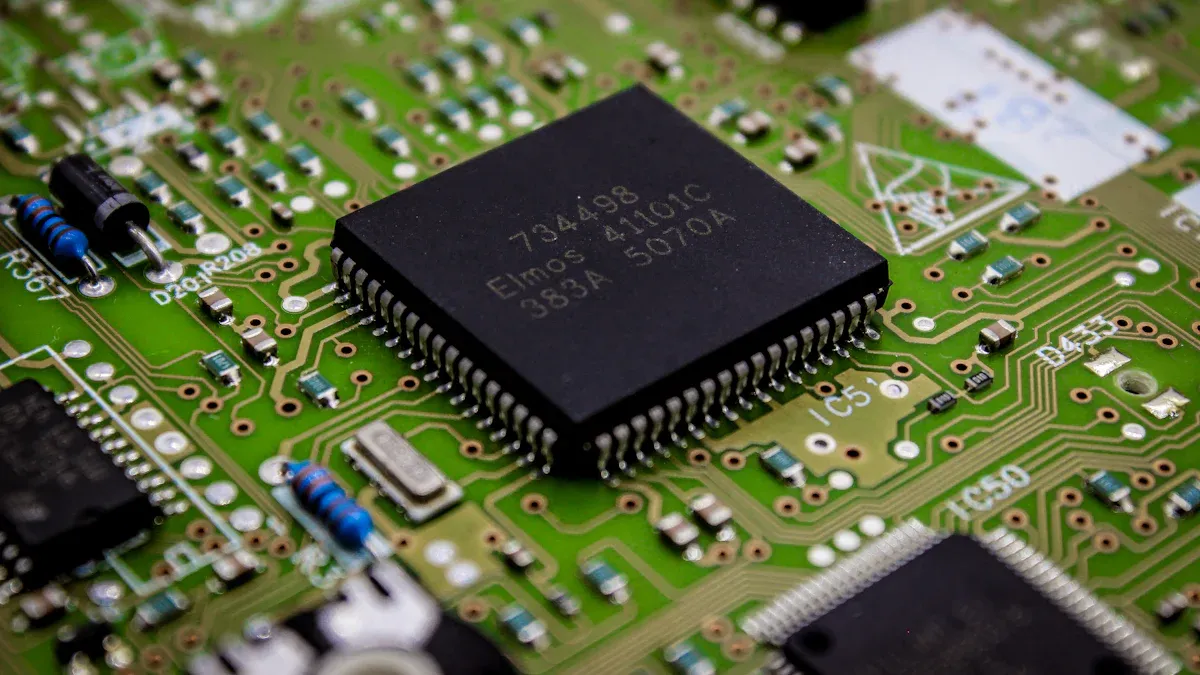

Integrated Circuits

Integrated circuits, or ICs, are the main parts of your ic circuit board. You can think of them as tiny chips that hold thousands or even millions of electronic parts like transistors, resistors, and capacitors. These chips handle important jobs such as processing data, amplifying signals, or controlling timing. When you use a device, the ICs work together to make sure everything runs smoothly and quickly.

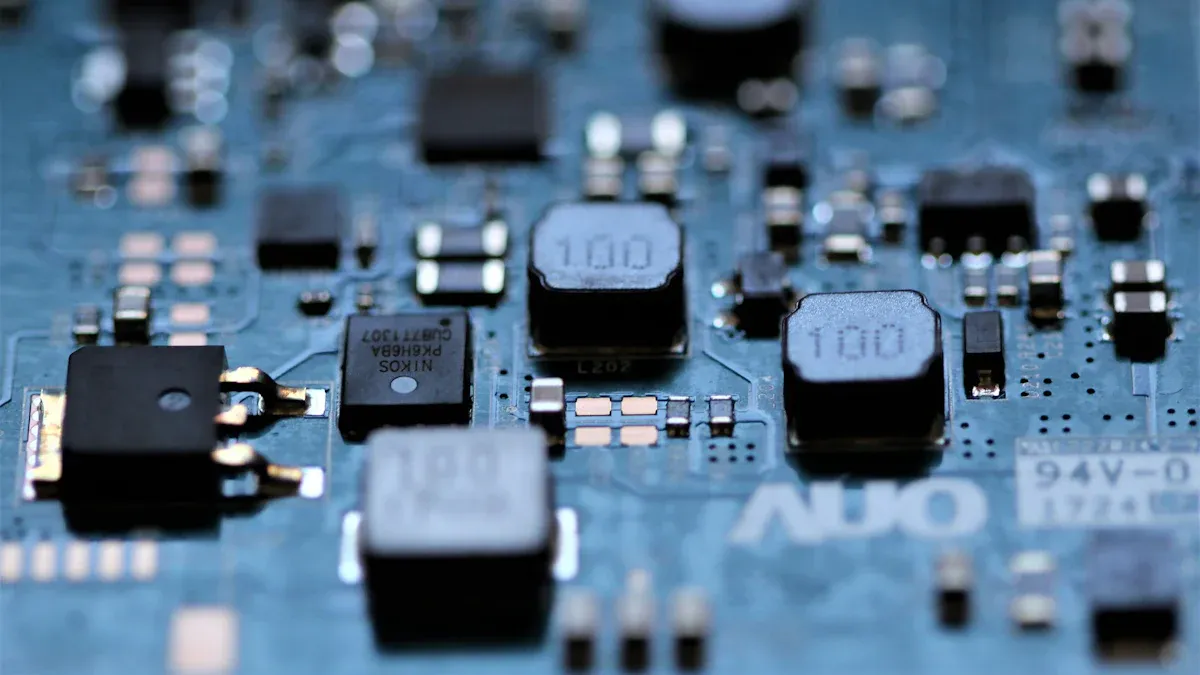

Other Components

You will find many other parts on an ic circuit board that help the ICs do their job. These include:

Resistors: They control the flow of electric current and help set the right voltage levels.

Capacitors: They store and release energy, filter signals, and smooth out voltage changes.

Inductors: They help with filtering and managing signals, especially in power circuits.

Transistors: They act as switches or amplifiers, making sure signals are strong and clear.

Diodes: They let current flow in only one direction, which protects your circuit from damage.

Connectors and Ports: These let you connect your board to other devices, like USB or HDMI cables.

Voltage Regulators: They keep the voltage steady so your ICs and other parts work safely.

Sensors and Actuators: Sensors detect things like light or temperature, while actuators turn electrical signals into actions.

Note: All these components connect through copper traces on the board. These traces act like tiny roads, letting signals travel between parts.

Board Structure

The physical structure of your ic circuit board is just as important as the parts on it. Most boards use several layers to fit all the needed connections and keep signals clean. Here’s what you might see:

Multilayer Boards: These have more than one layer of copper traces, which helps with complex designs.

High-Density Interconnect (HDI): This design packs more connections into a small space, perfect for advanced electronics.

Materials: Most boards use FR4, a strong and reliable base. Some special boards use ceramic for high heat or fast signals.

Shape and Size: Boards can be rectangular or custom-shaped to fit inside your device.

Thermal Management: Good layout and spacing help keep parts cool and working well.

Traces, Pads, and Vias: These features connect everything together and make sure signals move where they should.

When you put all these pieces together, your ic circuit board can route signals, manage power, and perform complex tasks with speed and accuracy.

IC Circuit Board Function

Signal Flow

When you look at an ic circuit board, you see a network of copper lines. These lines are called traces. They act like highways for electrical signals. Each trace connects different parts of the board. When you turn on your device, signals travel along these traces. The signals move from one component to another. For example, a signal might go from a sensor to an integrated circuit. The ic circuit board makes sure each signal reaches the right place at the right time.

Tip: Clean traces and good connections help signals move faster and with less noise.

You can find both analog and digital signals on the same board. Analog signals change smoothly, like the sound from a microphone. Digital signals switch between on and off, like the ones in a computer. Some boards use mixed-signal ICs. These chips handle both types of signals. This lets your device do more complex tasks.

Power Distribution

Every part on your ic circuit board needs power. The board has special traces for power and ground. These traces deliver electricity from the power source to each component. Voltage regulators on the board keep the power steady. If the voltage changes too much, your device might not work right.

You often see capacitors near the ICs. These small parts store energy and release it when needed. They help smooth out any bumps in the power supply. This keeps your board running safely and prevents damage.

Here is a simple table showing how power moves on the board:

Power Source | Voltage Regulator | ICs and Components |

|---|---|---|

Battery or Adapter | Keeps voltage steady | Uses power to work |

Note: Good power distribution helps your device last longer and work better.

Core Tasks

The ic circuit board does many important jobs. The main tasks depend on the ICs you use. Some ICs process data, like the chips in your phone or computer. Others amplify signals, which is useful in speakers or radios. Timing ICs keep everything in sync, so your device works smoothly.

You might use analog ICs for tasks like audio processing. Digital ICs handle things like calculations and logic. Mixed-signal ICs combine both, letting your device talk to the real world and process information at the same time.

Processing: Chips handle data and run programs.

Amplification: Circuits boost weak signals.

Timing: Special chips keep actions in order.

Control: ICs manage sensors, motors, and displays.

When you put all these tasks together, your ic circuit board becomes the brain of your device. It lets you enjoy fast, reliable, and smart electronics every day.

Types and Packaging

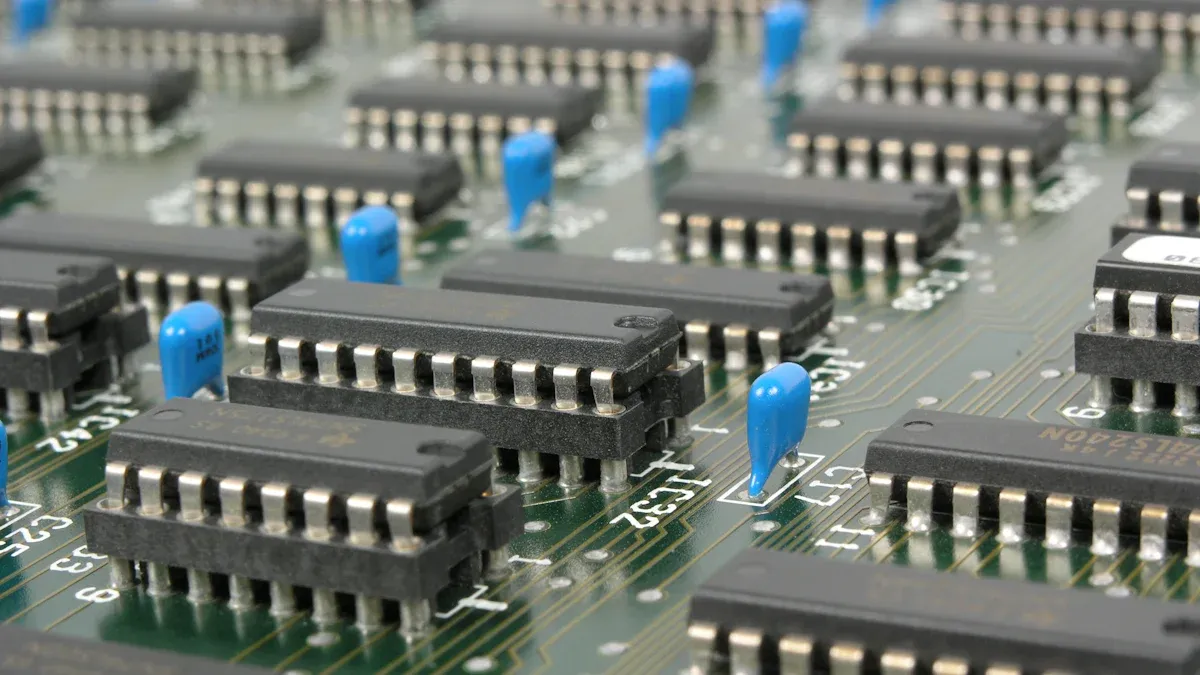

Board Types

You can choose from several board types to match your project’s needs. The most common are single-layer, double-layer, and multi-layer boards. Single-layer boards have one layer of copper traces. Double-layer boards add another layer, which helps with more complex circuits. Multi-layer boards stack several layers together. This design saves space and improves performance. You often see multi-layer boards in computers and smartphones.

Some boards use high-density interconnect (HDI) technology. HDI boards pack more connections into a smaller area. This makes them perfect for advanced electronics where space is tight. Flex boards bend and twist, so you can fit them into unusual shapes or moving parts.

Note: Multi-layer and HDI boards help manage heat and signal flow in powerful devices.

IC Packages

IC packages come in many shapes and sizes. The package type affects how you mount the chip and how well it handles heat and signals. Here is a table comparing some common IC packages:

Package Type | Mounting Style | Pin Count Range | Footprint Size | Thermal Performance | Impact on Board Design and Performance |

|---|---|---|---|---|---|

DIP | Through-hole | 8 to 64 | Larger | Low | Needs more space and wider traces; simple but less efficient. |

QFP | Surface-mount | 32 to 256 | Moderate | Moderate | Requires careful layout for heat and signal quality. |

BGA | Surface-mount | 100 to 1000+ | Smaller | High | Allows more pins and better heat control; needs precise design. |

CSP | Surface-mount | 16 to 200 | Smallest | High | Demands advanced layout and heat management. |

You should know that advanced packages like BGA and CSP need special design steps. These include thermal vias, controlled impedance traces, and careful spacing. These features help manage heat and keep signals clean. Choosing the right package balances size, performance, and cost.

Specialized Boards

Some projects need boards built for tough jobs. Specialized boards handle high power, high frequency, or harsh environments. Here is a quick look at some types:

Specialized PCB Type | Key Features / Design Demands | Typical Applications / Use Cases |

|---|---|---|

Multi-Layer PCBs | Good heat control, long life, compact size | Power systems, battery management |

Heavy Copper PCBs | Thick copper, handles high current, strong | Automotive, industrial, medical, marine |

HDI (High-Density Interconnect) | Dense design, manages heat well | Battery management, voltage converters |

Flex PCBs | Flexible, good for moving parts | Energy storage, battery systems |

Ceramic PCBs | High voltage isolation, tough in harsh places | High voltage control, transformers, harsh environments |

Tip: When you design for special needs, you must think about heat, voltage, and durability. Regulatory standards like RoHS also guide your material choices and processes to keep devices safe and eco-friendly.

Applications

Consumer Devices

You use electronics every day that rely on advanced circuit boards. Smartphones, tablets, and laptops all depend on these boards to process information, store data, and connect to other devices. Game consoles and smart TVs also use them to deliver fast graphics and smooth performance. In wearable devices like fitness trackers and smartwatches, small and efficient boards help save battery life and fit into tiny spaces. Home appliances, such as washing machines and refrigerators, use these boards to control settings and improve energy efficiency.

Tip: When you choose a new device, look for features like fast response and long battery life. These often come from smart circuit board design.

Industrial Use

Factories and warehouses use circuit boards to automate and control many tasks. You find these boards in:

Robots that move parts or assemble products

Packaging lines that sort and seal items

Printing machines that manage high-speed jobs

Timers and sensors that keep processes on track

Automated control systems that monitor and adjust machines

Forklifts and other vehicles that move goods safely

These boards help you improve safety, boost productivity, and reduce errors in industrial settings.

Communication

Modern communication depends on reliable circuit boards. You see them in smartphones, routers, and even smart home devices. These boards handle both wired and wireless connections, making sure your messages and data travel quickly and safely. The table below shows how different interfaces work in communication devices and infrastructure:

Interface Type | Role in Communication Devices and Infrastructure |

|---|---|

Wired Interfaces (e.g., UART, SPI, I2C, USB, Ethernet) | Enable reliable data, power, and control signal transmission between components within devices, ensuring low-loss and compatible communication pathways. |

Wireless Interfaces (e.g., Bluetooth, Wi-Fi, Z-Wave) | Facilitate cable-free communication between devices, supporting protocols for smart home and IoT applications with features like mesh networking and low power consumption. |

PCB Interfaces (Protocols and Signal Lines) | Define methods for data exchange over physical connections, crucial for efficient protocol layering, minimizing signal loss and crosstalk, and supporting advanced communication techniques. |

Connectors (Physical Hardware) | Provide the physical link for PCB interfaces but are distinct from the communication protocols themselves. |

These features let you enjoy fast internet, clear calls, and smart connections at home and work.

IC Circuit Board vs. PCB

Key Differences

You might wonder how an ic circuit board compares to a regular PCB. Both types support and connect electronic parts, but they serve different roles. An ic circuit board always includes integrated circuits as its main feature. A standard PCB may only have basic components like resistors or capacitors.

Here is a table to help you see the differences:

Feature | IC Circuit Board | Standard PCB |

|---|---|---|

Main Component | Integrated circuits (ICs) | Discrete components |

Complexity | High | Low to medium |

Size | Usually smaller | Can be larger |

Function | Advanced processing | Basic connections |

Tip: If your project needs smart features or fast processing, you should choose an ic circuit board.

Selection Tips

You need to pick the right board for your project. Start by listing what your device must do. If you need data processing, signal control, or smart functions, look for a board with integrated circuits. For simple tasks, a basic PCB might work.

Check the size and shape you need.

Think about how much power your device will use.

Make sure the board supports all your components.

Ask if you need special features like heat control or flexible design.

Remember: The right choice saves you time and money.

Maintenance

You can keep your board working longer with good care. Clean the board with a soft brush to remove dust. Check for loose parts or broken traces. If you see any damage, fix it right away. Store your boards in a dry place to prevent rust or corrosion.

Handle boards by the edges to avoid static.

Use proper tools when you repair or replace parts.

Test your board after any repair to make sure it works.

Regular checks help you avoid bigger problems later.

An ic circuit board lets you build powerful, compact devices by connecting many parts on a single board. When you understand its components and how they work together, you can design better electronics.

Remember: Careful layout, quality materials, and thorough testing help you improve performance and reliability.

You see ic circuit boards in everything from smartphones to industrial machines. These boards drive the miniaturization and speed that modern electronics need.

FAQ

What is the main job of an IC circuit board?

You use an IC circuit board to connect and support chips and other parts. The board routes signals and power so your device can process data, control actions, and work safely.

How do you know if your board has an integrated circuit?

Look for small black chips with many legs or pins. These chips often have codes or numbers printed on top. You can also check your device’s manual for a parts list.

Can you repair a damaged IC circuit board?

You can fix simple problems like loose parts or broken traces. Use a soldering iron and replacement parts. For damaged ICs, you may need special tools or help from a technician.

Why do some boards have many layers?

Many layers help you fit more connections in a small space. This design keeps signals clean and lets your device run faster. You see this in smartphones and computers.

What happens if you use the wrong IC on your board?

The board may not work or could get damaged. Always match the IC’s type, size, and voltage to your board’s design. Check datasheets before you install any chip.

See Also

Understanding Optocoupler IC Chips And Their Functionality

How Integrated Battery Monitor ICs Operate And Function

Exploring The Purpose And Function Of IC Demodulators

Gate Inverter IC Chips Explained And Their Working Process

Battery Charge Controller ICs And Their Operational Mechanism