Your 2025 Guide to Choosing the Best ADS6149IRGZ Supplier

Procuring components is increasingly complex in the dynamic 2025 market. Specialized parts, like the ADS6149IRGZ, demand careful attention. Strategic supplier selection is vital for your project's success. It helps you mitigate supply chain risks. You also maintain a competitive edge. This guide offers comprehensive help. You can make informed decisions about your ADS6149IRGZ suppliers.

Key Takeaways

Always check if your ADS6149IRGZ parts are real. Fake parts can cause big problems. A good supplier will show you where the parts came from.

Choose suppliers who deliver on time and have good prices. The cheapest price is not always the best. Think about quality and support too.

Look for suppliers who offer good technical help and have quality certificates. This means they know their products and care about making them well.

Do not rely on just one supplier. Use a few different suppliers for your parts. This keeps your projects safe if one supplier has problems.

Keep an eye on the market and how your suppliers are doing. This helps you plan for the future and avoid surprises.

I. Understanding the 2025 ADS6149IRGZ Market

A. Current Market Trends for ADS6149IRGZ

The market for electronic components like ADS6149IRGZ is always changing. In 2025, you will see continued high demand. Industries such as automotive, consumer electronics, industrial automation, AI, and datacenters all need these chips. This high demand creates strong competition for available parts. You must understand these trends to plan your purchases effectively.

B. 2025 Supply Chain Challenges

You will face several supply chain challenges in 2025. The supply chain remains unstable. This is especially true for components with long lead times or single sources. Geopolitical events also cause problems. Sanctions, loss of neon gas capacity, and tensions in key regions affect production. You might also see skilled labor shortages. These shortages limit how much manufacturers can produce. Tariffs and trade tensions increase costs and make sourcing harder. Scaling up production is difficult due to long equipment lead times and labor scarcity.

Consider the lead times for semiconductors:

Weeks | |

|---|---|

Q1 2020 | 8-12 |

Q1 2023 | 26-52 |

Q4 2023 | 22-50 |

2025 (Projection) | 12-40 |

These numbers show how volatile lead times can be. You need to prepare for these fluctuations.

C. Proactive Supplier Vetting Importance

You must vet your suppliers carefully. Inadequate vetting creates many risks. You could face supply chain disruptions. Counterfeit components might enter your system. Quality verification issues can arise. Cybersecurity threats also become a concern. Partnering with unverified suppliers leads to costly delays. You might face compliance violations. Your products could even fail. This damages your reputation and costs you money.

Look for these red flags during vetting:

Quality and Certification Gaps: The supplier lacks ISO or AS certifications. They might not be part of industry bodies like ERAI.

Inspection and Testing Risks: They do not have multi-phase inspection protocols. Their testing equipment might be old or missing. Staff may not be trained for sensitive components.

Communication Red Flags: You get slow or inconsistent responses. They give vague answers to your questions. They might pressure you to buy quickly.

You need to avoid these issues. Proactive vetting protects your projects and your business.

II. Key Criteria for ADS6149IRGZ Suppliers

A. Authenticity and Traceability of ADS6149IRGZ

Authenticity is your top concern when you choose an ADS6149IRGZ supplier. Counterfeit components cause catastrophic failures. They damage your reputation. They lead to costly recalls. You must ensure every part you receive is genuine. A reliable supplier provides full traceability. You can track the component from its origin to your hands. They offer clear documentation and verification processes.

You can verify authenticity through several methods:

Documentation and Packaging Verification: Check supporting documents. These include Certificate of Conformity or Delivery Notes. Compare them with purchased products. Look for consistent model, name, batch number, quantity, and manufacturer details. Verify appropriate signs on outer packaging.

Visual Inspection of Appearance Quality: Observe the device appearance. Compare markings like model, batch, and serial numbers with documentation. Check for signs of use on pins. Ensure size compliance. Look for scratches that indicate refurbishment.

Detailed Inspection of Marking and Refurbishment: Conduct solvent resistance tests. Use isopropyl alcohol and mineral spirits. This detects refurbished markings.

X-Ray Structural Inspection: Check structural compliance. Look at bonding wire diameter and number. Verify bonding locations, chip size, and frame dimensions. Assess package reliability. Check for void conditions.

Micro-area Composition Analysis: Profile device materials in-depth. Examine frame elements or pin plating. Use comparative testing. Verify documentation accuracy. Ensure material consistency across batches.

Open Internal Inspection: Use metallurgical microscopy. Observe internal structure and chip top layer. Check the chip model number and logo accuracy. Compare bonding interconnect status with X-ray results.

Scanning Electron Microscopy Inspection: This advanced technique provides detailed surface and structural analysis.

Other common verification methods include:

Visual Inspection: Look for inconsistencies in appearance. These include spelling errors or slanted wording. Check discrepancies in sizing measurements. An Acetone wash can reveal original markings after 'blacktopping'.

X-Ray Inspection: Examine internal structures. Look at the die and wire bonds. Check for delamination. Compare them to manufacturer specifications or authentic parts.

Electrical Testing: Compare functional and parametric requirements. Use manufacturer specifications. This determines if a part is genuine.

Decapsulation: This destructive process removes the mold compound. You can visually inspect internal structures under a high-powered microscope. Look for manufacturer markings, die defects, and correct typography.

B. Supply Chain Reliability and Lead Times

A dependable supply chain keeps your projects on schedule. You need a supplier who consistently delivers on time. Long lead times can delay your production. Unreliable suppliers create uncertainty. You should look for a supplier with a proven track record of timely deliveries. They manage their logistics effectively.

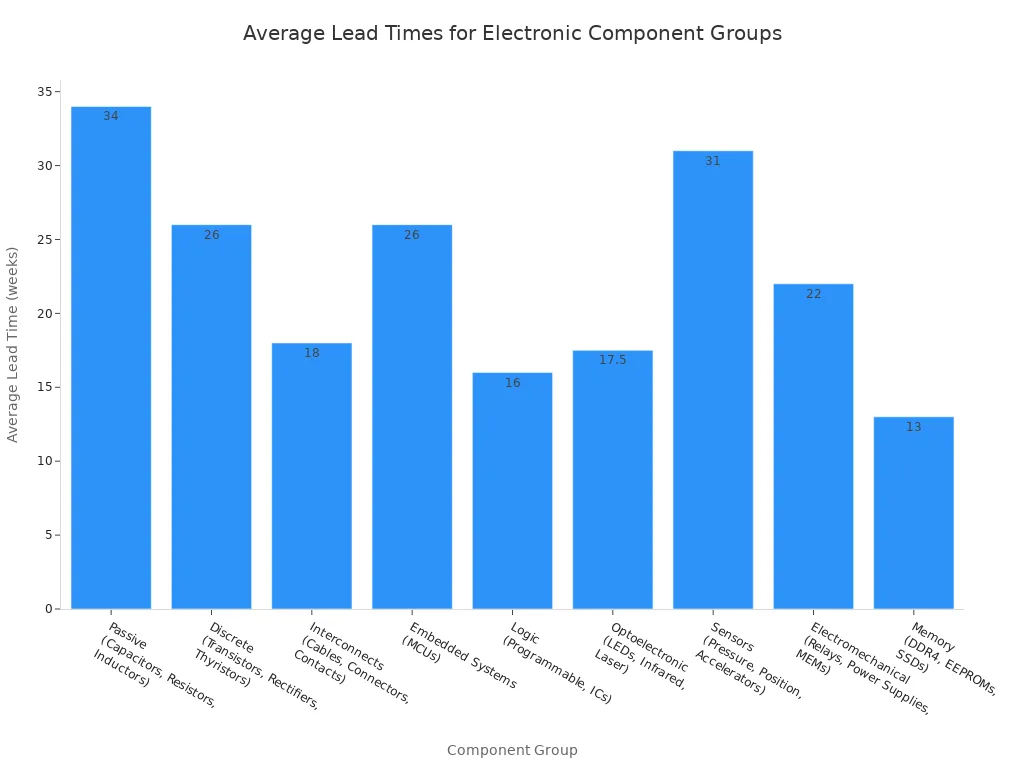

Consider these average lead times for various electronic components. This helps you benchmark supplier performance:

Component Group | Average Lead Time (weeks) |

|---|---|

Passive (Capacitors, Resistors, Inductors) | 34 |

Discrete (Transistors, Rectifiers, Thyristors) | 26 |

Interconnects (Cables, Connectors, Contacts) | 18 |

Embedded Systems (MCUs) | 26 |

Logic (Programmable, ICs) | 16 |

Optoelectronic (LEDs, Infrared, Laser) | 17.5 |

Sensors (Pressure, Position, Accelerators) | 31 |

Electromechanical (Relays, Power Supplies, MEMs) | 22 |

Memory (DDR4, EEPROMs, SSDs) | 13 |

These figures show you the typical waiting periods. Your supplier should meet or beat these industry standards.

C. Pricing and Cost-Effectiveness

You always seek cost-effective solutions. However, the lowest price does not always mean the best value. You must consider the total cost of ownership. This includes quality, reliability, and support. A good supplier offers competitive pricing. They also provide transparent cost structures. You can negotiate better terms with effective strategies.

Here are effective strategies for negotiating favorable pricing and achieving cost-effectiveness:

Contract Review: Regularly re-evaluate terms and conditions with suppliers. Do this especially in long-term relationships. Identify cost reduction opportunities or eligible upgrades.

Request Discounts: Proactively ask vendors for discounts. Do this even as a first-time buyer. Ask for large volume purchases. Eligibility might arise from status upgrades or contract renegotiations.

Avoid Maverick Spending: Implement clear procurement procedures. Ensure all team members adhere to them. This prevents unauthorized or unapproved spending. Such spending can deplete budgets.

Proper Planning: Use data analysis, past events, and future forecasts. Use administrative resources for thorough planning. Do this at every procurement stage. Avoid costly emergency purchases.

Supplier/Vendor Review and Change: Conduct comprehensive reviews. Compare current suppliers against alternatives. Ensure competitive pricing. Consider changing vendors if better options exist.

Review Procurement Needs: Implement robust inventory management. Assess actual needs. Avoid overstocking. Prevent unnecessary purchases. Ask critical questions about current stock and future requirements.

Review Order Quality: Prioritize higher-quality goods. Their longevity can lead to long-term cost savings. This reduces the frequency of replacements.

Enhanced Supplier Relationship Management: Foster strong relationships with suppliers. Gain access to discounts and premium services. Achieve favorable contract negotiations. Enjoy smoother procurement experiences.

Use Reverse Auction Technique: Publicize procurement needs. Invite suppliers to bid competitively. The lowest bid wins. This drives down costs.

Adopt E-procurement Methods: Integrate technology into the supply chain. Get better data insights. Achieve real-time tracking. Optimize documentation. This leads to overall cost savings.

You can also use these strategies:

Understand Supplier Costs: Gain deep insight into what drives your supplier's pricing. This includes raw material costs. This knowledge prevents overpaying. It helps justify price adjustments.

Ask Informed Questions: Research fair prices. Then, challenge suppliers who resist negotiation. Inquire about underlying reasons for their stance. Do this especially if internal departments have limited options to a single supplier.

Leverage Knowledge: Use your understanding of supplier cost drivers and market dynamics. Ensure fair pricing. Avoid 'price creep' (unjustified price hikes). Avoid 'margin creep' (suppliers not lowering prices when their costs decrease). Contribute to overall profitability.

D. Technical Support and Expertise

You might encounter technical challenges. A knowledgeable supplier offers excellent technical support. They understand the ADS6149IRGZ and its applications. Their experts can answer your questions. They provide guidance on integration and troubleshooting. You need a partner who offers more than just parts. They offer solutions.

E. Quality Control and Certifications

Quality control is non-negotiable. You need components that perform as expected. A reputable supplier has robust quality management systems. They follow strict inspection protocols. Certifications demonstrate their commitment to quality. Look for industry standards like ISO 9001 or AS9100. These show a dedication to excellence. They ensure consistent product quality.

F. Inventory Management and Stocking

Your supplier's inventory practices directly impact your operations. You need access to parts when you need them. A supplier with strong inventory management can prevent stockouts. They offer various stocking programs. These include just-in-time delivery or buffer stock agreements. This helps you manage your own inventory efficiently. It reduces your holding costs. You gain flexibility in your production schedule.

III. Types of ADS6149IRGZ Suppliers

A. Authorized Distributors: Benefits and Considerations

You can choose authorized distributors. They source components directly from the original manufacturer. This guarantees authenticity for your ADS6149IRGZ parts. You receive full manufacturer warranties. You also get access to the latest product revisions. Their supply chain is typically very reliable. However, you might face higher prices. They offer less flexibility in terms or pricing. Lead times can also be longer if they do not have the specific part in stock. Consider these factors when you prioritize authenticity and direct support.

B. Independent Distributors: Risk Mitigation and Vetting

Independent distributors present another option. They often provide access to older or even obsolete parts. You might find more competitive pricing here. They can also offer faster delivery for items they have in stock. But you must understand the risks. You could encounter counterfeit components. Manufacturer warranties are typically not available. The quality of parts can vary significantly. You must mitigate these risks.

Consider these vetting steps:

Check their reputation: Look for industry reviews and testimonials.

Demand quality checks: Ensure they perform thorough inspections.

Verify traceability: Ask for documentation proving the part's origin.

Request samples: Test parts before making a large purchase.

C. Brokers and Online Marketplaces: Navigating Risks

Brokers and online marketplaces offer quick access to components. They help you find hard-to-find parts quickly. Prices are often very attractive. However, these sources carry the highest risk. Counterfeit parts are a significant concern. You will likely get no traceability. There is no manufacturer warranty. Quality is often inconsistent. Scams can also occur. You must navigate these risks with extreme caution. Perform thorough due diligence on any seller. Consider using third-party testing services for critical components like the ADS6149IRGZ. Only use reputable platforms with strong buyer protection policies. This approach protects your projects from costly failures.

IV. Selecting Your ADS6149IRGZ Supplier: A Step-by-Step Process

Choosing the right supplier for your ADS6149IRGZ components is a critical process. You need a structured approach. This section guides you through finding, shortlisting, and evaluating potential suppliers.

A. Define Your ADS6149IRGZ Requirements

Before you start looking, you must know exactly what you need. Clearly defining your requirements saves time and prevents mistakes. Think about these key areas for your ADS6149IRGZ components:

Technical Specifications: What are the exact electrical, mechanical, and environmental specifications? Do you need specific packaging or temperature ranges?

Quantity and Delivery Schedule: How many units do you need? When do you need them? Do you require staggered deliveries or a single bulk shipment?

Quality Standards: What quality certifications are essential? Do you have specific testing requirements?

Budget Constraints: What is your target price per unit?

Compliance: Are there any industry-specific regulations or certifications your supplier must meet?

A clear understanding of these points helps you find suppliers who can truly meet your needs.

B. Researching Potential ADS6149IRGZ Suppliers

Once you know your requirements, you can start your search. You have several ways to find potential suppliers:

Industry Directories: Online and print directories list component suppliers.

Trade Shows and Conferences: These events let you meet suppliers directly and see their products.

Online Searches: Use specific keywords related to ADS6149IRGZ and electronic component suppliers.

Referrals and Recommendations: Ask colleagues or industry contacts for their trusted suppliers.

After you find potential suppliers, do some initial screening. Visit their websites. Look at their product lines, certifications, and customer testimonials. This helps you create a preliminary list of candidates.

C. Request for Quotation (RFQ) and Information (RFI)

You use formal documents to gather detailed information from potential suppliers. These documents help you compare options fairly.

Request for Information (RFI): You use an RFI at the beginning of your procurement process. It helps you gather general information about vendor capabilities. You explore the market and define your needs.

Request for Quotation (RFQ): You use an RFQ when you know exactly what you want to buy. You are looking for the best price for specific products or services.

Here is a comparison of RFI and RFQ:

Feature | RFI (Request for Information) | RFQ (Request for Quote) |

|---|---|---|

Purpose | To gather general information about vendor capabilities and solutions. | To get pricing, delivery terms, and other commercial details for a product or service. |

Buyer Intent | You are exploring the market, defining needs, and shortlisting vendors. | You know exactly what you want and need a cost/time estimate. |

Decision Factor | Qualitative: Capabilities, relevance, and compatibility with your needs. | Quantitative: Lowest price, fastest delivery, basic compliance. |

Length & Detail | Short, open-ended questions or surveys | Short and structured with product specs and quantity |

When to Use | At the beginning of a procurement process to inform next steps | For standardized products/services with clear requirements |

Vendor’s Role | Educate, position capabilities, and get invited to the next step (RFQ or RFP) | Offer the most competitive quote and meet delivery terms |

When you create an RFQ for ADS6149IRGZ, include these key elements:

Product Description: Clearly explain your needs. Include technical specifications, materials, and features.

Quantity: State the number of units you need. This helps vendors calculate total pricing.

Delivery Timeline: Provide your expected delivery date or project timeline.

Pricing Format: Give instructions on how to present pricing. You might include a template.

Payment Terms: Detail how and when you plan to pay.

Evaluation Criteria: List the factors you will use to compare responses. These include price, timeline, past experience, or vendor reputation.

Submission Instructions: Give guidelines on where and how to send responses. Include deadlines, contact information, and required formats.

Follow these best practices for your RFQ process:

Include clear instructions for completion and a submission due date. Allow enough time for bidders to respond.

Attach your terms and conditions.

Establish a way for potential suppliers to ask questions and receive answers. Ensure all bidders get the same information.

Keep bids confidential to ensure a fair result.

Close bidding on the due date. Open all bids immediately.

Document all actions. This includes the number of bids sent/received, evaluation criteria, committee members, and the final decision.

Notify unsuccessful bidders and thank them for their participation.

D. Due Diligence and Supplier Audits

After you receive responses, you must perform due diligence. This means thoroughly investigating potential suppliers. Supplier audits are a key part of this process.

Follow these steps for a successful audit:

Identify Audit Goals: Clearly define what you want to achieve. Are you checking quality assurance, regulatory compliance, financial stability, or supply chain reliability? Your goals should be specific and measurable.

Develop Criteria (Pre-Audit): Create standards and benchmarks to evaluate suppliers. This ensures consistent and objective assessments. Involve a team from procurement, legal, finance, and quality control.

Consider these criteria when you evaluate suppliers:

Criteria | Description |

|---|---|

Supplier's financial stability | Evaluate their financial health. Look at statements, credit reports, and their ability to fulfill orders. |

Legal compliance and certifications | Verify they follow laws and regulations. Check for required industry certifications and licenses. |

Quality management systems | Assess their commitment to quality. Review their systems, certifications (like ISO 9001), and quality control approach. |

Capacity and lead times | Determine their production capacity. Check if they can meet your delivery schedules. |

Customer references | Speak to other customers to understand their experience. |

Price, quality, delivery, service | Evaluate their overall performance in these key areas. |

Data collection | Assess how they collect and use data to improve their processes. |

Here are best practices for conducting due diligence:

Clear Policy: Create a clear policy for supplier vetting.

Segment by Risk: Categorize suppliers based on the risk they pose.

Risk-Based Approach: Focus your due diligence efforts on higher-risk suppliers.

Ongoing Monitoring: Continuously monitor supplier performance, not just at the start.

Technology: Use tools to help with data collection and analysis.

Independent Verification: Do not rely solely on supplier-provided information. Verify claims independently.

Cross-Departmental Collaboration: Involve different departments in the review process.

Documentation: Keep detailed records of all due diligence activities.

Ethical Standards: Ensure suppliers meet your ethical and sustainability standards.

Corrective Actions: Have a plan for addressing any issues found during due diligence.

E. Negotiate Terms and Contracts

Once you shortlist suppliers, you enter the negotiation phase. Your goal is to secure favorable terms that protect your interests. Negotiate these key areas:

Pricing: Discuss unit costs, volume discounts, and payment terms.

Delivery Schedules: Confirm lead times and delivery windows.

Quality Assurance: Agree on inspection processes, defect rates, and return policies.

Warranties and Guarantees: Understand the coverage for defects or failures.

Service Level Agreements (SLAs): Define expectations for technical support and responsiveness.

Intellectual Property: Clarify ownership and usage rights if custom work is involved.

Ensure all agreed-upon terms are clearly documented in a legally binding contract. This protects both parties and sets clear expectations.

F. Supplier Relationship Management (SRM) Plan

Your relationship with a supplier does not end after the contract is signed. Effective Supplier Relationship Management (SRM) is crucial for long-term success. An SRM plan helps you maximize value and minimize risks.

Key components of an effective SRM plan include:

Supplier Selection and Onboarding: Establish clear processes for bringing new suppliers on board.

Performance Management: Regularly monitor and evaluate supplier performance against agreed-upon metrics.

Risk Management: Identify and mitigate potential risks in the supply chain.

Collaboration and Communication: Foster open communication and collaboration with your suppliers.

Contract Management: Ensure contracts are up-to-date and terms are met.

Continuous Improvement: Work with suppliers to find ways to improve processes and reduce costs.

Follow these steps to build a strong SRM plan:

Supplier Segmentation: Categorize your suppliers based on their importance and impact on your business.

Key Performance Indicators (KPIs): Define clear metrics to measure supplier performance.

Relationship Strategy: Develop a specific strategy for each supplier segment.

Engagement: Regularly communicate and meet with your suppliers.

Collaboration: Work together on problem-solving and innovation.

Performance Monitoring: Track KPIs and provide feedback.

Continuous Improvement: Implement joint initiatives to enhance efficiency and quality.

Contract Management and Renewal: Proactively manage contracts and plan for renewals.

A strong SRM plan turns suppliers into strategic partners. This ensures a reliable and efficient supply of your ADS6149IRGZ components.

V. Future-Proofing Your ADS6149IRGZ Supply Chain

You must protect your supply chain for ADS6149IRGZ components. This ensures your projects continue without interruption. Proactive strategies help you manage future challenges.

A. Building Redundancy with Multiple Suppliers

Relying on a single supplier creates risk. You should build redundancy. Use multiple suppliers for your ADS6149IRGZ components. This protects you from disruptions. If one supplier faces issues, another can step in. This strategy minimizes delays. It also reduces your dependence on any single source. You maintain flexibility in your procurement.

B. Monitoring Market Changes and Performance

You need to stay informed about the market. Monitor changes and supplier performance regularly. Tools like Part Analytics' BOM IQ automate Bill of Materials reviews. They use AI to find alternate parts. They also detect lifecycle risks, like End-of-Life components, up to 12 months ahead. RFQ IQ helps you with data-driven sourcing. It auto-populates RFQs and benchmarks supplier quotes. You can also use Predictive Risk Management to monitor supplier financial health and geopolitical exposure. Other tools like SourceDay track KPIs such as on-time delivery and lead time. Veridion offers supplier discovery and risk monitoring with AI updates. Methodologies include structured performance reviews and regular audits. These help you track progress and identify improvements.

C. Strategies for Long-Term Availability

You can ensure long-term availability for critical components. Prioritize transparency. Demand regular updates and market intelligence from your suppliers. Establish global logistics backup plans. This includes multi-region inventories and alternative sourcing channels. Partner with certified distributors. They defend against hidden procurement risks. This lets your team focus on core tasks. Follow basic inventory management practices. Consider component availability during the design phase. Use multiple sources. Make large, blanket orders. Utilize component database software for obsolescence forecasting. You can also adapt product design. Use more common or alternative components. This removes non-essential parts causing delays.

You must take a strategic and proactive approach to ADS6149IRGZ supplier selection in 2025. Prioritize authenticity, reliability, technical support, and long-term viability. Following these outlined steps helps you confidently secure your ADS6149IRGZ supply. You minimize risks. You also ensure your projects and products succeed. This builds resilience for years to come.

FAQ

How do I verify ADS6149IRGZ authenticity?

You must check documentation and perform visual inspections. X-ray analysis and electrical testing also confirm genuine parts. Always demand full traceability from your supplier. This ensures you receive authentic components.

What are the main risks with independent distributors?

You face higher risks of counterfeit parts and inconsistent quality. Manufacturer warranties are usually absent. Always vet these suppliers thoroughly. Demand quality checks and traceability documents to protect your project.

Why should I use multiple suppliers for ADS6149IRGZ?

You build redundancy. This protects your supply chain from disruptions if one supplier has issues. It minimizes delays and reduces dependence on a single source. You gain flexibility in your procurement strategy.

What is the purpose of an RFQ?

You use an RFQ (Request for Quotation) to get specific pricing and delivery terms. You know exactly what you need to buy. It helps you compare offers from different vendors fairly and make an informed decision.

How can I build strong supplier relationships?

You build trust through open communication and collaboration. Regularly monitor performance and provide feedback. Work together on improvements and problem-solving. This turns your suppliers into strategic partners for long-term success.

See Also

Finding Reliable ADI Authorized Distributors for Your Needs in 2025

Discovering the Best Synchronous Buck Converter Chips for 2025 Projects

Leading RF Component Suppliers Essential for 5G System Development in 2025

Key Trends Driving the Evolution of the Analog IC Industry by 2025

Analog Devices' Strategies for Building a Robust Chip Supply Chain Resilience