HM24-1A69-20-6: Essential Specs You Need to Know

This article details the critical specifications of the HM24-1A69-20-6 high voltage reed relay. It features a single Form A contact, a 24V coil, and an impressive 100W/3A/10kV contact rating. Understanding these precise specifications is crucial for proper application and optimal performance in high-voltage electronic designs. Ignoring them can lead to significant issues, such as contact damage from hot switching or reduced voltage stand-off over time. Engineers and designers working with demanding applications benefit greatly from knowing these specs. This knowledge prevents common failures and ensures reliable operation.

Key Takeaways

The HM24-1A69-20-6 is a strong relay. It can switch up to 10,000 volts safely.

This relay uses a 24-volt power supply. This makes it work with many common systems.

It has sealed contacts. This protects it from dirt and water. This helps it last a long time.

The relay switches very fast. It also keeps electricity separate. This makes it safe and reliable.

It can handle tough conditions. It resists shock and vibration. It works in many temperatures.

HM24-1A69-20-6 Electrical Specifications

The HM24-1A69-20-6 stands out as a high-voltage reed relay. Its electrical specifications define its performance and suitability for demanding applications. Engineers must understand these details for proper circuit design.

Contact Form: 1 Form A (SPST-NO)

The HM24-1A69-20-6 features a 1 Form A contact configuration. This means it has a Single Pole, Single Throw, Normally Open (SPST-NO) contact. In its normal, unenergized state, the contacts remain open. When the coil receives power, the contacts close, completing the circuit. This simple configuration offers reliable switching for many applications.

Coil Voltage: 24 VDC

This relay operates with a 24 VDC coil voltage. This standard voltage makes it compatible with many industrial and control systems. Applying 24 VDC to the coil energizes the relay, causing the contacts to switch. Designers must ensure their power supply provides a stable 24 VDC for consistent operation.

High Voltage Switching and Breakdown

The HM24-1A69-20-6 handles impressive voltage levels. It offers a 10 kVDC/AC switching voltage. This means it can safely switch circuits carrying up to 10,000 volts. Its breakdown voltage reaches 15 kVDC. This rating indicates the maximum voltage the relay can withstand across its open contacts without arcing or insulation failure.

Misensor's high-voltage reed relays are capable of switching voltage up to 10KV. Coto Technology's 5500 Series high-voltage reed relays offer a switching voltage of up to 7.5KV. Pickering's Series 68 high voltage reed relays are capable of switching up to 6kV.

The HM24-1A69-20-6 compares favorably with other high-voltage relays in the market. The leakage distance, which is the shortest path along the surface of an insulating material between two conductive parts, measures greater than 32mm. This large distance helps prevent surface arcing. Some versions of this relay also feature a breakdown voltage up to 4 kVDC and include internal magnetic shielding. This shielding protects against external magnetic fields, ensuring stable operation.

Contact Rating: Power and Current

The HM24-1A69-20-6 boasts a robust contact rating. It handles a maximum rated power of 100W. It also switches a maximum current of 3A. These ratings indicate the power and current the contacts can safely manage without damage.

The contact material significantly influences a reed relay's maximum contact rating.

Contact Material | Maximum Contact Rating (VA) |

|---|---|

Plated and Sintered Gold | 15 |

Mercury-Wetted | 50 |

Tungsten | High loads |

Plated and sintered gold contacts are common. They offer a 15 VA rating and a long operational life. Tungsten contacts excel at switching high loads, such as lamps and solenoids. Mercury-wetted contacts provide a higher rating of 50 VA. They also eliminate operate bounce and maintain consistent, low contact resistance. However, mercury-wetted contacts are position-sensitive. The 100W rating of the HM24-1A69-20-6 suggests a robust contact material, likely tungsten or a specialized alloy, designed for high-power applications.

Insulation Resistance and Isolation

Insulation resistance is a critical specification for high-voltage relays. It measures how well the relay's insulation prevents current leakage. High insulation resistance ensures excellent isolation between the coil and contacts, and between open contacts.

The Coto Technology 9104 series high-voltage molded SIP reed relays specify a minimum insulation resistance of 10^11 Ω. These relays are explicitly listed for use in medical equipment applications.

The Standex Electronics SHV Series reed relay offers an insulation resistance greater than 5 × 10^11 Ω. This series is suitable for medical equipment, including applications like portable defibrillators and diagnostics.

Specialized high-voltage reed relays can switch up to 10,000 VDC. Their breakdown voltage ratings reach 15,000 VDC. These relays are crucial in medical technologies where insulation integrity and safety are paramount. The BH Series reed relay, designed for high-precision switching, features a breakdown voltage of 3 kVDC and above. It is noted for its ultra-low leakage current, which falls within the picoampere range. This low leakage current results from its high insulation resistance of up to 10 TΩ. The HM24-1A69-20-6's high breakdown voltage implies excellent insulation resistance and minimal leakage current, vital for safety and performance in sensitive circuits.

Switching Speed

Reed relays are known for their fast switching speeds. The HM24-1A69-20-6 is no exception. Fast switching minimizes arc duration and reduces wear on the contacts.

Specification | Value |

|---|---|

Operate Time | 0.5 ms typical |

Release Time | 0.1 ms typical |

The typical operate time for a high-speed reed relay is 0.5 milliseconds. The typical release time is even faster, at 0.1 milliseconds. These rapid response times make the HM24-1A69-20-6 suitable for applications requiring quick and precise control.

HM24-1A69-20-6 Mechanical Specifications

The mechanical specifications of a reed relay are just as important as its electrical characteristics. These details ensure the relay fits correctly and performs reliably in its intended environment. Designers must consider these physical attributes for successful integration.

Physical Dimensions and Footprint

The HM24-1A69-20-6 has precise physical dimensions. It measures 68mm in length, 19mm in width, and 19.8mm in height. These exact measurements are crucial for circuit board layout and enclosure design. Engineers use these figures to ensure the relay fits within the available space. A proper footprint prevents interference with other components.

Operating Temperature Range

Electronic components must operate reliably across various temperatures. High-voltage reed relays often work in demanding industrial settings. The HM24-1A69-20-6 is designed to withstand a wide temperature range. For example, many high-voltage reed relays, like the 9270 Series, operate stably from -40ºC to 125ºC. This broad range makes them suitable for industrial applications. These include Automated Test Equipment, Instrumentation, and Telecom markets. Such robust temperature performance ensures consistent operation even in harsh conditions.

Shock and Vibration Resistance

Relays in industrial or mobile applications often face physical stress. The HM24-1A69-20-6 offers strong resistance to both shock and vibration. It withstands a shock of 50g for a 1/2 sine wave duration of 11ms. This rating means the relay can survive sudden impacts without damage. Its vibration resistance is a maximum of 20. This ensures stable performance even when subjected to continuous shaking.

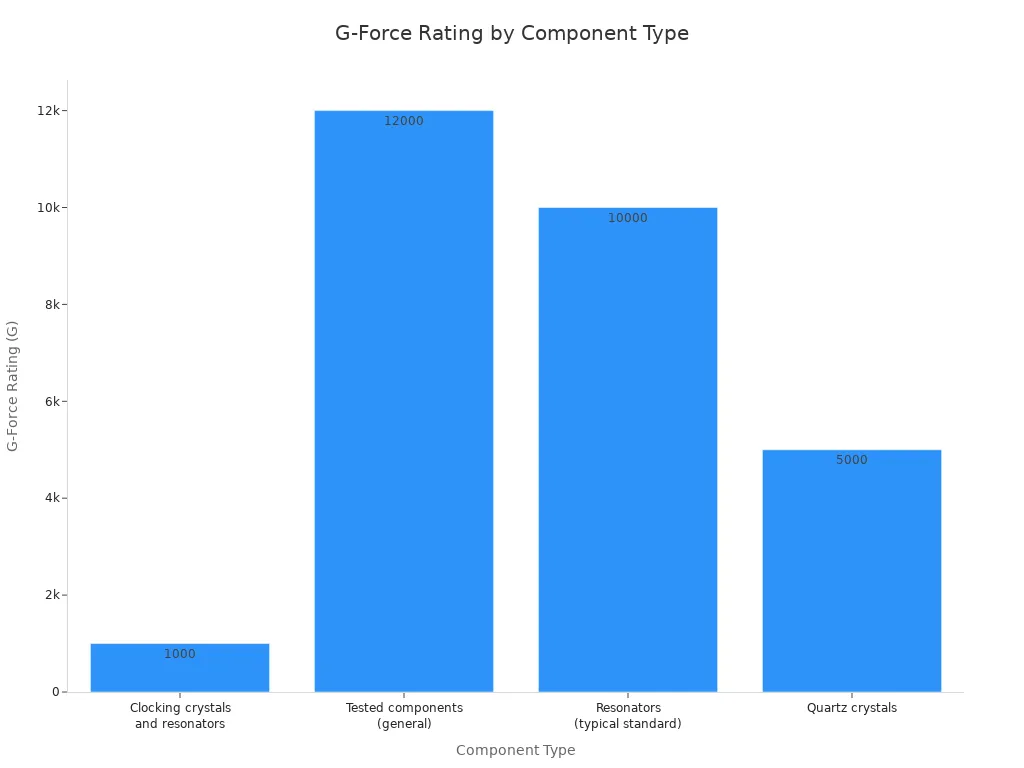

Different electronic components have varying shock resistance levels:

Component Type | G-Force Rating | Duration |

|---|---|---|

Clocking crystals and resonators | 1,000 G | milliseconds |

Tested components (general) | 12,000 G | N/A |

Resonators (typical standard) | 10,000 G | 200 microseconds |

Quartz crystals | 5,000 G | 300 microseconds |

The HM24-1A69-20-6's shock rating shows its durability in challenging environments.

Life Expectancy

A reed relay's life expectancy depends on several factors. The way a relay switches current significantly impacts its operational lifespan. Understanding these factors helps predict how long the relay will last in an application.

Hot Switching: This occurs when the relay switches a live circuit. It greatly reduces the relay's life. Hot switching creates uneven contact surfaces. This concentrates switching energy and can lead to contact welding. Reed relays have lower hot switch capacity compared to electromagnetic relays (EMRs).

Resistive Loads: The lifespan with resistive loads depends on the percentage of rated power.

Less than 10% of rated power: The lifespan is close to the mechanical life.

30% of rated power: The lifespan reduces by a factor of ten compared to mechanical life.

100% of rated power: The lifespan matches the datasheet value for the switching system.

Inductive Loads: These loads generate a back EMF spike when the circuit opens. This spike significantly affects lifespan. The lifespan strongly depends on the current, following a square law relationship.

Capacitive Loads: These loads produce high inrush currents when the circuit closes. This can cause contact welding. Lifespan decreases sharply with increasing voltage, following at least a square law relationship. Capacitive inrush current can heat and soften or melt contacts, leading to welds.

Proper application of the HM24-1A69-20-6, considering these load types, ensures its long-term reliability.

Key Features and Benefits

The HM24-1A69-20-6 offers several key features. These features provide significant benefits for various applications. It is a dry reed relay, designed for high performance.

High Reliability and Long Life

The HM24-1A69-20-6 provides high reliability. Its sealed construction protects the contacts. The contacts sit inside a glass tube. This design shields internal parts from dust and moisture. These contaminants often cause problems in open relays. Superior manufacturing processes also help. These processes use special contact materials and technology. They extend the relay's operational life. They also keep contact resistance stable. Reed relays switch faster than other relays. They also last longer mechanically. This makes them very reliable for demanding uses.

Low Contact Resistance

Low contact resistance is very important. It minimizes energy loss in circuits. This is especially true with high current loads. High resistance causes voltage drops. It also increases heat at contact points. This degrades electrical performance. Materials like silver or gold have low contact resistance. They improve efficiency and reliability. The HM24-1A69-20-6 maintains low contact resistance. This ensures efficient current flow.

Hermetically Sealed Contacts

The HM24-1A69-20-6 uses hermetically sealed contacts. Glass material seals the contacts. This seal stops contaminants from entering the contact area. The contact area is critical for the switch. The glass envelope often contains inert gas or a vacuum. This significantly extends the relay's mechanical life. This sealed environment prevents moisture and contaminants from reaching the contacts. It also suppresses arc formation. This design ensures long-term durability.

High-Speed Switching and Isolation

The HM24-1A69-20-6 offers high-speed switching. It also provides excellent isolation. Reed relays have superior insulation resistance. Solid-state relays (SSRs) have a leakage current. This means their insulation resistance is not as high. Reed relays combine the reliability and speed of solid-state relays. They also offer the isolation benefits of electromechanical relays. Their unique construction, with ferromagnetic blades sealed in a glass tube, provides this superior isolation.

The HM24-1A69-20-6 high voltage reed relay offers critical specifications. It features a 24V coil, a 100W/3A/10kV contact rating, and a Form A configuration. Its robust mechanical design ensures durability. These characteristics make it ideal for demanding applications. Its high voltage capability and dry reed construction provide reliable, high-speed switching and excellent isolation. The 10kV contact rating is crucial for EV battery management systems, medical imaging equipment, renewable energy infrastructure, and Industry 4.0 applications. Always consult the detailed datasheet for specific application requirements. Proper integration in high-voltage circuits is essential. Understanding these specifications is fundamental for successful design and implementation.

FAQ

What does "1 Form A contact" mean for the HM24-1A69-20-6?

The "1 Form A contact" means the relay has a Single Pole, Single Throw, Normally Open (SPST-NO) contact. The circuit remains open when the relay is off. It closes when the coil receives power. This simple setup offers reliable switching.

Why is the 24 VDC coil voltage significant?

The 24 VDC coil voltage makes the relay compatible with many industrial and control systems. Engineers must provide a stable 24 VDC for consistent operation. This standard voltage simplifies integration into existing designs.

What is the importance of the 10 kV switching voltage?

The 10 kV switching voltage allows the relay to safely switch circuits carrying up to 10,000 volts. This high rating is crucial for demanding high-voltage applications. It ensures safety and performance in powerful systems.

How does the hermetically sealed contact design benefit the relay?

Hermetically sealed contacts protect the internal components from dust, moisture, and contaminants. This design significantly extends the relay's mechanical life. It also ensures long-term durability and consistent performance in harsh environments.

What factors influence the HM24-1A69-20-6's life expectancy?

Factors like hot switching, the type of load (resistive, inductive, capacitive), and the percentage of rated power affect lifespan. Proper application, considering these load types, ensures the relay's long-term reliability.

See Also

Essential MOSFET Fundamentals: A Comprehensive Guide for Electronics Hobbyists

Exploring Key Characteristics: The Versatile 74HC32 Logic Gate Integrated Circuit

Rapid Procurement Strategies: Sourcing Electronic Parts During Urgent Situations

Discovering Why ON Semiconductor's Power Management Solutions Are Indispensable

Demystifying Digital Serial Temperature Sensors: Their Function and Applications