What Are Battery Charge Controller ICs and How Do They Work

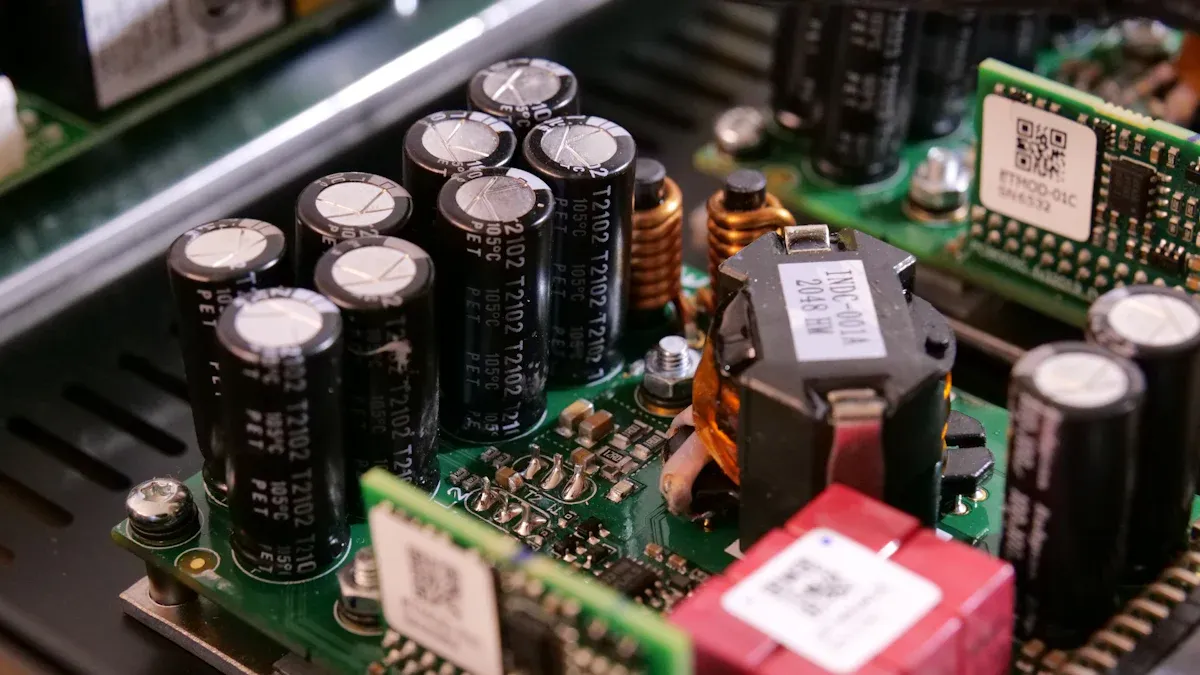

Battery charge controller ICs are specialized integrated circuits designed to regulate how batteries charge. They ensure that your battery receives the correct amount of voltage and current, preventing damage from overcharging or overheating. These ICs play a vital role in modern technology, especially with the growing demand for efficient energy management.

The global battery charging IC market was valued at USD 6.5 billion in 2023.

It is projected to reach USD 12.5 billion by 2032, with a CAGR of 7.5%.

This growth highlights how essential these devices have become in managing energy safely and efficiently. Companies like Tesla rely on advanced battery management systems to optimize battery performance and safety, showcasing the importance of these ICs in real-world applications.

Key Takeaways

Battery charge controller ICs control voltage and current to stop overcharging. This helps batteries last longer and work better.

These ICs have safety features like stopping too much voltage or current. This keeps devices safe and prevents overheating problems.

They manage energy well, wasting less power. This makes them important for things like phones and electric cars.

Small designs of these ICs save space in devices. This allows adding more features without losing performance.

More people want electric cars and renewable energy. This shows how important these ICs are in today’s technology.

How Battery Charge Controller ICs Work

Battery charge controller ICs are the backbone of efficient and safe battery management. They ensure your batteries operate within optimal parameters, preventing damage and maximizing performance. Let’s explore how these ICs function.

Voltage and Current Regulation

Voltage and current regulation is a critical function of battery charge controller ICs. These ICs monitor and adjust the voltage and current supplied to the battery, ensuring it stays within safe limits. For example, the LTC4162 and LTC4015 models demonstrate precise regulation capabilities:

Feature | LTC4162 | LTC4015 |

|---|---|---|

Charge Current Regulation | ±5% up to 3.2 A | ±2% up to 20 A |

Charge Voltage Regulation | ±0.75% | ±1.25% |

Input Voltage Range | 4.5 V to 35 V | 4.5 V to 35 V |

Monitoring Parameters | Input voltage, input current, battery voltage, battery current, battery temperature, die temperature, BSR | Input voltage, input current, battery voltage, battery current, battery temperature, BSR |

Communication Interface | Two-wire I2C | Two-wire I2C |

Battery Chemistry Support | Li-Ion/polymer, LiFePO4, LA | Li-Ion/polymer, LiFePO4, LA |

Special Features | Active MPPT, PowerPath management | High precision coulomb counter |

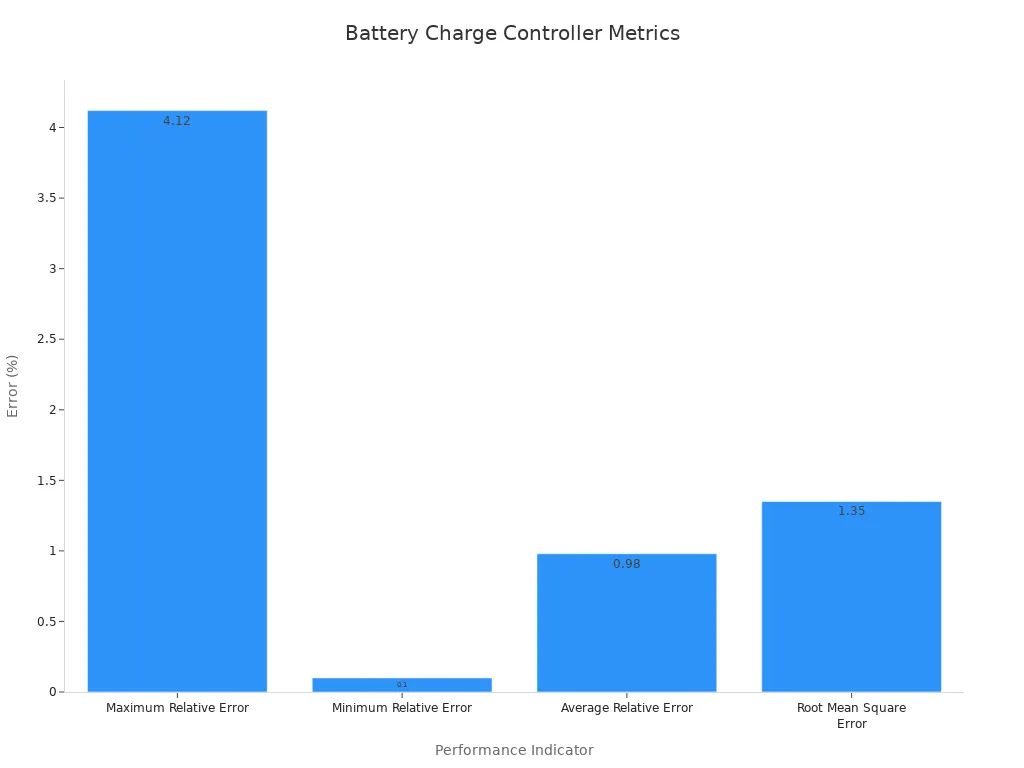

This precise regulation minimizes errors, as shown in the following performance metrics:

Performance Indicator | Value |

|---|---|

Maximum Relative Error | |

Minimum Relative Error | 0.1% |

Average Relative Error | 0.98% |

Root Mean Square Error | 1.35% |

These features ensure your battery receives the right amount of power, enhancing its lifespan and performance.

Charge Termination Mechanisms

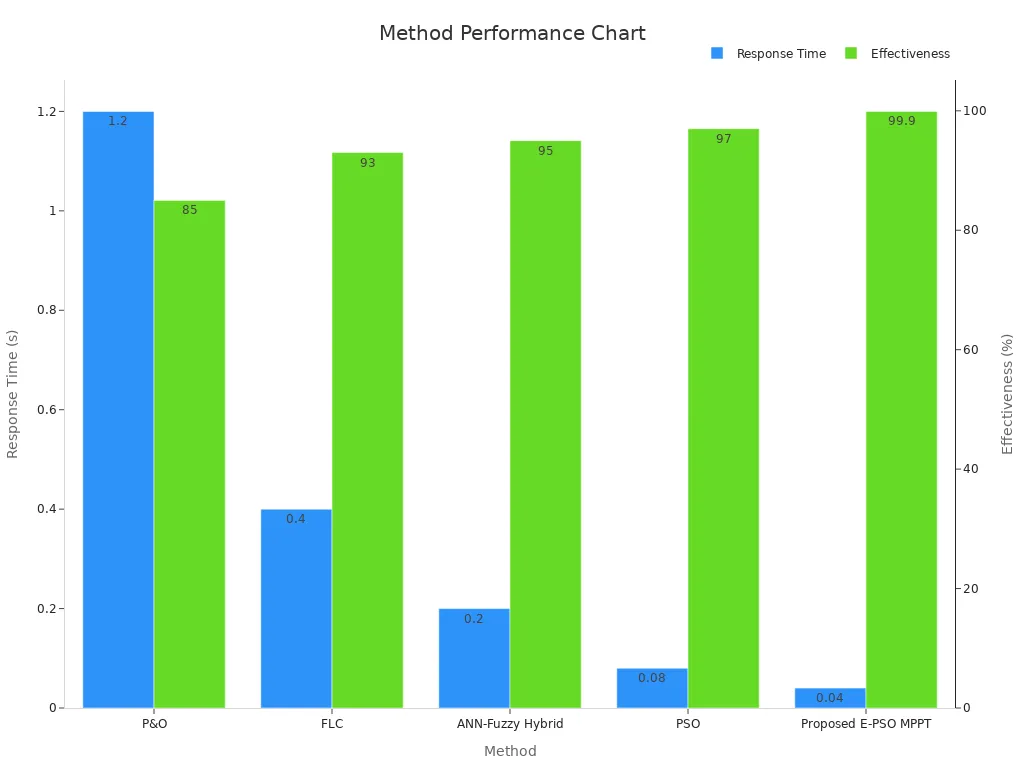

Battery charge controller ICs also manage charge termination. This process stops charging when the battery reaches full capacity, preventing overcharging. Advanced methods like the proposed E-PSO MPPT strategy achieve remarkable results:

Global maximum power point tracking efficiency: 99.99%

Tracking time: 0.85 seconds

Other methods, such as P&O and FLC, are less effective in comparison. The table below highlights the differences:

Method | Response Time (s) | Effectiveness (%) | PSC Adaptability | Real-Time Validation |

|---|---|---|---|---|

P&O | 1.2 | 85 | Low | No |

FLC | 0.4 | 93 | Medium | No |

ANN-Fuzzy Hybrid | 0.2 | 95 | Medium | No |

PSO | 0.08 | 97 | Medium | Yes |

Proposed E-PSO MPPT | 0.04 | High | Yes (DSP) |

By implementing these mechanisms, battery charge controller ICs ensure efficient energy use and prevent unnecessary wear on your battery.

Safety Features

Safety is a top priority in battery management. Battery charge controller ICs include features to protect against overcharging, overheating, and short circuits. Certifications like LANSI/UL 2202 and ANSI/UL 2594 validate these safety measures:

Certification Standard | Description |

|---|---|

LANSI/UL 2202 | Standard for DC Charging Equipment for Electric Vehicles |

ANSI/UL 2594 | Standard for Electric Vehicle Supply Equipment (EVSE) |

ANSI/UL 2251 | Standard for Plugs, Receptacles and Couplers for Electric Vehicles |

UL 3202 | Outline of Investigation for Mobile Electric Vehicle Charging Systems Integrated with Energy Storage Systems |

Additionally, organizations like UL Solutions and Intertek emphasize the importance of adhering to these standards. These safety features not only protect your battery but also ensure the safety of the devices and systems they power.

Key Features of Battery Charge Controller ICs

Efficiency in Energy Management

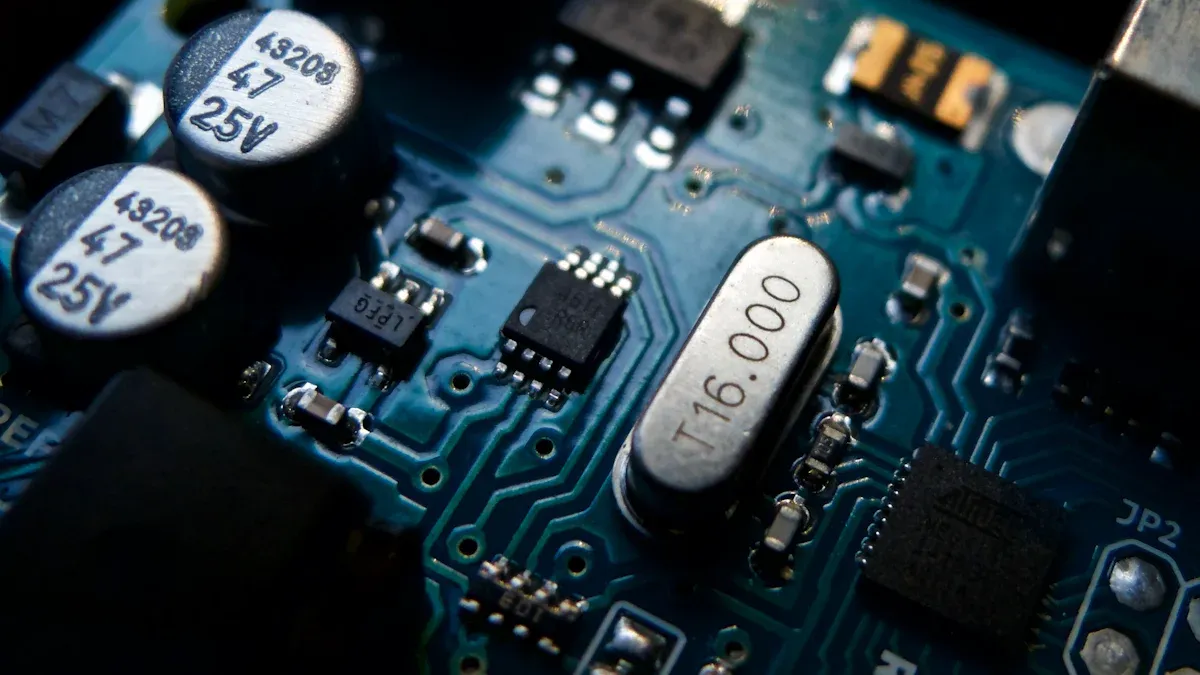

Battery charge controller ICs excel in managing energy efficiently. They use advanced techniques to monitor and regulate the state of charge (SOC) in batteries. SOC measurement methods, such as current and voltage monitoring, ensure precise energy management. Specialized fuel-gauge ICs implement these methods, providing accurate SOC estimates. This precision minimizes energy waste and extends battery life.

Modern architectures, like buck and boost converters, further enhance efficiency. These converters optimize power delivery by adjusting voltage levels to match the battery's requirements. Some ICs even use Single-Inductor Multiple-Output (SIMO) designs, which reduce energy losses by integrating multiple outputs into a single system. This design is particularly effective in portable devices, where energy conservation is critical.

Compact Design

Battery charge controller ICs are designed to save space without compromising functionality. Their compact size makes them ideal for applications where space is limited, such as smartphones, wearables, and medical devices. Despite their small footprint, these ICs integrate multiple features, including voltage regulation, temperature monitoring, and safety mechanisms.

For lithium-ion batteries, the charging profile involves a constant current phase followed by a constant voltage phase. This process requires precise control, which these ICs deliver in a compact form. Their ability to combine multiple functions into a single chip reduces the need for additional components, simplifying circuit design and saving valuable space.

Reliability and Durability

Reliability is a cornerstone of battery charge controller ICs. These devices monitor critical parameters like voltage, current, and temperature to ensure safe operation. Protection circuitry halts charging if any parameter exceeds safe limits, preventing damage to the battery and connected devices.

In industries like automotive, compliance with ISO 26262 ensures functional safety. This standard is crucial for electric vehicles, where battery performance directly impacts safety and efficiency. By adhering to such rigorous standards, these ICs deliver consistent performance over time, even in demanding environments. Their durability makes them a trusted choice for applications ranging from consumer electronics to renewable energy systems.

Applications of Battery Charge Controller ICs

Battery charge controller ICs play a crucial role in various industries. Their ability to regulate and optimize battery performance makes them indispensable in modern technology. Let’s explore their applications in consumer electronics, the automotive industry, and renewable energy systems.

Consumer Electronics

You interact with consumer electronics daily, from smartphones to laptops. These devices rely on efficient battery management to deliver consistent performance. Battery charge controller ICs ensure your gadgets charge safely and efficiently. They monitor battery temperature, regulate current, and include safety features to prevent overheating or overcharging.

Here’s a breakdown of key features in consumer electronics:

Feature | Description |

|---|---|

Monitors Li-ion battery temperature during charging to ensure safe operation. | |

Charge Current Control | Regulates charge current based on temperature to prevent overheating. |

Safety Features | Includes thermal shutdown and over-voltage monitoring to protect the battery. |

These features enhance the reliability of your devices, ensuring they last longer and perform better. For example, smartphones use these ICs to manage fast charging while preventing damage to the battery. Without them, your devices would face risks like overheating or reduced battery life.

Automotive Industry

Electric vehicles (EVs) and hybrid cars depend heavily on battery charge controller ICs. These ICs manage the complex charging requirements of large battery packs, ensuring optimal performance. They regulate voltage and current to prevent overcharging, which can damage the battery.

In EVs, these ICs also support regenerative braking systems. This feature allows the vehicle to recover energy during braking and store it in the battery. By doing so, the ICs improve energy efficiency and extend the driving range. Additionally, they monitor battery health, ensuring your vehicle operates safely and reliably.

Battery charge controller ICs also comply with strict automotive safety standards, such as ISO 26262. This ensures they meet the high safety and performance demands of the automotive industry. Whether it’s a Tesla or a hybrid SUV, these ICs are essential for efficient and safe battery management.

Renewable Energy Systems

Renewable energy systems, like solar panels and wind turbines, rely on battery storage to provide consistent power. Battery charge controller ICs play a vital role in these systems by managing the charging process of storage batteries. They ensure the batteries charge efficiently, even under varying environmental conditions.

For instance, in solar energy systems, these ICs use maximum power point tracking (MPPT) to optimize energy conversion. MPPT ensures the solar panels operate at their peak efficiency, maximizing the energy stored in the battery. This technology is crucial for off-grid systems, where reliable energy storage is essential.

Additionally, these ICs protect batteries from overcharging and deep discharging, which can significantly reduce their lifespan. By maintaining the health of the batteries, they contribute to the overall efficiency and sustainability of renewable energy systems. Whether you’re powering a remote cabin or a large solar farm, these ICs ensure your energy storage system performs at its best.

Medical Devices

Medical devices rely heavily on precise and reliable power management. You might not realize it, but devices like pacemakers, infusion pumps, and portable diagnostic tools depend on batteries to function. A battery charge controller IC ensures these devices operate safely and efficiently by managing the charging process.

In medical applications, safety and accuracy are critical. A battery charge controller IC monitors the battery's voltage, current, and temperature. It prevents overcharging, which could damage the battery or cause it to overheat. For example, in a portable oxygen concentrator, the IC ensures the battery charges correctly, so the device remains dependable for patients who need it.

These ICs also extend battery life. Medical devices often run continuously or for long periods. By regulating the charging process, the IC reduces wear on the battery. This means fewer replacements and lower maintenance costs. For a hospital or clinic, this reliability can make a significant difference in patient care.

Another advantage is the compact design of these ICs. Many medical devices are small and portable. A battery charge controller IC integrates multiple functions into a single chip, saving space. This allows manufacturers to design lightweight and user-friendly devices without compromising performance.

In addition, these ICs support various battery chemistries, including lithium-ion and nickel-metal hydride. This flexibility makes them suitable for a wide range of medical devices. Whether it's a wearable heart monitor or a surgical tool, the IC adapts to the specific power requirements of the device.

You can see how vital these ICs are in the medical field. They ensure devices remain safe, efficient, and reliable, ultimately improving patient outcomes.

Benefits of Battery Charge Controller ICs

Extended Battery Life

You want your devices to last as long as possible, and that starts with protecting the battery. A Battery Charge Controller IC ensures your battery charges and discharges within safe limits. By preventing overcharging, it reduces stress on the battery's internal components. This helps maintain its capacity over time.

These ICs also manage the depth of discharge, which is how much energy you use before recharging. Keeping this within an optimal range prevents unnecessary wear. For example, lithium-ion batteries benefit from controlled charging cycles, which extend their lifespan significantly. With this technology, you can enjoy longer-lasting devices and fewer battery replacements.

Enhanced Safety

Safety is critical when dealing with batteries. A Battery Charge Controller IC includes multiple protection mechanisms to keep you and your devices safe. These features prevent dangerous situations like overheating or short circuits.

Here’s a breakdown of the safety measures these ICs provide:

Protection Type | Description |

|---|---|

Over-Current Protection | Prevents excessive current flow during charging or discharging, reducing overheating risk. |

Over-Voltage Protection | Prevents charging beyond safe limits, preserving battery life. |

Under-Voltage Protection | Prevents discharging below safe limits, avoiding potential battery failure. |

Over-Temperature Protection | Keeps battery within safe temperature range, mitigating damage from extreme heat. |

Under-Temperature Protection | Maintains battery within safe temperature range, preventing damage from extreme cold. |

These safeguards ensure your battery operates within safe parameters, reducing the risk of accidents and improving reliability.

Improved Performance

A well-managed battery performs better. By regulating voltage and current, a Battery Charge Controller IC ensures your battery delivers consistent power. This means your devices run smoothly without unexpected shutdowns.

These ICs also optimize charging speed. Fast-charging technologies rely on precise control to deliver power quickly without overheating. Whether you’re charging a smartphone or an electric vehicle, the IC balances speed and safety.

Additionally, these controllers monitor battery health in real time. They adjust charging parameters based on the battery’s condition, ensuring peak performance throughout its life. With this level of control, you get reliable, efficient energy for all your devices.

Battery charge controller ICs are essential for modern technology. They ensure your devices charge safely, efficiently, and reliably. By managing voltage, current, and temperature, these ICs protect batteries and extend their lifespan.

You can see their growing importance in sustainable energy solutions. The rise of electric vehicles and renewable energy systems highlights the need for advanced power management. Smart grids and IoT devices also rely on these technologies to optimize energy use. With a projected CAGR of 6% in IoT markets and 14% in wearables by 2028, battery charge controller ICs will continue shaping the future of energy efficiency.

FAQ

What is the main purpose of a battery charge controller IC?

A battery charge controller IC ensures your battery charges safely and efficiently. It regulates voltage and current, prevents overcharging, and protects against overheating. This helps extend battery life and maintain device performance.

Can a battery charge controller IC work with all types of batteries?

Most battery charge controller ICs support multiple chemistries, like lithium-ion, lead-acid, and nickel-metal hydride. Always check the IC's specifications to ensure compatibility with your battery type.

How does a battery charge controller IC improve safety?

It includes features like over-voltage, over-current, and temperature protection. These safeguards prevent overheating, short circuits, and other risks, ensuring your battery and device remain safe during operation.

Why is voltage regulation important in battery charging?

Voltage regulation ensures your battery receives the correct amount of power. Without it, overcharging could damage the battery, while undercharging might reduce its capacity. Proper regulation maximizes battery lifespan and efficiency.

Are battery charge controller ICs used in renewable energy systems?

Yes! These ICs manage the charging of storage batteries in solar and wind energy systems. They optimize energy storage, protect batteries from overcharging, and ensure reliable power delivery even in fluctuating conditions.

💡 Tip: Always choose a battery charge controller IC that matches your application’s power and safety requirements for the best results.

See Also

Exploring The Functions Of Battery Charger Controller ICs

IC Line Drivers: Their Role And Functionality In Electronics

Industrial Control Chips: Understanding Their Function In Automation