How to Design Pressure Sensor Circuits for Beginners

Pressure Sensor curcuits are designed to measure physical pressure and transform it into an electrical signal. These Pressure Sensor curcuits are essential components in devices such as smartphones, wearables, and smart home systems. For beginners, working on Pressure Sensor curcuits provides a practical way to explore sensors and electronics.

The demand for Pressure Sensor curcuits is increasing rapidly, fueled by industries like consumer electronics, where smart devices and wearables rely on advanced sensing technologies. Gaining expertise in designing Pressure Sensor curcuits not only deepens your understanding of the technology behind modern gadgets but also equips you to tackle more complex projects in the future.

Key Takeaways

Learn the main parts of pressure sensors: sensing part, signal circuit, and casing. Knowing these helps you design better circuits.

Pick the right pressure sensor for your job. Gauge, absolute, and differential sensors work differently, so choose what fits your needs.

Use correct wiring and calibration to get accurate results. Test and adjust your circuits often to keep them working well.

Use affordable materials and smart building methods to improve designs. Try different setups to make sensors more sensitive and save money.

Check out books, online classes, and groups to learn more about pressure sensors and electronics.

Basics of Pressure Sensor Circuits

How pressure sensors work

Pressure sensors detect physical pressure and convert it into an electrical signal. This process typically involves a sensing element that deforms under pressure, causing a measurable change in its electrical properties. For example, piezoresistive sensors rely on changes in resistance, while capacitive sensors measure variations in capacitance.

To better understand how these sensors operate, consider the following technical aspects:

Aspect | Description |

|---|---|

Mechanism | The elastic porous structure of the sensor changes under compression, affecting capacitance. |

Simulation | Electric field distribution is analyzed using specialized software like COMSOL. |

Performance | Modern sensors, such as those based on Laser-Induced Graphene (LIG), offer competitive performance compared to traditional designs. |

These principles allow pressure sensors to function reliably in various applications, from industrial equipment to consumer electronics.

Key components of pressure sensors

Pressure sensors consist of several critical components that determine their performance and suitability for specific tasks. Here are the key elements you should know:

Sensing Element: The core part that reacts to pressure changes, such as a diaphragm or piezoelectric crystal.

Signal Conditioning Circuit: Amplifies and processes the raw signal from the sensing element.

Housing: Protects the internal components from environmental factors like dust, moisture, and temperature extremes.

Electrical Connections: Ensure proper communication between the sensor and the external circuit.

When selecting components for your Pressure Sensor circuits, consider the following performance metrics:

Accuracy: Ensures precise pressure readings for reliable operation.

Range: Allows customization for specific pressure levels, from low to high.

Material Compatibility: Prevents damage when exposed to corrosive substances.

Response Time: Supports real-time monitoring in dynamic environments.

Durability: Withstands harsh conditions, including vibrations and temperature fluctuations.

Understanding these components will help you design circuits that meet your project's requirements.

Types of pressure sensors and their applications

Pressure sensors come in various types, each suited for specific applications. Below is a comparison of the most common types:

Sensor Type | Features | |

|---|---|---|

Gauge Pressure Sensors | Fast response time, suitable for routine monitoring, affected by environment | |

Absolute Pressure Sensors | ±0.05% FS to ±0.01% FS | Higher accuracy, unaffected by atmospheric changes, suitable for precision |

Differential Pressure Sensors | ±0.1% FS to ±0.02% FS | Suitable for flow and process monitoring, requires stable environment |

Gauge Pressure Sensors: Ideal for measuring pressure relative to atmospheric pressure, commonly used in tire pressure monitoring systems.

Absolute Pressure Sensors: Measure pressure relative to a vacuum, making them perfect for applications like altimeters and weather stations.

Differential Pressure Sensors: Compare pressure between two points, often used in HVAC systems and industrial process control.

By understanding the strengths and limitations of each type, you can choose the right sensor for your Pressure Sensor circuits.

Step-by-Step Guide to Building Pressure Sensor Circuits

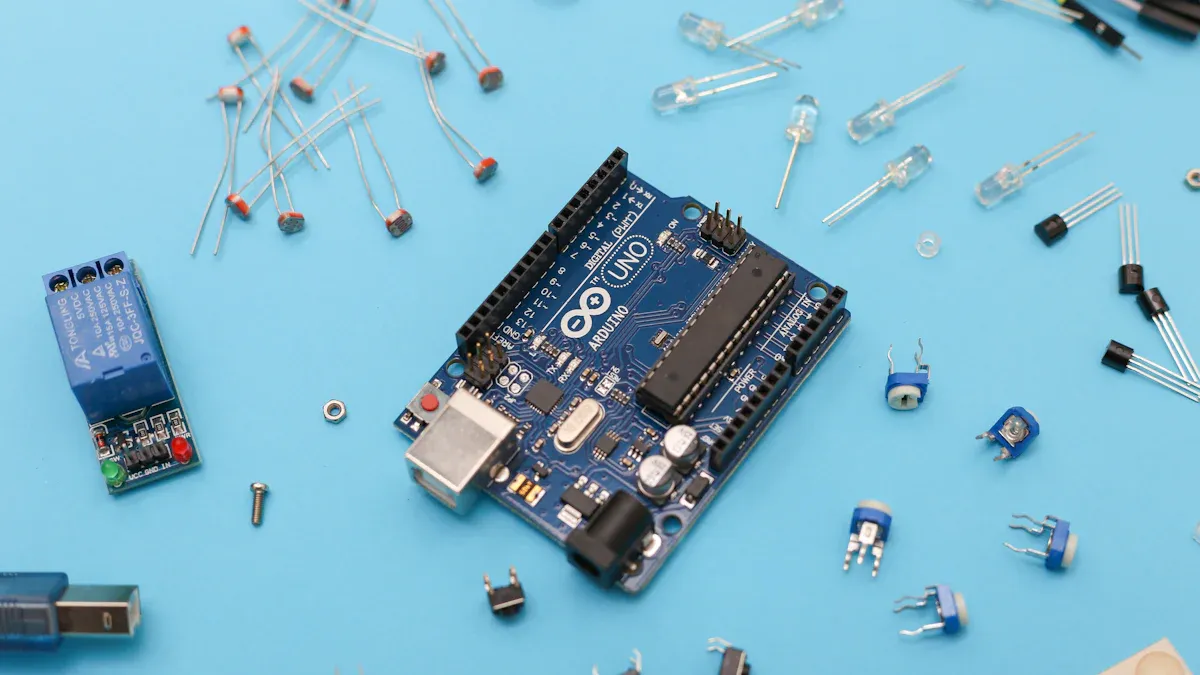

Required components for pressure sensor circuits

To build Pressure Sensor circuits, you need a set of essential components that work together to measure and process pressure data. Here’s a list of the key parts you’ll need:

Capacitors and Resistors: These regulate voltage and current within the circuit.

Inductors and Transistors: Inductors store energy, while transistors amplify or switch signals.

Oscillators and Resonators: These generate stable frequencies for signal processing.

Semiconductor Chips: These form the core of the sensor’s functionality.

Processors and Memory Chips: These handle data processing and storage.

When selecting components, prioritize quality benchmarks. For example, in applications like oil and gas exploration, components must withstand extreme conditions such as high temperatures (up to 200ºC) and vibrations. Vendors often provide ratings for high-pressure and high-temperature environments, ensuring durability and reliability.

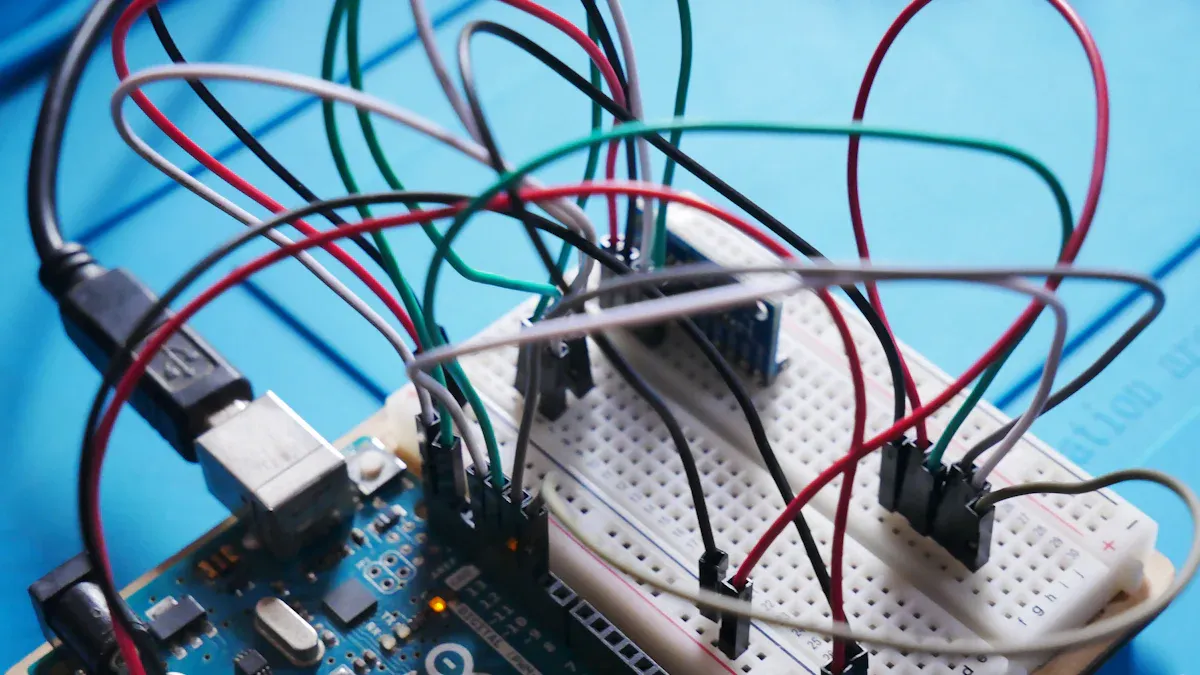

Connecting components effectively

Proper wiring and connections are crucial for the performance of Pressure Sensor circuits. Follow these steps to ensure optimal results:

Connect the Pressure Sensor Pad Components: Insert the leads of the sensor into the interface electronics. Attach the power supply securely. Use a multimeter to test the connections and monitor feedback.

Optimize Wiring Practices: Ensure the electrical wiring is robust and consistent across different media. Misaligned coils can impact performance, so align them carefully to maintain signal integrity.

Adjust Sensitivity: Use a screwdriver to fine-tune the potentiometer. This adjustment increases or decreases the sensor’s sensitivity based on your requirements.

By following these practices, you can enhance the circuit’s reliability and minimize issues like signal noise or interference.

Calibrating and testing the circuit

Calibration ensures the accuracy of Pressure Sensor circuits by eliminating distortions caused by external factors. Here’s how you can calibrate and test your circuit:

Use Known Signal Frequencies: Apply specific frequencies to adjust the system and eliminate errors.

Implement Calibration Algorithms: Techniques like Pade approximation and least squares support vector machines (LSSVM) improve accuracy significantly. These methods reduce nonlinearity and temperature drift, achieving calibration precision up to 0.01% FS.

Test Across Temperature Points: Use a high-precision piston-type pressure gauge to test the circuit at various temperatures and pressure ranges. For example:

Calibration Process

Temperature Points (°C)

Pressure Range (MPa)

Accuracy (%)

High-precision piston-type pressure gauge

-10, 0, 10, 20, 30, 40

0 to 40

0.001% FS

Testing ensures the circuit performs reliably under different conditions. Regular calibration keeps the sensor accurate and responsive over time.

Adjusting sensitivity and ensuring accuracy

Fine-tuning the sensitivity of your pressure sensor circuit is essential for achieving accurate and reliable measurements. Sensitivity adjustments allow the sensor to respond appropriately to varying pressure levels, while accuracy ensures that the readings reflect real-world conditions. Here’s how you can adjust sensitivity and maintain accuracy in your circuit design.

Methods to Adjust Sensitivity

You can use several techniques to modify the sensitivity of your pressure sensor circuit. These methods help you tailor the sensor’s response to meet the specific needs of your application:

Temperature-Dependent Adjustments: Some sensors utilize changes in temperature to modify their sensitivity. This approach eliminates the need to replace the sensor when adjusting the measurement range.

Material Properties: The Young’s modulus of the sensor material plays a significant role in sensitivity. Prototypes have demonstrated that altering this property can result in a sensitivity change ranging from 100-fold to 1000-fold.

Structural Enhancements: Adding a thin steel plate to the sensor can reduce discrepancies between theoretical and measured values, improving overall performance.

By implementing these techniques, you can achieve a more responsive and adaptable sensor circuit.

Ensuring Accuracy in Measurements

Accuracy is just as important as sensitivity. Without accurate readings, your pressure sensor circuit may fail to deliver reliable data. The following calibration methods can help you maintain high accuracy:

Method | Description |

|---|---|

Circuit Design Optimization | Adjusts sensor parameters using an equivalent circuit model to enhance sensitivity. |

High-Accuracy Calibration | Uses a piecewise linear fitting method to achieve linearity above 99%. |

Inverse Model Calibration | Employs an RBF neural network for precise calibration, reducing errors to less than 0.7%. |

In Situ Calibration | Applies a least squares best fit of a low-order polynomial for improved calibration accuracy. |

These methods ensure that your circuit delivers consistent and precise readings, even under variable conditions.

Practical Tips for Balancing Sensitivity and Accuracy

When working on your pressure sensor circuit, keep these tips in mind to strike the right balance between sensitivity and accuracy:

Test Across Different Conditions: Evaluate the sensor’s performance under various temperatures and pressure ranges. This helps identify any inconsistencies in sensitivity or accuracy.

Use High-Quality Components: Invest in components that meet industry standards for durability and precision. High-quality materials reduce the risk of errors caused by environmental factors.

Regular Calibration: Periodically calibrate your circuit to account for wear and tear or changes in the operating environment. This ensures long-term reliability.

By following these steps, you can optimize your pressure sensor circuit for both sensitivity and accuracy, making it suitable for a wide range of applications.

Troubleshooting Pressure Sensor Circuits

Addressing power supply mismatches

Power supply mismatches can disrupt the performance of your pressure sensor circuits. To address this issue, start by verifying the voltage and current requirements of your sensor. Use a multimeter to measure the actual supply voltage and ensure it matches the sensor's specifications. If the supply voltage is too high, consider adding a voltage regulator to stabilize it. For low voltage, check the power source and connections for faults.

Another common problem arises from inconsistent power delivery. You can resolve this by using capacitors to filter out fluctuations. Place a decoupling capacitor near the sensor to smooth out noise in the power supply. Additionally, ensure that your circuit's ground connections are secure and free of resistance, as poor grounding can lead to erratic behavior.

Reducing signal noise and interference

Signal noise and interference can distort the readings of your pressure sensor circuits. To minimize these issues, you can use advanced noise reduction techniques. The table below highlights some effective methods:

Advantages | Disadvantages | |

|---|---|---|

Fourier Transform | Effective for periodic signals | Limited to frequency domain analysis |

Wavelet Transform | Better for non-periodic signals | Complexity in choosing basis function |

Empirical Modal Decomposition (EMD) | Adaptive decomposition | Lacks theoretical foundation; modal aliasing issues |

Variational Modal Decomposition (VMD) | High efficiency; suitable for nonlinear signals | Complexity in parameter selection |

For practical applications, shield your circuit from electromagnetic interference by using shielded cables and placing the sensor away from high-frequency devices. Twisting signal wires can also help reduce electromagnetic coupling.

Fixing incorrect or inconsistent readings

Incorrect or inconsistent readings often stem from installation errors or environmental factors. Follow these steps to troubleshoot effectively:

Check the sensor's installation and positioning. Ensure it is securely mounted and aligned correctly.

Inspect the sealing and protection mechanisms to prevent environmental damage.

Verify calibration settings and recalibrate the sensor if necessary.

Assess electrical connections for loose or faulty wiring.

Evaluate environmental conditions, such as temperature or humidity, that may affect performance.

Examine the sensor for mechanical issues, such as wear or damage.

For long-term reliability, regularly clean the sensor, check seals for integrity, and monitor environmental conditions. Conduct periodic calibration to maintain accuracy.

Ensuring component compatibility

When designing pressure sensor circuits, ensuring that all components work together seamlessly is crucial. If components are incompatible, your circuit may fail to function properly or produce inaccurate readings. Here’s how you can verify and maintain compatibility in your designs.

1. Match Electrical Specifications

Every component in your circuit has specific electrical requirements. You need to check the following parameters:

Voltage Range: Ensure the power supply matches the voltage requirements of the sensor and other components.

Current Ratings: Verify that the current drawn by the sensor does not exceed the capacity of your power source.

Signal Levels: Confirm that the output signal from the sensor aligns with the input range of your processing unit.

For example, if your sensor outputs an analog signal, but your microcontroller only accepts digital signals, you’ll need an analog-to-digital converter (ADC).

2. Check Physical Compatibility

Physical compatibility is just as important as electrical compatibility. Components must fit together properly to avoid mechanical issues.

Pin Configuration: Ensure the pin layout of the sensor matches the socket or breadboard you’re using.

Size and Shape: Verify that the components fit within the available space on your circuit board.

Connector Types: Use compatible connectors to avoid loose or unreliable connections.

💡 Tip: Always refer to the datasheets of your components. These documents provide detailed specifications and guidelines for proper usage.

3. Test for Environmental Suitability

Your circuit may operate in various environments, so you need to ensure that all components can withstand the conditions.

Environmental Factor | What to Check | Example Solution |

|---|---|---|

Temperature | Operating temperature range | Use high-temperature-rated sensors |

Humidity | Resistance to moisture | Apply conformal coating |

Vibration | Mechanical stability | Use vibration-resistant housings |

By addressing these factors, you can prevent failures caused by environmental stress.

4. Perform Compatibility Testing

Before finalizing your design, test the circuit to ensure all components work together. Use a multimeter or oscilloscope to measure voltages, currents, and signals at different points in the circuit. Look for irregularities that might indicate compatibility issues.

By following these steps, you can build a reliable pressure sensor circuit that performs well under various conditions.

Practical Tips for Pressure Sensor Circuits

Selecting cost-effective materials

Choosing the right materials for your Pressure Sensor circuits can significantly reduce costs without compromising performance. You should focus on optimizing the design and material properties to achieve efficiency. Research studies have highlighted several strategies for cost-effective material selection:

Study | Focus | Findings |

|---|---|---|

Wang et al. (2006) | Diaphragm design | Reducing diaphragm thickness and side length enhances resonance frequency, lowering production costs. |

Ferreira et al. (2012) | Piezoresistive sensor optimization | Varying membrane thickness and edge length improves sensitivity and linearity, leading to manufacturing savings. |

Rajavelu et al. (2014) | Perforated membranes | Proposed perforated membranes for enhanced sensitivity, suggesting a cost-effective design approach. |

Chou et al. (2009) | Thermal and packaging effects | Optimized packaging designs reduce costs associated with stability issues. |

You can apply these findings by selecting thinner diaphragms or perforated membranes for your designs. These adjustments improve performance while keeping production costs low. Always evaluate the trade-offs between material cost and durability to ensure long-term reliability.

Prototyping and testing efficiently

Efficient prototyping and testing help you refine your Pressure Sensor circuits while saving time and resources. Several techniques have demonstrated their effectiveness in achieving reliable results:

Prototyping Technique | Quantitative Outcome | Notes |

|---|---|---|

Dynamic pressure vs. resistance test | Repeatability accuracy of 95.6% with a standard deviation of 4.4% for 300 kPa load | Good repeatability for low-cost printed flexible sensor |

Dynamic load cycling | Pressure vs. resistance curves extracted from 101 load cycles | Tested with a frequency of 1 Hz, showing the sensor's performance under dynamic conditions |

In-socket testing | Comparison of sensor performance on flat vs. curved surfaces | Demonstrates adaptability of the sensor in different applications |

You can start by using dynamic pressure tests to evaluate the sensor’s repeatability. Load cycling tests help you understand how the sensor performs under varying conditions. For applications requiring flexibility, in-socket testing ensures the sensor adapts to different surfaces. These methods allow you to identify weaknesses early and improve your designs effectively.

Improving designs over time

Improving your Pressure Sensor circuits is an ongoing process. You should regularly analyze performance data and incorporate feedback to enhance your designs. Start by experimenting with different materials and configurations. For example, adjusting membrane thickness or adding perforations can boost sensitivity and reduce costs.

You can also explore advanced calibration techniques to improve accuracy. Using algorithms like piecewise linear fitting or neural networks ensures your sensors deliver precise readings. Testing under diverse conditions, such as varying temperatures or pressures, helps you identify areas for improvement.

💡 Tip: Keep a detailed log of your experiments and results. This documentation helps you track progress and avoid repeating mistakes.

By continuously refining your designs, you can create circuits that are both cost-effective and reliable, meeting the demands of various applications.

Resources for further learning

Expanding your knowledge about Pressure Sensor circuits can open doors to more advanced projects and applications. Here are some resources to help you continue your learning journey:

Books and Publications

Practical Electronics for Inventors by Paul Scherz and Simon Monk: This book covers essential electronics concepts, including sensors, in an easy-to-understand way.

Sensor Technology Handbook by Jon S. Wilson: A comprehensive guide to various sensors, including pressure sensors, with practical examples.

Online Courses and Tutorials

Coursera: Look for courses like "Introduction to Sensors" or "Electronics for Beginners." These courses often include hands-on projects.

YouTube Channels: Channels like GreatScott! and EEVblog offer tutorials on building and troubleshooting sensor circuits.

Simulation Tools

Tinkercad: A beginner-friendly platform for simulating circuits, including those with pressure sensors.

LTspice: A more advanced tool for simulating and analyzing electronic circuits.

Communities and Forums

Reddit: Subreddits like r/Electronics and r/AskElectronics are great for asking questions and sharing ideas.

Stack Exchange: The Electrical Engineering section provides detailed answers to technical questions.

💡 Tip: Always verify the credibility of your sources. Look for materials authored by experts or endorsed by reputable organizations.

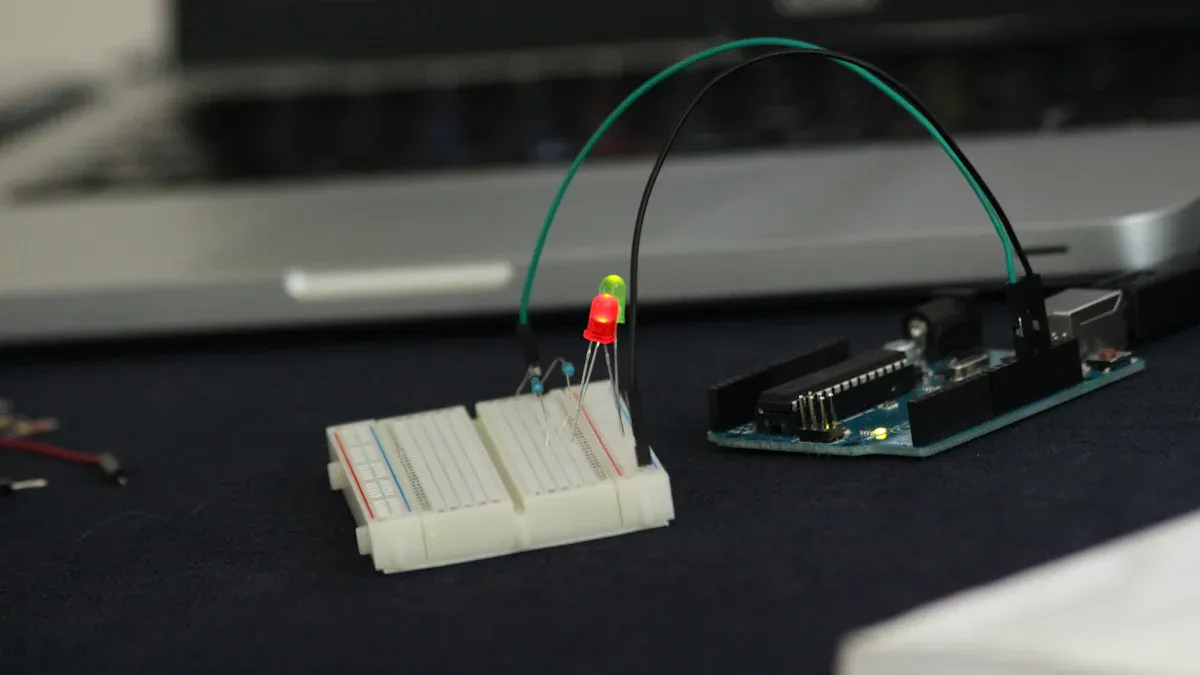

Hands-On Practice

Purchase affordable sensor kits from platforms like SparkFun or Adafruit. These kits often include tutorials to guide you through building and testing circuits.

Experiment with different types of pressure sensors to understand their unique characteristics and applications.

By exploring these resources, you can deepen your understanding of Pressure Sensor circuits and build confidence in your skills. Continuous learning and practice will help you tackle more complex projects over time.

Designing and building pressure sensor circuits involves several key steps. You start by defining clear specifications to match your project’s needs. Testing under real-world conditions ensures the circuit performs reliably. Using structured problem-solving methods, like the 8-D process, helps you identify and fix issues effectively.

Experimentation plays a vital role in improving your designs. Try different configurations and materials to enhance performance. Regular troubleshooting and refinement keep your circuits accurate and durable. With practice, you’ll gain confidence and create circuits suited for diverse applications.

FAQ

What is the best type of pressure sensor for beginners?

Start with piezoresistive sensors. They are affordable, easy to use, and widely available. These sensors work well for basic applications like monitoring air pressure or detecting force.

How do you test a pressure sensor circuit?

Use a multimeter to check voltage and current. Apply known pressure levels to the sensor and compare the output readings to expected values. Regular testing ensures accuracy.

Can you use pressure sensors in extreme environments?

Yes, but choose sensors rated for high temperatures, humidity, or vibrations. Look for materials like stainless steel or ceramics that withstand harsh conditions.

How do you reduce noise in sensor readings?

Use shielded cables and place capacitors near the sensor. Twisting signal wires also minimizes electromagnetic interference. These techniques improve signal clarity.

Where can you buy pressure sensor components?

Purchase components from online stores like SparkFun, Adafruit, or Digi-Key. These platforms offer affordable kits and detailed tutorials for beginners.

See Also

Exploring The Fundamentals And Uses Of Analog IC Design

Essential MOSFET Concepts Every Electronics Hobbyist Should Know

An Overview Of Temperature Sensor Chips And Their Functions

Exploring The Functions And Applications Of Photodiode ICs

A Comprehensive Guide To Digital Integrated Circuits In Electronics