Understanding AC to DC Switching Converters and Their Functionality

An AC to DC switching converter transforms alternating current (AC) from your wall outlet into the direct current (DC) required by most electronic devices. This process ensures a stable and efficient power supply for gadgets like smartphones, laptops, and LED lights. With more than 5.4 billion internet users in 2023, the need for reliable power solutions has never been greater. The market for these converters reflects this demand, growing from USD 3.2 billion in 2024 to a projected USD 5 billion by 2032. These converters play a critical role in keeping modern devices running smoothly.

Key Takeaways

AC to DC converters change wall power into energy for gadgets like phones and laptops.

These converters save energy, cut waste, and lower power costs.

Small designs make them great for tight spaces, like in cars or small devices.

Picking a good converter means checking power needs, voltage, and safety.

Buying good converters keeps devices working well and lasting longer.

What is an AC to DC Switching Converter?

Definition and Purpose

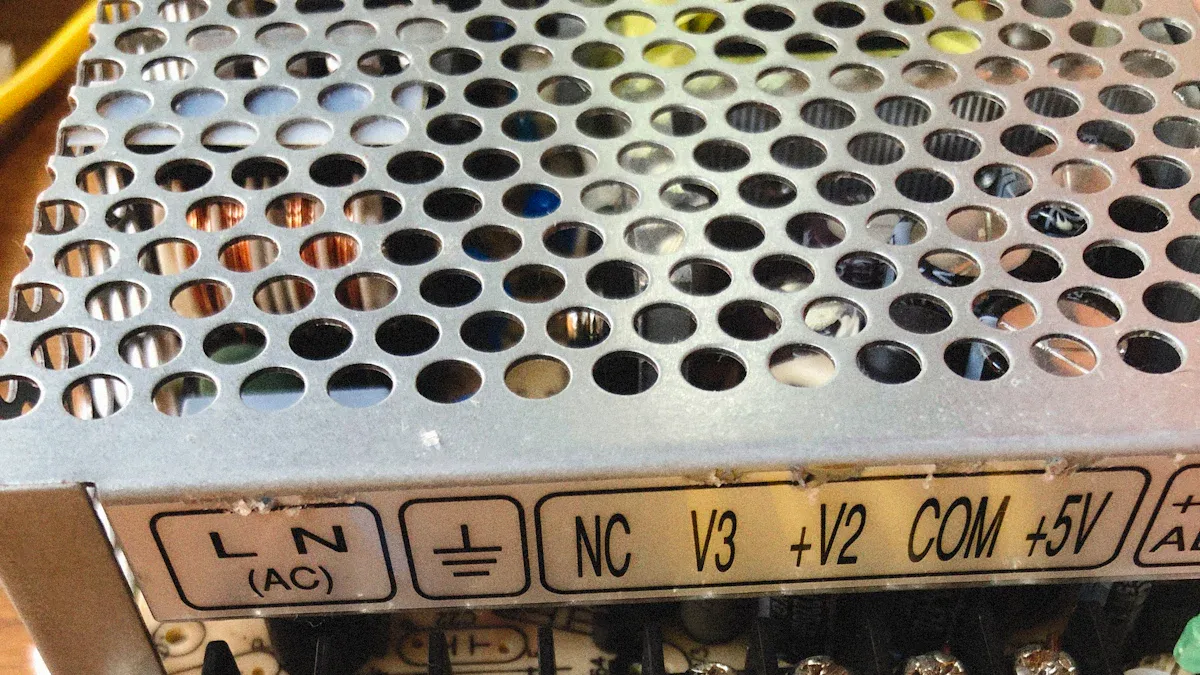

An AC to DC switching converter is a device that transforms alternating current (AC) into direct current (DC). This process is essential because most electronic devices, such as smartphones and laptops, operate on DC power. The converter achieves this transformation through a series of steps, including rectification, filtering, and voltage regulation.

Rectification is the first step, where diodes allow current to flow in only one direction, converting AC into pulsating DC. There are two main types of rectifiers:

Half-wave rectifiers, which use a single diode and are less efficient.

Full-wave rectifiers, which use multiple diodes to achieve higher efficiency.

After rectification, the converter uses capacitors and inductors to smooth out voltage ripples, ensuring a steady DC output. Finally, a regulation system maintains a consistent voltage level, even when the input voltage or load changes. Switching regulators, in particular, are highly efficient and widely used in modern converters.

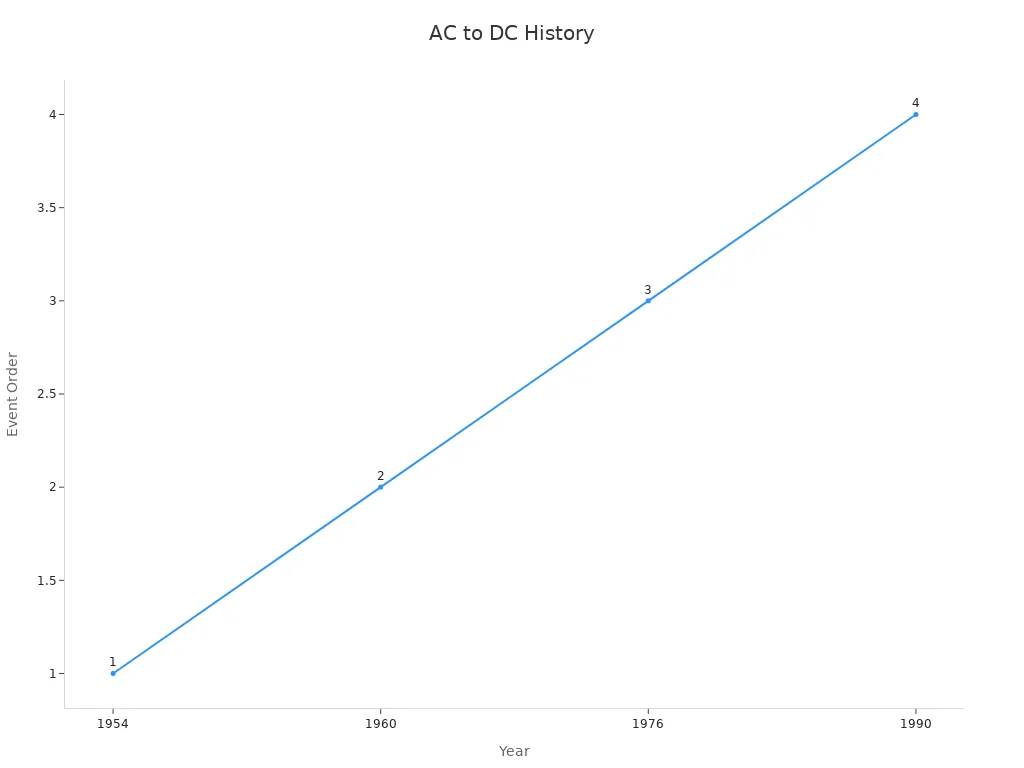

Did you know? The first significant advancement in switching technology came in 1976 with the SG1524 PWM controller, which paved the way for modern AC to DC switching converters.

Applications in Electronics

AC to DC switching converters are vital in powering a wide range of electronic devices. Their versatility makes them indispensable in various industries. Here are some examples:

Application Area | Examples |

|---|---|

Household Appliances | Refrigerators, computers, televisions, chargers for handheld electronics |

Medical Equipment | Essential for various medical devices |

Aerospace Industry | Used in avionics and other systems |

Transportation Systems | Integral to electric vehicles and systems |

In household appliances, these converters ensure that devices like televisions and chargers receive the correct DC voltage. In the medical field, they power critical equipment, ensuring reliability and precision. The aerospace industry relies on them for avionics systems, where compact and efficient designs are crucial. Similarly, electric vehicles depend on these converters to manage power distribution effectively.

As technology advances, the demand for compact, efficient, and reliable AC to DC switching converters continues to grow. Their role in modern electronics highlights their importance in everyday life.

How Does an AC to DC Switching Converter Work?

Conversion Process Overview

An AC to DC switching converter operates through a series of well-defined steps. The process begins with the input AC voltage, which alternates between positive and negative cycles. The converter first rectifies this alternating current into a pulsating direct current using diodes. This rectified current then passes through a transformer, which adjusts the voltage level to match the device's requirements.

The next step involves filtering the pulsating DC to smooth out any voltage ripples. Capacitors and inductors play a key role here, ensuring the output voltage remains steady. Finally, the control circuit regulates the voltage, maintaining a consistent output even when the input voltage or load conditions fluctuate.

Feature | Description |

|---|---|

Schematic Diagram | Figure A1 illustrates a typical converter configuration with transistors, a transformer, and a biasing network. |

The transistors operate out of phase, switching when the transformer saturates, leading to a duty cycle of 50%. | |

Waveforms | Figure A2 shows the waveforms associated with the converter's operation, including current spikes and noise characteristics. |

Noise Issues | The operation generates high-frequency current spikes that can affect precision analog systems, as detailed in the analysis. |

The table above highlights the operational characteristics of a typical AC to DC switching converter. The transistors, which act as switches, play a critical role in controlling the flow of current. By switching on and off at precise intervals, they ensure efficient energy transfer while minimizing power loss.

Tip: Understanding the schematic diagram of a converter can help you visualize how each component contributes to the overall process.

Role of High-Frequency Switching

High-frequency switching is a defining feature of modern AC to DC switching converters. This technique involves rapidly turning the transistors on and off, often at frequencies exceeding 20 kHz. The high switching frequency allows the converter to use smaller transformers and capacitors, resulting in a compact and lightweight design.

For example, the Vicor PI33xx buck regulator uses zero-voltage switching (ZVS) technology to achieve a peak efficiency of 98%. It delivers up to 120W of output power while maintaining a compact size of just 25 x 21.5mm. This high efficiency is possible because ZVS minimizes energy loss during the switching process.

High-frequency switching also improves the converter's response time. It enables the device to quickly adapt to changes in input voltage or load conditions, ensuring a stable output. However, it can introduce challenges such as noise and electromagnetic interference (EMI). Engineers address these issues by carefully designing the layout and shielding of the converter.

Key findings from technical studies on high-frequency switching include:

Leakage inductance in transformers significantly impacts efficiency.

Increasing switching frequencies can lead to voltage stress on components.

Precise control of leakage inductance is essential for optimal performance.

These insights highlight the importance of balancing high-frequency operation with careful design considerations. By doing so, you can achieve both efficiency and reliability in your AC to DC switching converter.

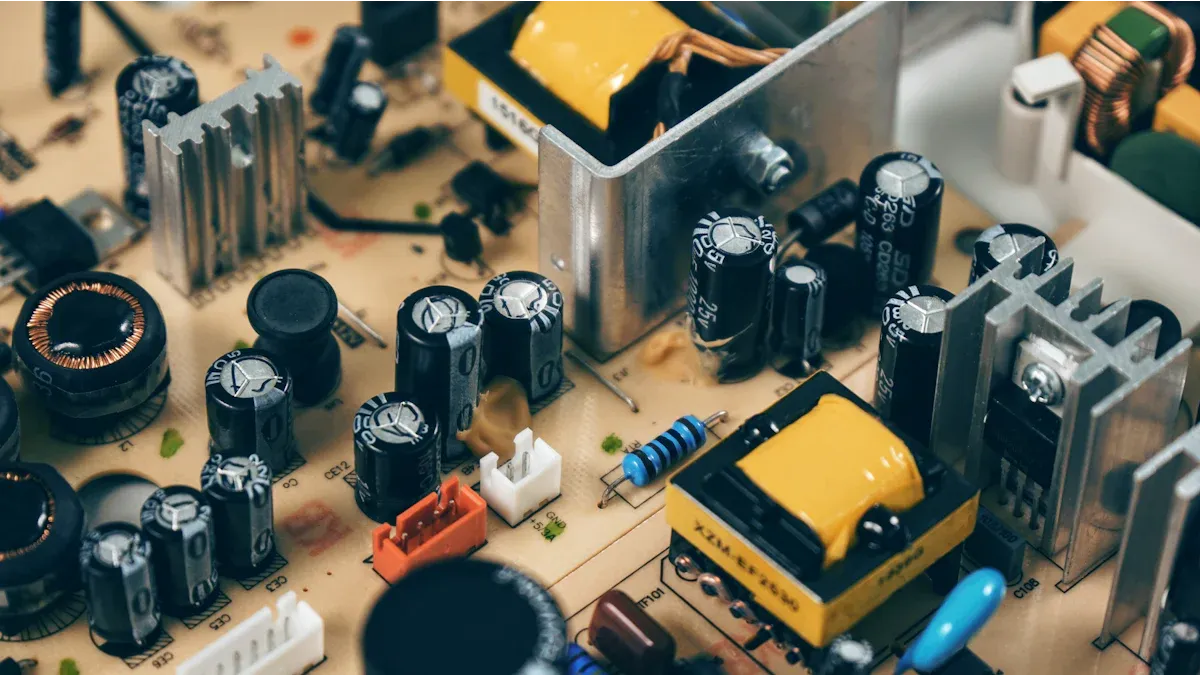

Components of an AC to DC Switching Converter

Transformer Functionality

The transformer in an AC to DC switching converter plays a crucial role in adjusting voltage levels. It uses electromagnetic induction to transfer energy between its primary and secondary windings. This process allows the converter to step up or step down the voltage as needed. For example, if your device requires a lower voltage than the input, the transformer reduces it efficiently.

Transformers achieve high efficiency, often exceeding 97%. Power transformers, in particular, can reach efficiencies above 99%. This efficiency depends on minimizing losses such as copper losses (from the winding resistance) and iron losses (from the core material). While achieving 100% efficiency is impossible, careful design ensures minimal energy waste.

Fun Fact: Transformers rely on Faraday’s Law, which states that a changing magnetic field induces a voltage. This principle is the backbone of voltage adjustment in converters.

Diodes for Rectification

Diodes are essential for converting AC into DC. They allow current to flow in only one direction, effectively blocking the reverse flow. This process, known as rectification, is the first step in converting AC power to DC. A rectifier circuit typically uses multiple diodes to improve efficiency and reliability.

Comparing different rectification methods highlights the importance of diodes. For instance:

Converter Type | Efficiency | Reliability |

|---|---|---|

Synchronous Rectification Boost | Moderate | |

Diode Rectification Boost | 95.2% | High |

Diodes in rectifiers ensure stable power conversion, making them indispensable in an AC to DC switching converter.

Filters for Voltage Smoothing

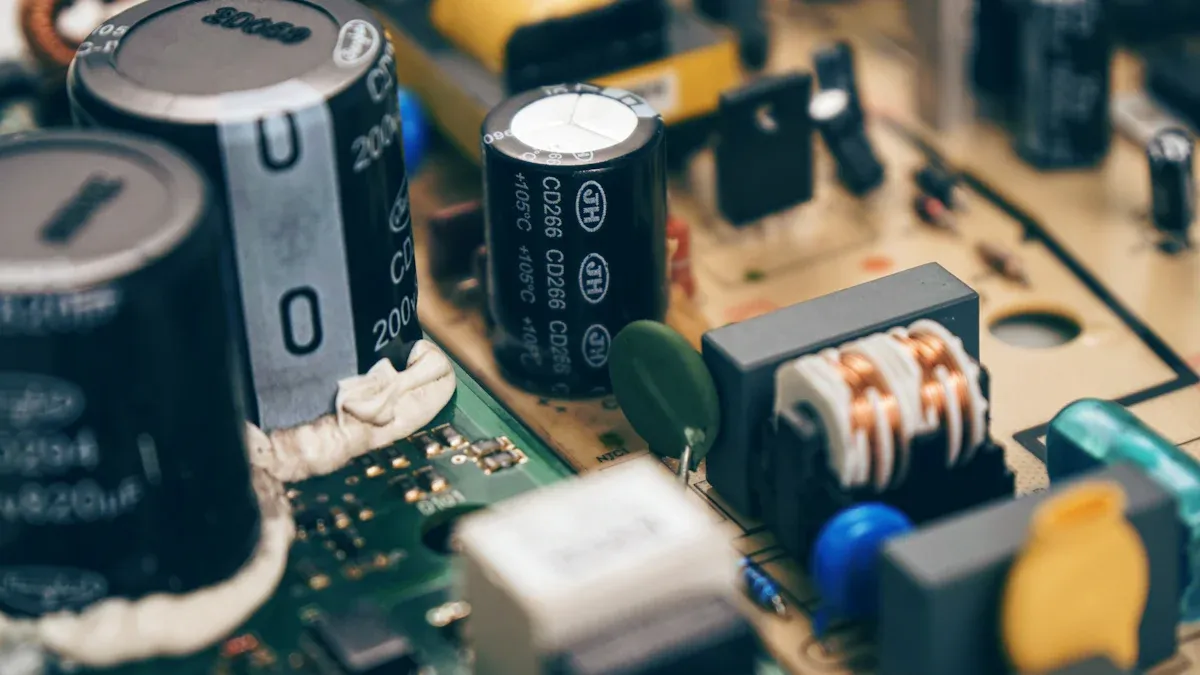

After rectification, the output still contains ripples, which can disrupt sensitive electronics. Filters, composed of capacitors and inductors, smooth out these ripples to provide a steady DC voltage. The output capacitor, often labeled as C**o, reduces load ripple voltage, improving power quality. Meanwhile, the inductor stores energy and ensures continuous current flow during switching intervals.

Filters also enhance the converter's performance by eliminating grid-side ripples. This ensures that the input current remains consistent, reducing the risk of interference with other devices. By combining capacitors and inductors, filters create a clean and reliable power supply for your electronics.

Control Circuit for Regulation

The control circuit in an AC to DC switching converter ensures that the output voltage remains stable, even when the input voltage or load conditions change. It acts as the brain of the converter, constantly monitoring and adjusting the system to deliver consistent performance. Without this component, your electronic devices could experience power fluctuations, leading to inefficiency or even damage.

Control circuits use feedback mechanisms to regulate voltage. A sensor measures the output voltage and compares it to a reference value. If the output deviates from the desired level, the control circuit adjusts the switching activity of the transistors. This process ensures that the converter maintains a steady output, regardless of external changes.

Modern control circuits often employ advanced techniques to optimize performance. For instance, traditional Proportional-Integral-Derivative (PID) controllers are widely used due to their simplicity and reliability. However, researchers have developed more sophisticated controllers, such as Fractional Order PID (FOPID) and Tilt-Integral-Derivative (TID) controllers. These advanced systems improve the converter's ability to adapt to dynamic changes while maintaining robust performance. A recent study introduced a new controller, PIDn(1+PD), which uses the GEO algorithm to enhance transient response and frequency characteristics. This innovation demonstrates how advanced control techniques can significantly improve the efficiency and reliability of converters.

Tip: When choosing a converter, look for one with a high-quality control circuit. It ensures better performance and protects your devices from power irregularities.

By regulating the switching process, the control circuit not only stabilizes the output but also enhances the overall efficiency of the AC to DC switching converter. This makes it an essential component in delivering reliable power to your electronics.

Benefits of AC to DC Switching Converters

Efficiency and Energy Savings

You can achieve significant energy savings with an AC to DC switching converter. These devices use advanced control techniques and wide-bandgap semiconductors to enhance efficiency. By reducing power loss and minimizing energy waste, they ensure that your devices consume less electricity. This not only lowers your energy bills but also decreases greenhouse gas emissions, making them an environmentally friendly choice.

Key advantages of energy-efficient converters:

Reduced heat generation, which extends the lifespan of electronic components.

Lower energy consumption, contributing to sustainable practices.

Enhanced performance under varied operating conditions.

Switching converters are ideal for applications where energy efficiency is critical, such as in data centers, electric vehicles, and renewable energy systems. Their ability to deliver consistent power while conserving energy makes them indispensable in modern electronics.

Compact Design

The compact design of AC to DC switching converters offers you a practical solution for space-constrained applications. Innovations in packaging and component technologies have led to higher power density, allowing these converters to deliver exceptional performance in a smaller footprint. This trend is particularly evident in industries like automotive and consumer electronics, where space and weight are critical factors.

For example, electric and hybrid vehicles rely on compact converters to meet stringent automotive constraints. These converters are lightweight, efficient, and designed to minimize electromagnetic interference. Emerging technologies, such as high-power wide-bandgap semiconductors, further enhance their efficiency while reducing their size.

Compact designs also simplify system integration. Features like power factor correction and digital control reduce complexity, making it easier for you to incorporate these converters into your devices. Whether you're designing a portable gadget or an electric vehicle, compact converters provide the reliability and efficiency you need.

Cost-Effectiveness

Switching converters offer you a cost-effective solution for powering electronic devices. Their high efficiency reduces energy waste, lowering operational costs over time. Additionally, their compact design minimizes material usage, which translates to lower manufacturing costs.

These converters also deliver long-term savings by reducing maintenance requirements. Their robust design ensures reliable performance, even in demanding environments. For instance, converters used in industrial applications often feature durable components that withstand temperature fluctuations and voltage spikes.

By choosing an AC to DC switching converter, you invest in a technology that balances upfront costs with long-term benefits. Whether you're powering household appliances or industrial machinery, these converters provide an economical way to meet your energy needs.

Reliability in Performance

When choosing an AC to DC switching converter, reliability plays a key role in ensuring your devices operate smoothly over time. These converters undergo rigorous testing to guarantee stable performance under various conditions. Manufacturers design them to handle thermal stress, environmental changes, and long-term usage without compromising functionality.

To assess reliability, engineers perform several tests. Each test evaluates specific aspects of the converter's durability and stability. Here’s a breakdown of common reliability tests:

Test Type | Purpose |

|---|---|

Power Cycling Test | Simulates on/off cycles to assess thermal fatigue and electrical reliability. |

High Temperature Storage Life (HTSL) | Evaluates stability when stored at high temperatures to identify long-term degradation. |

High Temperature Operating Life (HTOL) | Assesses performance under high temperatures during active operation to identify potential failures. |

Temperature Humidity Test (THT) | Simulates real-world environments to identify issues like corrosion and material expansion. |

Temperature Cycle Test (TCT) | Assesses material compatibility and integrity under extreme temperature variations. |

Highly Accelerated Stress Test (HAST) | Accelerates aging to reveal weaknesses quickly, aiding in early defect identification. |

Thin Whisker Susceptibility Testing | Identifies susceptibility to metal whisker growth to prevent electrical failures. |

These tests ensure that your converter can withstand demanding conditions. For example, the High Temperature Operating Life (HTOL) test evaluates how well the converter performs under elevated temperatures during active use. This helps identify potential failures before they occur. Similarly, the Temperature Humidity Test (THT) simulates real-world environments to detect issues like corrosion or material expansion.

Reliable converters also feature robust designs that minimize wear and tear. Advanced materials and precise engineering reduce the risk of component failure. This means you can trust these devices to deliver consistent power, even in challenging environments. By investing in a reliable AC to DC switching converter, you ensure the longevity and stability of your electronic systems.

Tip: Look for converters that have passed rigorous reliability tests. This guarantees better performance and peace of mind for your devices.

Choosing the Right AC to DC Switching Converter

Power Requirements Assessment

Choosing the right AC to DC switching converter starts with understanding your power needs. You must evaluate the power requirements of your device to ensure compatibility. Stability is a key factor. A stable converter ensures your device operates without interruptions or damage. Metrics like crossover frequency, phase margin, and gain margin help assess stability. These metrics also reveal how well the converter handles sudden changes in power demand.

Control loops in power conversion circuits are another critical area to examine. They regulate the flow of power and maintain consistent performance. Measurement techniques for evaluating voltage regulator feedback loop stability can provide insights into how well the converter will perform under different conditions. By focusing on these factors, you can select a converter that meets your device's power needs effectively.

Input and Output Voltage Specifications

The input and output voltage specifications of a converter are crucial for its performance. The output voltage must meet specific accuracy requirements, typically within ±5%. This ensures your device receives the correct voltage for optimal operation. A mismatch in voltage can lead to inefficiency or even damage to your electronics.

Efficiency is another important consideration. It measures how well the converter transforms input power into usable output power. High efficiency minimizes energy loss, which often converts to heat. For example, converters can achieve up to 95% efficiency at high power levels. However, efficiency tends to drop at lower power levels. Understanding this relationship helps you choose a converter that balances performance and energy savings.

Efficiency and Thermal Management

Efficient converters not only save energy but also generate less heat. This reduces the need for extensive cooling systems, making the converter more compact and cost-effective. Thermal management becomes essential when dealing with high-power applications. Excessive heat can degrade components and shorten the lifespan of the converter.

To manage heat effectively, look for converters with advanced cooling designs. These may include heat sinks or fans to dissipate heat quickly. Wide-bandgap semiconductors are another innovation that improves efficiency while reducing heat generation. By prioritizing thermal management, you ensure the longevity and reliability of your AC to DC switching converter.

Size, Weight, and Cost Considerations

When selecting an AC to DC switching converter, size and weight play a significant role, especially for portable or space-constrained applications. Smaller converters fit easily into compact devices like smartphones or laptops. Lightweight designs reduce the overall weight of products, which is crucial for industries like aerospace and automotive. For example, electric vehicles benefit from lightweight converters that improve energy efficiency and performance.

Cost is another critical factor. Compact and lightweight converters often use advanced materials and technologies, which can increase their initial price. However, their high efficiency and durability reduce long-term operational costs. You save money on energy bills and maintenance over time.

To balance size, weight, and cost, consider these tips:

Evaluate your application needs: Portable devices may prioritize size, while industrial systems may focus on durability.

Compare power density: Higher power density means more power in a smaller package.

Assess long-term savings: A slightly higher upfront cost can lead to lower energy and maintenance expenses.

Tip: Look for converters with innovative designs, such as wide-bandgap semiconductors. These offer high efficiency in a compact form.

Safety Standards Compliance

Safety should always be a top priority when choosing an AC to DC switching converter. Certified converters meet strict safety standards, ensuring reliable and hazard-free operation. Certifications like cTUV, TUVus, and GS Mark confirm compliance with international safety requirements. These certifications are supported by regular audits and factory inspections.

Key safety measures include:

Surveillance audits: These verify that the converter continues to meet safety standards over time.

Factory inspections: These ensure that manufacturing processes adhere to safety guidelines.

By choosing a certified converter, you protect your devices and ensure user safety. Always check for labels or documentation that confirm compliance with recognized standards.

Note: Certified converters not only enhance safety but also improve reliability, making them a smart investment for your electronics.

An AC to DC switching converter plays a vital role in powering modern electronics. It ensures your devices receive efficient, reliable, and stable energy. Its compact design and energy-saving features make it an essential component in industries ranging from consumer electronics to transportation. These converters also adapt to evolving technologies, paving the way for smarter and more sustainable power solutions. As advancements in power electronics continue, you can expect even greater efficiency and versatility from these devices, shaping the future of energy management.

FAQ

1. What is the difference between AC and DC power?

AC (alternating current) changes direction periodically, while DC (direct current) flows in one direction. Most household outlets provide AC power, but electronic devices like smartphones and laptops require DC power to operate efficiently.

2. Why are AC to DC switching converters more efficient than linear converters?

Switching converters use high-frequency switching to minimize energy loss. This method reduces heat generation and improves efficiency. Linear converters, on the other hand, dissipate excess energy as heat, making them less efficient for high-power applications.

3. Can AC to DC switching converters handle voltage fluctuations?

Yes, they can. These converters include control circuits that regulate output voltage. This ensures stable performance even when input voltage or load conditions change unexpectedly.

4. Are AC to DC switching converters safe to use?

Certified converters meet international safety standards. Look for certifications like UL or CE to ensure reliability. These devices undergo rigorous testing to protect your electronics and prevent hazards like overheating or short circuits.

5. How do I choose the right converter for my device?

Start by checking your device's power requirements. Match the input and output voltage specifications. Consider efficiency, size, and safety certifications. For portable devices, prioritize compact designs. For industrial use, focus on durability and reliability.

Tip: Always consult your device manual for specific power requirements before purchasing a converter.

See Also

Exploring Fundamental Concepts and Uses of Analog IC Design

The Importance of Integrated Circuits in Today's Electronics

The Functionality of PLC Components in Automation Systems

Defining IC Demodulators and Their Functions Explained

Understanding Industrial Control Chips and Their Automation Functions