What Are High Density Optically Coupled Isolators and Their Uses

High Density Optically Coupled Isolators are essential components that use light to transmit electrical signals between separate circuits. You’ll find these isolators crucial for maintaining electrical isolation, which protects sensitive systems and ensures safe operation. Their design prevents direct electrical contact between circuits, reducing risks like short circuits or voltage spikes.

These High Density Optically Coupled Isolators shine in safety-critical applications due to their impressive performance metrics: insulation voltages that withstand high stress, up to 8kV ESD protection, and robust transient immunity of ±250kV/μs. Their ability to operate efficiently in extreme temperatures further enhances their reliability. You’ll see them widely adopted in industrial, medical, and consumer electronics for their compact yet powerful design.

Key Takeaways

High Density Optically Coupled Isolators keep parts safe from voltage surges. They help devices work safely in many situations.

These isolators block noise by using light to send signals. This keeps messages clear, even in places with lots of electrical interference.

Their small size fits into tight spaces, making them great for gadgets and portable medical tools.

When picking an isolator, check voltage limits, speed, and compatibility. This ensures it works well for your needs.

Using good isolators makes systems safer and more reliable. They are especially useful in medical tools and factory machines.

How High-Density Optically Coupled Isolators Work

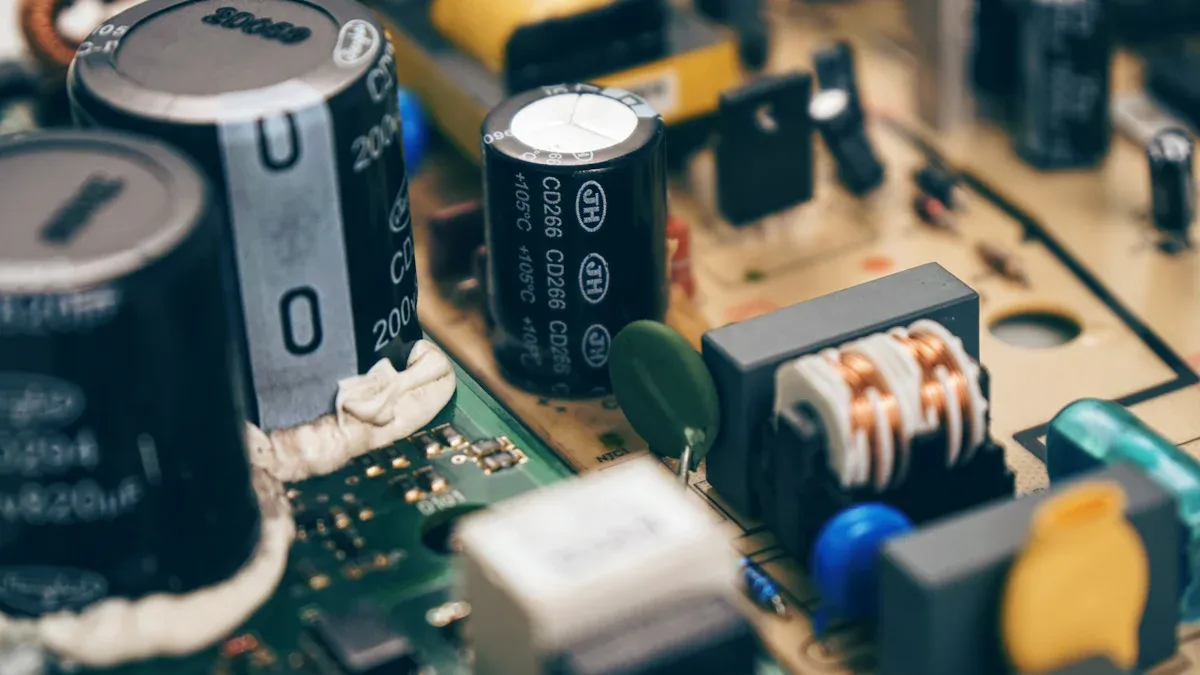

Components of Optically Coupled Isolators

To understand how high-density optically coupled isolators function, you first need to know their key components. These isolators consist of two primary parts: a light-emitting diode (LED) and a photodetector. The LED generates light when an electrical signal passes through it. This light travels across an insulating barrier to the photodetector, which converts the light back into an electrical signal.

In high-density configurations, multiple LED-photodetector pairs are integrated into a compact package. This design allows you to achieve higher performance while saving space. Additional components, such as optical filters and signal amplifiers, may also be included to enhance signal clarity and strength.

Mechanism of Optical Coupling

The optical coupling process is what makes these isolators unique. When the LED emits light, the photodetector on the other side of the barrier captures it. This light transmission ensures that no direct electrical connection exists between the input and output circuits. As a result, you get complete electrical isolation, which protects sensitive components from voltage surges and noise.

The efficiency of this mechanism depends on several factors, including the internal quantum efficiency (IQE) of the LED and the specific detectivity (D*) of the photodetector. For example, at 800 K, the IQE reaches 22%, while the detectivity varies with temperature, as shown below:

Parameter | Value at 800 K | Value at 600 K | Value at 400 K | Value at 300 K |

|---|---|---|---|---|

Internal Quantum Efficiency (IQE) | 22% | N/A | N/A | N/A |

Specific Detectivity (D*) | N/A | 22G Jones | 17G Jones | 12G Jones |

Current Transfer Ratio (CTR) | N/A | N/A | N/A | Low below 200 K |

This table highlights how temperature affects the performance of optical coupling. You can see that higher temperatures generally improve detectivity, which is crucial for maintaining signal integrity.

Role of High-Density Configurations in Enhancing Performance

High-density configurations take the basic concept of optical coupling and elevate it. By integrating multiple isolators into a single package, these designs reduce resistance and improve current transfer. Studies have shown that increasing the number of vias and the height of metal lines in semiconductor interconnects lowers resistance. This optimization enhances power efficiency and reliability in electronic devices.

Aspect | Findings |

|---|---|

Study Focus | Efficiency of high-density configurations in semiconductor interconnects |

Methodology | Comparison of theoretical and actual resistance values through current-voltage measurements |

Key Result | Increased number of vias and height of metal lines led to lower resistance, optimizing current transfer |

Conclusion | Proposed structures enhance power efficiency and reliability in high-density electronic devices |

For you, this means that high-density optically coupled isolators not only save space but also deliver superior performance. They ensure faster signal transmission, better noise immunity, and greater reliability, making them ideal for modern electronic systems.

Key Features and Advantages

Electrical Isolation for Safety

High Density Optically Coupled Isolators excel at providing electrical isolation. They separate input and output circuits, ensuring that no direct electrical connection exists between them. This isolation protects sensitive components from voltage spikes, surges, and short circuits. You can rely on these isolators to safeguard your devices, especially in high-voltage environments.

Tip: Use optically coupled isolators in safety-critical systems to prevent electrical hazards and ensure compliance with safety standards.

Their ability to withstand high insulation voltages makes them ideal for industrial and medical applications. For example, in medical devices, they protect patients from electrical shocks by isolating the patient-connected circuits from the power supply.

Noise Immunity and Signal Integrity

Electrical noise can disrupt signal transmission, leading to errors and reduced performance. High Density Optically Coupled Isolators solve this problem by using light to transmit signals. Light-based transmission is immune to electromagnetic interference (EMI) and radio frequency interference (RFI).

You’ll notice improved signal integrity when using these isolators in noisy environments, such as factories or data centers. Their design ensures that the transmitted signal remains clear and accurate, even in the presence of strong interference. This feature is particularly valuable in telecommunications and industrial automation, where reliable communication is essential.

High Data Transfer Rates for Efficient Communication

Modern electronic systems demand fast and efficient data transfer. High Density Optically Coupled Isolators meet this need by offering high-speed signal transmission. Some models support data rates of up to several megabits per second, making them suitable for high-performance applications.

Note: Faster data transfer rates reduce latency, improving the overall efficiency of your system.

Their compact design allows you to integrate them into space-constrained devices without compromising performance. Whether you’re working on a consumer electronics project or a complex industrial system, these isolators ensure efficient communication while saving valuable space.

Compact Design for Space-Constrained Applications

High-density optically coupled isolators offer a compact design that fits perfectly into devices with limited space. You’ll find this feature especially useful when working on projects where every millimeter counts, such as consumer electronics or portable medical devices.

Why Compact Design Matters

Space constraints often challenge engineers and designers. Smaller devices require components that deliver high performance without taking up too much room. High-density isolators solve this problem by integrating multiple optical channels into a single package. This design reduces the overall footprint while maintaining functionality.

Tip: Use compact isolators in applications like smartphones, tablets, and wearable devices to maximize space efficiency without sacrificing performance.

Benefits of Compact Isolators

Efficient Use of Space: These isolators pack multiple channels into a small form factor, freeing up room for other components.

Lightweight Construction: Their reduced size contributes to lighter devices, which is crucial for portable applications.

Simplified Installation: Compact designs make it easier to fit isolators into tight spaces, speeding up assembly processes.

Real-World Applications

You’ll see compact isolators in industries like telecommunications, where networking equipment demands high performance in small enclosures. They also play a key role in medical devices, ensuring patient safety while keeping the equipment lightweight and portable.

Note: Compact isolators don’t just save space; they also enhance reliability by reducing the risk of mechanical stress during installation.

A Quick Example

Imagine designing a wearable heart monitor. You need components that ensure electrical isolation for patient safety while fitting into a slim, lightweight device. High-density optically coupled isolators meet these requirements, making them an ideal choice for such applications.

Emoji Insight: 🛠️ Compact isolators are the tools that help you build smarter, smaller, and safer devices.

Applications Across Industries

Telecommunications: Signal Isolation in Networking Equipment

Telecommunications systems rely on uninterrupted and high-quality signal transmission. High Density Optically Coupled Isolators play a vital role in ensuring this reliability. These isolators protect laser sources in fiber optic communication systems, preventing damage caused by electrical surges or noise. By isolating circuits, they maintain signal integrity, which is essential for efficient data transfer.

Recent advancements in fiber optic technology have further expanded their applications. With faster data transmission speeds and increased bandwidth capacity, optical isolators are now indispensable in modern telecommunications infrastructure. For example, the deployment of 5G networks and fiber-to-the-home (FTTH) services requires robust isolators to handle high-speed internet demands.

Market Insight: The global optical isolator market is projected to reach $1.1 billion by 2030, driven by increasing demand in telecommunications and data centers.

You’ll find these isolators in networking equipment like routers, switches, and optical transceivers. Their ability to ensure reliable communication makes them a cornerstone of the telecommunications industry.

Medical Devices: Ensuring Patient Safety in Electrical Systems

Medical devices must prioritize patient safety, especially when electrical systems are involved. High Density Optically Coupled Isolators provide the necessary electrical isolation to protect patients from potential hazards. These isolators separate patient-connected circuits from the power supply, reducing the risk of electrical shocks.

Their compact design makes them ideal for portable medical devices like wearable heart monitors and infusion pumps. By integrating multiple optical channels into a small package, these isolators save space while maintaining high performance.

Performance Highlight: Optical isolators are increasingly utilized in medical applications due to advancements in fiber optic technology, which enhance their efficiency and reliability.

You’ll see these isolators in imaging systems, diagnostic equipment, and monitoring devices. Their ability to operate in extreme conditions ensures consistent performance, even in demanding medical environments.

Industrial Automation: Reliable Operation in Factory Settings

Factories depend on automation systems to maintain productivity and efficiency. High Density Optically Coupled Isolators ensure the reliability of these systems by providing electrical isolation and noise immunity. They protect sensitive components from voltage spikes and electromagnetic interference, which are common in industrial environments.

These isolators also support high-speed data transfer, enabling seamless communication between automated machines. For example, robotic arms and conveyor systems rely on precise signal transmission to perform their tasks accurately.

Industry Trend: Rising product utilization in industrial automation highlights the importance of optical isolators in maintaining safety and effectiveness.

You’ll find these isolators in programmable logic controllers (PLCs), motor drives, and sensor interfaces. Their robust design ensures long-term reliability, making them a trusted choice for factory settings.

Consumer Electronics: Enhancing Device Performance

High Density Optically Coupled Isolators play a key role in improving the performance of consumer electronics. These isolators ensure reliable signal transmission, which is essential for devices like smartphones, tablets, and gaming consoles. By isolating circuits, they protect sensitive components from electrical noise and voltage fluctuations.

You’ll notice their impact in devices that require high-speed data transfer. For example, modern televisions and streaming devices rely on these isolators to maintain signal clarity while handling large amounts of data. Their ability to operate efficiently in compact spaces makes them ideal for portable electronics, where every millimeter matters.

Benefits for Consumer Electronics

Enhanced Reliability: These isolators prevent electrical interference, ensuring consistent device performance.

Improved Safety: They protect circuits from voltage spikes, reducing the risk of damage.

Compact Design: Their small size allows integration into slim and lightweight devices.

Tip: When designing consumer electronics, choose isolators that offer high data transfer rates and noise immunity for optimal performance.

Real-Life Example

Imagine a high-performance gaming console. It needs components that can handle fast data processing without compromising reliability. High Density Optically Coupled Isolators ensure smooth communication between the console’s processor and graphics unit, delivering an immersive gaming experience.

Emerging Applications: Power Supply Feedback Systems and Ground Loop Isolation

High Density Optically Coupled Isolators are finding new applications in advanced electronic systems. Power supply feedback systems benefit from their ability to provide precise signal isolation. These systems require accurate feedback to regulate voltage and current, and isolators ensure that the feedback signals remain unaffected by electrical noise.

Ground loop isolation is another area where these isolators excel. Ground loops occur when multiple devices share a common ground, leading to unwanted noise and interference. By isolating circuits, optically coupled isolators eliminate these issues, improving the overall performance of interconnected systems.

Advantages in Emerging Applications

Noise Reduction: These isolators minimize interference caused by ground loops.

Improved Efficiency: They enhance the accuracy of power supply feedback systems.

Versatility: Their design adapts to various emerging technologies.

Note: Ground loop isolation is particularly important in audio equipment, where even minor noise can affect sound quality.

Future Potential

As technology advances, you’ll see these isolators integrated into more innovative applications. From renewable energy systems to electric vehicles, their ability to ensure reliable signal transmission and electrical isolation makes them indispensable.

Choosing the Right High-Density Optically Coupled Isolator

Factors to Consider: Voltage Ratings, Speed, and Compatibility

When selecting High Density Optically Coupled Isolators, you need to evaluate several technical factors to ensure they meet your system's requirements. Start by considering the highest voltage the isolator must handle. The isolation voltage, which can reach up to 10 kV in some devices, determines how well the isolator protects against voltage differences between circuits.

Next, assess the speed of data transfer. If your application involves fast data links, choose isolators with higher bandwidth. Basic models support around 10 MHz, but advanced ones can handle much faster rates. Also, check if the isolator is compatible with the type of signal you need to isolate, whether it's DC, AC, or high-speed data lines.

Other factors include the current transfer ratio (CTR), which depends on the input signal, and the power requirements of the output. You should also plan for thermal management to ensure the isolator operates reliably under varying conditions.

Tip: Always match the isolator's specifications to your system's needs to avoid performance issues.

Matching System Requirements: Ensuring Optimal Performance

To achieve optimal performance, you must align the isolator's capabilities with your system's demands. For instance, if your design involves high-speed communication, prioritize isolators with low propagation delay and high data rates. In contrast, for industrial applications, focus on isolators with robust noise immunity and high transient voltage protection.

Consider how the isolator integrates into your design. Compact models are ideal for space-constrained devices, while larger ones may offer additional features like enhanced thermal stability. By understanding your system's requirements, you can select an isolator that ensures both safety and efficiency.

Note: Proper integration of the isolator into your design can also reduce the risk of overheating and improve long-term reliability.

Balancing Cost and Performance: Making Informed Decisions

While high-performance isolators offer advanced features, they often come at a higher cost. To make an informed decision, balance your budget with the performance requirements of your application. For example, if you're designing a consumer electronic device, you might prioritize cost-effective isolators with moderate performance. However, for critical systems like medical devices, investing in premium isolators with superior safety features is essential.

Compare different models based on their specifications and price. Look for isolators that provide the best value without compromising on key features like isolation voltage, speed, and compatibility.

Reminder: A well-chosen isolator not only saves costs but also enhances the overall reliability of your system.

High-density optically coupled isolators are essential for ensuring safety, reliability, and efficiency in electronic systems. Their ability to provide electrical isolation and noise immunity makes them versatile across industries like telecommunications, medical devices, and industrial automation.

When choosing the right isolator, focus on your application’s specific needs. Evaluate disturbing frequencies, environmental factors, and required isolation levels. Narrow your options by calculating the natural frequency and considering temperature or load direction. This approach ensures you select an isolator that balances performance, cost, and long-term reliability.

Tip: Matching isolator specifications to your system’s requirements guarantees optimal performance and durability.

FAQ

1. What makes high-density optically coupled isolators different from regular isolators?

High-density isolators integrate multiple optical channels into a compact package. This design saves space and boosts performance. You’ll notice faster signal transmission, better noise immunity, and improved reliability compared to standard isolators.

2. Can high-density optically coupled isolators handle extreme temperatures?

Yes, these isolators operate efficiently in extreme temperatures. Their robust design ensures reliable performance in both high-heat and cold environments, making them suitable for industrial and outdoor applications.

3. How do optically coupled isolators improve safety in medical devices?

They isolate patient-connected circuits from the power supply. This separation prevents electrical shocks and ensures compliance with safety standards. You’ll find them essential in wearable monitors and diagnostic equipment.

4. Are high-density isolators suitable for consumer electronics?

Absolutely! Their compact design fits perfectly into space-constrained devices like smartphones and gaming consoles. They also enhance signal clarity and protect circuits from electrical noise.

5. What should you consider when choosing an isolator for your system?

Focus on isolation voltage, data transfer speed, and compatibility with your signal type. Match the isolator’s specifications to your system’s requirements for optimal performance and reliability.

Tip: Always check the isolator’s thermal management capabilities for long-term durability.

See Also

Exploring The Functions And Applications Of Photodiode ICs

Understanding The Features Of High-Performance Microcontroller ICs

Defining IC Audio Signal Processors And Their Main Attributes

IC Line Drivers Explained: Their Functionality In Electronics