What is a Hotswap Controller Chip and How Does It Work

A Hotswap Controller chip lets you safely add or remove parts from a powered system without shutting it down. This chip controls power flow and protects sensitive electronics from sudden current surges. You avoid damage and keep your system running, even under tough conditions. The table below shows how these chips, along with TVS diodes, handle extreme power events to protect equipment and maintain uptime:

Parameter | Value / Description |

|---|---|

Peak Pulse Power Rating | |

Pulse Current Values (IP) | 120A, 160A, 480A |

Maximum Ambient Temperature | Up to 125°C |

Power Margin Requirement | 50% margin above peak power |

Key Takeaways

A Hotswap Controller chip lets you safely add or remove parts from a powered system without shutting it down, protecting your equipment from sudden current surges.

The chip controls inrush current by slowly powering new components, preventing damage and ensuring smooth startup every time you insert a board or module.

It provides fast fault protection by detecting overcurrent, short circuits, and overheating, quickly shutting down power to avoid system damage.

Many chips offer real-time monitoring and alerts, helping you spot problems early and keep your system running reliably.

Hotswap Controller chips are essential in servers, telecom, live backplanes, and modular electronics to maintain uptime and simplify maintenance.

Hotswap Controller Chip Basics

What It Is

A Hotswap Controller chip is a small electronic device that helps you safely connect or disconnect parts of a system while it is still powered on. You do not need to turn off the whole system to add or remove a board or module. This chip manages the flow of electricity and keeps your equipment safe from sudden changes in current or voltage.

When you use a Hotswap Controller chip, you protect sensitive electronics from damage. You also make sure your system keeps running, even if you need to swap out a part.

Here are some key functions that show what a Hotswap Controller chip does:

Controls inrush current by slowly charging the board’s capacitor. This prevents large current surges when you insert a new component.

Isolates faults like overcurrent, overvoltage, or undervoltage by disconnecting the faulty part or sending an alert.

Manages power by watching each unit and switching to backup power if needed, so your load does not get interrupted.

Provides electrostatic discharge (ESD) protection to keep sensitive parts safe during insertion or removal.

Monitors status with indicators or system interfaces, letting you know if power is good or if there is a problem.

Core Purpose

The main goal of a Hotswap Controller chip is to keep your system safe and reliable when you add or remove parts while power is on. You avoid sudden spikes in current that can harm your equipment. The chip also helps you manage faults and keep your system running smoothly.

You can see how these chips work by looking at real-world benchmarks. For example, the ADM1177 hot-swap controller uses a soft-start function to slowly increase the current, which keeps the load safe. It uses a timer to limit how long an overcurrent event can last, protecting the system from damage. The chip only lets power flow after the supply voltage is high enough, then it charges the load capacitor in a controlled way.

Benchmark Example | Description | Key Reliability Features | Load Condition Illustration |

|---|---|---|---|

MAX4370 Hot-Swap Controller | Limits inrush current during startup and monitors current continuously. | Dual overcurrent protection, temperature stability, circuit breaker, autoretry, power-control, I²C. | Start-up waveforms show controlled current and fault response under load. |

MAX5902 Hot-Swap Controller | Gradually enhances MOSFET to limit inrush current based on load capacitance. | Thermal shutdown, undervoltage lockout, power-good signal, circuit breaker with autoretry or latch-off. | Load voltage rises at a controlled rate; faults detected by voltage drop across MOSFET. |

ADM1177 Hot-Swap Controller | Soft-start ramps current; timer protects MOSFET during overcurrent events. | Soft-start, charge pump, timer for safe operation, programmable enable voltage, fault shutdown. | Example: 12V supply, 30A trip, 2000μF load; controlled charging and current limiting. |

Capacitor-Zener-FET Discrete Circuit | Limits inrush current by ramping gate voltage during power-up. | Simple inrush limiting at power-up only; needs fuse for fault protection. | Charging rate controlled by gate voltage; current limiting only at startup. |

PNP Transistor & Current-Sense Resistor | Senses and limits current continuously with PNP transistor. | Always-on current limiting; temperature-dependent; extra power loss in sense resistor. | Continuous current monitoring and limiting under changing load conditions. |

These examples show that a Hotswap Controller chip gives you reliable protection and smooth operation, even when load conditions change. You can trust these chips to keep your system safe and running, no matter what you plug in or remove.

How a Hotswap Controller Chip Works

Inrush Current Control

When you insert a new board or module into a live system, a sudden rush of current can flow into the load’s capacitors. This surge, called inrush current, can damage sensitive parts or cause the system to shut down. A Hotswap Controller chip manages this by sensing the current through a small resistor. It uses this information to control a MOSFET, which acts like a gate for the power.

You will notice that the chip keeps the voltage drop across the sense resistor within a safe range, usually between 25mV and 50mV. Some chips detect short circuits at even lower voltages. For example, one controller limits inrush current to about 3.4A, which matches a 16mV drop across the resistor. Another controller can set the limit to 2.8A with a 22.2mV drop. This careful control lets the chip ramp up the voltage slowly, protecting your system from sudden spikes.

The chip can also adjust how fast it allows the voltage to rise, known as slew rate control. You can program current limits and set how the chip responds to different types of surges. If a fast, high current fault happens, the chip shuts down power right away. If a smaller glitch occurs, it may wait a short time before acting. This flexibility helps you keep your system safe during every insertion.

Tip: By using a Hotswap Controller chip, you make sure that every new component gets powered up smoothly, without risking damage to your system.

Power-Up Sequencing

Power-up sequencing is another important job for the Hotswap Controller chip. When you add a new board, the chip does not just turn on power instantly. Instead, it checks that the supply voltage is high enough and that no faults exist. Only then does it allow power to flow to the load.

You can set the chip to follow a specific order when powering up different parts of your system. This prevents problems that can happen if some parts turn on before others. The chip uses timers and voltage monitors to manage this process. It charges the load’s capacitors in a controlled way, making sure the voltage rises smoothly.

If the chip detects a problem, such as low voltage or a fault, it stops the power-up process. This keeps your system stable and prevents damage. You get a reliable startup every time you insert a new module.

Fault Protection

Fault protection is a key feature that keeps your system running safely. The Hotswap Controller chip watches for several types of faults, including overcurrent, short-circuit, and overheating. When it senses a problem, it acts quickly to protect your equipment.

Here is a table showing how the chip handles different faults:

Fault Protection Type | Description | Key Metrics / Thresholds |

|---|---|---|

Overcurrent Protection | Limits or disconnects power if current gets too high. | Current limit 0.5–3A; eFuse up to 3× normal; fast action |

Short-Circuit Protection | Cuts off power almost instantly if a hard short occurs. | Response time as fast as 5µs; immediate shutoff |

Thermal Shutdown | Turns off power if the chip gets too hot. | Shutdown at 150–180°C; restarts after cooling |

You also get other protections, such as under voltage lockout and fault signaling. The chip can send alerts if it finds a problem, and it can show you when power is good. These features help you spot issues early and keep your system safe during live operation.

Note: Fast fault detection and response are critical. The chip can shut down power in microseconds, stopping damage before it starts.

With these protections, you can trust the Hotswap Controller chip to prevent voltage spikes and system faults. It gives you peace of mind when working with live systems.

Functions & Protections

Overcurrent & Short-Circuit

You rely on a Hotswap Controller chip to protect your system from dangerous current spikes. When too much current flows, the chip reacts fast to stop damage. It uses a sense resistor to measure current and sets strict limits. For example, some chips set a current limit at 5.6 A, controlled by a resistor. Inrush current at startup stays low, around 0.66 A, which helps protect the main transistor. The chip can detect two levels of overcurrent, using thresholds like 50 mV and 150 mV. If a short circuit happens, the chip responds in as little as 150 to 320 nanoseconds. This speed is about a million times faster than a regular fuse. You get better protection and less stress on your equipment.

Feature | Value / Detail | Benefit |

|---|---|---|

Current Limit | 5.6 A | Prevents overloads |

Inrush Current Limit | 0.66 A | Reduces startup stress |

Overcurrent Thresholds | 50 mV, 150 mV | Two-level fault detection |

Short-Circuit Reaction Time | Ultra-fast shutdown | |

Reset Capability | Resettable | No need to replace fuses |

eFuse Integration

Many modern systems use eFuse technology for even more precise protection. You can program timers to ignore short, harmless current spikes, so the chip only reacts to real faults. eFuses share current between power switches, which keeps heat low and spreads the load. The controller checks total current and balances it, so your system stays reliable. You also get features like adjustable slew rate, which controls how fast voltage rises and keeps inrush current low. eFuses protect against overvoltage, overcurrent, and overheating. They also log faults and monitor the health of the power switches, making it easier to spot problems early.

Key eFuse features:

User-programmable blanking timer to avoid false trips

Active current sharing for balanced load

Fast analog current monitoring with ±3% accuracy

Adjustable output slew rate for safe startups

Integrated fault logging for predictive maintenance

Status Monitoring

You need to know the health of your system at all times. Hotswap Controller chips offer real-time monitoring and feedback. They check voltage, current, and temperature many times each second. For example, some chips measure current and voltage ten times per second and store the data for you to read. The chip can alert you right away if it finds a problem, like overcurrent or undervoltage. You can use software tools to see these alerts and logs. This helps you fix issues before they cause downtime.

Monitored Parameter | Description | Update Rate | How You Get Data |

|---|---|---|---|

Current | Measures board current | 10 times/second | Read via I2C |

Output Voltage | Checks output voltage | 10 times/second | Read via I2C |

Fault Conditions | Logs overcurrent, undervoltage, etc | On event | Alerts host immediately |

Tip: Real-time monitoring lets you catch problems early and keep your system running smoothly.

Applications of Hotswap Controller Chips

Server & Telecom Systems

You depend on servers and telecom systems to run without interruption. If you need to replace a power module or add a new board, you want the system to keep working. A Hotswap Controller chip helps you do this safely. It controls the power flow and protects against sudden surges or faults. Many data centers use these chips to keep their equipment running 24/7.

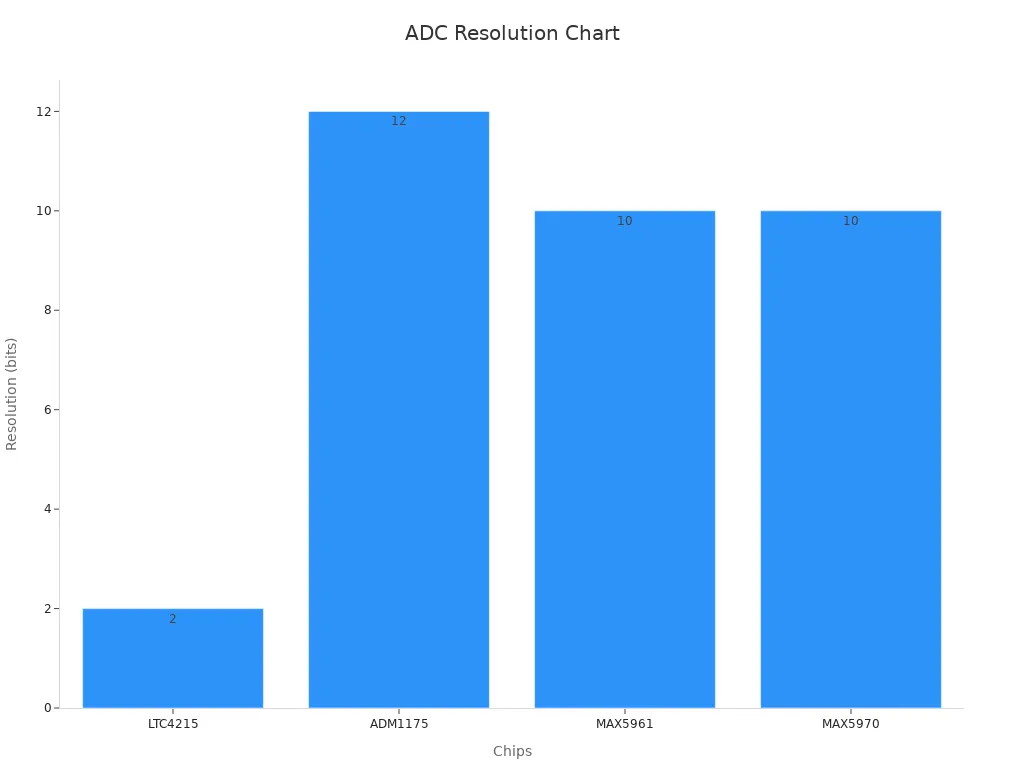

You can see how different chips compare by looking at their features. The table below shows key parameters for several popular models:

Parameter | LTC4215 | ADM1175 | MAX5961 | MAX5970 |

|---|---|---|---|---|

ADC Resolution (bits) | 2 | 12 | 10 | 10 |

Conversion Rate (Hz) | 10 | N/A | 10,000 | 10,000 |

History "Depth" (samples) | 1 | 1 | 50 | 50 |

INL (Integral Nonlinearity) | 0.2 LSB, 0.5 LSB | N/A | 0.5 LSB | 0.5 LSB |

Full-Scale Error (voltage, current) | ±5.5 LSB, ±5.0 LSB | ±60 LSB, ±100 LSB | ±10 LSB, ±30 LSB | ±10 LSB, ±30 LSB |

Interface | I²C/SMBus™ | I²C | I²C/SMBus™ | I²C/SMBus™ |

High-Speed Voltage Range (V) | 2.9 to 15 | 3.15 to 13.2 | 0 to 16 | 0 to 16 |

GATE Pullup Current (µA) | 20 | 12 | 5 | 5 |

GATE Pulldown Current (mA) | 1 | 2 | 0.5 | 0.5 |

Slow-Trip Circuit-Breaker Threshold (mV) | 25 | 85 | 12.5, 25, 50 (programmable) | 12.5, 25, 50 (programmable) |

Fast-Trip Circuit-Breaker Threshold | N/A | 115 mV | 125%-200% of slow trip | 125%-200% of slow trip |

You can also compare ADC resolution for these chips in the chart below:

Tip: High ADC resolution and fast conversion rates help you monitor power more accurately, which keeps your servers and telecom systems safe.

Live Backplanes

You often find live backplanes in storage arrays and network switches. These systems let you plug in or remove boards while the main system stays powered. If you use a Hotswap Controller chip, you can add or swap boards without causing downtime. The chip manages inrush current and protects against short circuits. You get a stable system, even when you make changes on the fly.

You can:

Add new storage drives without shutting down the system.

Replace faulty network cards while the rest of the system keeps working.

Monitor each slot for faults or power issues.

This approach helps you keep your network or storage running smoothly, even during upgrades or repairs.

Modular Electronics

Many modern devices use modular designs. You might see this in industrial controls, test equipment, or medical devices. Each module can have its own power needs. If you use a Hotswap Controller chip, you protect each module from power surges and faults. You can swap out parts quickly and safely.

Key benefits for modular electronics:

Faster repairs and upgrades

Less risk of damaging sensitive parts

Real-time monitoring for each module

Note: Using these chips in modular systems helps you build safer, more reliable products that are easy to maintain.

You gain many advantages when you use a Hotswap Controller chip in your designs.

You protect your system from damage by limiting inrush current and controlling voltage rise.

You keep your equipment running by avoiding power supply collapse and handling faults quickly.

You get features like undervoltage lockout, thermal protection, and programmable current limits, which help your system stay safe and reliable.

If you want continuous operation and easy maintenance, add a Hotswap Controller chip to your next project.

FAQ

What happens if you do not use a hotswap controller chip?

If you skip the chip, you risk damaging your electronics. Sudden current surges can burn components or cause system crashes. You may also lose important data or face unexpected downtime.

Can you use a hotswap controller chip with any power supply?

You can use most hotswap controller chips with standard DC power supplies. Always check the chip’s voltage and current ratings. Make sure they match your system’s needs for safe operation.

How do you know if a hotswap controller chip is working?

You can check status LEDs or read data from the chip using I²C. Many chips send alerts if they detect a problem. You will see normal operation if the system powers up smoothly and no faults appear.

Do hotswap controller chips need extra cooling?

Most chips work well without extra cooling in normal conditions. If your system runs hot or uses high current, you may need a heatsink or better airflow. Always follow the manufacturer’s guidelines.

See Also

Understanding The Role And Operation Of Current Controller Chips

Exploring The Purpose And Functionality Of Interface Control Chips

Step By Step Guide To Replacing WQFN40 Switch Chips In Nintendo

A Comprehensive Overview Of Communication Chips And Their Functions

An Introduction To Computer Chips And Their Operational Mechanisms