Innovations Driving Domestic Memory Chip Manufacturing in 2025

Domestic memory chips are transforming the tech world in 2025. Big numbers illustrate their impact: approximately $450 billion has been invested in chip innovations since 2022. Plans for 17 new factories will enable the U.S. to produce 30% of advanced domestic memory chips by 2032. This shift is not only about technology; it also concerns jobs and economic growth. Each year, 200,000 new jobs are created, contributing $25 billion to the economy. Domestic memory chips account for 34% of all industry spending, highlighting their crucial role in this transformation.

Key Takeaways

Making memory chips at home will grow a lot. 17 new factories will make 30% of advanced chips by 2032.

AI designs are changing how chips are made. Chips are now faster and use less energy, helping things like self-driving cars work better.

Chips that save energy cut costs by millions. They are important for AI and cloud systems to grow without harming the planet.

Making chips locally helps supply chains and creates jobs. It also reduces the need to buy chips from other countries and helps the economy.

Schools and companies must work together to train workers. This teamwork ensures skilled people for future chip-making jobs.

Technological Innovations in Domestic Memory Chips

AI-Driven Chip Designs

AI is changing how chips are made. These chips can now adjust to tasks instantly, improving speed and saving energy. AI programs study huge amounts of data to find useful patterns. This helps make better chip designs faster and more accurately.

Tip: AI-designed chips work well for tasks like learning machines, talking computers, and self-driving cars.

Factories use AI to build smarter chips with stronger computing power. This keeps domestic chips competitive worldwide. As AI improves, expect even smarter chips that push technology further.

Energy-Efficient Memory Technologies

New memory technologies help chips use less power. They focus on saving energy while staying fast. For example:

Save 18.8 GWh in three years compared to GPUs.

11% better energy use, saving 26 J per task.

20% less energy used, saving up to 40 J per task.

These changes lower costs, saving millions each year. New ideas like Processing-In-Memory (PIM) save even more energy, cutting 159 J per task for decision-making.

Note: Energy-saving chips are vital for AI, cloud systems, and cars, where power use affects growth and eco-friendliness.

Gate-All-Around Transistor Designs

Gate-all-around transistors are a big step forward for chips. They improve things like sensing, memory, and energy use. For example:

Feature | Improvement |

|---|---|

On/Off Ratio | 4.57 × 10^8 |

Sensing Margin | 3.2 μA μm−1 |

Memory Time | 1.07 s at 358 K |

Energy Use | 2.81 fJ (write '1') |

25.6 fJ (read '1') | |

5.45 × 10^−15 fJ (read '0') | |

Tiny (write '0' and hold) |

These transistors make chips work better, using less energy and lasting longer. Factories use them to meet modern needs with advanced designs.

Callout: Gate-all-around transistors help make smaller, faster, and more energy-saving chips, opening doors to new ideas.

Backside Power Delivery Enhancements

Backside power delivery changes how chips get energy. Power flows through the back instead of the front. This method lowers resistance and boosts efficiency. It keeps energy steady, even for tough tasks.

Here’s how backside power delivery helps:

Average IR drop is 81% lower than older methods.

Peak IR drop drops by 77%, keeping the chip’s bottom layer stable.

Wider power rails cut energy loss and improve reliability.

These upgrades make chips work better and last longer. They meet the need for faster computing in AI and cloud systems. Backside power delivery is now a key part of modern chip design.

Tip: Backside power delivery is vital for future chips, where saving energy and staying stable matter most.

Advanced Manufacturing Processes (e.g., 2nm Nodes)

Smaller processes like 2nm nodes are changing the chip industry. These methods make chips faster, smaller, and more powerful. They also save energy, which is important for AI and 5G.

Here’s what’s driving this change:

Trend Description | Growth Rate | Year |

|---|---|---|

Semiconductor market growth | 2025 | |

Advanced nodes capacity increase | 12% | 2025 |

Wafer manufacturing growth | 7% | 2025 |

Big companies like TSMC, Samsung, and Intel are investing in 2nm technology. This helps meet the demand for AI and high-speed computing. Using these methods keeps businesses ahead in the chip market.

Callout: Advanced processes are key to making chips for AI, 5G, and future tech.

Cutting-Edge Packaging Techniques

Packaging methods protect chips and improve how they work. New ideas like 3D stacking and chiplet integration are changing this area. These methods combine many chips into one package, making them faster and better.

Benefits of advanced packaging include:

Better heat control stops chips from overheating.

Faster communication between chips reduces delays.

Smaller packages make devices easier to carry.

These improvements are important for AI, cars, and cloud systems. Using new packaging methods creates chips that fit modern needs.

Note: Packaging innovations are leading the next big tech changes.

Supply Chain Dynamics in Semiconductor Manufacturing

Shift Toward Localized Production

Making chips closer to home is changing the industry. It lowers risks from global problems like pandemics. COVID-19 showed how much the U.S. depends on imports for chip materials. For instance, the U.S. gets 90% of its titanium and all its gallium from other countries. Producing chips locally reduces this dependence and strengthens the industry worldwide.

Big investments are helping this change happen. Intel is spending $100 billion to build factories in the U.S. and Europe. These factories aim to make supply chains stronger and faster. Local production also saves time and money by cutting shipping costs. This helps meet the growing need for advanced chips in AI and cars.

Tip: Making chips locally creates jobs and boosts your community’s economy.

Building Supply Chain Resilience

Strong supply chains are key for making chips. Problems like natural disasters or factory shutdowns can stop production. Fires and strikes often close factories, delaying chip making. Climate change is another worry, with many leaders seeing it as a big threat.

Semiconductors don’t last as long as they used to. Their average lifespan dropped from 30 years in 1970 to just 10 years now. This means companies must adapt quickly. To stay strong, manufacturers use more suppliers, better technology, and emergency plans. These steps help keep chip production steady during tough times.

Callout: Strong supply chains keep chip production going, even when problems arise.

Role of Government Policies and Funding

Government rules and money help the chip industry grow. Laws like the Chips and Science Act give funds and rewards for making chips locally. Agencies like DARPA and the Department of Energy support research to improve chip technology. These efforts help companies stay ahead in the global market.

Tax breaks and clean energy projects encourage building factories in states like Texas and Arizona. These factories boost production and make supply chains stronger. The Chips and Science Act has doubled spending on research, keeping the U.S. a leader in chip innovation.

Note: Laws like the Chips and Science Act help the chip industry grow and stay strong.

Domestic Collaboration Between Industry and Academia

When companies and schools work together, they improve chip-making. They share ideas, create new tools, and train future workers. These partnerships help make better chips and grow the industry.

The National Institute of Standards and Technology (NIST) says measuring tools are key. Over 800 people from companies, schools, and government work together. This teamwork helps make sure new tools are high-quality and compete globally.

Groups like the National Science Foundation (NSF) and Micron Foundation focus on teaching. They give students hands-on learning chances and fair access to training. They also add industry rules to school lessons, helping students get ready for chip-making jobs.

Benefits of these partnerships include:

Better training for students joining the workforce.

New learning materials made for industry needs.

Real-world projects for students to practice skills.

Schools and companies also share tools and ideas. The National Academy of Engineering says this saves money and improves learning. By sharing, schools can offer better lessons and tools. Students learn with the latest technology to prepare for future jobs.

These partnerships are important for a strong chip-making industry. They make sure students have the skills to succeed in this fast-changing field. Working together, schools and companies build a strong future for chip-making.

Challenges and Opportunities in Domestic Semiconductor Manufacturing

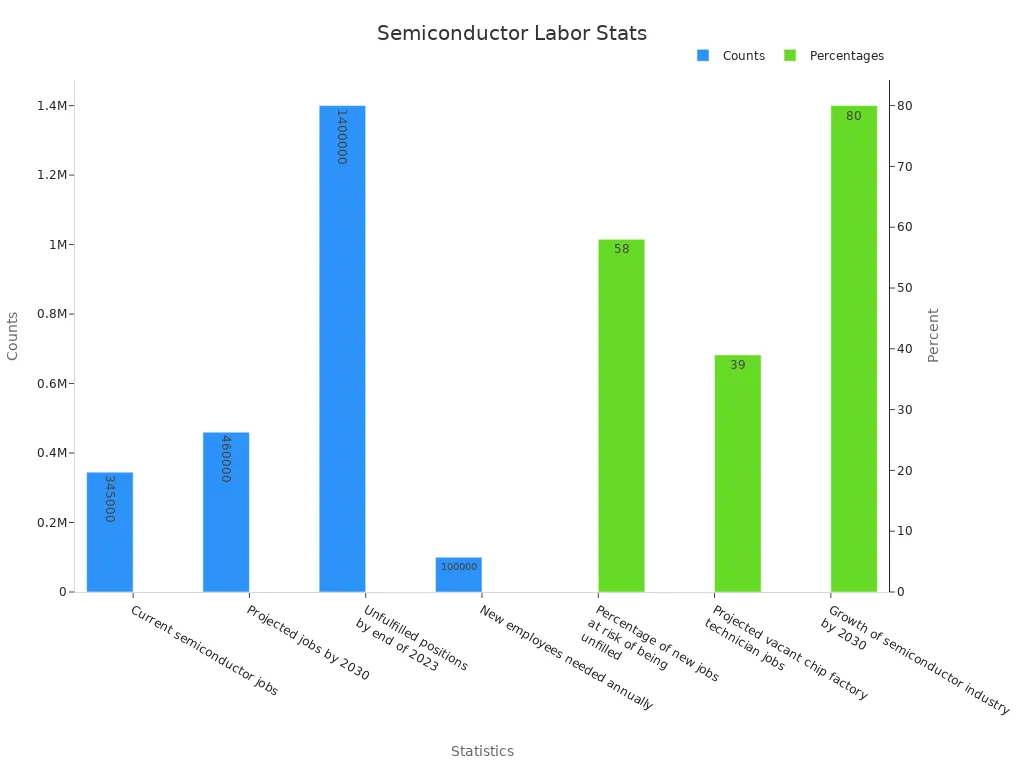

Labor Shortages in Semiconductor Manufacturing

The semiconductor industry faces a big problem: not enough workers. Demand for chips is growing, but fewer people are making them. Many skilled workers are retiring, and younger workers aren't replacing them fast enough. This slows production and new ideas, making it hard to meet needs like AI memory.

Statistic Description | Value |

|---|---|

Current semiconductor jobs | 345,000 |

Projected jobs by 2030 | 460,000 |

Percentage of new jobs at risk of being unfilled | 58% |

Projected vacant chip factory technician jobs | 39% |

Unfulfilled positions by end of 2023 | 1.4 million |

Growth of semiconductor industry by 2030 | 80% |

New employees needed annually | 100,000 |

Graduate students in complementary programs | < 100,000 |

There are over 70,000 open technical jobs in the U.S. Many skilled workers are leaving for better-paying software jobs. This makes it harder for factories to find the right people.

Tip: Schools and companies can work together to train students. This helps prepare them for chip-making jobs and fills the worker gap.

Market Fluctuations and Economic Pressures

Money problems and changing markets make chip production harder. Tariffs and supply chain issues raise costs. For example, U.S. tariffs on Chinese chips will go from 25% to 50% by 2025. This makes it more expensive to produce chips in the U.S.

Evidence Type | Description |

|---|---|

$280 billion in federal subsidies, with $39 billion allocated for fabrication plants. | |

Tariffs Impact | Proposed tariffs of 25% on imported semiconductors could increase costs. |

Dependency on Taiwan | 44.2% of U.S. imports of advanced chips come from Taiwan. |

Cost Increase Warning | U.S. production could double chip costs, affecting consumer electronics. |

Global Economic Impact | A Taiwan conflict could reduce global GDP by $10 trillion. |

The U.S. depends on Taiwan for advanced chips, which is risky. If tensions rise, the global chip market could face big problems. Higher costs also mean pricier electronics for consumers.

Callout: The CHIPS Act offers help. It gives money to build factories and reduce reliance on foreign chips.

Sustainability and Environmental Concerns

Making chips uses a lot of water and energy. Droughts are making water harder to find. By 2025, two-thirds of people worldwide may face water shortages, says WWF.

Year | Emissions (megaton CO2e) | Global Emissions (gigaton CO2e) | Semiconductor Share (%) |

|---|---|---|---|

2021 | 76.5 | 37.9 | 0.2 |

Year | Projected Emissions (million metric tons CO2e) | Growth Rate (%) |

|---|---|---|

2020 | 168 | N/A |

2030 | 277 | 8.3 |

Making chips also adds to carbon emissions. By 2030, emissions from chip production will grow by 8.3%, reaching 277 million metric tons of CO2e. This raises concerns about the environment.

Note: Using energy-saving technologies can lower emissions and save resources. Ideas like Processing-In-Memory (PIM) and backside power delivery help meet AI needs while protecting the planet.

Growth Opportunities in AI, Automotive, and Cloud Computing

The semiconductor industry is finding new chances in AI, cars, and cloud systems. These areas need advanced memory chips, offering room for growth and new ideas.

AI: Changing How Chips Are Used

AI is changing how chips work in many fields. It helps with machine learning, talking computers, and robots. The AI chip market is growing fast, with a yearly growth rate of 34.84% until 2035. This rise comes from the need for chips that handle big data quickly and well.

AI also helps make chips better. By 2034, the AI for Semiconductor Manufacturing Market will grow to $192.3 billion, up from $46.3 billion in 2024. AI tools are making chip design, building, and testing faster and smarter.

Tip: AI chips are key for self-driving cars, smart assistants, and data predictions. Using AI tech keeps you ahead in this fast-changing area.

Automotive: Boosting New Ideas

The car industry is changing with electric cars and self-driving systems. These need memory chips for tasks like maps, sensors, and quick decisions.

Modern cars use chips for fast communication between parts. AI-powered chips help with features like smart cruise control and crash prevention. As electric and self-driving cars grow, the need for advanced chips will increase.

Callout: Cars are pushing chip tech forward, giving makers chances to create special solutions for this growing market.

Cloud Computing: Supporting Digital Growth

Cloud computing is growing fast, needing better ways to store data. People use cloud services for videos, apps, and more. This growth needs memory chips that handle big tasks while saving energy.

AI chips are important for cloud systems. They speed up data work and improve AI models in the cloud. As businesses use AI tools, the need for cloud-ready chips will grow.

Sector | Growth Rate | Key Reasons |

|---|---|---|

AI Chip Market | 34.84% CAGR | Needs in cars and cloud systems |

Semiconductor AI | 15.3% CAGR | Making and using AI |

Note: Cloud systems need chips that are fast, save energy, and work well. Using energy-saving tech helps this area grow in a green way.

AI, cars, and cloud systems are shaping the future of memory chips. Focusing on these areas can bring big growth and new ideas to the semiconductor industry.

Future Outlook for Domestic Memory Chip Manufacturing

Long-Term Implications for Domestic Semiconductor Industry

The U.S. memory chip industry will grow a lot soon. Investments in factories and tools are making this happen. For example:

Statistic | Value | Year |

|---|---|---|

U.S. chip manufacturing capacity growth | by 2032 | |

U.S. share of global spending on chips | 28% | 2024-2032 |

U.S. global chip production share rise | 10% to 14% | 2022 to 2032 |

Private money invested in chip industry | $450 billion | since CHIPS Act |

Jobs added in chip industry | 56,000 | N/A |

These numbers show how important U.S. chips are becoming worldwide. As the U.S. makes more chips, there will be more jobs and stronger supply chains. New ideas in chip technology will also grow.

Tip: Making chips locally reduces imports and helps the economy grow.

Potential for Global Leadership in Memory Chip Manufacturing

The world’s memory chip market is growing fast, giving U.S. makers a chance to lead. In 2023, the market was worth $210 billion. By 2032, it could reach $718 billion, growing 14.1% each year. This growth comes from the need for faster, energy-saving memory chips.

AI is a big reason for this growth. High-bandwidth memory (HBM) grew 150% in 2023 and may grow over 200% in 2024. U.S. makers can lead by focusing on advanced memory chips.

Callout: Investing in new technology can make you a leader in the memory chip market.

Emerging Trends to Watch Beyond 2025

Some trends will shape the future of U.S. memory chip making:

AI Demand: AI will need faster and smarter memory chips.

Eco-Friendly Processes: Green manufacturing will become more important.

New Packaging: Ideas like 3D stacking will change how chips are made.

DRAM makers are focusing on HBM, which affects DDR5 memory. This creates challenges but also new chances for chip makers.

Note: Watching these trends will help you stay competitive in the chip industry.

In 2025, making memory chips at home shows big progress. New ideas like AI designs and energy-saving tech cut factory energy use by over 20%. They also make finding mistakes 97% accurate. Building factories locally, with tax breaks and worker training, grew U.S. production from 0% in 2015 to match South Korea by 2025. More AI, cars, and cloud systems need better chips, boosting demand. This opens doors for the U.S. to lead in memory chip making. It’s an exciting time for chip technology to grow and improve.

FAQ

1. Why is domestic memory chip manufacturing important?

Making chips locally reduces the need for imports. It helps the economy grow and creates jobs. Local production also keeps supply chains strong during global problems.

Tip: Supporting local factories helps your community and brings new technology closer to home.

2. How does AI make memory chip designs better?

AI studies data to improve how chips are made. It makes production faster and reduces mistakes. AI-designed chips work better and save energy for things like smart cars and talking computers.

Note: AI-designed chips stay ahead in the fast-moving tech world.

3. What problems does the semiconductor industry face?

The chip industry struggles with not enough workers, high costs, and environmental issues. You can help by supporting worker training and eco-friendly ideas.

Callout: Skilled workers and green solutions are key to solving these problems.

4. Why is saving energy important for memory chips?

Energy-saving chips use less power and cost less to run. They are better for the planet and work well for AI, cloud systems, and cars.

Emoji Insight: 🌱 Energy-efficient chips help create a cleaner future.

5. How can you get ready for a job in chip-making?

Learn STEM subjects and get hands-on experience. Look for internships or programs with schools and companies.

Tip: Jobs in AI, cars, and cloud systems offer exciting career choices.

See Also

Key Developments Influencing Analog IC Sector By 2025

Leading Advancements in Medical Imaging Chip Technology 2025

New Developments in Automotive Chip Technologies Emerging Now

Exploring Low Power IoT Chip Tech And Its Uses

Guidelines for Deploying Smart Lighting Solutions Using MCUs