What Is an Embedded Programmable Logic Chip and How Does It Work

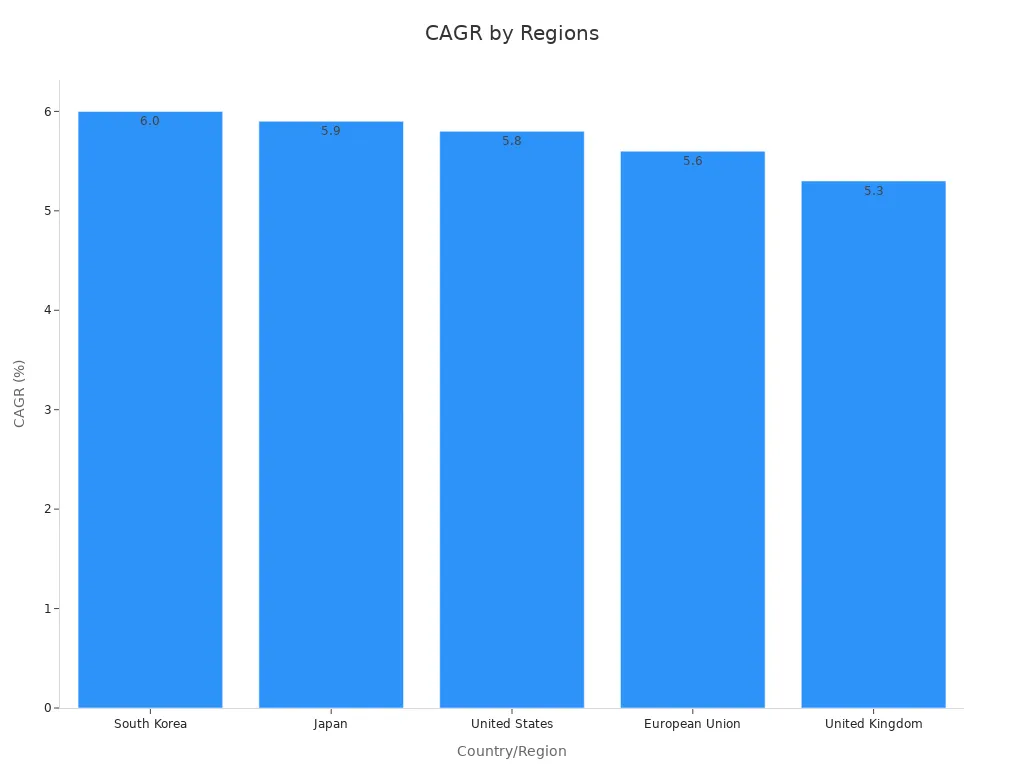

An Embedded Programmable Logic Chip is a small electronic component that engineers use to control and customize how devices work. This chip helps machines process data quickly and adapt to new tasks, making it important for smart devices and automation. Many industries choose these chips because they support artificial intelligence, 5G, and the Internet of Things. The market for these chips is growing fast, with an expected value of $10.9 billion by 2035.

Metric | Value |

|---|---|

Market Size (2025) | USD 6.2B |

Market Size (2035F) | USD 10.9B |

CAGR (2025 to 2035) | 5.8% |

Key Takeaways

Embedded programmable logic chips let engineers create custom digital circuits that control devices quickly and reliably.

These chips use low power, offer fast response times, and can be reprogrammed after installation to update features easily.

They connect well with sensors and other parts, making them ideal for smart devices, factory automation, and automotive systems.

Compared to microcontrollers and FPGAs, these chips balance speed, flexibility, and cost for many real-time control tasks.

Their use grows fast across industries, helping save energy, reduce costs, and support new technologies like AI, 5G, and IoT.

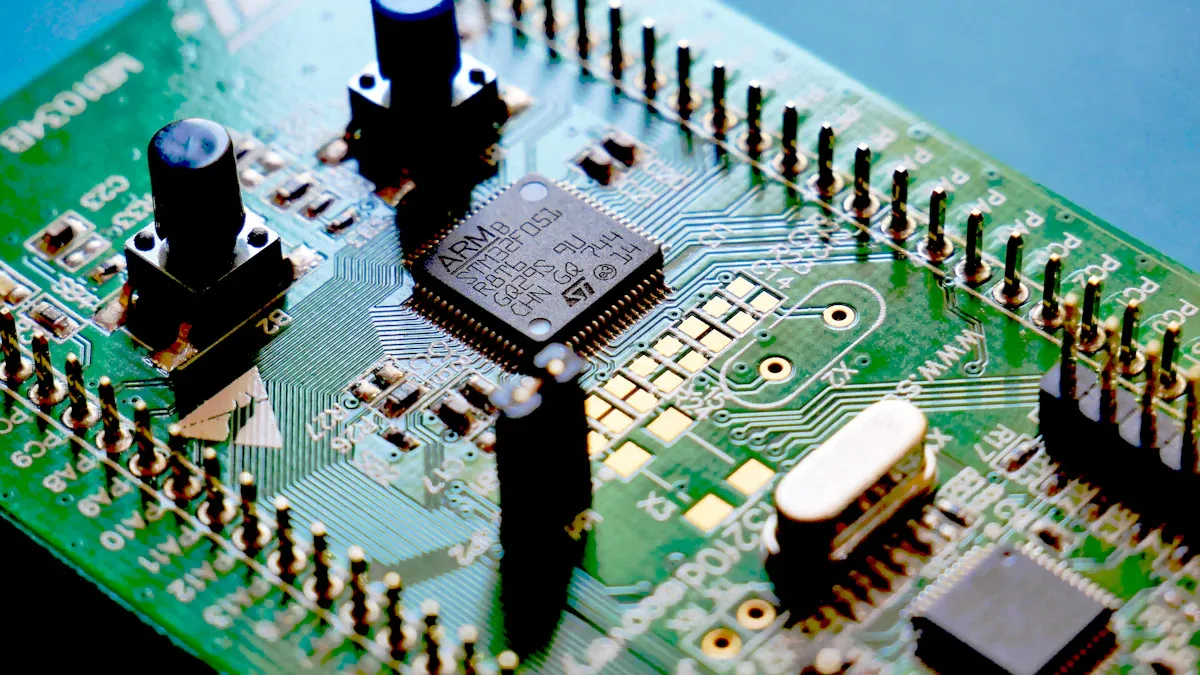

Embedded Programmable Logic Chip Basics

Definition

An Embedded Programmable Logic Chip is a type of electronic device that engineers use to create custom digital circuits inside machines. This chip contains many small building blocks called logic blocks or macrocells. These blocks connect through special channels that engineers can program to perform different tasks. The chip also includes input and output blocks, which help it talk to other parts of a system.

Most Embedded Programmable Logic Chips use non-volatile memory, such as Flash or EEPROM, to store their configuration. This means the chip remembers its setup even when the power is off. Engineers program these chips using special languages like VHDL or Verilog. After programming, the chip can control how signals move and how devices respond in real time. These chips work well in systems that need fast and reliable control, such as cars, factory machines, and communication equipment.

Note: Industry benchmarks show that these chips offer low power use, fast response, and high reliability. They often serve as the "glue" that connects different parts of a system, making them important for many modern devices.

Key Features

Embedded Programmable Logic Chips stand out because of their unique features. Here are some of the most important ones:

Custom Logic Functions: Engineers can program the chip to perform specific tasks, making it flexible for many uses.

Low Power Consumption: The chip uses less energy, which helps in battery-powered and energy-saving devices.

Fast and Predictable Response: The chip’s fixed routing allows for quick and reliable operation, which is important for real-time control.

Reprogrammability: Users can change the chip’s function after installation, allowing updates and improvements without replacing hardware.

High Reliability: These chips go through strict tests, such as thermal stress and voltage checks, to ensure they work well in tough conditions. They also use error correction methods to reduce the chance of mistakes.

Integration with Other Devices: The chip can connect with sensors, motors, and other electronic parts, making it useful in many types of systems.

Feature | Description |

|---|---|

Logic Blocks | Small units that perform logic operations |

Programmable Interconnect | Channels that link logic blocks in custom ways |

Non-volatile Memory | Stores configuration even when power is off |

Fast Response | Provides low latency for real-time control |

Low Power Use | Suitable for portable and energy-efficient applications |

Reliability | Tested for long life and stable operation in harsh environments |

Error Correction | Built-in methods to detect and fix small errors |

These features make the Embedded Programmable Logic Chip a strong choice for applications that need speed, flexibility, and reliability. For example, in factory automation, these chips help machines run smoothly for years with little downtime. In cars, they support safety systems that must work every time.

How It Works

Internal Structure

An Embedded Programmable Logic Chip contains several important parts inside. The main elements include logic blocks, programmable interconnects, and sometimes embedded processor cores. Logic blocks act like tiny decision-makers. They handle simple math and logic tasks. Programmable interconnects link these blocks together. This setup lets engineers create custom circuits for different jobs.

Some chips also have embedded processor cores. These cores work with the logic blocks to handle more complex tasks. The processor core runs software instructions, while the logic blocks manage fast, real-time operations. Together, they make the chip both flexible and powerful.

The table below shows how two common types of programmable logic devices, CPLDs and FPGAs, compare in their internal structure and performance:

Performance Indicator | CPLD Characteristics | FPGA Characteristics |

|---|---|---|

Timing Delay | Uniform and predictable due to continuous wiring structure | Segmented wiring causes less predictable timing delays |

Programming Flexibility | Logic block-level programming with fixed internal circuits | Logic gate-level programming with internal wiring changes |

Integration Level | Lower integration | Higher integration with complex wiring |

Speed and Timing Predictability | Faster speed and better timing predictability | Slower speed and less predictable timing |

Power Consumption | Generally higher, especially with higher integration | Lower power consumption |

Confidentiality | Offers better confidentiality | Provides lower confidentiality |

Programming Technology | Uses E2PROM or FLASH; retains data when powered off | SRAM-based; data lost when powered off, requires reload |

Note: The internal structure affects how fast and reliable the chip works in real-world systems.

Programming Process

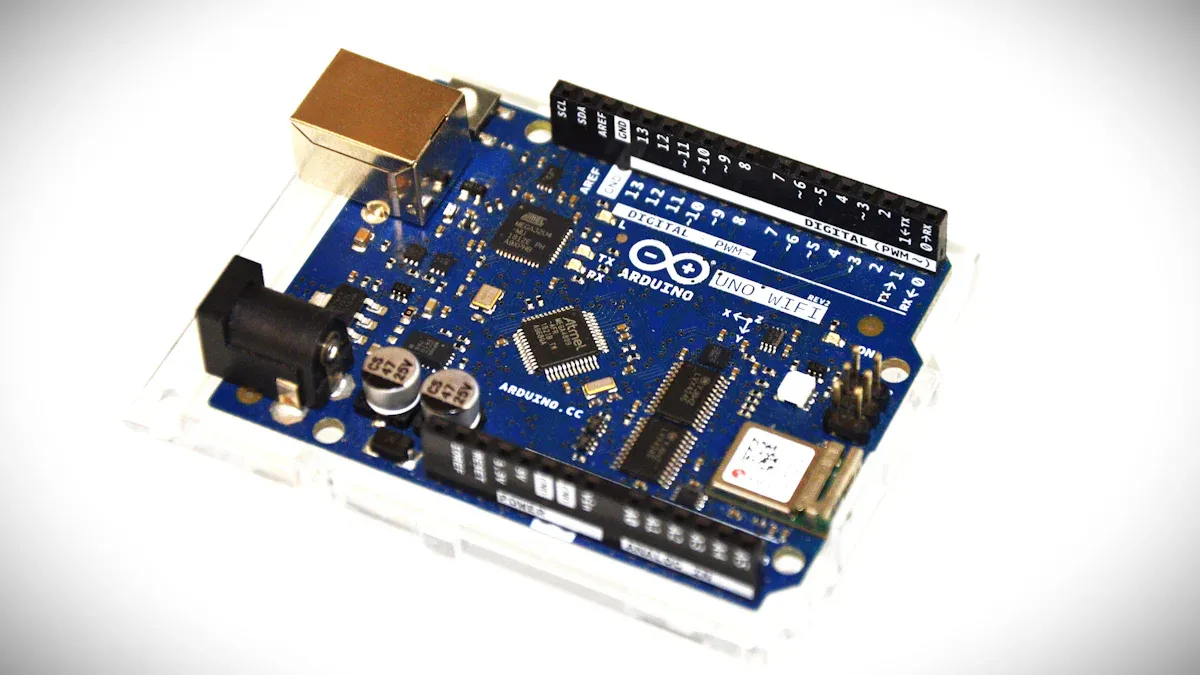

Engineers program an Embedded Programmable Logic Chip using special languages. The most common languages are VHDL and Verilog. These languages describe how the chip should process signals and make decisions. Some chips also support ladder logic, which is popular in industrial settings.

The programming process starts on a computer. Engineers write code that describes the desired logic. They use software tools to check for errors and simulate how the chip will behave. After testing, they load the program into the chip using a programmer device or through a direct connection.

One key feature is reconfigurability. Users can change the chip’s function even after installation. This means they can update the chip to fix bugs or add new features without replacing the hardware. The chip stores its program in non-volatile memory, so it keeps its settings even when powered off.

Tip: Reconfigurable chips help companies save time and money during product updates.

Integration in Systems

An Embedded Programmable Logic Chip fits easily into many types of electronic systems. It connects to sensors, motors, displays, and other devices using flexible input and output (I/O) pins. These pins support standard interfaces like SPI, I2C, UART, and GPIO. This flexibility allows the chip to work with many different parts.

The chip often acts as a bridge between different system components. For example, it can collect data from sensors, process the information, and send commands to motors or displays. In some cases, the chip works alongside a microcontroller or processor. The processor handles complex software tasks, while the programmable logic manages fast, real-time control.

Many engineers choose these chips for their ability to adapt to changing needs. They can quickly prototype new ideas and customize systems for special applications. This makes the Embedded Programmable Logic Chip a popular choice in fields like industrial automation, automotive electronics, and smart devices.

Device Comparison

FPGAs vs. Embedded Programmable Logic Chip

Field-Programmable Gate Arrays (FPGAs) and embedded programmable logic chips share some similarities, but they serve different needs. FPGAs, made by companies like Xilinx and Intel, offer high processing power and flexibility. These chips handle complex algorithms and high-speed data tasks in places like data centers, telecommunications, and medical imaging. FPGAs use hardware-level parallelism, which means they can process many tasks at the same time. This makes them ideal for real-time systems that need fast and predictable results.

Embedded programmable logic chips, on the other hand, focus on custom control and integration in smaller systems. They often use less power and cost less to develop. While FPGAs excel in high-performance and data-heavy jobs, embedded programmable logic chips fit best in applications that need reliable, flexible control without the complexity or power draw of large FPGAs.

FPGAs guarantee nanosecond-level timing and handle parallel numeric calculations better than microcontrollers or basic programmable logic chips. However, they require more specialized skills and longer development times.

Microcontrollers vs. Embedded Programmable Logic Chip

Microcontrollers and embedded programmable logic chips both control electronic devices, but they work in different ways. Microcontrollers run instructions one after another, using software to manage tasks. They work well in simple, battery-powered devices because they use very little energy and have sleep modes to save power.

Embedded programmable logic chips use hardware to process signals and make decisions quickly. They can change their function after installation, which helps when updates or fixes are needed. Microcontrollers offer easier and cheaper development, but they cannot match the speed and real-time control of programmable logic chips in demanding tasks.

Feature | Microcontroller | Embedded Programmable Logic Chip |

|---|---|---|

Processing Style | Sequential | Parallel/Custom Hardware |

Power Consumption | Very Low | Low to Moderate |

Development Complexity | Simple | Moderate |

Real-Time Performance | Limited | High |

Reprogrammability | Firmware Updates | Hardware Logic Updates |

Unique Role

Embedded programmable logic chips fill a special place in modern electronics. They appear in many industries, including consumer electronics, automotive, telecommunications, industrial automation, aerospace, and defense. These chips adapt quickly to new standards and changing needs, making them valuable for products that must evolve over time.

Consumer electronics use these chips to keep up with fast-changing technology.

Cars rely on them for safety, entertainment, and electric vehicle systems.

Telecom companies use them to support new standards like 5G.

Factories and robots depend on them for smart automation and control.

Aerospace and defense trust them for reliable, mission-critical systems.

These chips offer short lead times, lower upfront costs, and no minimum order requirements. They allow in-system updates and combine well with other components, such as microcontrollers and ASICs. This flexibility and broad adoption set embedded programmable logic chips apart from other system parts, making them a key choice for engineers who need both speed and adaptability.

Pros and Cons

Advantages

Embedded programmable logic chips offer many benefits for modern electronics. These chips help engineers create custom solutions that fit specific needs. They provide high flexibility, allowing quick changes and updates without replacing hardware. Many systems use these chips to save energy and reduce costs.

Some of the most important advantages include:

Faster Processing: These chips can handle tasks up to three times faster than traditional CPUs or GPUs, especially in AI and analytics.

Lower Power Use: Devices with these chips often use up to 40% less power, making them ideal for portable gadgets and satellites.

Reduced Latency: Systems see up to 55% lower delays in parallel processing and up to 70% less latency in trading algorithms.

Cost Savings: Companies can cut prototyping costs by up to 70% and reduce inventory by 35% by using fewer controllers.

Quick Feature Updates: Engineers can update features 60% faster compared to ASIC-based systems.

System Improvement Category | Measurable Advantage | Comparative Context |

|---|---|---|

Logic Density | 35% increase | Previous FPGA generations |

Power Consumption | Up to 40% lower | Portable and satellite devices |

Processing Speed | Up to 3x faster | CPU/GPU-only systems |

Latency Reduction | 55% lower | ASICs and MCUs |

Energy Efficiency | 40% less power | CPU-only servers |

Development Cost Savings | Up to 70% reduction | ASIC development |

Inventory Cost Reduction | 35% fewer SKUs | Multi-controller setups |

Feature Update Speed | 60% faster | ASIC-based systems |

Hybrid Architectures | 2x faster analytics | CPU+FPGA, GPU+FPGA, hybrid SoC |

A new approach for embedding model predictive control on a chip shows that these chips can deliver high speed and low power while keeping costs down. This design uses fewer transistors, which means less energy use and smaller size, but still keeps strong control performance.

Disadvantages

Despite many strengths, embedded programmable logic chips also have some drawbacks. These chips can face reliability issues due to faults from manufacturing defects, aging, or harsh environments. For example, exposure to radiation or electromagnetic interference can cause errors during operation. Over time, these problems may lead to permanent damage or unexpected failures, especially in safety-critical systems.

Quantitative studies show that these chips can struggle with complex tasks. As models grow larger, power use and latency can increase. In some cases, spiking neural networks on these chips use 19% more power than other types, and high inference latency can reduce energy savings. Advanced frameworks help improve speed and throughput, but balancing performance, power, and resources remains a challenge compared to embedded GPUs.

Engineers must weigh these limitations when choosing embedded programmable logic chips for demanding or long-life applications.

Applications

Industrial Automation

Factories and production lines use embedded programmable logic chips to control machines and processes. These chips connect to sensors, motors, and programmable logic controllers (PLCs). They help machines react quickly to changes, such as a sensor detecting a jam or a motor needing to stop. Many companies use these chips to improve safety and reduce downtime. Engineers can update the chip’s logic to match new production needs, which helps factories stay flexible. Integration with drives and SoC (System on Chip) platforms allows for smooth communication between different parts of a system. This setup supports real-time monitoring and fast decision-making.

Consumer Electronics

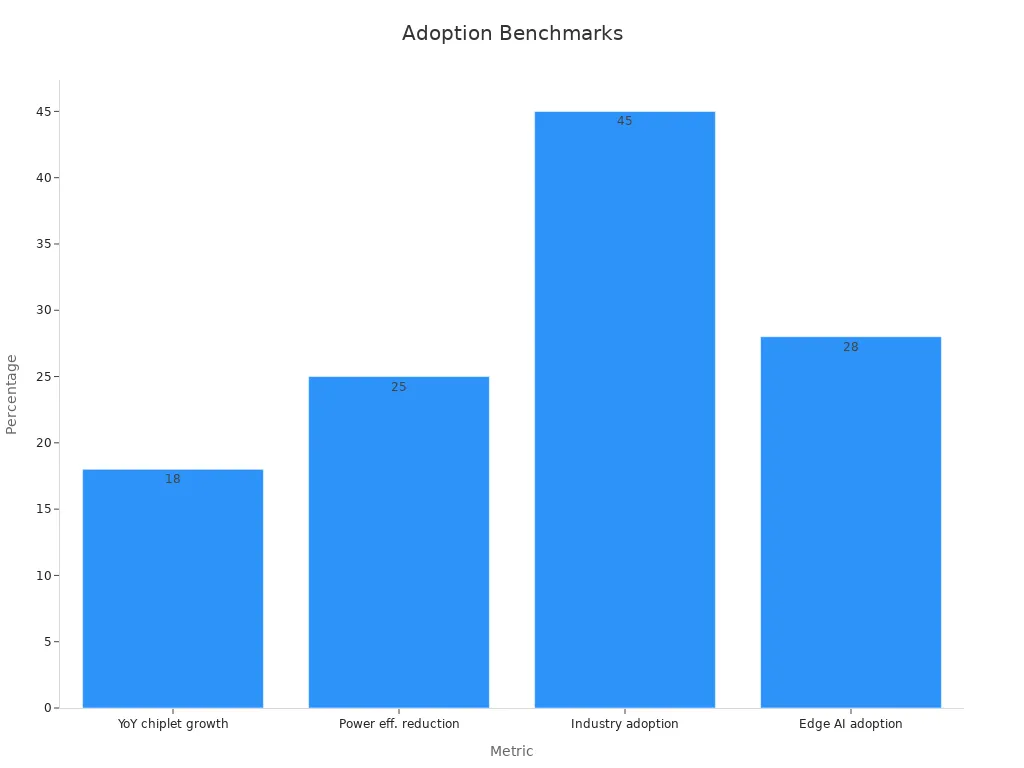

Consumer electronics rely on embedded programmable logic chips for smart features and energy savings. Devices like smart TVs, home assistants, and wearable gadgets use these chips to manage data and connect to other devices. The adoption of programmable logic devices in consumer electronics has grown by 18% year-over-year. Companies see a 25% drop in power use for server applications that use chiplet-based SoCs. Over 28% of edge devices now use AI engines built on these chips. These numbers show strong industry acceptance and efficiency gains.

Metric / Aspect | Value / Description |

|---|---|

Year-over-year chiplet adoption growth | 18% increase in consumer electronics |

Power efficiency improvement | 25% reduction in power consumption in server applications using chiplet-based SoCs |

UCIe 1.1 protocol bandwidth | Up to 64 GT/s enabling higher bandwidth interconnects |

Industry adoption | Over 45% of data center processor companies integrated chiplets (20% faster time-to-market, 15% cost savings) |

Edge computing AI hardware adoption | Over 28% of edge devices use AI inference engines built on chiplets |

Custom Controls

Engineers use embedded programmable logic chips to create custom control solutions for many industries. These chips support rapid prototyping, which means teams can test ideas and make changes quickly. The market for simple programmable logic devices (SPLDs) is growing at a rate of 6.4% each year from 2025 to 2032. Key benefits include design flexibility, fewer components, and faster time-to-market. Companies in automotive, telecommunications, and consumer electronics drive this demand. Integration of AI, IoT, and miniaturization trends also boost their use.

Aspect | Details |

|---|---|

Market Growth | SPLD market projected CAGR of 6.4% from 2025 to 2032 |

Key Benefits | Rapid prototyping, design flexibility, component reduction, efficient resource utilization, shortened time-to-market |

Market Drivers | Increasing demand for customizable electronics in automotive, consumer electronics, telecommunications |

Technological Trends | Integration of AI/ML, IoT applications, miniaturization, low power consumption, open-source ecosystems |

Embedded programmable logic chips help engineers build smarter, more adaptable systems. They support fast changes and new features, making them a top choice for modern technology projects.

An Embedded Programmable Logic Chip gives engineers the power to design custom solutions for many devices. These chips combine high flexibility, strong performance, and low power use. Modern designs now include features like embedded memory and special I/O pins, which help systems run faster and use less energy. Their ability to adapt makes them important for future technology in fields from consumer electronics to aerospace.

FAQ

What makes an embedded programmable logic chip different from a regular microcontroller?

An embedded programmable logic chip uses hardware to process tasks in parallel. A microcontroller runs instructions one after another. This chip can change its function after installation, while a microcontroller usually cannot.

Can engineers reprogram these chips after installing them in a device?

Yes, engineers can update the chip’s logic even after installation. This feature allows quick fixes or new features without replacing the hardware. Many industries value this flexibility.

Where do people use embedded programmable logic chips most often?

Engineers use these chips in cars, factories, smart home devices, and robots. They help control machines, process sensor data, and connect different parts of a system.

Do embedded programmable logic chips save energy?

Yes, these chips use less power than many other control devices. They help battery-powered gadgets and large machines run longer and more efficiently.

What programming languages work with these chips?

Most engineers use VHDL or Verilog to program these chips. Some chips also support ladder logic, which is common in factory automation.

Tip: Learning VHDL or Verilog helps engineers create custom solutions with these chips.

See Also

Understanding Programmable Logic Chips And Their Functionality

Exploring Computer Chips And How They Operate Effectively

A Comprehensive Guide To Communication Chips And Operation