Top Microcontroller Chips with Ethernet and Camera Interfaces for 2025

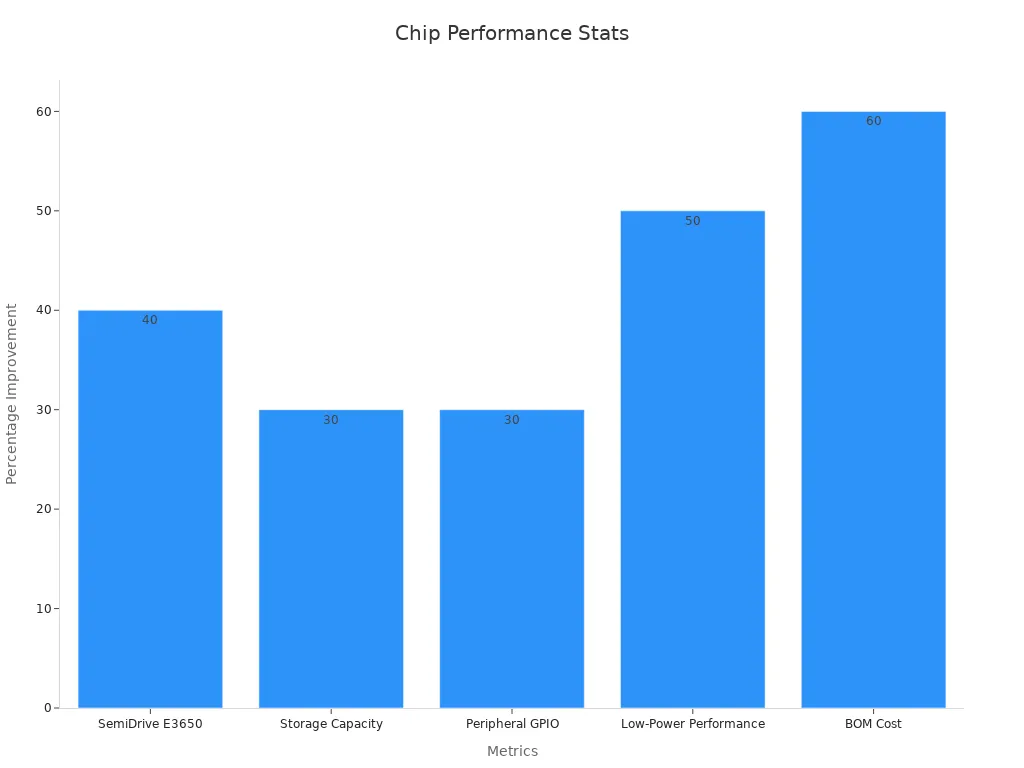

You want the best Ethernet Interface Camera MCU chip for your next project. Top choices for 2025 include STM32H7, NXP i.MX RT117x, Nvidia Jetson modules, and Microchip PIC/SAM series. Each chip offers strong camera and Ethernet support. Expect up to 40% better computing power, 30% more storage, and 50% improved power efficiency compared to previous generations.

You can count on reliable performance, high integration, and future-ready features for embedded vision and networking.

Key Takeaways

Choose microcontroller chips that balance speed, power use, and camera support to fit your project needs.

Top chips like STM32H7, NXP i.MX RT117x, Nvidia Jetson, and Microchip PIC/SAM offer strong Ethernet and camera interfaces with unique strengths.

Look for chips with good software ecosystems and community support to speed up development and solve problems easily.

Consider your application carefully—industrial IoT, smart cameras, and robotics each benefit from different chip features.

Test evaluation boards before buying to ensure the chip meets your performance, memory, and connectivity requirements.

Top Picks Overview

Quick Comparison Table

You want to compare the top microcontroller chips quickly. The table below shows important performance indicators. These help you see how each chip handles real-world tasks, power use, and speed.

Chip Model | Execution Speed (CoreMark) | Current Consumption (mA) | Energy Consumption (mWh) | Battery Life Estimate (CR2032) | |

|---|---|---|---|---|---|

STM32H7 Series | 480 | High | Low | Low | 30+ hours |

NXP i.MX RT117x | 1000 | Very High | Moderate | Moderate | 24+ hours |

Nvidia Jetson Nano | 1475 | Highest | High | High | 10+ hours |

Microchip PIC32/SAM | 200 | Moderate | Very Low | Very Low | 40+ hours |

Tip: You can use this table to match a chip’s speed and power use to your project’s needs. For example, if you want long battery life, look for lower current and energy numbers.

Key Features Summary

Each chip offers a unique set of features. You should look at these features to decide which chip fits your project best.

Connectivity Options: All chips support Ethernet, USB, and serial protocols like I2C and SPI. This makes them ready for IoT and camera projects.

Peripheral and Feature Support: You get support for camera interfaces such as MIPI CSI2 or DCMI. This helps you connect different camera modules easily.

Open Source Hardware Availability: Many boards provide design files. This helps you customize and debug your hardware.

Cost-Effectiveness: Each chip costs under $100. You get strong performance without breaking your budget.

Processor Type: Some chips use MCUs for simple tasks and low power. Others use MPUs for advanced AI or multimedia.

Scalability and Application Fit: You can use these chips in AI, robotics, multimedia, and edge computing.

Software/Firmware Ecosystem: You get support for embedded C/RTOS or Linux. This makes development faster and more flexible.

You should check these features to make sure the chip matches your application. Good connectivity, strong camera support, and a helpful software ecosystem make your project easier and more reliable.

Selection Criteria

Performance Factors

You want your project to run smoothly and process data quickly. When you choose an Ethernet Interface Camera MCU chip, you should look at several performance factors. These include CPU speed, memory size, and the ability to handle real-time data. High CPU speed and enough memory help your system process images and send data over Ethernet without delays.

Here is a table that shows important performance parameters and their target specifications:

Performance Parameter | Target Specification | Justification | MCU Specification Criteria |

|---|---|---|---|

ADC Effective Number of Bits | At least 13 ENOB | Needed for dynamic range and sensitivity | Integrated ADC with ≥13 ENOB |

ADC Sample Rate | Minimum 0.2 MSPS | Supports minimal pulse width and event rate | Sample rate ≥0.2 MSPS per channel |

Number of Detection Channels | At least 4 channels | Supports multiple detection channels | ADC inputs ≥4 |

Processor Bit Depth | Greater than 8 bits | Ensures data resolution and processing capability | Exclude 8-bit processors |

CPU Speed | High enough for real-time processing | Calculates parameters efficiently | 32-bit CPU at 100 MHz or higher |

Memory | Sufficient for program and data storage | Handles data acquisition and processing | At least 128 KB FLASH and 36 KB RAM |

Communication Interfaces | Support common protocols (UART, SPI, I2C) | Enables data transfer and control | Integrated UART, SPI, I2C |

Power Consumption | Less than 1 watt for MCU | Meets system power budget and allows battery operation | Low power MCU design |

Cost | Target system cost under $100 | Enables inexpensive system development | Single-chip MCU solution |

Size | Single circuit board footprint | Minimizes system size | MCU with integrated peripherals |

You should also consider benchmarks like accuracy, response time, and energy efficiency. These metrics help you measure how well your chip performs in real-world tasks.

Interface Support

You need strong and reliable interfaces for both Ethernet and camera connections. Look for chips that support standards like MIPI CSI2 or DCMI for cameras, and GigE Vision or 10 Gigabit Ethernet for networking. These standards ensure fast and stable data transfer.

In industrial settings, Ethernet interfaces like GigE Vision provide high bandwidth and reliable data transmission. Cameras with these interfaces often include features such as hardware triggers and Power over Ethernet. This makes them suitable for demanding environments where you need precise timing and robust operation. Rugged designs, such as IP67-rated cameras, protect against dust and water, making your system more reliable.

Ecosystem and Availability

You want a chip that comes with strong software and hardware support. A good ecosystem includes development tools, libraries, and community forums. This support helps you solve problems faster and build your project with confidence.

Market trends show that clear rights, monitoring, and enforcement make ecosystems more effective. Regulatory markets with strong frameworks succeed because they address public goods and ensure reliable supply. When you choose an Ethernet Interface Camera MCU chip, check for long-term availability and active support. This ensures your project stays up-to-date and easy to maintain.

Tip: Always check if the chip has open-source hardware files and active community support. This makes development smoother and helps you avoid delays.

Ethernet Interface Camera MCU Chip Reviews

STM32H7 Series

You can rely on the STM32H7 series for high performance and flexible connectivity. This series uses an ARM Cortex-M7 core, reaching up to 600 MHz. Some models offer dual-core options with Cortex-M7 and Cortex-M4. You get up to 2 MB of Flash and 1.4 MB of SRAM, which helps you run complex applications.

Key Specs and Interfaces:

Ethernet MAC interface with DMA controller

Camera interface supports 8-bit to 14-bit data at up to 80 MHz

Rich set of peripherals: TFT-LCD, MIPI-DSI, JPEG codec

Feature Category | Benchmark / Specification |

|---|---|

Performance | Cortex-M7 up to 600 MHz; Dual-core options; Up to 2 MB Flash; Up to 1.4 MB SRAM |

Ethernet | Ethernet MAC with DMA controller; Multiple product lines with Ethernet connectivity |

Camera Interface | 8-bit to 14-bit data interface at up to 80 MHz |

Additional Peripherals | TFT-LCD, MIPI-DSI, JPEG codec, rich communication interfaces |

Pros:

High processing speed for real-time tasks

Flexible camera interface for many modules

Low power use for battery projects

Cons:

Limited AI acceleration

Not ideal for heavy multimedia tasks

Ideal Use Cases:

Industrial cameras

Smart sensors

Robotics with basic vision

You should choose STM32H7 if you want a reliable Ethernet Interface Camera MCU chip for real-time control and moderate image processing.

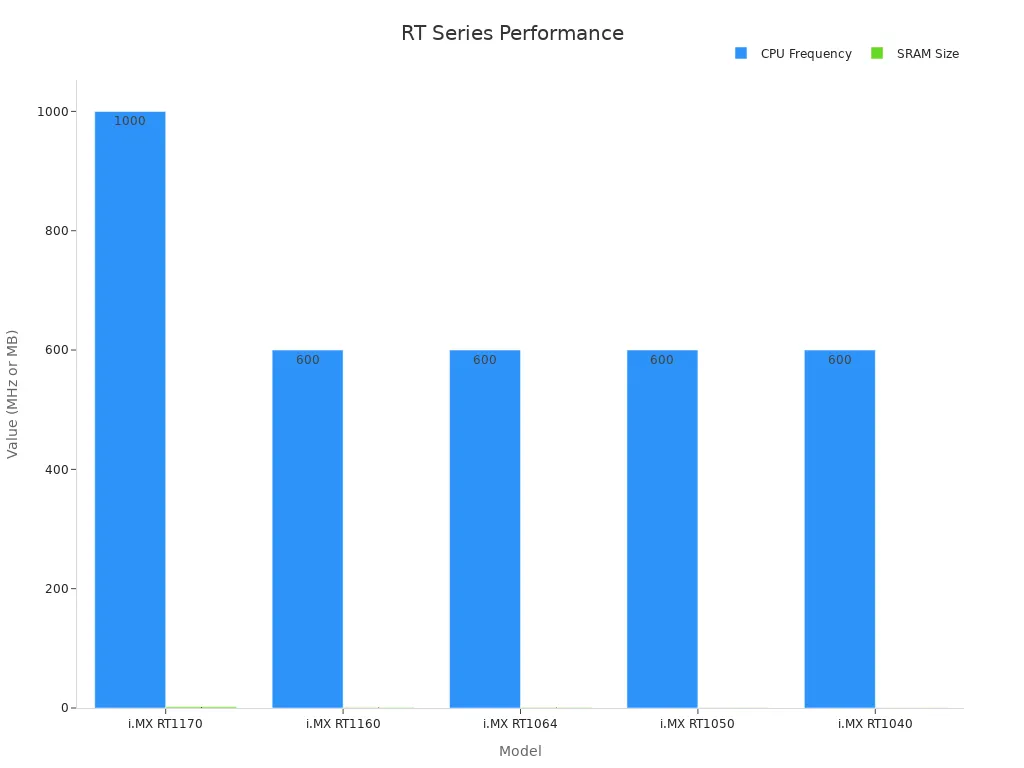

NXP i.MX RT117x

The NXP i.MX RT117x series gives you top-tier performance for demanding projects. You get an Arm Cortex-M7 core running at up to 1 GHz, paired with a Cortex-M4 at 400 MHz. This series offers up to 2 MB of SRAM and advanced graphics support. You can use MIPI-CSI for camera input and up to three Ethernet ports with Gbps speeds.

Model | CPU Core(s) | Max CPU Frequency | SRAM Size | Key Interfaces and Features | Package |

|---|---|---|---|---|---|

i.MX RT1170 | Arm Cortex-M7 + M4 | 1 GHz (M7), 400 MHz (M4) | 2 MB | Advanced 2D graphics, MIPI-CSI, MIPI-DSI, 3x Ethernet up to Gbps with TSN/AVB, UART, SPI, I2C, USB, 3x CAN-FD, secure boot, crypto engines | 289 BGA |

i.MX RT1160 | Arm Cortex-M7 + M4 | 600 MHz (M7), 240 MHz (M4) | 1 MB | Advanced 2D graphics, MIPI-CSI, MIPI-DSI, 3x Ethernet up to Gbps with TSN/AVB, UART, SPI, I2C, USB, 3x CAN-FD, secure boot, crypto engines | 289 BGA |

You can run real-time operating systems like Zephyr and use fast internal memory for code execution. The series supports flexible boot options and memory expansion. Evaluation kits help you test and validate your design.

Pros:

Very high CPU speed and memory

Multiple Ethernet ports with advanced features

MIPI-CSI camera support for high-quality imaging

Cons:

Higher power use than basic MCUs

More complex to develop for beginners

Ideal Use Cases:

Industrial automation

Smart cameras with advanced vision

Edge computing with real-time networking

If you need an Ethernet Interface Camera MCU chip for high-speed vision and networking, the i.MX RT117x series stands out.

Nvidia Jetson Modules

Nvidia Jetson modules give you powerful AI and vision capabilities. You get Gigabit Ethernet and multiple camera connectors. The Jetson Xavier NX Developer Kit includes two MIPI CSI camera connectors and a Gigabit Ethernet port. You can use USB 3.1 and wireless modules for extra connectivity. The JetPack SDK supports AI and computer vision development.

Jetson Xavier NX Developer Kit has Gigabit Ethernet (RJ45) and two MIPI CSI camera connectors.

Nova Developer Kit with Jetson AGX Orin SOM supports multiple camera connectors and up to 10 GbE Ethernet.

ADLINK's EOS-JNX system uses Jetson Xavier NX and features Smart PoE for camera applications.

Advantech's MIC-717-OX AI NVR solution integrates Jetson Orin NX, supporting 8x PoE and 2x 1 GbE RJ-45 ports.

You can connect several cameras and process video streams with high AI performance. The modules support GPU-accelerated frameworks like TensorRT and CUDA-enabled OpenCV DNN. This helps you process camera data in real time and send results over Ethernet.

Pros:

Strong AI and vision processing

Multiple camera and Ethernet options

Rich software ecosystem

Cons:

Higher power consumption

More expensive than standard MCUs

Ideal Use Cases:

Smart surveillance

Robotics with advanced AI

Edge AI vision systems

Choose Nvidia Jetson modules if you want top-level AI and vision in your Ethernet Interface Camera MCU chip project.

Microchip PIC/SAM Series

Microchip’s PIC32 and SAM series offer reliable performance for embedded vision and networking. You get 32-bit MCUs with Ethernet MAC and camera interfaces. The SAM E70 and SAMA5D2 families provide up to 300 MHz CPU speed and support for external memory. You can use parallel camera interfaces and 10/100 Mbps Ethernet.

Key Specs and Interfaces:

32-bit ARM Cortex-M7 or ARM Cortex-A5 cores

Up to 300 MHz CPU speed

Ethernet MAC with IEEE 1588 support

Parallel camera interface (up to 12 bits)

Support for external SDRAM and Flash

Pros:

Low power use for battery operation

Good balance of cost and features

Long-term availability and strong support

Cons:

Limited AI and graphics acceleration

Lower camera bandwidth than MIPI-CSI systems

Ideal Use Cases:

Industrial IoT sensors

Entry-level smart cameras

Connected devices with basic vision

You should pick Microchip PIC/SAM series if you want a cost-effective Ethernet Interface Camera MCU chip for simple vision and networking tasks.

Application Scenarios

Industrial IoT

You can use these microcontroller chips to build smarter industrial IoT systems. These chips help you collect data, control machines, and connect sensors directly to the network. You get faster processing and better control at the edge of your system.

You save time because the microcontroller can process tasks in parallel. This reduces processing time by about 17.5% compared to older gateways.

You can scale your system easily. The architecture lets you add new features or devices without major changes.

The microcontroller acts as the “brain” of your system. It handles data and makes decisions locally, so you do not need to send everything to a central server.

You lower costs by using platforms like ARM. This gives you more efficiency without spending more money.

Real-world companies have used these chips and seen better performance in their factories.

Tip: Choose a chip with strong Ethernet and camera support for industrial IoT. This helps you monitor machines, track products, and keep your system running smoothly.

Smart Cameras

You can create smart cameras that do more than just capture images. These microcontroller chips let your camera analyze pictures, detect objects, and send alerts over Ethernet. You get real-time image processing and fast data transfer.

Use the camera interface to connect high-quality sensors.

Process images on the chip to spot problems or count items.

Send results to your control center using Ethernet, so you get instant updates.

Smart cameras help you improve security, manage inventory, and automate inspections. You can set up these systems in factories, warehouses, or even public spaces.

Robotics and Automation

You can build robots and automated machines that see and react to their environment. Microcontroller chips with Ethernet and camera interfaces give your robots the power to move, sense, and communicate.

A mobile robot with a NodeMCU and ESP8266 chip can monitor pipelines or tunnels. It uses MQTT for fast wireless communication, which works better than HTTP.

The robot saves data to the cloud quickly, making it useful for real-time inspection.

Microcontrollers help robots control motors, read sensors, and avoid obstacles. This leads to precise movements and less manual work.

Companies use these chips to speed up production and improve quality. Robots can detect objects and move on their own.

Note: Microcontroller chips make your automation projects smarter and more reliable. You get better performance, easier maintenance, and higher productivity.

Buying and Development Tips

Sourcing Chips

You want to find reliable sources for microcontroller chips with Ethernet and camera interfaces. Start by checking trusted platforms that list supplier and stock information. Look for chips that match your project’s needs in performance, memory, and interface support. The table below shows what you should look for when sourcing:

Feature Category | Details |

|---|---|

Core | |

Memory | Up to 3MB Flash, 1MB SRAM (with ECC protection) |

Ethernet Interface | 10/100M or integrated Ethernet MAC with DMA |

Camera Interface | 8-bit to 16-bit camera video interface |

Security Features | TrustZone, cryptographic engine, tamper protection |

Peripheral Support | UART, SPI, I2C, CAN, USB, ADC, DAC, PWM timers |

Application Examples | Industrial control, security cameras, IoT, robotics |

Sourcing Platform | AMEYA360 with supplier and stock information |

Tip: Always check for up-to-date stock and supplier reliability. Supply chain disruptions can affect availability, so plan ahead.

Development Tools

You need the right development tools to speed up your project. Choose toolchains and libraries that support your chip. Good tools help you write, test, and debug code quickly. Many developers use automated code review tools and continuous integration systems to catch errors early. You should also use evaluation boards to test chip performance before finalizing your design. This helps you confirm that the chip meets your requirements for speed, memory, and connectivity.

Use industry-standard design patterns for better reliability.

Try shift-left testing to find problems sooner.

Maintain clear records of your design decisions.

Using proven tools and practices makes your development process smoother and more efficient.

Community Support

Strong community support can make your project easier. You benefit from active forums, open-source software, and vendor-backed resources. Many users prefer STM32 chips because of their helpful communities and cost-effectiveness. Community discussions often reveal real-world issues and solutions, helping you avoid common mistakes. Open-source ecosystems like Zephyr RTOS give you ready-made drivers and networking support, saving you time.

You also gain from mentorship programs and help desks set up by chip vendors. These resources offer guidance, access to equipment, and business advice. When you join a strong community, you get answers faster and build better products.

A vibrant community helps you solve problems quickly and keeps your project on track.

You now know the top Ethernet Interface Camera MCU chip options for 2025. Each chip offers unique strengths. STM32H7 gives you real-time control. NXP i.MX RT117x brings high speed. Nvidia Jetson modules deliver strong AI. Microchip PIC/SAM series keeps costs low. Match your project needs to the chip’s features. Check the ecosystem and support before you buy. Start by testing evaluation boards and comparing specs.

FAQ

What is the main advantage of using a microcontroller with both Ethernet and camera interfaces?

You can process images and send data over a network in real time. This setup helps you build smart devices that see and communicate quickly.

Can you use these chips for AI tasks?

Yes, you can use Nvidia Jetson modules for AI tasks. These modules support deep learning and computer vision. Other chips handle basic image processing but have limited AI power.

How do you choose the right chip for your project?

Start by listing your needs:

Speed

Camera type

Network speed

Power use

You should match these needs to the chip’s features and check for good software support.

Do you need special tools to develop with these chips?

You need development boards, software kits, and debugging tools. Most vendors offer starter kits and free software. These tools help you test and build your project faster.

Are these chips suitable for battery-powered devices?

Many chips, like STM32H7 and Microchip PIC/SAM, use low power. You can use them in battery-powered devices. Nvidia Jetson modules use more power and fit best in plugged-in systems.

See Also

Best Embedded System Microcontrollers To Watch In 2025

Leading Advances In Medical Imaging Processor Chips For 2025

Exploring Industrial D Flash Microcontrollers And Their Uses

A Guide To Low Power IoT Chip Tech And Applications

Defining High Performance Microcontroller Integrated Circuits Today