What Are High Voltage Power Modules and Their Uses

High voltage power modules are specialized devices that manage and regulate electrical energy at elevated voltage levels. These modules play a vital role in ensuring the safe and efficient operation of high-power systems. You’ll find them indispensable in applications like power transmission, industrial equipment, and renewable energy systems.

Their importance lies in their ability to handle high voltage and current demands while improving energy efficiency. For instance:

The high voltage IGBT module market reached a value of USD 6.8 billion in 2023.

It is expected to grow to USD 11.5 billion by 2032, with a CAGR of 5.8%.

Advancements in semiconductors, such as SiC and GaN, further enhance their performance, making these modules essential for modern electrification and sustainability efforts.

Key Takeaways

High voltage power modules help control electricity at high levels. They ensure safety and work well in many uses.

These modules save energy and are reliable. They are important in fields like green energy, hospitals, and factories.

Picking AC or DC modules depends on the need. AC works for sending power far away. DC is better for nearby systems.

New materials like SiC and GaN make these modules better. They handle heat well and use energy more efficiently.

In the future, smaller and better power modules will be needed. This is because of new technology and the push for clean energy.

What Are High Voltage Power Modules?

Definition and Overview

High voltage power modules are specialized devices designed to manage and regulate electrical energy at high voltage levels. You’ll find these modules essential for applications requiring precise control and efficient power delivery. They serve as the backbone of systems that demand reliability and performance under extreme electrical conditions.

These modules are widely used in industries like renewable energy, healthcare, and aerospace. Their ability to handle high power loads makes them indispensable for modern technology. For example, advancements in semiconductor materials like silicon carbide (SiC) and gallium nitride (GaN) have significantly improved their efficiency and reliability.

A study highlights the importance of reliability in high voltage applications. It introduces an advanced fault diagnosis approach for high-voltage circuit breakers using an ensemble echo state neural network. This methodology improves diagnostic performance by fusing evidence from multiple modules, showcasing the critical role of high voltage power modules in ensuring system efficiency.

Key Insights:

High voltage power modules are evolving due to regulatory changes and technological advancements.

Intelligent systems integrated into these modules enhance reliability for critical applications.

Their market is expected to grow from USD 412.74 million in 2024 to USD 544.58 million by 2030, at a CAGR of 4.72%.

Key Features and Characteristics

High voltage power modules offer several features that make them suitable for demanding applications. You’ll notice their ability to handle dynamic load conditions, maintain voltage stability, and recover quickly from load changes. These characteristics ensure consistent performance even in challenging environments.

Performance Metrics:

Recovery times typically range from individual to tens of milliseconds.

Voltage droop depends on factors like output capacitance, load current magnitude, and load step duration.

Specifications often include a 10% to 90% voltage recovery time and allowable voltage overshoot percentages.

These modules also incorporate advanced insulation techniques to prevent electrical leakage and ensure safety. Their modular designs allow for easy integration into various systems, making them versatile and adaptable.

Aspect | Details |

|---|---|

Applications | Used in radar arrays, semiconductor manufacturing, and other advanced technology sectors. |

Technological Innovations | Advances in semiconductor materials like SiC and GaN enhance efficiency. |

Regulatory Impact | New regulations drive shifts towards solid-state architectures for better performance. |

By leveraging these features, high voltage power modules enable industries to achieve higher efficiency, lower energy losses, and improved system reliability.

Components and Configurations of High Voltage Power Modules

Core Components

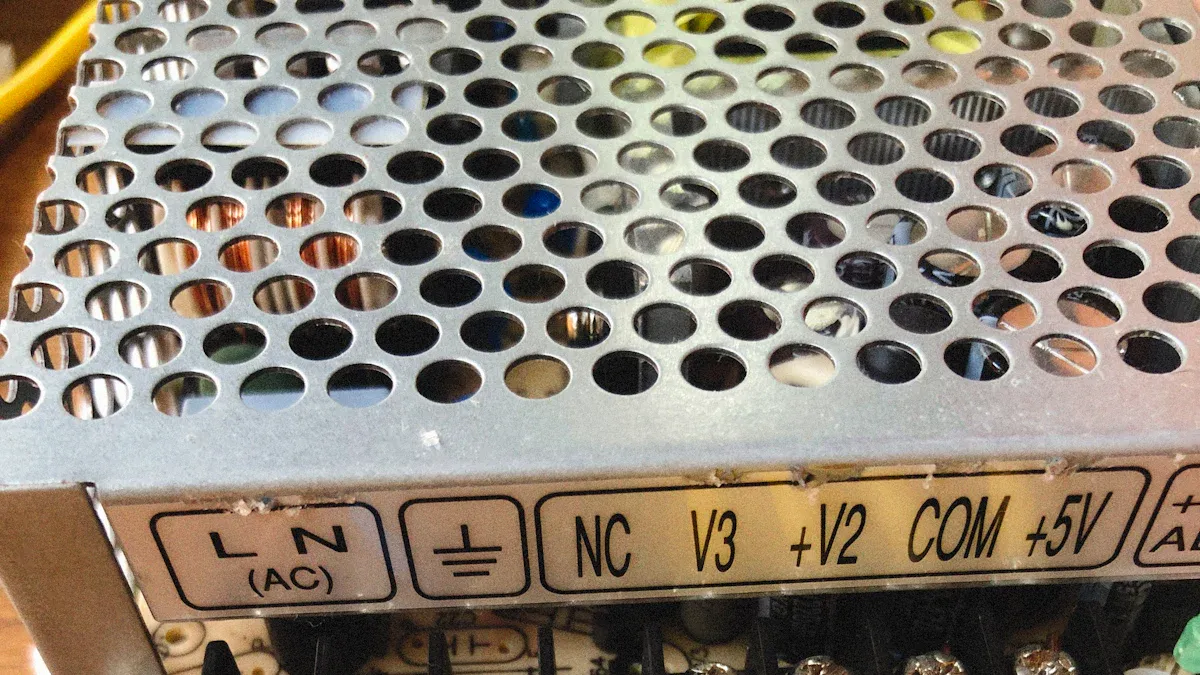

High voltage power modules rely on several critical components to function effectively. Each part plays a unique role in ensuring the module operates safely and efficiently under high voltage conditions.

Semiconductors: These are the heart of the module. They control the flow of electricity and enable switching operations. Modern semiconductors, like silicon carbide (SiC) and gallium nitride (GaN), offer higher efficiency and better thermal performance.

Capacitors: These store and release electrical energy as needed. They help stabilize voltage levels and reduce fluctuations in the system.

Insulation: Insulation materials prevent electrical leakage and protect the module from damage. Advanced insulation can withstand up to 7 kV (AC) and resist high humidity and static dust.

Studies have shown that insulation strength tests and partial discharge analysis are essential for maintaining reliability. These tests help identify weak points and ensure the module can handle extreme conditions.

Significance | Configuration | |

|---|---|---|

Power Electronics | High complexity due to numerous components | Includes semiconductors, capacitors, and microcontrollers |

Protective Relays | Disconnect components during faults | Located in substations, connected to circuit breakers and transformers |

Substations | Transform voltage levels and switch connections | Various configurations, including breaker-and-a-half for high-voltage systems |

Common Configurations and Designs

The design of a high voltage power module determines its performance and adaptability. You’ll find that these modules come in various configurations to suit different applications.

Modular Designs: These consist of separate, interchangeable units. Modular designs make it easier to replace faulty components and scale systems as needed.

Integrated Systems: These combine all components into a single unit. Integrated systems save space and reduce complexity, making them ideal for compact applications.

Breaker-and-a-Half Configuration: This design is common in substations. It provides flexibility and reliability by allowing multiple connections and easy fault isolation.

Each configuration has its advantages. Modular designs offer flexibility, while integrated systems focus on efficiency. The choice depends on your specific needs and the application’s requirements.

Types of High Voltage Power Modules

AC Modules vs. DC Modules

High voltage power modules are designed to handle either alternating current (AC) or direct current (DC), depending on the application. AC modules are commonly used in systems where power needs to be transmitted over long distances. These modules excel in applications like power grids and industrial equipment. Their ability to step up or step down voltage levels efficiently makes them ideal for large-scale energy distribution.

On the other hand, DC modules are better suited for applications requiring stable and consistent power. You’ll find them in renewable energy systems like solar panels and electric vehicles. DC modules are also essential for high-precision equipment, as they minimize power fluctuations.

Tip: When choosing between AC and DC modules, consider the type of load and the distance over which power needs to be transmitted. AC modules are better for long distances, while DC modules work well for localized systems.

Modular vs. Integrated Systems

When it comes to design, high voltage power modules can be modular or integrated. Modular systems offer flexibility and adaptability. You can add or replace modules without disrupting the entire system. This design reduces costs and time by simplifying the process and allowing you to reuse existing modules. Modular systems also enhance performance through better thermal management and optimized power density.

Modular systems allow you to adapt to changing needs.

They foster innovation by enabling experimentation with different configurations.

Integrated systems, however, combine all components into a single unit. These systems save space and reduce complexity, making them ideal for compact applications. For example, digital transformers, a type of integrated system, achieve a 98% reduction in copper cable length compared to traditional current transformers. They also operate with lower burdens, reducing costs significantly.

Traditional current transformers require a burden of 100 VA and cost 100%.

Digital transformers operate with a burden of 2.5 VA and cost 65% at 145 kV, 79% at 245 kV, and 87% at 550 kV.

Types Based on Voltage Range

High voltage power modules are categorized by the voltage range they handle. These categories include low, medium, and high voltage.

Low Voltage (LV): These modules operate up to 1,000 volts AC or 1,500 volts DC. You’ll find them in residential wiring, commercial buildings, and small industrial machinery.

Medium Voltage (MV): These modules handle voltages from 1,000 to 35,000 volts. They are used in distribution networks, large industrial facilities, and mining operations.

High Voltage (HV): Modules in this category operate above 35,000 volts. They are essential for transmission lines, electric railways, and large-scale industrial plants.

Different organizations define these ranges slightly differently. For instance, ANSI defines medium voltage as 2,400 to 69,000 volts, while IEEE considers anything above 1,000 volts and up to 35,000 volts as medium voltage.

Understanding these categories helps you select the right module for your application. Low voltage modules suit smaller systems, while medium and high voltage modules are better for industrial and large-scale operations.

Applications in Modern Industries

Renewable Energy (e.g., solar and wind power systems)

High voltage power modules play a critical role in renewable energy systems like solar and wind power. These systems require efficient power conversion and distribution to handle varying energy outputs. You’ll find that high voltage modules ensure stable energy transmission from renewable sources to the grid or storage systems.

Renewable energy systems operate across different voltage levels. High voltage modules, operating above 24 kV, are essential for large-scale solar farms and wind turbines. Medium voltage modules, ranging from 1 kV to 24 kV, are used in smaller energy systems. Low voltage modules, below 1 kV, are suitable for residential solar panels and localized energy applications.

Description | |

|---|---|

High Voltage | Above 24 kV, relevant for renewable energy systems such as solar and wind power. |

Medium Voltage | Between 1 kV and 24 kV, also applicable in various energy systems. |

Low Voltage | Below 1 kV, used in smaller scale energy applications. |

By using high voltage power modules, renewable energy systems achieve better efficiency and reliability. These modules help reduce energy losses during transmission, making renewable energy more sustainable and cost-effective.

Healthcare (e.g., medical imaging and diagnostic equipment)

In healthcare, high voltage power modules are vital for powering advanced medical equipment. Devices like X-ray machines, CT scanners, and MRI systems rely on these modules to deliver precise and stable power. You’ll notice that these machines require high voltage to generate the energy needed for imaging and diagnostics.

For example, X-ray machines use high voltage to accelerate electrons, producing the X-rays necessary for imaging. High voltage power modules ensure that the voltage remains stable, which is crucial for obtaining clear and accurate images. Similarly, MRI systems depend on these modules to power their superconducting magnets, enabling detailed scans of the human body.

The reliability of high voltage power modules directly impacts patient care. Stable power delivery reduces the risk of equipment failure, ensuring that diagnostic procedures run smoothly. This reliability makes these modules indispensable in modern healthcare facilities.

Manufacturing and Automation

Manufacturing and automation industries rely heavily on high voltage power modules to power machinery and industrial processes. These modules support applications like industrial drives, robotics, and HVAC systems. You’ll find that they enable precise control of power, which is essential for maintaining efficiency and productivity.

The market for high voltage power modules in manufacturing is segmented by voltage range. Modules in the 600 V to 1,199 V range are widely used in home appliances and industrial drives. The demand for modules above 1,200 V is growing due to their applications in electric vehicles and advanced automation systems. For instance, the International Energy Agency reported a 10% increase in electric car sales from 2020 to 2022. This growth highlights the importance of high voltage modules in automotive manufacturing and industrial automation.

High voltage power modules also contribute to energy efficiency in manufacturing. By minimizing energy losses and optimizing power delivery, these modules help industries reduce operational costs and environmental impact. Their role in automation and robotics further enhances productivity, making them a cornerstone of modern manufacturing.

Aerospace and Defense

High voltage power modules are essential in aerospace and defense systems. These industries demand reliable and efficient power solutions to operate under extreme conditions. You’ll find these modules powering radar systems, satellite communication devices, and advanced avionics. Their ability to handle high voltage ensures stable performance in critical applications.

In aerospace, high voltage power modules support systems like electric propulsion and energy storage. Electric propulsion systems rely on these modules to convert and regulate power for thrusters. This technology reduces fuel consumption and increases efficiency, making it ideal for long-duration space missions.

Defense applications benefit from the precision and reliability of high voltage power modules. For example, radar systems require stable power to detect and track objects accurately. These modules also play a role in powering directed energy weapons, which use high-energy lasers for defense purposes.

Note: High voltage power modules must meet stringent safety and reliability standards. Their performance directly impacts mission success and operational safety.

Emerging Applications (e.g., particle acceleration, edge computing)

High voltage power modules are driving innovation in emerging fields like particle acceleration and edge computing. These applications demand advanced power solutions to achieve high efficiency and precision.

Particle Acceleration

Particle accelerators rely on high voltage power modules to generate the energy needed to accelerate particles to high speeds. You’ll find these modules in research facilities and medical applications, such as cancer treatment using proton therapy. Recent advancements in semiconductor materials, like gallium oxide (β-Ga₂O₃), are enhancing the performance of these modules.

Gallium oxide offers a high breakdown field, making it ideal for high-voltage applications.

β-Ga₂O₃ MOSFETs exhibit ultra-low leakage current, outperforming traditional silicon carbide (SiC) and gallium nitride (GaN) devices.

AI-driven simulations predict the performance of β-Ga₂O₃ transistors, enabling their use in advanced particle acceleration systems.

Edge Computing

Edge computing requires efficient power management to support AI-driven data centers and real-time processing. High voltage power modules optimize power delivery, reducing energy losses and improving system reliability.

Parasitic losses in GaN and SiC devices limit efficiency, necessitating advanced optimization techniques.

AI-optimized inverters for electric vehicles improve real-time control and reduce losses.

Neuro-symbolic AI automates the design of power circuits, minimizing electromagnetic interference.

These advancements highlight the role of high voltage power modules in enabling cutting-edge technologies. By leveraging innovative materials and AI-driven designs, these modules are paving the way for breakthroughs in science and technology.

Benefits and Future Trends

Advantages of High Voltage Power Modules

High voltage power modules offer several advantages that make them indispensable in modern industries. Their ability to efficiently control and convert electrical energy enhances system reliability and reduces energy losses. For example, high voltage IGBT modules are widely used in renewable energy systems and electric vehicles. These modules ensure optimal power quality, which is critical for maintaining the performance of advanced systems.

Recent advancements in cooling systems and wide-bandgap semiconductors, such as silicon carbide (SiC), have further improved the efficiency of these modules. SiC materials allow for better thermal management, enabling the modules to operate at higher temperatures without compromising performance. This makes them ideal for applications requiring consistent power delivery under demanding conditions.

Tip: When selecting a high voltage power module, consider its efficiency and thermal management capabilities. These factors directly impact the module's performance and lifespan.

Innovations and Future Developments in the Field

The future of high voltage power modules looks promising, with several innovations on the horizon. Industries like automotive, telecommunications, and healthcare are driving demand for more efficient and compact power solutions.

In the automotive sector, advanced power modules are critical for energy conversion in electric and hybrid vehicles.

Consumer electronics increasingly rely on these modules for efficient power delivery.

Telecommunications and healthcare sectors depend on reliable modules for power management in critical systems.

Technological advancements in semiconductor materials, such as gallium nitride (GaN), are also shaping the future of these modules. GaN technology offers superior efficiency and thermal performance, making it a game-changer for high-power applications. Additionally, the integration of smart technologies enables real-time monitoring and diagnostics, improving system reliability.

Title | Authors | Publication Details | Year |

|---|---|---|---|

DC–DC Topology for Interfacing a Wireless Power Transfer System | M. Elshaer, C. Bell, A. Hamid, J. Wang | IEEE Transactions on Industry Applications, vol. 57, no. 6, pp. 5552-5561 | 2021 |

Hardware Design of Medium Voltage SiC-based Modular Multilevel Converters | K. Wang, D. Ma, B. Hu, J. Wang, A. Singh, B. Mather | 2021 IEEE 8th Workshop on Wide Bandgap Power Devices and Applications (WiPDA), pp. 339-344 | 2021 |

The miniaturization of power modules is another exciting development. Smaller modules reduce size and weight while maintaining efficiency, making them suitable for compact applications like electric vehicles and portable medical devices.

These innovations highlight the potential of high voltage power modules to revolutionize industries. By adopting cutting-edge technologies, you can achieve greater efficiency, reliability, and sustainability in your applications.

High voltage power modules are transforming industries by enabling efficient energy management and reliable power delivery. You see their impact in renewable energy systems, healthcare equipment, and advanced manufacturing processes. These modules drive technological advancements through innovations in semiconductor materials and digital controls, reshaping performance standards and market dynamics.

Their role in supporting sustainable energy solutions is vital. By reducing energy losses and optimizing power conversion, they help you achieve greener and more cost-effective operations. Future developments in materials and smart technologies promise even greater efficiency and expanded applications, paving the way for breakthroughs in science and industry.

FAQ

What are the main advantages of high voltage power modules?

High voltage power modules improve energy efficiency, reduce power losses, and enhance system reliability. They also support compact designs and advanced thermal management, making them ideal for demanding applications like renewable energy, healthcare, and aerospace.

How do you choose between AC and DC high voltage power modules?

Consider the application. AC modules work best for long-distance power transmission, while DC modules suit localized systems requiring stable power, such as solar panels or electric vehicles. Evaluate your system's load type and distance requirements.

Are high voltage power modules safe to use?

Yes, they include advanced insulation and safety features to prevent electrical leakage and overheating. Regular maintenance and adherence to manufacturer guidelines ensure safe operation in high-voltage environments.

Can high voltage power modules handle extreme conditions?

Absolutely! These modules are designed to operate under challenging conditions, including high temperatures, humidity, and electrical stress. Materials like silicon carbide (SiC) and gallium nitride (GaN) enhance their durability and performance.

What industries benefit the most from high voltage power modules?

Industries like renewable energy, healthcare, manufacturing, aerospace, and defense rely heavily on these modules. They enable efficient power management, ensuring stable performance in critical applications like wind turbines, medical imaging, and radar systems.

Tip: Always consult an expert to select the right module for your specific industry needs.

See Also

Understanding High Density Optically Coupled Isolators And Their Applications

Exploring Three-Terminal Voltage Regulators And Their Functionality

The Role And Applications Of Photodiode Sensor Integrated Circuits

An Overview Of P-Channel Powertrench MOSFETs And Their Uses

Implementing Schottky Barrier Power Rectifiers In Electronic Circuits